PACKAGES

PRODUCTS

BAG STYLES

Capsules

Capsules have been a very reliable and widely accepted method form of encapsulation for nutraceutical formulas.

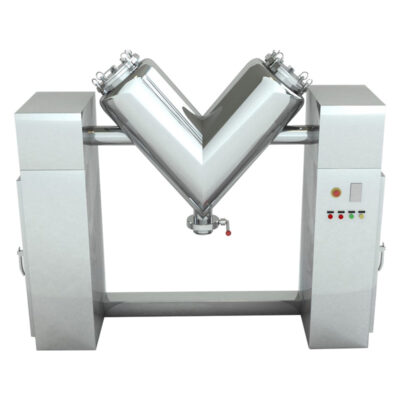

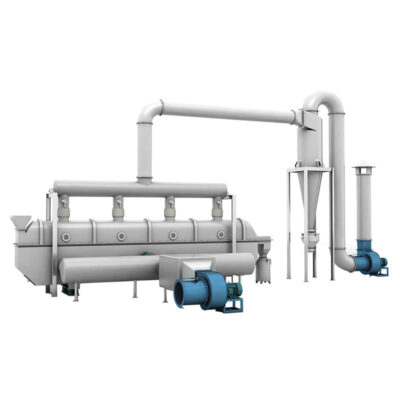

Before encapsulation, your formula must be blended to ensure even distribution of ingredients in each capsule.The powders within the capsules have to be prepared in two ways,wet granulation and dry granulation process.

AIPAK offers a wide range of wet granulation machines,fluid bed dryers,blenders and pharmaceutical dryers for making your formula ready and mixed.

The dry granulation blend is to apply immense pressure and force to make your powder more compact and increase the bulk density.

Once all ingredients in your formula are blended, they are to be filled into empty capsules.

AIPAK has various automatic capsule filling machines for your choice to fill the powder in whatever your gelatin,vegetable or pullulan capsule shells.

After that,each of your capsule will need to be polished of any excess powder for a clean finished look and triple inspected for any defects.

AIPAK has automatic capsule polishing machine or capsule sorter to make your capsule more appealing as well as sorting out the unqualified capsules.

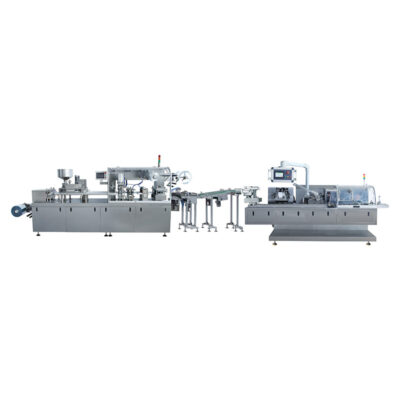

The last step is to pack your filled capsule,at AIPAK,we have first packaging tools-blister packaging machine,to pack your capsules in cavities or pockets made up of thermoformed plastic or cold-formed aluminum film to protect your capsules from mositure or easy to store.

The secondary packaging tools-tablet counting machine and cartoning machine are to count your capsules and make it filled into bottle or make your blister packed capsules cartoning into box.

Machines For Capsules

Videos For Capsules

Frequently Asked Questions

You need to determine the density of your formulation to answer this question. For powder formulations, use the tapped density value. For pellets or granules, use the bulk density. Once you have this information and you know the target fill weight, you can ask us for ask a capacity chart,

using this chart as an example, encapsulating 500 milligrams of a powder with a tapped density of 0.8 gram per milliliter would require a size 0 capsule.

The traditional approach is to perform a quality check on a small sample (usually 10 capsules) every 30 or 60 minutes when you take a weight -check sample.

While this is certainly a good procedure and one that my capsule flling department followed for many years, we still visualy inspected the batches to remove defects that were not always found in the routine quality checks.

Every time we analyzed a quality problem, we discovered a high correlation between the setup of the capsule flling machine and the incidence rate of defects. Based on this, we began to check a large sample for acceptable quality level (AQL) after every machine setup and after every major repair.

After adjusting the machine to hit the target fill weight, we would perform a sustained run for 5 to 10 minutes, stop, and then carefully inspect every capsule for defects. Using such a large sample highlighted specific defects that, in most cases, we could attribute to machine setup.

The best method for determining suitability is to conduct compatibility studies of the API and the excipients.

There are two major API characteristics that can be problematic: moisture sensitivity and hygroscopicity.

Moisture sensitivity. Two-piece gelatin capsule shellshave moisture content between 13 and 16 percent, and the moisture can interact with the encapsulated product and cause stability problems.Hygroscopicity. Once encapsulated, hygroscopic products will remove moisture from the gelatin capsule shell, which leads to brittleness once moisture content drops below 10 percent.

There are two capsule alternatives to address the problems associated with these types of formulations:Hydroxypropyl methylcellulose (HPMC) capsules and gelatin-polyethylene glycol (PEG) capsules.

The capsule flling and dosing mechanisms for pellets and granules are based on volumetric filling, by using either a dosing chamber or a vacuum dosator or by directly flling into the capsule body. Inconsistency can result from

- Large differences in the pellet/granule particle size

- Agglomeration of the pellets/granules

- Poor flow characteristics

- Insufficient level of pellets in the supply hopper that fills the dosing chamber

- Electrostatic charge that retards the transfer from the dosing chamber to the capsule body

In many cases, the pellets or granules have a functional coating that controls release. It's important to verify that the dosing system and the material handling system (product feeder) are not abrading the coating, which could affect the release profile.

Products that comprise a blend of different pellets raise the issue of content uniformity, particularly when the blend includes high- and low-dose pellet groups. The pellets may segregate (de- blend) during feeding or encapsulation. Since many of the modern flling machines can be equipped with more than one pellet feeding system, you can resolve this problem by feeding the pellet prod-ucts separately.

Empty two-piece gelatin capsules are shipped with a moisture content between 13 to 16 percent. It is important that this moisture content is maintained.

Avoid exposing the capsules to high temperatures or to cycles of high and low temperatures.

There is also a tremendous volume of air inside the capsule that can extract or release moisture from the capsule.

Maintain the area where you store the capsules at 15° to 25°C and 35 to 55 percent relative humidity (RH). Do not store empty capsules in freezers. The empty capsules are also very sus-

ceptible to damage because the capsule walls are unsupported.

Filled capsules. The storage requirements for flled capsules are based on the product stability profile.

The warehouse storage areas should be temperature-mapped and monitored to ensure the room temperature is under control and that product-specific refrigeration/RH requirements are maintained. Ideally, the storage area would be equipped with alarms and there would be prod-

uct-specific product handling procedures that explain how to deal with out-of-limit temperature/humidity incidents.

If the product is stored in bulk containers for a significant period of time prior to packaging, you should institute procedures to monitor bulk product stability.

General storage recommendations. Protect the capsules from direct sunlight by storing them away from windows and skylights. They should also be stored away from radiators, heat registers, hot water pipes, and steam pipes. Keep the capsules out from under potential sources of water condensation, such as water pipes, and keep pallet loads off the floor.

Both work equally well. Both break down in the acid environment of the stomach within 15 minutes. Vegetable capsules sell at a higher price than gelatin. They are generally used by people who do not want to eat animal products. Gelatin capsules are made from Kosher and Halal Beef Gelatin.