Eye Drop Filling Machine

No Bottle No Filling

No Bottle No Add Stoppering

No Stopping No Add Cap

AIPAK Eye Drop Filling Machine

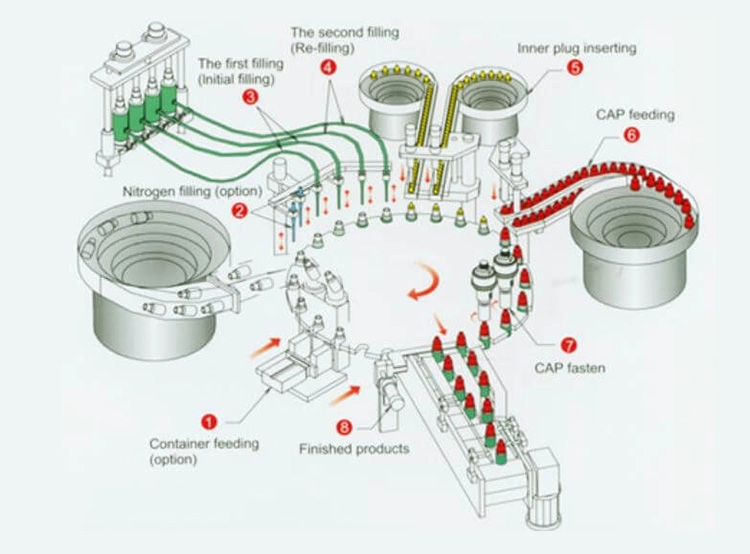

AIPAK Eye Drop Filling Machine Production Line is suitable for eye drops and all kinds of bottle packaging,stoppering,capping. This eye drop filling machine production line completes automatic liquid filling,manipulator add stoppering and cap,capping.According to customer technological reqirements configuration can add bottle feeder or unscrambler.Can effective complete bottle sending,no bottle no filling,no bottle no add stoppering,No stopping no add cap;The machine stoppering and add cap structure upgrading by AIPAK technical team,stoppering and add cap structure use manipulator,precise alignment,finished pass rate more than 99.9%. AIPAK eye drop filling machine performance stable.According packaging materials can be customized.The increased isolation protection system can complete aseptic produce.According to customer technological requirements configuration can satisfy different specifications and production speed.

The Buyer's Guide

Eye Drop Filling Machine: The Ultimate Buying Guide in 2025

A recent research at Columbia University Irving Medical Center has developed a kind of eye drop that could prevent vision loss after retinal vein occlusion, that is ,a major cause of blindness for millions of adults worldwide.

Then here comes the question,how that eye drops filled ?

It is the eye drop filling machine.

Now,I am going to use this guide to introduce various aspects from application,benefits,working principle ,troubleshooting and FAQ about this eye drop filling machine.

You will become an industrial eye drop filling expert read through.

Let’s drive to the topic of the subject directly.

1.What is An Eye Drop Filling Machine?

An Eye Drop Filling Machine is a specially designed machine that is used for filling different types of liquids into vials and bottles.

AIPAK Eye Drop Filling Machine

This machine is used in different industries to serve a different purpose like, it is used in the medical field for the filling of different medicines in a bottle, in the chemical industry machine is used for filling different type of chemicals in bottles/vials.

An Eye Drop Filling Machine gives accuracy to your production by filling the right volume of filling material in a bottle.

2.Where is the Eye Drop Filling Machine used?

An Eye Drop Filling Machine is used in different industries for different purposes.

Pharmaceutical/Medical Industry

In the medical field/industry the Eye Drop Filling Machine is used for filling the Eye Dosage or for some other parts of the body like the ear, nose, etc.

Eye Drops Filling-Picture Credits: edible oil

Different types of medicine can be filled in bottles/vials. You can fill the medicine or dosage up to different levels with the help of the machine.

Chemical Industry

Eye Drop Filling Machine is used for filling different types of chemicals inside the chemical industry.

For the testing of different chemicals in the laboratory Eye Drop Filler is used to fill different types of chemicals in different types of vials/bottles.

