Your Best Flow Wrap Machine

- Advanced & Intuitive

- User-friendly Software

- Automatic Bag Length Detection

- Adjustable Bag Former & Pitch

AIPAK Flow Wrap Machine

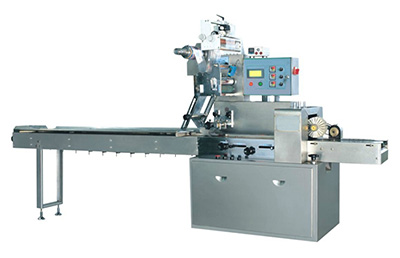

AIPAK flow wrap machine is also known as pillow packing machine, horizontal form fill seal machine (HFFS), is a machine that performs three tasks in one fluid and continuous operation-forming horizontal bags from a single roll of film, filling the bags with products, and sealing, discharging the finished package. The whole process is protective, consistent that heat is applied to the bottom and ends of the film to form a sealed, flexible package.

AIPAK flow wrap machine is favored by lots of customers all over the world, from small scale to large scale companies with high speed wrapping requirements. It has been widely used for a variety of products from food, bake goods to regular household items and stationary.

The Buyer's Guide

Flow Wrap Machine: The Complete Buying Guide In 2025

Bartelt Harold and Donald Bartelt developed a machine that can fill and seal pre-made envelopes for electrical components.This invention which was fast and labor-saving paved the way to the development of first ever horizontal form fill and seal machines or HFFS.

Flow wrapping machine is a type of HFFS that employs single roll of film to make horizontal bags; because of this out of many packaging processes flow wrapping is one of the most commonly used method employed by packaging experts in the industry to pack products of any shape or size.

This blog will pique your interest with facts about flow wrapping, flow wrap machine and a brief comparison of flow wrap equipment with other packaging instruments. Bringing you Flow Wrap Machine: The Complete Buying Guide In 2023. In this blog we will cover.

1.What is flow wrapping?

Flow wrapping also known as Horizontal Form-Fill-Seal (HFFS) is a type of primary packaging process employed in food, confectionary, cosmetic and health care industries to protect products from degradation, spoilage and contamination. Flow wrapping is brought about by flow wrapping machines or flow wrappers that employ heat sealable films such as PET/PE, nylon etc. for packaging.

Flow wrappers use heat and pressure to make an uptight seal which prevents unnecessary movement of the product. Some flow wrapping machines are also equipped with gas flushers that further stabilizes the products against environmental degradation.

2.Flow wrapping vs overwrapping. What is the difference?

You will find a number of packaging that sound similar but serve different purposes, each having their own advantages and uses. Flow wrapping and overwrapping are example of such packaging process. Differences between these two packaging processes are given below.

| Flow wrapping | Over wrapping |

|

|

|

|

3.Equipment required to perform flow wrapping; a brief overview.

The process of making pouches of different sizes and shapes, filling and sealing of products whether a chocolate bar or any medical device by unwinding of film is done by machines known as flow wrappers. These machines are low on budget, serve multipurpose and provide total control of packaging processes.

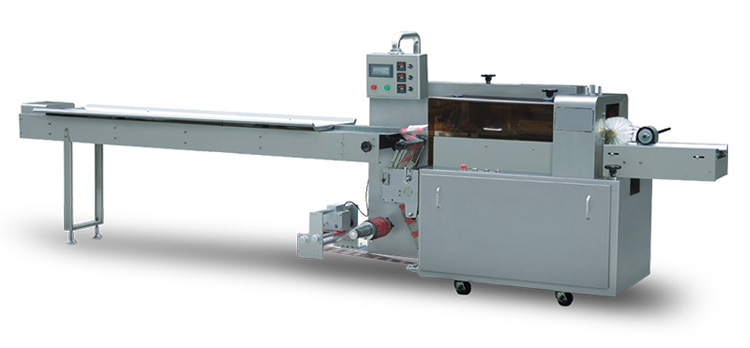

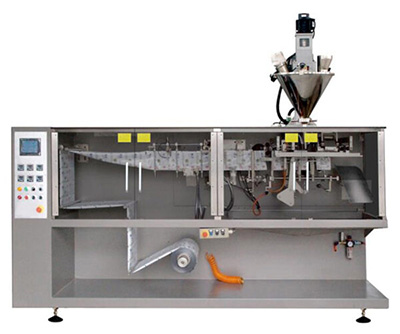

AIPAK flow wrap machine

Most popular flow wrappers in the market have a horizontal lay out where the film travels in the horizontal direction and the entire operation is carried out horizontally. These machines are collectively call as horizontal Form-Fill-Seal or HFFS. However, if you have space constraint, fret not! Some vertical ones are also available.

