Mixing-granulating-drying in one-step

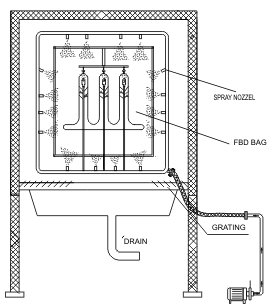

Adopting double chamber filtering bags system, removing dust completely

Adopting multi-fluid nozzle, it guarantees that the formed granule is uniform and the content of powder is very low

Can choose 2 bar explosion-proof design

Designed, manufactured and laid out by GMP

No cross pollution between the material and air

Operates under closed negative pressure, no dust explosion

Want A Free Consultation

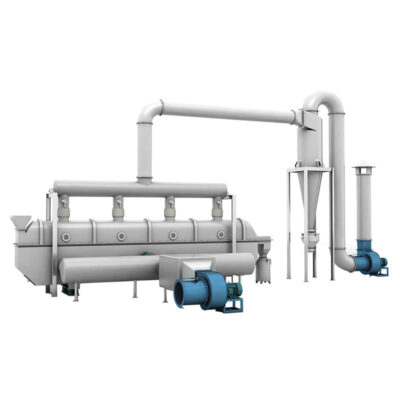

FG Series Fluid bed Dryer-bed dryer, fbd dryer, fluid bed dryer manufacturer

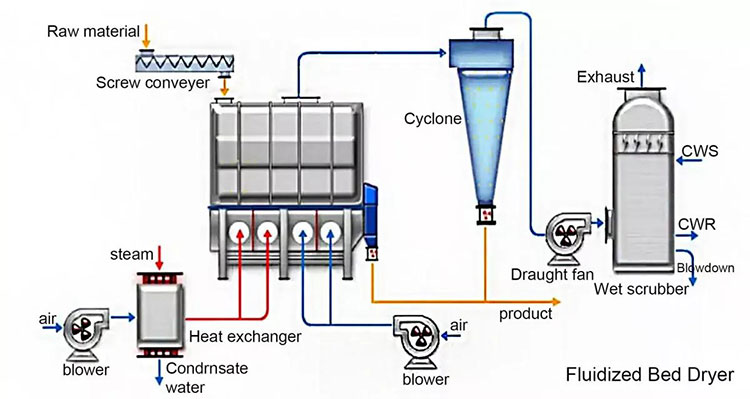

AIPAK FG series Fluid bed dryer is the special equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules. By using powder granulation, AIPAK fluid bed dryer can be used to improve the liquidity and thinner dust. By using powder granulation, to improve solubility property.You will get your mixing, granulation, drying finished in one device.

The fluid bed dryer has been widely used in Pharmaceutical Industry, Foodstuff Industry, Spice Industry, Chemical Industry, etc.

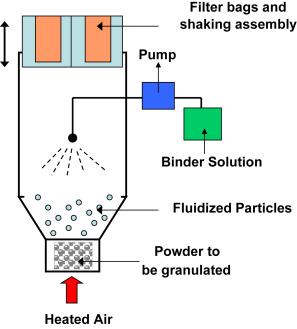

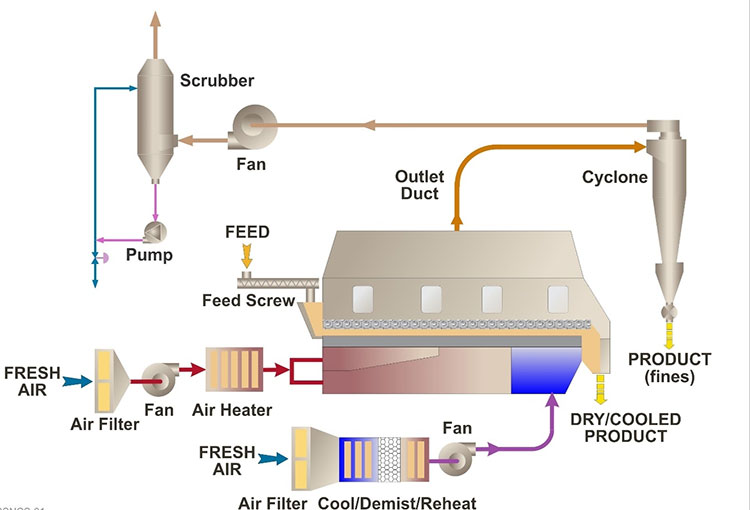

The working principle of this FG series fluid bed dryer is the powder granule in the fluid bed appears in the state of fluidization. It is preheated and mixed with clean and heated air. At the same time, the solution of adhesive is sprayed into the container. It makes the particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulating is evaporated. The process is carried out continuously. Finally, it forms ideal, uniform and porous granules.