Chemical Filling using Eye Drop Filling Machine

Chemists use the Eye Drop Filled bottles for checking the reaction using a different type of chemicals so the machine is very useful in the chemical industry as well.

Cosmetics industry

In the cosmetics industry, Eye Drop Filler is also used for filling various liquid cosmetic products into vials/bottles like nail paints and other different products.

Various beauty items can be filled using the Eye Drop Filling Machine.

Food Industry

The food industry is one of the most common and useful industries in the present world the Eye Drop Filling Machine is used in filling different liquid eatable products into bottles.

Drinks & Pure Water

Products like, cold drinks, juices, and other liquid products that you use in daily life or for your business purpose can be filled into vials/bottles, and then you can store the bottles for a longer time.

3.What will you benefit from Eye Drop Filling Machine?

There are some following Benefits that you can get by using the Eye Drop Filling Machine.

High Speed Filling

Benefits/Advantages of Eye Drop Filling Machine.

- The machine will help you to give perfect production quality with less time consumption.

- It is easy for you to operate it and you can also do the cleaning on your own.

- The machine works through the sensors so if there is no bottle inside the machine filling will not be done.

- The touch screen feature of the machine gives you the flexibility to use the machine according to your requirements.

- The monitor display will help you to easily control all the functions and working of the machine.

- The machine is easy to clean and makes it germ-free without making any pollution.

- There is a shrinking function present in the machine which helps the bottles not drop any dosage after the filling.

- PLC Control System of the machine can also help you increase or decrease the filling speed.

- It is very reliable to fill the liquids up to an accurate level.

- The Machine is made up according to the standard quality with standard certification.

- You can easily change the inside temperature of the machine during the filling.

- Maintenance of the machine is easy you can open all the individual parts for cleaning purposes or for replacement.

- Machine can also help you for capping the bottles precisely with the help of a pneumatic system which holds the air pressure.

4.Are there any Disadvantages of Eye Drop Filling Machine?

Disadvantages of An Eye Drop Filling Machine

There are some following drawbacks of the Machine.

- The machine lacks the accuracy to fill the eye drops up to the perfect volume or measurement.

- Due to the large size of some Eye Drop Filling Machines, they require more space and more labor for their working.

- The cost of the machine is very hard to achieve although it is expensive to buy the machine.

- The liquid of the Eye Drops makes it hard for storing and safe after the filling.

5. How many types of Eye Drop Filling Machines are there?

There are three types of Eye Drop Filling machines.

- Manual Eye Drop Filling Machine.

- Semi-Automatic Eye Drop Filling Machine.

- Fully Automatic Eye Drop Filling Machine.

Manual Eye Drop Filling Machine

This type of machine present in different sizes with different rates as you know you have to operate the machine manually.

You can fill the vials and bottles of different sizes like 5ml, 10, ml, and 15ml for this purpose you may need more labor, and will be costly for you.

The machine of small size that can fill the small bottles like, 5ml and 10ml will cost you from $8,000 to $10,000 as I said before size of the machine will depend on the cost.

Manual Eye Drop Filling Machine

Semi-Automatic Eye Drop Filling Machine

Some of the parts of this machine will be automatic and others may not like the filling will be done automatically but the capping will be done manually.

The Semi-Automatic Filling Machine will also be available in different sizes you can choose one according to your needs & requirements.

Fully Automatic Eye Drop Filling Machine

This machine is Fully Automatic use to fill the different sizes of bottles and vials using the automatic screw bowl which helps to accurately fill the bottles and also do the capping.

The Fully Automatic Eye Drop Filling Machine is capable to fill different sizes of bottles like 5ml, 15ml to 50ml.

The Auto setup of the machine makes it flexible to adjust according to the filling bottles/vials.

AIPAK Fully Automatic Eye Drop Filling Machine

6.What are the Main Components of Eye Drop Filling Machine?

These are the main parts of the Eye Drop Filling Machine.