These machines use composite materials and the recommended films are PET/PE. Also other materials can be used such as PET/plated, nylon, AL/PE etc.

4.Industrial applications of flow wrap machine?

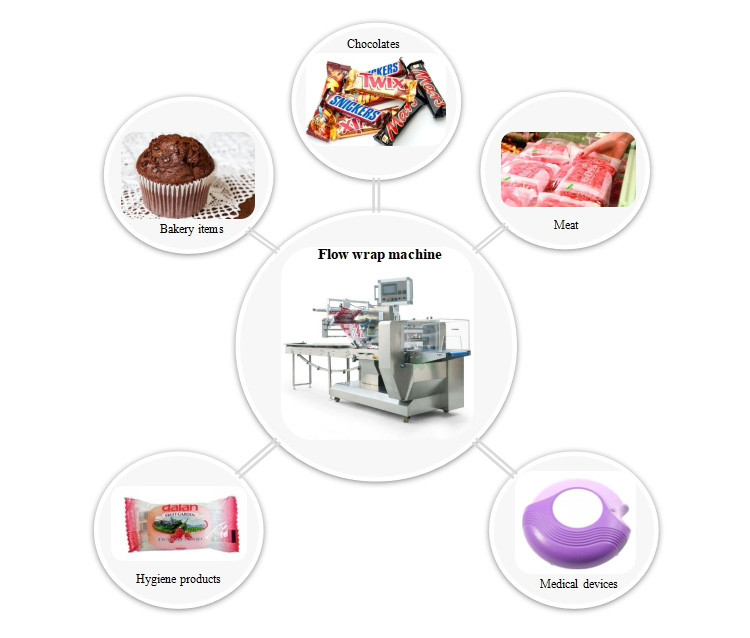

The industrial applications of flow wrap machine are as followed:

Pharmaceutical Industry

The flow wrapping machine is designed to produce a flexible primary or secondary packaging of large and small batches of pharmaceutical and medical products. For example calibration fluids, blister packs, syringes, IV bags, inhalers, etc.

Chemical Industry

A flow wrapping machine has suitable forming, filling, and sealing options best for potential hazardous chemical products. This machine is high in demand as it offers complete environmental, personal, and product safety.