AIPAK fluid bed dryer adopts antistatic filtering mediums, that ensure safe operation. Its caking agent atomizer adopts a multi-fluid spray gun to maintain uniform spray particles and to increase the rate of qualified products greatly.

The fluid bed dryer is a no-dead corner equipment that is easy and rapid of feeding or discharging materials and clean of washing to satisfy the GMP standard.

FEATURE

1.The structure of fluidization bed is round so as to avoid the dead angle.

2.Inside the hopper there is a stirrer in order to avoid agglomeration of raw material and forming canal of flow.

3.The granule is discharged through the method of turning over. In this way it is very convenient. The discharging system can be designed as required, too.

4.It is operated at the condition of negative pressure and seal. The air is filtered. Therefore it is simple in operation and convenient in clean. It is an ideal equipment that is in conformity with the requirements of GMP.

5.The drying speed is fast and the temperature is uniform. In general, the drying time is 15-45 minutes each batch.

6.Use screw to extrude and vibrate granule and granulate the granule with the method of humidity, high speed and mixing

7.Suitable for drying humidity block or powder raw material in the fields such as pharmaceutical, foodstuff, feed stuff, chemical industries and so on

8.The raw material that large in granule and small in block and having adhesive property

9.Suitable for raw materials, its volume will be changed when dry, such as giantarum, polyacrylamide, etc.

DATA SHEET

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586

Drier Machine Related Products

Drier Machine Related Posts

Drier Machine Related Videos

The Buyer's Guide

Fluid Bed Dryer: Your Complete Solution Guide In 2021

A Fluid bed dryer, otherwise called a liquid bed dryer, is one of the things you ought to think about buying. You're likely asking yourself a ton of inquiries about this machine works. You might have been confused what does fluid bed dryer do, cost and what is the best place to get so?

Do you run a drug producing factory? Suppose you're pondering to get one. It is plainly obvious that you might want to buy different sorts of machines.

These are the portion of the considerations that are going through your mind? In the event that you addressed indeed, you've came at at the right place We'll give you a bit by bit manual for purchasing a reliable fluid bed dryer in this article.

1.What is Fluid Bed Dryer?

AIPAK Fluid Bed Dryer

Fluid Bed Dryer is a process of drying the material used in the granulation process in the tablet formulation.

This equipment is used in pharmaceutical industries to lessen the amount of powder and grains in the tablets.

Fluid Bed dryer is a machine which converts the hard particle to the soft fluid type material.

In addition, the Fluid Bed Dryer is also used in the preparation of food, in the dairy products and in the chemical industries for drying the material.

The machine basically works on the principle of Fluidization. We will talk briefly about this principle.

This machine is now available in the models with the advanced drying techniques which is the better one from the old ones. This new model works with the more efficiency than the previous one.

The Fluid Bed Dryer can dry the granules or powder in a very easy way. The hot air is used for moisturizing the process of drying. This equipment lifts up the tablet and hot air sucks all the moisture present in the tablet.

It also can be very helpful in drying every kind of material and also it increases the life period of the product with the good quality assurance. It is also a very fast process of drying tablets and other materials.

2.What is the reason behind the usage of Fluid Bed Dryer?

The Fluid Bed Dryer gives a great help to the industry in drying tablets at very fast and rapid speed.

Increases the Lifetime

This equipment increases the life period of the product you actually dried from it.

And this can be done by using Fluid Bed Dryer in drying of the granules for increasing their life period. So, this is the only process of increasing the lifespan of the product.

Because it is the best method for removing all moisture from the granules present on it.