Peristaltic Pumps

It is used to measure the amount of eye drop in the eye drop filling machine. You can handle it from the control panel of the Machine

Control Panel

It is the main component of the machine. You can handle all the working of the machine from the control panel. The Control panel consists of a touchscreen that allows you to see things digitally.

Pneumatic System

It controls the pressure of air in the machine it has the responsibility that how much eye drop push in the container.

Electric System

When you are putting the eye drop in the containers. It is the system that gives power to the eye filler machine.

Automatic Sensors

It is an automatic sensor that checks that the container is present on the machine before throwing the eye drop in the container. This automatic sensor reduces the waste of eye drop liquid. It overall increases the life of the machine.

Parts of Eye Drop Filling Machine

Reciprocating Filling Nozzle

It is a very important part of the machine. This is the nozzle that drops the liquid into the container.

Conveyor System

It is the transport system of the machine that moves the container from one place to another place for different purposes like filling the liquid and capping the container.

Main Drive System

It is the most important part of the eye drop filling machine. It is the engine of the machine that keeps the machine working.

Vibratory Feeder

This part of the machine takes all the container of eye drop filling machine of the machine to their units.

Different Parts of Eye Drop Filling Machine

Chute System

The chute is liable for conveying the situated spouters with the help of the vibratory feeder to the fitting station.

Capping System

The purpose of this part is to pick up the cap and put it on the eye drop container. It comprises cap setting gadgets, cap in-feed containers, well being hood gadgets, and the laminar stream framework.

you must sure there is a vacuum suction when you pick and put the cap on the eye drop container. There is enough protection on the cap to stop the leaking of the liquid.

Plugging System

This part of the Eye drop Filling Machine is to check the capping of the eye drop container so that there is a vacuum in the bottle and liquid will not leak from it.

Bottle Rejection System

This part of the machine is to check all the containers and if there is any defect in them. It will reject this container.

7.What are the Main Features of AIPAK Eye Drop Filling Machine?

These are the main features of the AIPAK Eye Drop Filling Machine.

AIPAK Eye Drop Filling Machine

Easy to operate

This machine is very easy to operate because there is very little human effort required. You can control all the things from the control panel of the machine-like how much liquid you must put in the vail.

Speed control

You can adjust the speed of the machine that how much production you want, and you can easily increase or decrease the speed of the machine.

Computerized control

This machine has a display control system that makes the process very easy if there is less eye drop liquid in the machine you can easily see it on the control panel. You can easily change the amount of liquid without turning off the machine.

Auto Control System

Automatic Counting

This machine is automatically counting all the eye drops that this machine is producing so you do not have to count the products.

Accuracy of Machine

This machine is very accurate you can control how much liquid you want in the container. It will surely put that much liquid in the container easily you can set anything from the control panel.

Safe from Corrosion

This machine is safe from corrosion because all the part which touch the liquid made of stainless steel.

Advanced Sensor system

Eye drop filler has a very advanced sensor system installed in it. If there is a container missing it will automatically identify there is a missing container on the tray and it will not spill any liquid from the nozzle.

Capping System

The capping system of the machine is very advanced first it pickup the cap then puts it on the container then it closes the cap that way so that no liquid could leak from it and it also works on vacuum theory.

Production Capacity

It has a very good production capacity. This machine made 4200 to 4800 pieces per hour.

Auto Rejection System

When the whole process of filling the dosage and capping of the product is complete then at the end there is an auto rejection system. This system checks every product if it sees any defect in any of the products it will automatically reject this product.

Quality Standards

This machine is made according to the standard of GMP and has CE certification which makes sure that all the electronic part of the machine is safe. It also has these certifications ISO, FDA, USP, PhEur, and Japanese pharma Copeia.

Other Features of Eye Drop Filling Machine

- All the parts which make contact with the liquid are made up of Stainless Steel so the machine can remain stain-free.

- Body structure of the machine is also made up of Stainless Steel called 304 Pipe.

- Easy to operate all the functions by using the 3D touch panel.

- If there is no vial/bottle present inside the machine will be stopped.