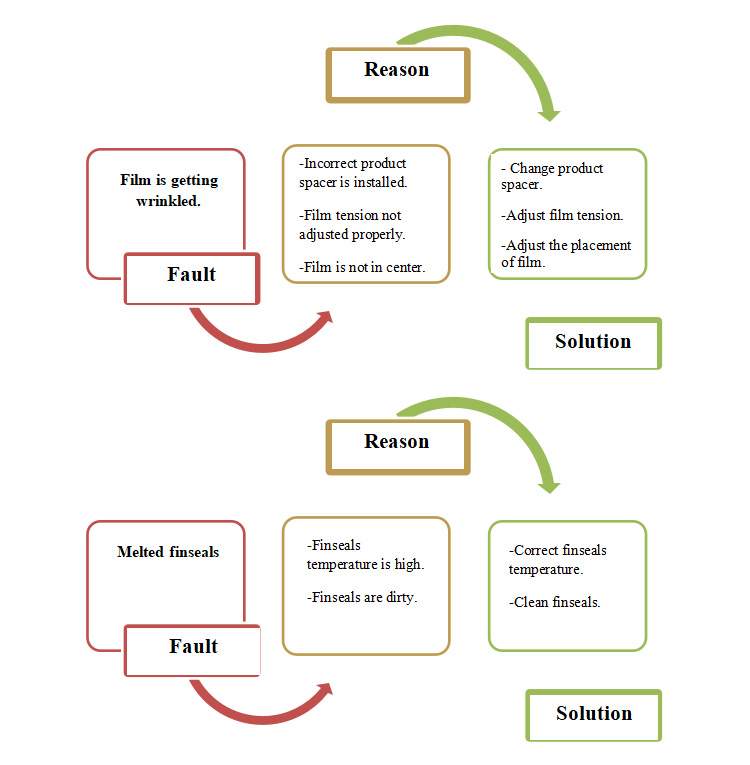

Cosmetic Industry

A flow wrapping machine is an excellent solution for the protection of cosmetic products such as facial masks, peel-off, shampoo, moisturizer, etc. The machine is equipped with advanced features such as gas flushers that increase the product stability by clearing out with moisture content and microbial contents.

Vegetable & Fruit Industry

To meet seasonally varying workloads in the vegetable and fruit industry, the flow wrapping machine is perfect with its flexibility and high-speed outcomes. The formation of packing and sealing around the product ensures safety and extended shelf life.

Agricultural Industry

Flow wrapping machines for agriculture packaging are as diverse as the range of products themselves. For example, pesticides, herbicides, growth enhancers, crop seeds, etc. can all be flow wrapped using flow wrappers.

Confectionary Industry

Flow wrapping machine in combination with a reliable infeed system ensures gentle wrapping of soft and sticky confectionery products and efficiently seal them for safe and hassle free distribution.

Poultry and Meat Industry

Flow wrapping machine guarantees 100% freshness of poultry and meat products because of its brilliant barrier film covering. Machine customized features make demanding tasks possible such as product information printed on the film.

5.How many types of flow wrap machines are available in the market?

Flow wrap machines are one of the most versatile piece of equipment available in the market. From semi-automatic machines to fully automatic robotic unit, that will meet your production demands can be acquired from local and international manufacturers.

Semi-automatic flow wrap machine

This equipment is ideal for small scale businesses or laboratory scale work. Robust and accurate in working these machines only differ in the degree of automation. However, most semi-automatic flow wrap machines can later be attached to an automatic production line or upgraded to meet large scale production demands.

Semi-automatic flow wrap machine

Semi-automatic flow wrap machines have a sturdy built quality, having a stainless steel main body and parts that come in contact with the product which meet regulatory requirements. Most machines have a production capacity of 250 pieces in a minute. These equipment are low on budget and has minimum maintenance cost.

Automatic flow wrap machine

AIPAK APK-450B automatic flow wrap machine

Automatic flow wrap machines are integrated with top notch electronic which include automatic in-feed system, fail safe features and multiple programs that make flow wraps of different sizes and shapes. Also, these machines can be attached to a complete robotic unit that runs entire operation virtually without human efforts.

6.Features of an automatic flow wrap machine. How can you benefit from this equipment?

Features of an automatic flow wrap machine differ from model to model and between manufacturers. Standard features of the machine that will help you to select the best equipment as per your needs are mentioned below.

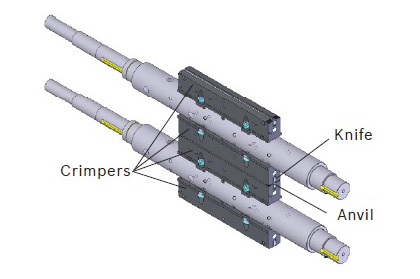

Production capacity: Automatic flow wrap machine is fast, it can produce 150 packages per minute if you have opted for standard version that has 1 crimper per shaft. A customized one with two crimpers can produce 250 packages per minute, meeting high production demand.

Precise operations: Your machine is equipped with electronics such as unwinder with sensors which detect the reel position; automatically adjusting it if required thereby ensuring accurate cut and precise seal which saves time and prevents material wastage. Also, these sensors can detect reel size halting machine when reel ends for smooth changeover.

Automation with customization: Versatility of this machine is not only in its working but also in the accessories such as length of conveyer, production capacity; induction of multiple crimpers and infeed system that can be customized to include robotic arms for smooth labor effective precise operations.