The problem occurs in the wrapping of different products of dairy and in the food wrapping or in industries because the products are not dried and they expire before their actual period of life.

So, this Fluid Bed Dryer dries the products in an effective manner which helps in increasing the lifespan of the products.

And also, it gives very less damage to the product during the drying process.

Quality Assurance

The Fluid Bed Dryer also increases the quality of the granules and other material.

Because the equipment sucks all the moisture from the product which makes the better-quality products.

So, it works at a constant speed and gives you the better version of the products.

Uniform Drying

The Fluid Bed Dryer is a type of equipment which uniformly dries the product and makes its better shape.

So, it is a very smooth and effective method of drying products uniformly according the need of yours.

Saves time

The Fluid Bed dryer is special equipment which makes the work easy and dries the granules in less time. It saves great time for the industrialist in drying the granules.

It is a very fast method of getting the desirable products in a dry form.

3.What are the Advantages of the Fluid Bed Dryer?

There are some main advantages of the Fluid Bed Dryer are as follows:

Efficient Drying

The great advantage of the Fluid Bed Dryer is that it gives very high efficiency in drying the granules or other materials.

The equipment gives its best to make products at the great efficiency level with its unique type of working.

In this drying process the hot air dries the moisture from the product very efficiently.

Uniform Drying

The next main advantage of Fluid Bed Dryer is the uniform drying. The equipment gives you the uniform drying of the product and gives you the guarantee for that too.

It also makes it easy for you to get the product uniformly at good quality. So, it is better to use this drying equipment for making uniform drying from it.

Uniform Granulation Credit: nicomac.com

Fast Drying

The Fluid Bed Dryer has another important advantage. It dries the granules at very high speed in very less time. So, it is a time saver as well. No other dryer works at the speed of a Fluid Bed Dryer.

Requires Less Maintenance

This is one of the biggest advantages of the equipment. The Fluid Bed Dryer requires very less maintenance. So, it means that it is very easy to maintain.

So, the regular maintenance required for it just like in the simple way to keep it clean from the dust.

Lessens the Number of Errors

The more the number of the errors the lesser the efficiency. The lesser the efficiency the lesser the productivity.

So, in one way or another a number of errors affects lots of things in the process. But this equipment doesn’t give errors in the working. So, it is consistent and smooth in working.

Less worker needed

There is no doubt that labor is expensive and every day the cost of labor is increasing. Laborers will require pay rates, rewards, breaks, excursion days just as other pay.

This isn't the situation with regards to the Fluid Bed Dryer. It requires very less staff to work with this equipment.

Easy to Use

Another important advantage of the machine is that it is very easy to use as compared to the other ones. It doesn’t need any special technique to operate with it.

4.What are the Disadvantages of the Fluid Bed Dryer?

The Fluid Bed Dryer also have some disadvantages that are as follows:

Bad Fluidization

The bad fluidization can be occurring in the Fluid Bed Dryer. It is because of the excessiveness dampness of the feed.

Fluidization Credit: sciencedirect.com

Flammability Danger

The Fluid Bed Dryer can be dangerous due to the high rise of the gas and hot air in it.

So, don’t try any toxic material for fluidization because it can lift up the fire explosion.

Flammability Danger Credit: opuskineticenergy.com

Bad Eliminator of Organic Solvents

Another disadvantage of Fluid Bed Dryer is that it is not a good eliminator of the organic solvent when it is needed in the drying process.

Doesn’t have enhanced gas managing

The Fluid Bed Dryer doesn’t have an enhanced gas managing system which effects the efficiency of the Fluid Bed Dryer.

Product Lost Possibility

The main disadvantage of the FLUID Bed Dryer is that there is a great possibility of the loss of product.

5.Which industries use Fluid Bed Dryer?

The Fluid Bed Dryer is widely used in different type of industries.

The industries that use Fluid Bed Dryer are as follows:

Chemical Industries

The Fluid Bed Dryer is commonly used in chemical industries for drying the chemicals.

So, the moisture on the chemicals can be removed from the Fluid Bed Dryer. Some chemicals have a great quantity of moisture on them and Fluid Bed Dryer removes all the moisture and then they become ready to use in the industries.

