PACKAGES

PRODUCTS

BAG STYLES

Powder

Understanding pharmaceutical particle and powder characterization is key to efficient pharmaceutical manufacturing processes and products where they involve suspensions and bulk powders. Particle size and powder properties will influence bulk physical properties, such as the flowability of a powder, which in turn, will impact processing, blending, tableting, dissolution, delivery and bioavailability.

Powders may also be used to describe a type of pharmaceutical preparation, that is, a medicated powder intended for internal or external use.

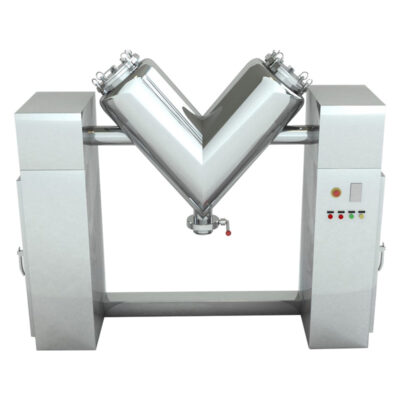

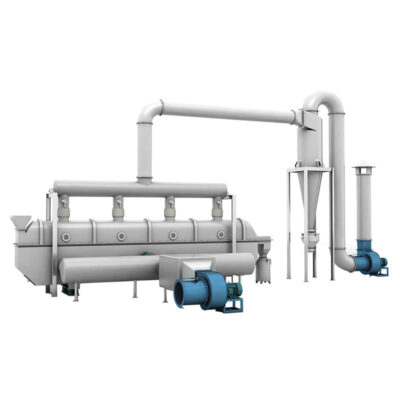

AIPAK offers various kinds of powder process machines include the sifter machine ,crusher machine,bin mixer,bin blender,dryer machine,granulation machine.With which you will be more easy to administer your drugs from hard vegetables such as roots,barks and woods.

The powder filling machine from AIPAK will make you easy fill your various kinds of dry powder filling bottles, like protein powder ,pepper powder ,and other backing powder ,coffee powder organic powder ect. It is also suit for packing powder and small granular materials, such as veterinary medicine, granular additive, white granulated sugar, cotton,sugar, glucose, solid beverage, pharmaceutical solids, carbon powder, talcum powder, pesticides, dyes, flavors and fragrances.

Machines For Powder

Videos For Powder

Frequently Asked Questions

A pharmaceutical powder is defined as a dry, solid substance, composed of finely divided drugs with or without excipients and intended for internal or external use. It is a solid substance in finely divided state typically obtained by crushing, grinding, or comminuting.

Properly prepared, powders have a uniform, small particle size (varying 10nm-1000μm) that has an elegant appearance. In general, powders are more stable than liquid dosage forms and are rapidly soluble, enabling the drug to be absorbed quickly.

Powders can be broadly classified by the way they are presented/dispensed to the user into bulk powders and divided powders. Other classifications of powders are based on particle size and based on use.

Bulk powders are dry, free-flowing preparations consisting of one or a mixture of finely powdered substances and intended for internal application (e.g., bulk powders for internal use) or external application (e.g., bulk powders for external use). They are supplied in bulk or large quantities and are used for less potent drugs.

Divided powders, or chartulae, are powders in which the individual dose has been packed separately. The traditional packing of divided powders is in wrapped paper. Volatile or hygroscopic drugs are wrapped in aluminium foil or plastic bags.

You will get below benefits from pharmaceutical powders as below:

- There is a wide choice of ingredients, and the dose can easily be achieved for patient administration.

- Powders have better physicochemical stability and longer shelf life compared to liquid dosage forms. For example, the shelf life of powders for antibiotic syrups is 2 to 3 years, but once reconstituted with water it is 1 to 2 weeks.

- Children and adults who have trouble swallowing tablets or capsules may find powders more acceptable.

- A large dose that cannot be administered in other forms can be administered as powder. For example, if the dose of a drug is 1 to 5 g it is sometimes not feasible to manufacture tablets to supply the drug to the patient.

- A rapid dispersion of drugs occurs in the stomach when given in powder forms rather than in compressed form.

- Dissolution rate of oral powders containing water-soluble drugs is generally faster than tablets or capsules, in which disintegration of the tablet or the capsule shell is required prior to dissolution. 7. A powder can be dispersed in water or another liquid and more easily swallowed.

- Oral powders can be mixed with beverage or applesauce immediately before use.

- Manufacturing of powder dosage form is economic, hence, product cost is quite economic as compared to other dosage forms.

- Powders offer a lot of flexibility in compounding solids.

There are some disadvantages of pharmaceutical powders as below:

- Powders are not the dosage form of choice for drugs with unpleasant taste. This is because masking of unpleasant tastes may be a problem with this type of preparation.

- Drugs that deteriorate rapidly with exposure to atmosphere or acidic pH should not be dispensed as powders. For example, ferrous iron salts are easily oxidized and should not be administered as powders.

- Powders are bulky and inconvenient to carry.

- Powders are not a suitable dosage form for the administration of drugs that are inactivated in the stomach or drugs which can cause damage to the stomach.

- Dispensing potent drugs requiring low doses as powders (e.g., bulk powders) may not be appropriate. This is because individual doses are usually extracted from the bulk using a 5 ml spoon, which is subject to variation in spoon fill (e.g., level or heaped spoonfuls).

- Powders are not well suited for dispensing hygroscopic or deliquescent drugs.

Granulation is the process of preparing granules, or physical aggre-gates of powders, in which the original particles can still be identified. Granulation commonly involves adhesion of multiple particles of more than one type of powders. This may be achieved with or without the use of water or naturally adhesive hydrophilic polymers, known as binders. Accordingly, granulation is classified based on the means of achieving the adhesion of its powder components into dry granulation or wet granulation.

AIPAK offer two kinds of granulation machine for the processing of powders:

Dry granulation involves compaction of a powder under compressive force of stainless steel rolls, followed by breaking of the compacts into granules of a desired size range. It does not involve any addition of water. The characteristics of the powder particles, such as adhesion, cohesion, fragility, and plasticity, determine the compactibility of a powder.

Wet granulation involves the addition of water, and a binder, to a powder, followed by mixing and removal of water. The binder that becomes well mixed and forms interparticle bonds during granula-tion maintains granules as loosely adhered powder masses even after drying and removal of water.