Product stability: To enhance product stability and shelf life standard version of flow wrap machine uses inert antimicrobial gases such as nitrogen, carbon monoxide and carbon dioxide to reduce oxygen levels up to 3% and also generate a barrier that preserves flow wrap contents.

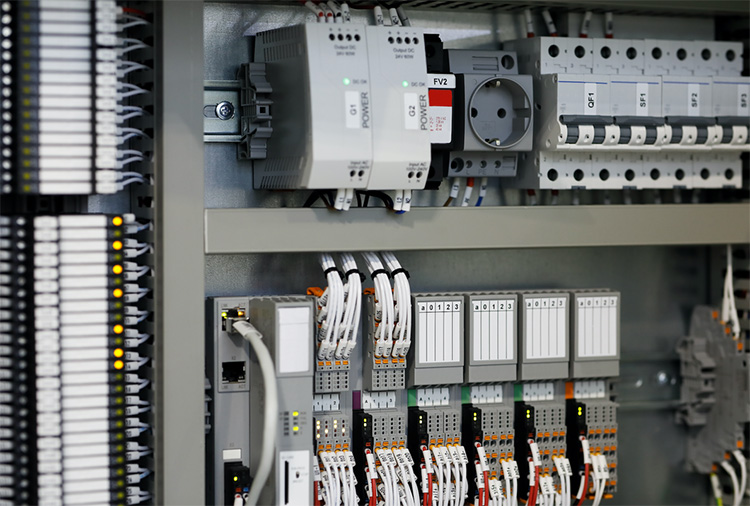

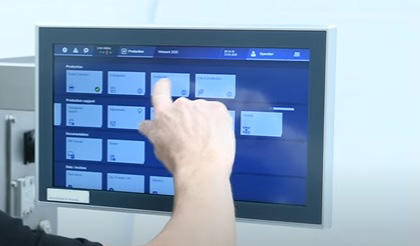

Artificial intelligence: Advance human machine interface (HMI) with PLC control having multiple languages and more than 100 programs make this machine easy to operate with minimum training. Entire operation is carried out without much human intervention making this machine desirable for meeting high production demands with consistency.

Long working life under belt: As per international regulatory requirement the main body and the parts that come in contact with the product is made of stainless steel which prevents cross contamination, improves the aesthetics of the machine, make it durable and sturdy, easy to clean and maintain.

International standards: Following international standards among other regulatory requirement products such as bakery items, confectionaries and some medical product are required to be labelled. This machine comes with labelling system than can print different labels on your package.

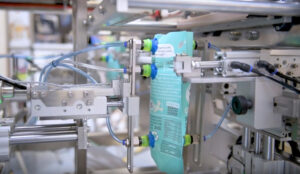

7.What are the targeted products for flow wrap machine?

Flow wrap machine is a versatile equipment that can pack almost anything. Below given is a figure of some of the items that can be packed using flow wrap machine.