Chemical Industry Credit: azocleantech.com

Pharmaceutical Industries

Pharmaceutical Industries also use Fluid Bed Dryer for the drying purposes.

In Pharmaceutical Industries the Fluid Bed Dryer is used to dry the moisture on the granules and the powder. Because some of the granules have most of the moisture on it.

Removing moisture on the granules can also help in the increase of lifespan of the medicines.

Pharmaceutical Industry Credit: Bangladesh.uz

Food Industries

The Fluid Bed Dryer is used in the Food Industries for drying purposes.

The equipment sucks all the moisture from the food products and makes them dry and also the products now after drying can be preserved for a long time.

The Fluid Bed Dryer can do multiple tasking in the food industries like drying and solvent removal.

Dairy Industries

The Fluid Bed Dryer is widely used in dairy industries to dry the dairy products.

Some of the dairy products have moisture on them which can harm the products. So, it is important to remove that moisture from the products to make it usable for a longer period of time and this can only be done by the Fluid Bed Dryer.

Metallurgical Industries

In Metallurgical Industries the Fluid Bed Dryer is used to dry metal products.

Everyone knows that metal products can be corroded if they have moisture on it. So,

For removing purposes, you have to use the equipment at any cost to avoid corroding.

Dye Industry

Fluid Bed Dryer is also used in the dye industry for removing the moisture.

Dye industries used Fluid Bed Dryer to dry cotton, leather, wool, silk, etc. The equipment sucks all the moisture from it and makes it dry.

6.What are the types of Fluid Bed Dryer?

There are two types of Fluid Bed Dryers that are mainly used in the industries.

Conventional

Conventional Fluid Bed Dryers used to dry the variety of products. This type of Fluid Bed Dryer is not modified. They don’t use the modified techniques.

This type dries a smaller number of granules and other items at one time. It also spoils less material while drying.

At the diminished pace of the drying chamber this machine is hesitant when managing the home at the low measure of drying zone where you can set the precise control for the residence period.

This equipment has some other kinds like:

- Plug Fluid Bed Dryer

- Semi-continuous Fluid Bed Dryer

- Continuous Fluid Bed Dryer

- Batch Fluid Bed Dryers

Conventional Fluid Bed Dryer Credit: researchgate.com

Modified

This is the other type of Fluid Bed Dryer. These Fluid Bed Dryers are the modified one rather than the conventional type.

These Fluid Bed Dryers are efficient ones and more modernized than the conventional one.

Moreover, these types of Fluid Bed Dryers have some modified components that are not available in the conventional one.

The advanced Fluid Bed Dryers are really helpful in drying the material. The new technologies present in the Modified makes the work more easy and more efficient.

The examples of Modified Fluid Bed Dryers are as follows:

- Recirculating Fluid Bed Dryer

- Swirl Fluid Bed Dryer

- Hybrid Fluid Bed Dryer

- Jetting Fluid Bed Dryer

- Vibrated Fluid Bed Dryer

- Heat Pump Fluid Bed Dryer

All these Fluid Bed Dryers are the ones which are modified in their technologies. They have more functions in it.

7.Compare Rotary and Fluid Bed Dryer?

Fluid Bed dryers and Rotary Bed Dryers contrast severally, each offering their own exceptional benefits and inconveniences. As a rule, the decision between a Rotary dryer and Fluid Bed Dryer is frequently directed by the material or explicit industry.

The Rotary Dryer is commonly used in industries like minerals and fertilizers. Furthermore, the Fluid Bed Dryer is more used in pharmaceutical industries, food industries and chemical industries.

Each one has some advantages and disadvantages. If a person requires more quantity of material to dry than the Fluid Bed Dryer will be beneficial for that because Rotary Dryer does not dry the material in very large amounts. So, it is chosen on the basis of the requirement by the person.

1.Consumption of Energy

The Rotary Dryer uses less energy to work and dry the equipment. The requirement of energy is very low here as compared to the Fluid Bed Dryer. It can also work at very less capacity during the consumption of energy. It is also less thermally efficient.

But on the other side, a Fluid Bed Dryer consumes more energy for working. The Fluid Bed Dryer works on the fluidization process which requires more energy to fluidiz material. The Fluid Bed Dryer is more thermally efficient because of the drying air which surrounds the granules.