- After the filling is done the machine will cap the bottles and precisely screw the caps.

- There is a mechanical plate or you can say that a bowl which holds the vials/bottles and the screw notch tight the caps while the bowl is spinning.

- If the size of the filling bottle is change then you can change bowl settings easily according to the requirements in the minimum time frame.

- Cleaning is easy you can remove all the individual parts of the machine.

- Co-centric nozzles allow the bottles/vials to fit inside perfectly for filling purposes.

- With the help of air pressure, the capping is done so that no filling material can be wasted during the movement of filled bottles.

- An Automatic Eye Drop Filling Machine can fill up to 40,000 bottles per hour.

- Different diameter bottles can be filled with the machine.

- User Friendly and easy to operate.

8.How does Eye Drop Filling Machine Work?

Eyes drop filling machines are good for use in the drug industry for the filling of liquid in 2 to 30 ml containers and for the packing process.

This machine has high accuracy in peristaltic pump filling, and it is very easy to use.

The main purpose of this machine is to fill the vail, Plug the vail, and screw capping.

1- In the first phase, the vail is on the stainless-steel conveyor which is always moving and then the vail moves onward to the star wheel which is used for ordering the things then the vail turns clockwise and enters the star wheel pocket then it is moved to the filling unit.

2- In the filling unit, the vail moves toward the filling nozzle where it is filled by the nozzle, then the vail moves onward to the nozzle placing unit. Where the nozzle is situated is come in the chute by a vibratory feeder which picks by vacuum pickup and places it on the vail.

After this process, it is transferred to another station by the star wheel.

3- In this unit, the cap is picked by the vacuum and placed on the head of the vail after this process it is moving toward the screw capping system where the cap is tightened by this unit.

You can adjust the force of screw capping after this process and it moves onward to the conveyor.

4-At the end there is a rejection system installed which looks for any defect in the machine if there is any defect in the product, it is automatically rejected by the rejection system after the filling of dosage and screw capping, and then it exits the conveyor for the packing process.

Working of Filling Machine Picture Courtesy-Photo Credits:Kwangdah.com

9.What are the Applicable Specifications of AIPAK Eye Drop Filling Machine?

These are the specification of the AIPAK eye drop filling machine.

Production Line of

Production Speed

There are two variations of this machine single head and double head. A single head eye drop machine produces 40 to 55 bottles per minute and a double head machine produces 60 to 100 bottles per minute.

Weight of Machine

The weight of the machine is in the range of 950 kilograms to 1200 kilograms.

Power Supply

This machine uses 220 volts to 380 volts of power. It uses an overall 2.5-kilowatt of electricity

The dimension of this machine

The length of this machine 7500 mm, the width of this machine is 2000 and the height of this machine is 1500 millimeters. These are the dimension 7500x2000x1500 mm.

Filling Error

The error percentage of filling the liquid in the container is less than two percent. This machine is very accurate.

Bottle breaking rate

As you know that this machine is very accurate bottle breaking rate of this machine is very low. The rate of bottle breaking is just 0.1 percent.

Capping and sealing

The pass rate of capping and sealing is very high. The pass rate of the capping and sealing is 99 percent.

Filling Range

The filling range of the machine is from 2 to 20 millimeter

Filling Needle

You can choose how many needles you want in the machine there are two variations one needle and two-needle variations

Capping type

The rotary type of cap is used in the capping process of this machine

Material of bottle

You can use a glass bottle or plastic bottle in this machine.

10.How To Compare Eye Drop Filling Machine and other Liquid Filling Machine?

| Eye Drop Filling Machine | Liquid Filling Machine |

| Eye drop filling machine can fill up to 100 bottles per minute. | The liquid filling machine can fill up to 120 bottles per minute. |

| The filling range of this machine is 2 ml to 20 ml. | The filling range of this machine is 5ml to 10 liters. |

| This machine comes with the option of one or two filling heads. | This machine comes with the option of up to twelve filling heads. |

| You cannot use the liquid with solid particles in this machine. | You can use the liquid with the solid particles in this machine. |

| This machine only fills the small containers. | This machine can fill large containers. |

| This machine is mostly used in the pharmaceutical industry. | This machine is mostly used in the food industry. |

11.What Other Equipment is needed to form a complete Eye Drop Filling Production Line?