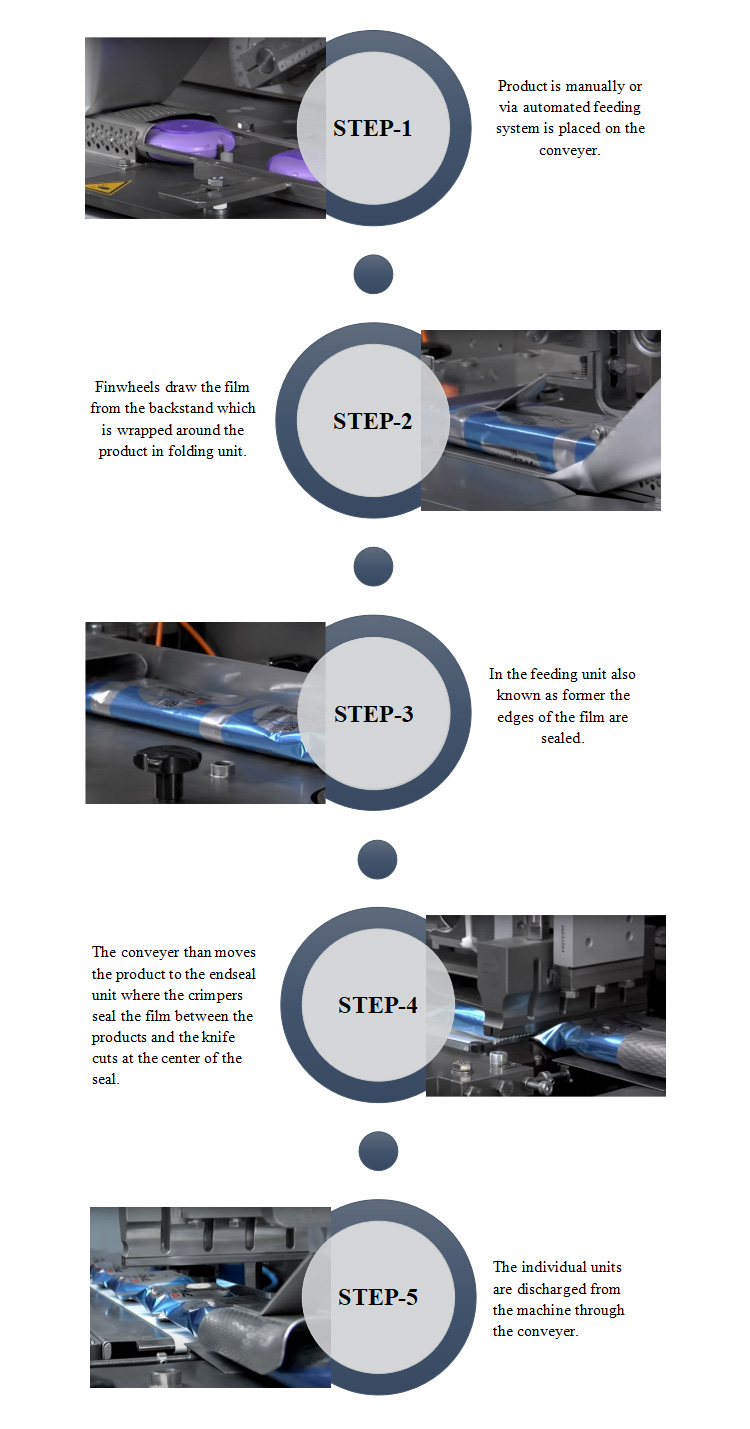

8.Working principle of an automatic flow wrap machine; a representation.

The automatic flow wrap machine is equipped with highly advanced electronics and user friendly interface that guarantee smooth operations with accuracy and precision. The entire operation is carried out in five easy steps that are explained below;

Working Principle of Flow wrap machine

9.What are the major components of flow wrap machine?

You should know by now that every model of flow wrap machine is different from another. Following advancements in the technology the components of the machine also change. However, you will find following necessary components in almost all models.

| UNIT | DESCRIPTION | PICTURE |

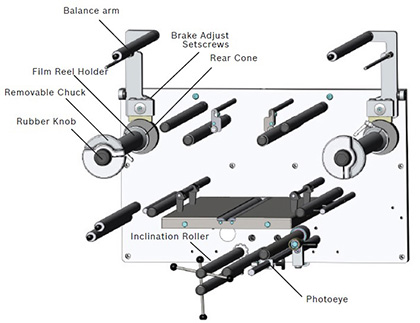

| Backstand | Backstand holds the film roll and feed it to the folding unit at correct angle maintaining tension all along. It consists of film reel holder, balance arm and guide rollers. |  |

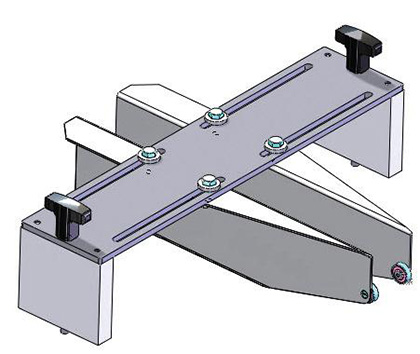

| Former | Folding unit also known as former wraps the roll around the product. Folding unit of varying sizes are available for different products. Most of these have adjustable wings. |  |

