PACKAGES

PRODUCTS

BAG STYLES

3-side Seal Pouch

3-side seal pouch has the similar shape with 4-side seal pouch,the main difference is both sides are sealed while 3-side if folded on 1 side.Generally,the bottom side of 3-side pouch is foled that allows your products flexible go inside the bottom of the pouch properly.

3-side seal pouches are commonly used for single serve applications ranging from nutritional supplements to instant soups.Depend on various specific requirements,3-side pouch may have a seal and opening either on the top or bottom.

Normally,flat 3-side pouch is appropriate for various applications in both food and non-food industries as they can be very narrow in shape to package products like scissors.

What’s more,the most important feature of 3-side pouch is in some cases,it allows furter packed in a folding carton or box,while the box is then displayed on shelf for retail.

3-side pouch will be your most economical flexible packaging option as it also allows you to brand at the front and back panels.Compared with 4 side seal bags,it has more bag volume,you will be more easy to access to products with the tear notch.

Any more,s-side pouch can used for markets of ground products,medical,nutritional products,household chemicals,meal kits,coffee,snack foods,frozen foods,pet food,etc.

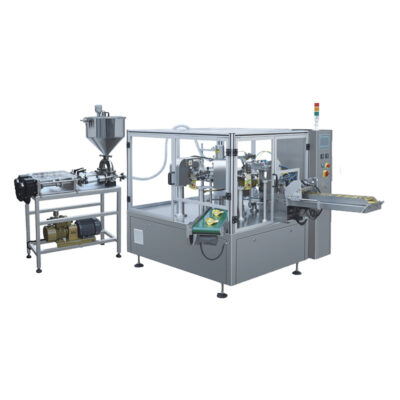

Machines For 3-side Seal Pouch

Videos For 3-side Seal Pouch

Frequently Asked Questions

Material used for 3-side pouch must pass through a quality assessment before they can be used in the manufacturing process.

While the best materials can be :

Polyethylene terephthalate (PET), foil, kraft paper, polyester (poly), aluminum, nylon, etc.

3-side pouch is widely used for pakcaging below:

- Fish and Seafood

- Beef jerky

- Dry food / powders

- Snack foods

- Soups, sauces and spices

- Pet treats

- Frozen food

- Sports nutrition

- Health and beauty

- Home care

- Horticulture

You will benefit from 3-side pouch from many aspects that include:

Reusability

A resealable 3-side seal pouch enables you to close, open and re-close the pouch at your convenience.

Different products

Since you are able to use the pouch beyond its initial use, you can use it to package different products.

Sustainable

Resealable 3-side seal pouch are economical because they can be used for a longer period provided, they remain in good shape.

This is sustainable to a small businesses that opt to use them to package their products.

Reduce wastage

3-side seal pouch are multi-use therefore, they reduce the rate of waste disposal associated with single-use pouches.

Generally,product details,instruction will be printed on the surface of 3-side seal pouch,actually,there are many printing options that including:

Digital printing

It is a way of direct printing digital images or text on media surface such as plastic, paper, fabric, etc.First you should send the image with PDF to the digital printing machine and then use the computer software to control the printing process.

Rotogravure Printing

This way can be also called gravure printing as it is a printing method that uses cylinders that are engraved on the surface.Then the depressions on the metal cylinder surface form the design pattern to be transferred on the pouches.And once the printing area is done it is moved to a drying area before it is ejected from the rotogravure machine.

Flexographic Printing

It is a way of printing that use flexible plates which are wound around the rotating cylinders with the patterns on raised areas.The raised parts are then inked one color per cylinder and then pressed against the pouch surface to transfer the images.