2.Maintenance Required

In terms of maintenance of the equipment, both required some type of maintenance.

The Rotary Dryer requires more maintenance.

While the Fluid Bed Dryer requires less maintenance as compared to the Rotary.

3.Spatial Footprint

The Rotary Dryer has larger special footprints than the Fluid Bed Dryer because of their larger and immense sizes.

On the other hand, Fluid Bed Dryer requires smaller footprints due to its small size which is a great advantage. These Dryers are modernized dryers and ready to face all type of situations.

4.Operational Considerations

Rotary Dryers didn’t affect the fluctuations in the drying process. The requirement of supervision is very low here.

While, the Fluid Bed Dryer is not good facing these types of situations. Fluctuations in the drying can cause big problems which result in bad drying.

8.What are the different factors affecting Drying?

There are basically four different factors affecting drying during the drying process.

These four are Air, Humidity, Temperature and Heat

Air

Air affects the drying badly due to this drying process faces a lot of problems. So, it is better to keep the equipment in an airtight room.

Humidity

Humidity is another main factor which affects the drying process during the drying of the material.

Temperature

The third factor which affects the drying badly is the temperature. So, set the accurate temperature for drying to avoid this factor.

Heat

The last one which affects the Drying of Fluid Bed Dryer is the Heat factor. The immense or the less heat can cause problems in the drying. So, give the accurate amount of heat to avoid problems in the drying process.

9.What are the different components of Fluid Bed Dryer?

Main part of fluid bed dryer

The Fluid Bed Dryer has different components. These components work differently from one another.

The components of Fluid Bed Dryer are as follows:

Base Part

The stainless-steel tube connects the base part. The tube conveys the dry and hot air to the base part and also stops the intake of air when the tube is closed.

This base part also has the plenum chamber which works on the purpose of transferring air to the main tower.

Product Container

The product container works on the drying principle of the granules or the material provided. This part of the Fluid Bed Dryer clutches the wet material which needs to be dry.

The container also has the movable trolley which controls the movement of the granules in the product container.

Distributor Plates

After the product container, the distributor plates come and work in holding the flow of air and also give out the air to the container. The distributor plate is just a simple mesh or metal screen containing pierce holes in it.

Process Chamber

The Process Chamber is the component which works on the fluidization principle. Beneath the Process chamber, a product container is located.

This component fluidized the material by passing air from the main tower to the product chamber.

Filter Chamber

The filter chamber filters the material which is fluidized by the process chamber. It removes the unwanted material. This material cannot pass through the filter chamber. Filter chamber done filtering by the filter bags present in it.

These filter bags clean the material and pass it to the next step.

Cylindrical Pipes

The Fluid Bed Dryer has cylindrical pipes that are connected to the bowler. There is a device called the actuator. The function of this device is to collect the signals from the control system.

Blower

In the Fluid Bed dryer, you utilize a divergent kind of blower. Its fundamental parts incorporate the impellers, driveshaft, motor, casing, and gulf and outlet pipes.

During activity, the impeller turns, which likewise makes the air particles pivot. The impeller additionally impacts outward power on the air atoms making them move radially out.

On the outlet side, the air acquires a positive pressing factor and motor energy as it's removed. Inside the blower, the dislodging of air makes a negative pressing factor.

So, more wind streams into the blower. Radiating siphons are accordingly ideal for drawing air through opposition like dampers, filter bags, and so forth.

Our blower accompanies a progressively adjusted impeller. The cutting edges are bent in reverse importance as they face away from the heading of the wind current. The fluidized bed dryer modern blower additionally has an all-steel development with against vibration mounting to make it calmer.

Control Panel

The next and last component is the Control Panel. From the control panel, the administrator can handle the channel temperature, set the filter bag filtering time, start and stop the blower, lift and lower the product chamber, read the exhaust temperature, and that's just the beginning.

Settling on a PLC automatic control framework makes controlling the drying cycle more proficient. Senieer's fluid bed dryers additionally receive Siemen's smart touch input board for better human-machine interfacing.

These are all above the components of the Fluid Bed Dryer.