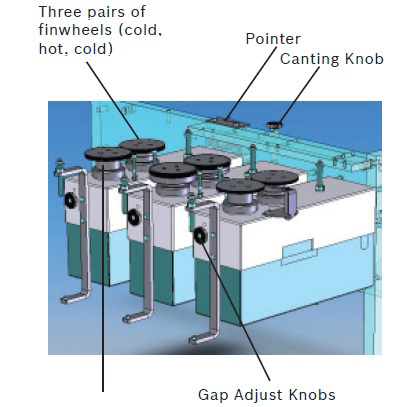

| Finseal | A sealing unit that seals the ends of the film with heat or ultrasound and pressure. It contains three pairs of wheels of which first and third pair perform cooling action whereas second pair heats the film. |  |

| Endseal | Endseal or crimpers cut the film and separate the product into packs of different sizes. |  |

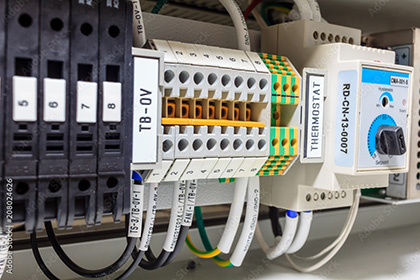

| TCU | Installed in the electric compartment temperature control unit or TCU controls the temperature of finseal and endseal units. Desired temperature can be maintained from control panel. |  |

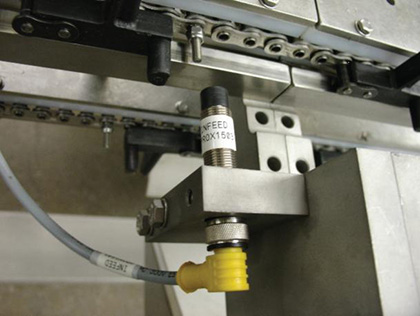

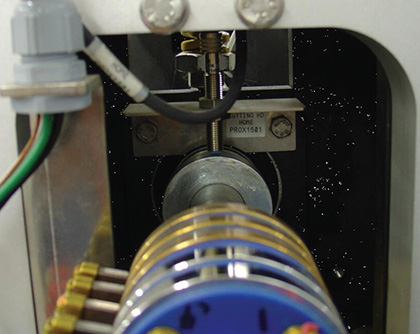

| ICS | Your machine is equipped with three different sensors including infeed chain position, film registration and cutting head sensors. ICS detects pusher pin on the infeed chain. |  |

| FRS-CHS | Film registration sensor detects the position of the printed material on the film performing necessary adjustment whereas CHS performs detection of the cutting flag. |  |

| Pneumatic | The pneumatic unit provides air pressure of 60 PSI. The main role of this unit is to filter the air supplied to the machine. |  |

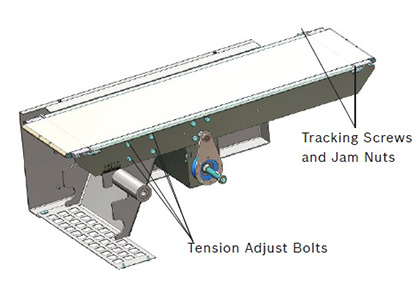

| Conveyer | It is present after the endseal unit. Conveyer consists of roller assembly, motor and conveyer belt. The tension in the belt is easily adjustable. You can also remove this unit from the machine. |  |

| HMI | Human machine interface is the most important component of an automatic machine that performs all the tasks including temperature and pressure control by a click of the button. |  |

Components of Flow wrap machine

10.Flow wrap vs sachet machine vs Doypack machine; a comparison.

Packaging machines are all similar in working principle i.e. they pack, fill and seal products but each machine produces distinctive packages, all because of units or parts that are unique to that machine. Below is a comparison between three popular packaging equipment

|

|

|

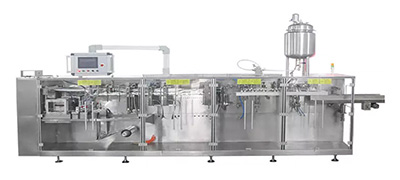

| Sachet packing machine | Doypack machine | Flow wrap machine |

| 1) This machine can produce 3 sides, 4 sides or a central seal with a tearing notch or cap for ease of opening. 2) This machine can be customized to stack, count and weigh sachets. 3) A standard version can produce 150 sachets in a minute. |