These are the equipment that is needed to form a complete Eye Drop Filling Production Line.

Air Compressor

An Air compressor is a device that is used to change power into potential energy with the help of a gasoline engine or electric motor. This air compressor stores more and more in the tank which increases the pressure of the air which is also called compressed air.

Closing station

The closing station is used for screw capping of the vails. In this closing station, there is a PVC screen control panel where you can adjust the force that you want to use for the capping of the vails.

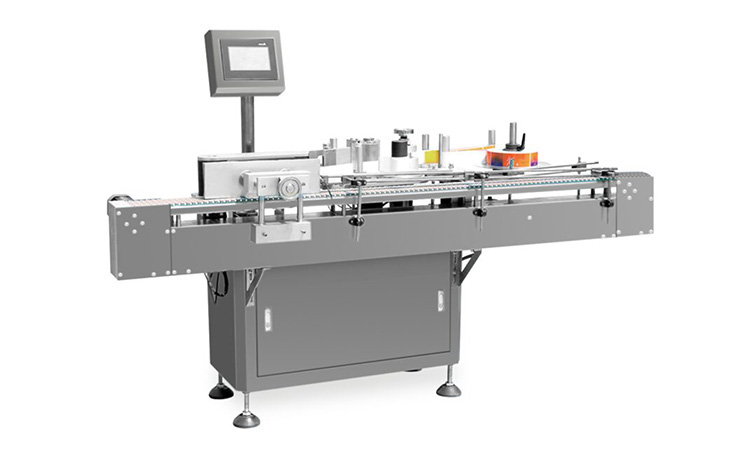

Labeling Machine

AIPAK Labeling Machine

This machine is used to print and apply the label on the product. This machine is used for printing and applying the label on plastic, fiber drums, and glass. Labeling machine used in many industries.

Ink Jet Coding Machine

Ink jet coding machines are used to print important data on the product. In the Eye drop filling process it is used to print the manufacturing date and expiry date of the product on the vail. You can also use this machine for many purposes.

Cartoning Machine

AIPAK Cartoning Machine

Cartoning machine is the type of packaging machine which is used to make the cartons and put the product in these cartons and after this sealing the cartons.

12.How many types of Capping can you make through the Eye Drop Filling Machine?

There are four types of the capping in a eye drop filling machine;

- Screw Caps with Thread

- Child Resistant Caps

- Crimp Flutes

- Press on Closure

Screw Caps with Thread

Ideal conclusion answer for applications including continued opening and shutting of the compartment.

A wide choice of sizes and liner designs conveys an ideal fit with every compartment and compound similarity with the example.

Tubing association covers and fluid conveyance frameworks for protected and simple fluid exchanges all through jugs.

Child Resistant Caps

Kid Resistant Closures and Packaging have been utilized to package medications, makeup, and family unit synthetic compounds.

The quantity of kids who have passed on from ingesting poisonous family substances has declined fundamentally since the CPSC United States Consumer Product Safety Commission guidelines were received.

Both CPSC and the U.S. Natural Protection Agency require the utilization of this bundling with specific items.

Child Resistant Caps

Crimp Flutes

A crimp flute pressing system is used in this type of capping which a metal disk is used that.

Thus, this circle holds an internal plate made of tough coating material to frame the real seal.

Crimp Flute Capping

Press on Closure /Capping

Press-on closures are held set up using undercuts or beads rather than strings/ any type of thread. They are once in a while called snap fit closing too.

These are some of the things that can be sealed with such type of capping;

- Bottles

- Jar

- Tube

- Can

Other than that, they can also be used for capping other things too.

13. Is there any Environment Requirement during the Eye Drop Filling Process?

Yes, there is a great process of eye drop filling. Eyed drops are being produced in the sterilized environment.

