PACKAGES

PRODUCTS

BAG STYLES

Granules

Granules are preparations consisting of solid, dry aggregates of powder particles sufficiently resistant to withstand handling. They are intended for oral administration. Some are swallowed as such, some are chewed and some are dissolved or dispersed in water or another suitable liquid before being administered.

Granules contain one or more active substances with or without excipients and, if necessary, suitable colouring and flavouring substances. They are mainly used for low-toxicity, high-dose drugs.

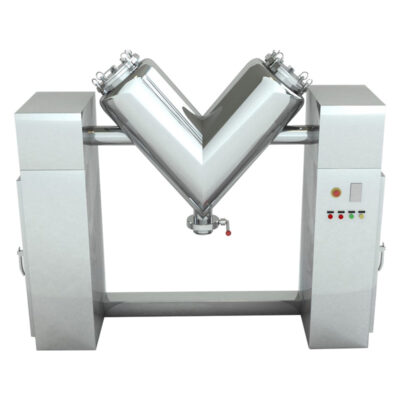

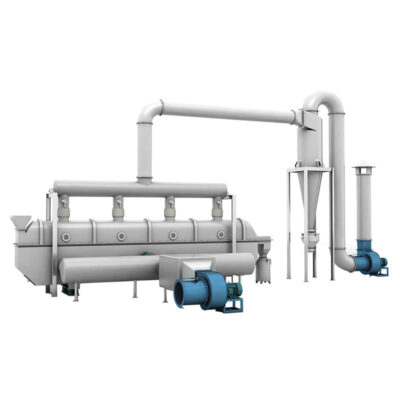

AIPAK various types of granulation machine,with the granulation process, small fine or coarse particles are converted into large agglomerates called granules. And generally, the granulation commences after initial dry mixing of the necessary powder ingredients along with the active pharmaceutical ingredient (API), so that a uniform distribution of each ingredient throughout the powder mixture is achieved.

The granulation technique may be widely categorized in to two types, dry granulation and wet granulation, based on the type of method used to facilitate the agglomeration of powder particles . Dry granulation uses mechanical compression (slugs) or compaction (roller compaction) to facilitate the agglomeration of dry powder particles, while the wet granulation uses granulation liquid (binder/solvent) to facilitate the agglomeration by formation of wet mass by adhesion.

AIPAK also provides sifter machine,bin mixer,bin blender,dry granulation machine,wet granulation machine and different models of dryer machine to make the granules good dosage form or be mixed with other excipients before tablet compaction or capsule filling.

Machines For Granules

Videos For Granules

Frequently Asked Questions

Granules can be classified into four types, effervescent granules, coated granules, gastro-resistant granules and modified-release granules.

Effervescent granules are uncoated granules generally containing acid substances and carbonates or hydrogen carbonates which react rapidly in the presence of water to release carbon dioxide. Coated granules consist of granules coated with one or more layers of mixtures of various excipients. The substances used as coatings (generally polymers) are usually applied as a solution or suspension in conditions in which evaporation of the vehicle occurs leaving a film of coating. Modified-release granules are coated or uncoated granules that contain special excipients or which are prepared by special procedures, or both, designed to modify the rate, the place or the time at which the active substance or substances are released. Gastro-resistant granules (also referred to as enteric-coated granules) are delayed-release granules that are intended to resist the gastric fluid and to release the active substance(s) in the intestine fluid.

Granules are produced to enhance the uniformity of the API in the final product, to increase the density of the blend so that it occupies less volume per unit weight for better storage and shipment, to facilitate metering or volumetric dispensing, to reduce dust during granulation process to reduce toxic exposure and process-related hazards, and to improve the appearance of the product.

Granules are designed to be taken with a small amount of food.

Sprinkle or stir the granules into a small amount of soft food (e.g. yogurt) or a small drink.

Your child should then swallow the food or drink straight away, without chewing. Make sure that they take it all.

You can also mix the granules with a spoonful of cold water and give it to your child to drink straight away, without chewing. Do not mix the granules with warm food or liquid.

Your child must take the granules within 15 minutes of opening the sachet. If the sachet has been open for more than 15 minutes, throw the contents away and use a new sachet.

Do not keep granules or a granule/food mixture to give later.

Granule is a related term of pellet.

As nouns the difference between granule and pellet is that granule is granule while pellet is a small, compressed, hard chunk of matter.

As verbs the difference between granule and pellet is that granule is while pellet is to form into pellets.

As an adjective granule is granulated.

Granules have smaller surface area than comparable volume of powder. Granules have smaller surface area than a comparable volume of powders. This makes granules more stable physically and chemically than the corresponding powders. Granules are less likely to cake or harden upon standing than are powders.

Granulation is the process of producing grains or granules. The size of a granule is typically in the range 0.2 – 4.0 mm. This term is often used in pharmaceutical industry since granulation is the process used in the production of tablets. There are three types of granulations as dry granulation, wet granulation, and direct blending. The main difference between dry and wet granulation is that dry granulation is the formation of granules without using any liquid solution whereas wet granulation is the formation of granules by adding a granulating liquid.