1) The unique feature of doypacks to stand in an upright position is because of W or S-fold bases. This machine differs from other machines in a specialized unit that make W and S-fold. 2) Typically this machine also has a unit that attaches bottle cap or zipper and can fill pre-made pouches. 3) Smallest doypack is bigger in size than sachets or flow wraps, a standard doypack model can produce up to 90 pouches is a minute. |

1) Flow wraps are not pre made pouches, these are made by wrapping film around products and sealing the edges together. This wrapping is performed by the unit known as former or folding unit. 2) With this machine you can wrap product of any geometric shape. 3) A standard version of flow wrapper can produce up to 150-250 flow wraps in a minute. |

11.Difference between flow wrap machine and shrink wrap machine.

Another machine that is very much similar to flow wrap machine is shrink wrap machine. Few difference between both HFFS machines are given below;

|

|

| Flow wrap machine | Shrink wrap machine |

| 1) Flow wrap machines are used as primary packaging as well as secondary packaging equipment. 2) Any suitable film is wrapped around the product and the edges are sealed with either heating or ultrasound. 3) Products that can be flow wrapped include food and confectionary items, medical devices etc. 4) This machine offers minimal movement within the wrap thereby reducing unwanted wastage. |

1) Shrink machines are mostly used for secondary packaging. 2) Transparent film is wrapped around the product which then runs through a heating chamber that shrinks it. 3) Meat, books, bottles and vegetables can be shrink wrapped using this machine. 4) It is cost effective, protects from dirt and humidity allows better storage. |

12.Maintenance and cleaning of flow wrap machine.

If you want to increase working life of machine you need to perform maintenance as per manufacturer’s recommendation. For this machine following daily, weekly, monthly and annually maintenance is recommended.

| Daily maintenance | Folding unit、Belt | Check bearing operation. Adjust tension of the belt. |