The manufacturing of eye drops requires the cleansing of the bottle filling station that is being monitored with more care of the sterilization steam used to sterilized eye drops.

20 spouts/Nozzles are used to fill a reformist line of plastic bottles. In this process, nozzles of bottles are being put into sterilization chambers which are being located straight under the station.

In this chamber, after that the nozzles are being presented to the steam to purify them.

In this process of sanitization, the conditions in which these are sterilized in the climate that is 80 degree refined water followed by 123 degree purified steam at 20psi for almost 30 minutes.

It is very important for the client to know that the equipment is being exactly kept for 30 minutes at 123 degree temperature.

The client should be sure about the exact temperature where the equipment is being placed.

Otherwise he can face difficulties in the accurate reading of the temperature.

14.What Quality Standards Should Eye Drop Filling Machine conform to?

There are some Quality standards which are set by the Good Manufacturing practice (GMP). So that the Eye Drop Filling machine is made according to the standards of GMP. This Eye Drop Filling Machine has CE certification which assures you that all the electronic pieces of machine are protected.

Furthermore, This Eye Drop Filling Machine has also the certifications of other authorities like:

ISO

The Eye Drop Filling machine has ISO standards which shows us the consistency of the machine. These standards make sure that the product has consistency in the work.

FDA

This machine also has FDA certification. This certification tells us about the product’s regulatory and its advertising status.

USP

This is stands for a Unique Selling Proposition. It assures us that the product accommodates the same components that are being listed on the label.

Ph. Eur

This Eye Drop Filling Machine also has the certification of Ph. Eur. This certificate tells us about the quality of a substance.

Japanese Pharmacopoeia

And the last one is Japanese Pharmacopoeia. This Eye Drop Filling machine has also the certification of this company. So, these all certifications tell us the validity of the machine.

15. What are the Common Problems of Eye Drop Filling Machines? How to solve them?

Yes there are some problems occurred in the filling of eye drops from the eye drop filling machine. These are

Non-accurate measuring

The very first problem faced in the filling of eye drops by eye drop filling machine is non-accurate measuring of the amount of eye drop in the eye drop bottle.

This machine has faced trouble in estimating the perfect measurement of eye drop to fill the eye drop bottle.

So, we can avoid non-accurate measuring by manufacturing the machines that can measure accurate amount of eye drops in the bottle.

Less Space

The second problem faced by the machine is that, there are very small spaces where we kept eye drop filling machine.

There are some large machines which require more space than the available spaces at the spot.

So we need to accommodate more space to overcome this problem to make eye drops from the eye drop filling machines.

Very Costly

The third and the second last problem is that eye drop filling machine is very costly to buy.

It’s not easy for everyone to purchase the machine because of its very higher rates.

So only the big companies can purchase it and make eye drops from the eye drop filling machine.

To overcome this problem you need to make the machines that are much cheaper in their rates as compared to these machines nowadays.

Storage Issues

The last but not the least one problem everyone is facing regarding to the eye drop filling machine is the stockpiling issues.

This machine has experienced less storage. It is not able to store large amount of eye drops.

So, this problem can be overcome by making such type of eye drop filling machines that has large spaces to store eye drops in them.

16.Which factors should you consider when buying an eye drop filling machine?

To enhance the products and fulfilling the expectations of the client's many eye drop filling machine manufacturers are now searching out approaches to enhance their products.

Finding realistic enhancements that also give an advantage to their clients in any region of operations is the thing that has the potential to provide eye drop filling machine manufacturers an aspect over their competitors.

AIPAK Eye Drop Filling Machine

So, you also have to check out the things before buying an eye drop filling machine that may affect your production and other factors like the level of automation you are looking for or the working area you have.

Now, you are going to check out these factors that may help you to buy your eye drop filling machine.

Container Type

Sometimes, there can be multiple systems that work properly for filling a given product.

However, for a few projects, in making the precise preference the container getting used is also taken into consideration. you could choose the overflow filler if you're going to use a clear container.