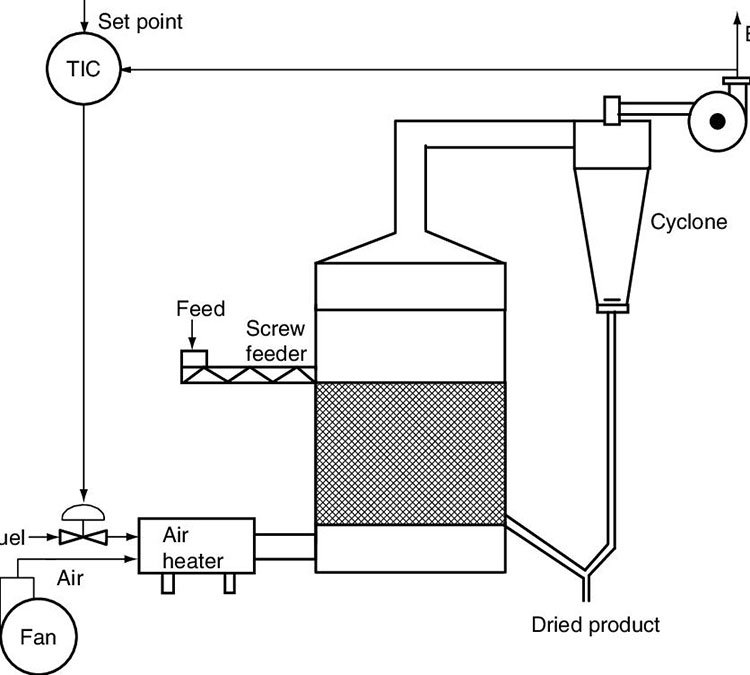

10.What is the working principal of Fluid Bed Dryer Machine?

Now the discussion continues on the working principle of Fluid Bed Dryer. In this section you will know that how the Fluid Bed Dryer works.

Working Principal of FBD- Photo Credit: Energy.co

Loading of Material

First you have to load some material in the Fluid Bed Dryer. Add some granules in it for drying. The material is loaded in the product chamber. And then the sucking of the moisture starts in the chamber by the feeding tube.

Air Inlet

This is the second step of working on a Fluid Bed Dryer. In this step you have to turn on the blower. This blower will move the air into the tower. And this is done with the help of lower plenum.

Process of Fluidization

This is the main step of working on a Fluid Bed Dryer. In this step fluidization of the material takes place.

In this process intel air is exploded by the powder bed. Due to the increase in the velocity of air the space also increases between the powder particles.

The Fluidization Process takes place in the different four steps:

- Smooth Fluidization

- Bubbling Fluidization

- Turbulent Fluidization

- Fast Fluidization

Drying Process

In this process drying of the granules or the material you have provided to the Fluid Bed Dryer has been done. At the end of the drying process, you have to set the level of the moisture of the solid particle is 1 percent or less than the 1 percent.

Preheating Process

In this process the moisture is being evaporated by the heat generated by the Fluid Bed Dryer. At the very first it dries slowly but after sometime the drying rate increases as more and more heat is sucked by the particles.

But in the preheating stage the moisture is still present on the particles in very small quantities. But when the temperature of the Fluid Bed Dryer rises enough then it evaporates all the moisture from the particle.

And this moisture is sucked by the fluid through the capillary action process.

And at the end when the moisture level reaches to the 1 percent, the drying will be stopped.

Shaking if Filter Bags

In this process of working of Fluid Bed Dryer, the shaking of filter bags again works on the drying process to free the material from the rest of the moisture present on it.

Filter bags suck moisture in their pores. And after that the mechanical shaking is done to remove the remaining moisture. Which is the best method to make free moisture material.

Exhausting of Material

And now this is the second last stage of the Fluid Bed Dryer. In this stage the exhaustion of the material is done. This also works on the removal of moisture if any particle is not moisture by the filter bags.

Process Flow Diagram of FBD Credit: gea.com

Discharging of the Material

So, this is the last stage of working for a Fluid Bed Dryer. In this stage the dried material is put out from the Fluid Bed Dryer. This work is done by the worker present there.