| Weekly maintenance |

|

|

| Monthly maintenance |

|

|

| Annual maintenance |

|

|

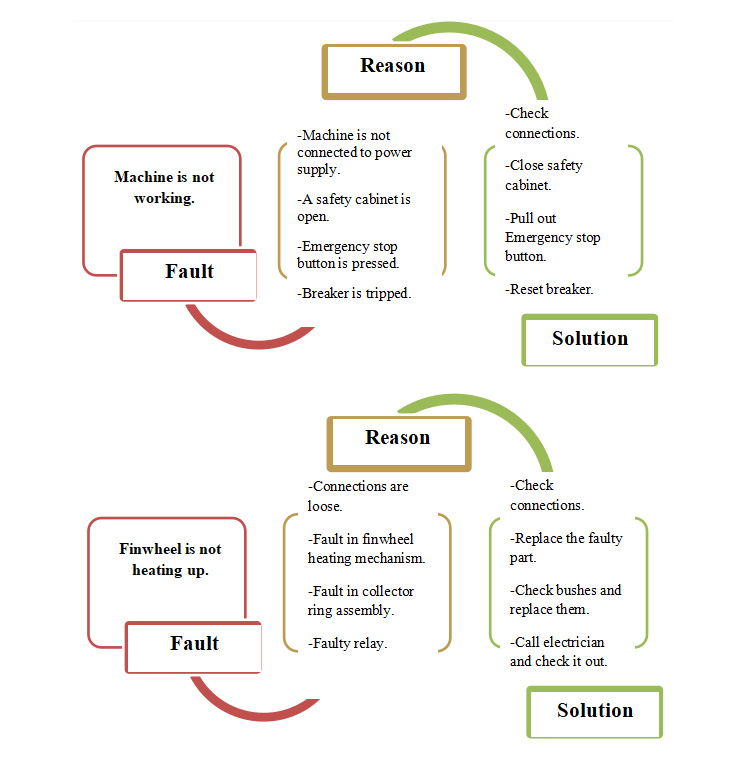

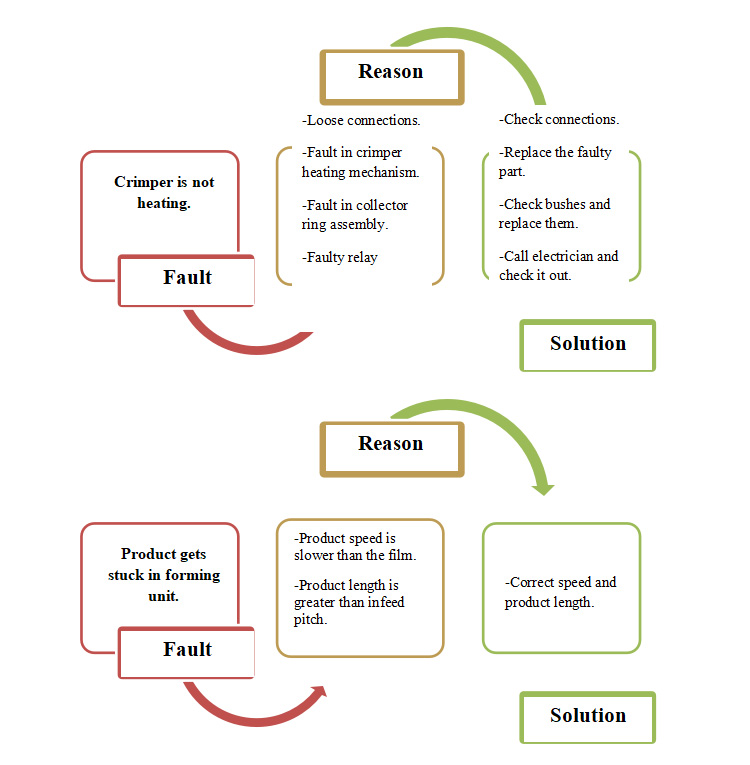

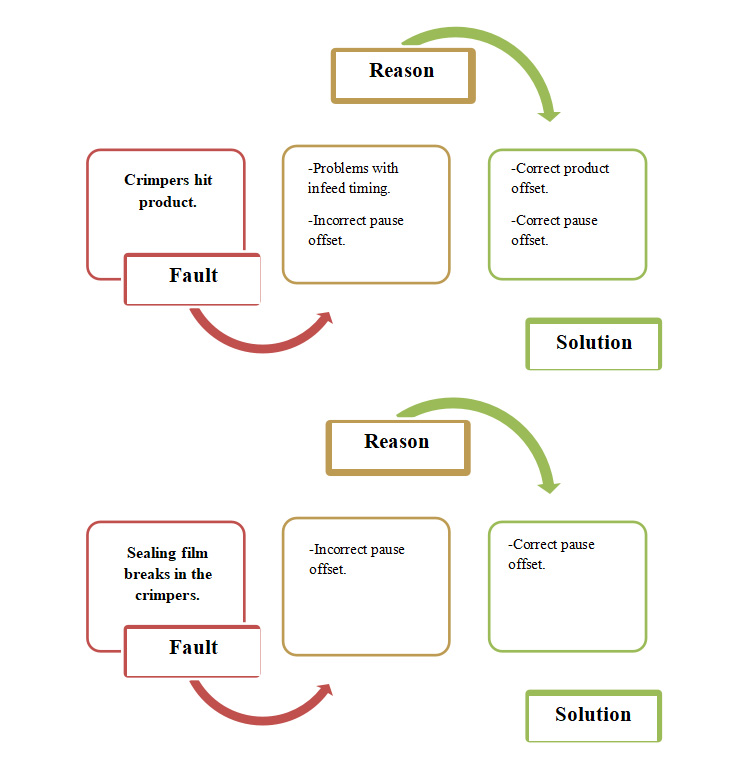

13.Trouble shooting of commonly occurring problems

Faults and operations go hand in hand. If you know your machine well than errors during routine work can be rectified without losing precious time and work efficiency. Some of the most commonly occurring faults have been discussed below. Always consult your machine manual for details;

Conclusion

The flow wrapping machine is a perfect balance of performance, product safety, hygiene, and quality. With over 15 years of experience in manufacturing pharmaceutical equipment; we pride ourselves on designing and building cost-effective and efficient solutions to meet your production needs. Need a Free Consultation or Quotation? We are here to help 24/7/365. We are AIPAK!

Flow Wrap Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586