This is since irrespective of small inconsistencies with inside the indoors quantity of the container it could fill every container to the identical stage.

Therefore, when the product receives to the shelf gives an appealing look.

Container Structure:

Through the structure of the container, the preference of the machine can also be decided.

Let us have an example for a specific container with a non-merit cap or lid, for an automated bottle filler which grabs bottles from the upside it can now no longer be suitable to head.

Likewise, when filling very extensive containers you can't use a bottle filler which grips by the side. Most bottle filler producers are usually inclined to check your containers and assist you to pick out the excellent system.

Packaging Material

Using big or small containers can affect the selection of the nozzles or the machine that you may use for packaging. Apart from the product itself, therefore in figuring out which filler will give a satisfactory match to any given project the packaging material getting used is some other essential component to remember.

What substance is it made of?

Aluminum glass or plastic, because every one of them needs their precise filling technique.

It is crucial to recognize which substance you're using, as this could assist select the perfect eye drop filling machine to purchase.

Fill Rate

This means the number of bottles you'll want to fill per hour.

You will be assisted by your manufacturing necessities in figuring out whether or not you'll cross for a

- Manual

- Semi-automated

- Completely automated system.

If you choose the semi-computerized type of machine, you are responsible to do manual hard work for fill method activation, bottle placement, and to dispose of the stuffed containers.

Therefore, it'll give you a slower rate at which the filling method is completed. In the case of Automated machines, less operator interaction is required, for this reason making sure a completely excessive filling fee.

To attain manufacturing demands, your preference for the quality filling system will consequently significantly rely on the number of bottles per minute filled.

Flow measurement

Even without the help of a flow meter, in a hydraulic system, you could still measure the flow rate.

You can measure the flow by a very easy technique which is through checking how much time it'll take to fill a container like a bucket with oil.

However, aside from being very hazardous, this thing doesn't sound technical. This is due

to the fact as soon as the oil is in the bucket, it's far out of circulation. It is not internal of the hydraulic system & is consequently uncovered to contamination.

Quality Compliance

You should consider that either eye drop filling machine is ensuring the hygiene and safety standards or not? Because it is the basic requirement and your machine has to follow the quality standards.

Technicalities

You have to consider the technicalities of the eye drop filling machine. The daily bases advancements that have brought revolutionary advancement.

Either the quality, speed, or performance of the machine is it up to the mark or not?

Your machine should combine with the existing production line and help out to enhance your production level.

Market Value & User Friendly

And last but not least the eye drop filling machine you are going to buy should have a good market value and reputation and it shouldn’t be complex. It must be more user-friendly and providing you the maximum output.

17.Is there any New Technology in Eye Drop Filling Machine?

The pharmaceutical industry is making great advancements in the respective field. Yes, there is a new technology in the eye drop filling machine as well. These advancements making workload less and production rate high.

The housing and surface are being done with stainless-steel. From corrosion-resistant stainless-steel, all liquid contacts are crafted. Liquid filling extent to be adjusted more precisely and flexibly.

To save you spills and the forming of foam, the liquid filler has followed processing ranges to be had for a slow upward motion from the lowest of the bottle. To make sure caps are tightened.

Now, the capping machine consists of cap vibrating feeding and capping with torque limiter.

The digital part of this system is managed through a smart PLC, making sure that no bottles are feeder now no longer plugs are inserted, now no longer liquid is filled and now no longer caps are capped.

It allows the entire manufacturing system to continue to be smooth with management over quality.

Now,

There are some new advanced eye drop filling machines that are given below:

DSG-120 Eye Drops Filling Machine (Mature Cutting-edge Technology)

For full automatic control, you can have this multi-axis motion control system with HCI and PLC

DSG-120 Eye Drops Filling Machine (Safe, Reliable and Trustworthy Products)

For enabling reliable and safe operations you can have this multi-axis motion control system.

Also, it assists us in allowing the extraordinarily low price of operation, decreasing the fault rates and maintenance.

Eye Drop Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586