And now your material is fully dried and ready for the next level. So, this is all done in the working of the Fluid Bed Dryer.

11.What are the Features of the Fluid Bed Dryer?

Every machine has some features according to customer’s demand. The Fluid Bed Dryer has some special features.

We can do the drying process as well as the process of maxing from the Fluid Bed Dryer with the help of the rapid mass and the transfer of heat.

The features of Fluid Bed Dryer are as follows:

Complete Cleaning of Equipment

The Fluid Bed Dryer is a type of equipment which thoroughly cleans everything.

We can do thorough cleaning of the Fluid Bed Dryer by putting the bag into the cleaned water for one hour or more than one hour. After doing this, wash the beg from the inner and outer side properly.

Cleaning Process Credit: sme.in

Contamination Process

In the Fluid Bed Dryer, the cross-contamination process is not done in it. There is very little risk of allergen transfer. So, your material is safe from the allergen material.

Steam Heating

The heating of steam and electric heating is eliminated from the Fluid Bed Dryer. Which is a very important feature of the equipment.

Usage of Antistatic

Moving to the next feature of Fluid Bed Dryer, antistatic filter material is used in it for working.

Give more time of residence

The Fluid Bed Dryer provides you more residence time than the normal one.

This will give you a better quality of the material.

Removing Bed Plates

Another feature of the Fluid Bed Dryer is that it removes the bed plates very easily without harming the plates.

Open Circuit Design

The Fluid Bed Dryer is designed such that the SSD and the partial can be recycled for the open circuit.

Provides Contact

The Fluid Bed Dryer has a special feature of provision of close contact between the cooling gases, drying and products.

GMP Requirements

The last but not the least feature of the Fluid Bed Dryer is that it fulfills the requirements of GMP for the process of sanitation.

12.What is the production capacity of the Fluid Bed Dryer?

The capacity of production of Fluid Bed Dryer totally depends on the size of equipment. So, it means that if you increase the size of equipment your production will automatically increase.

But the normal size Fluid Bed Dryer can produce up to 200kg to 250kg.

Production capacity is also dependent on the size of the product container.

If the Fluid Bed Dryer has a large product container then it will give you more production as compared to the smaller one.

13.What is the Average Power usage of the Fluid Bed Dryer?

The Fluid Bed Dryer uses no more power to operate. It consumes the normal power of electricity to work.

The two factors that you have to know about the Fluid Bed Dryer are:

- Power Source

- Power Consumption

The main supply of the Fluid Bed Dryer is connected to the power source.

So, now we talk about the two factors,

1.Power source:

It ranges from 220V/60Hz and 220V/50Hz

2.Power consumption:

The power consumption of a Fluid Bed Dryer is 2kW to 45kW.

So, these are the power consumptions of the Fluid Bed Dryer. Take a look at it before purchasing the Fluid Bed Dryer.

Power Supply Credit: en.wikipedia.org

14.What are different design variation in Fluid Bed Dryer?

The distributor plate is designed such that the fluidizing gas is sprayed evenly on the whole bed area. The gas velocity is set to a point that ensures only the fine material portion reaches the dust collector. Fluctuations of feed rate are diminished due to the high turndown ratio. Wear and tear parts of the machine don't come in contact with the product mostly.

- The Design Variations of Fluid Bed Dryer are as follows:

- Deep working Fluid Bed Dryers

- High Temperature Design Fluid Bed Dryers

- Plates and Contact tubes

- Blend Type Fluid Bed Dryer

- Integral design drying type of Fluid Bed Dryers

- Stages and Multiple zones type Fluid Bed Dryers

These above are only the variations in different designs of Fluid Bed Dryers.

15.What are the technical specs of the Fluid Bed Dryer?

In this section you will come to know the specifications of the Fluid Bed Dryer.

When you go to buy something from the market then don’t forget to take a look at the specifications of that product.

The Fluid Bed Dryers specifications mainly depend on the wide range components.

AIPAK Fluid Bed Dryer

The specifications of the Fluid Bed Dryer are as follows:

Capacity to Produce

This is the most important thing you have to know about the Fluid Bed Dryer before buying it. The production capacity of all the Fluid Bed Dryers is not the same. It varies differently.

The Production capacity mainly depends on the size of the product container. The normal size containers give the production up to 200kg to 250kg.

So, it is clear that the larger the size of product container, more the production rate of Fluid Bed Dryer.

Airflow Volume

This is also an important part of Fluid Bed Dryer. You should also take a look at it before buying the equipment.

If the rate of airflow is higher than the normal then it will give faster fluidization to you. So, these two factors are correlated to each other.

Power Consumption

The next one thing you have to know is the power consumption of a Fluid Bed Dryer.

The power consumption has the components which also uses power to work are:

- Blowers

- Electric heaters

If you know the exact power consumption of a Fluid Bed Dryer, then you will be able to judge the exact compatibility of the equipment.

Specifications of the Blower

The next component is the blower. The work of a blower is to push the air for fluidization in the chamber.

The speed of Fluidization also depends on the quality of the blower. If the blower is of good quality than you will get the fluidization at a faster rate. This will also affect the processing of material by fasting it.

The very important thing a good blower does is the supply of the exact amount that is needed for the fluidization process.

So, if you know all those things and all the specs of the blower. Then you will be able to buy a good quality blower.

Heater

This is the very main component of the Fluid Bed Dryer as it dries the material you have provided to the equipment for the drying process by heating.

If the heater is of good quality, then it will definitely affect the capacity of heating. So, you have to choose a heater the high heating capacity.

Motor

Another important component for the Fluid Bed Dryer is the Electric Motor. And also, you have a complete knowledge about the specification of the motor before buying it.

The important thing for your knowledge is that the Motor should be powerful. Because it has to rotate a blower for the maximum type of fluidization.

Another purpose of an electric motor is to cause movement of any part within the machine.

Spraying

It is crucial to take into consideration the type of spraying equipment used for the Fluid Bed Dryer.

However, application of the equipment decides the type of spraying mechanism to be used.

So, one has to be more careful while choosing the spraying technique.

Moreover, the nozzle of the spar can be changed according to the nature of the application.

Control System

Control system is a necessary element as it plays an important role in operating the machine and controlling it.

This feature is present in every Fluid Bed Dryer specially it is worth seeing in the modified one.

There is a touch screen in the control system to give the instructions to the machine.

Moreover, the control system is the one which tells you about any problem or difficulty occurring in the drying process.

So, it is the best key factor or spec of the Fluid Bed Dryer.

16.What are different Fluid Bed Dryer Quality Standards and Certifications?

Every equipment has some quality standards that are set by the unions. The quality standards insure us the equipment we are using is of good quality. The standards set by the organizations are as follows:

Good Manufacturing Practices (cGMP)

This is the famous organization and the Fluid Bed Dryer has the certification of that organization which tells the quality of the equipment is good. The material used in the equipment is of top quality.

cGMP standards Credit: spectrumchemical.com

Conformité Européenne (CE):

Moreover, the Fluid Bed Dryer also has the certification of the CE. It means that the machine is manufactured according to the standards of that organization.

CE Marking Credit: en.wikipedia.org

International Organization for Standardization (ISO):

Another famous organization is ISO. The Fluid Bed Dryer also meets the standard of that organization. It means that the machine fulfills all the requirements of the customer.

ISO Standard Credit: isotracker.com

Food and Drug Administration (FDA):

FDA is an organization for food and Drugs. This ensures the customer that the equipment is made up of a great quality. The features of this machine are of top level.

FDA Standard Credit: cspinet.org

Unique Selling Point (USP):

The USP is a U.S organization. The Fluid Bed Dryer confirms the standards of USP and make sure the equipment is usable for longer period of time.

USP Standard Credit: genengnews.com

European Pharmacopoeia (Ph. Eur):

A further organization of Europe that is European Pharmacopoeia which also confirms that the machine is made according to the quality standards set by them.

European Pharmacopoeia Credit: pharmamicroresources.com

Japanese Pharmacopoeia:

The Fluid Bed Dryer also has the certification of the Japanese Pharmacopoeia which is one of the famous organizations of the world. It means that the product is ready to use with no worries regarding the Quality standards and certifications.

Japanese Pharmacopoeia Credit: ebay.co.uk