All Sizes of Capsule Available

High Productivity & Fully Automatic

High Efficient & GMP Standard

Want A Free Consultation

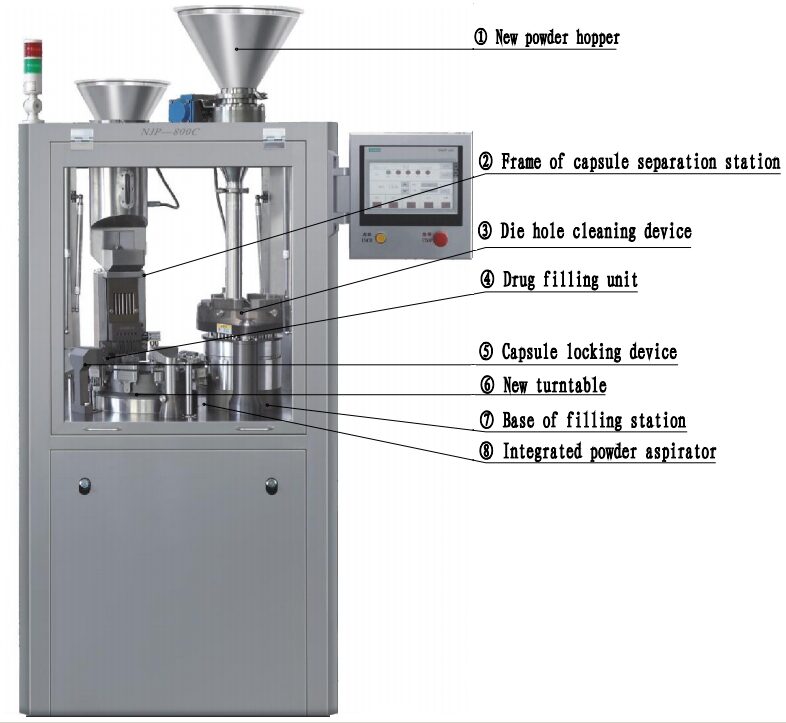

NJP-800C Automatic Capsule Filling Machine

AIPAK NJP-800 capsule filling machine manufactured by our company has been improved and innovated for several years. Now the third generation of 800 fully automatic capsule filling machines have advanced technology and excellent configuration. It not only has all kinds of performance and technical standards of the same type 800 in China. At the same time, three new technologies have been innovated, including two patents for the use of new models issued by the State Intellectual Property Office on May 11, 2016. Through continuous efforts , product performance and quality reached the most advanced level in China.

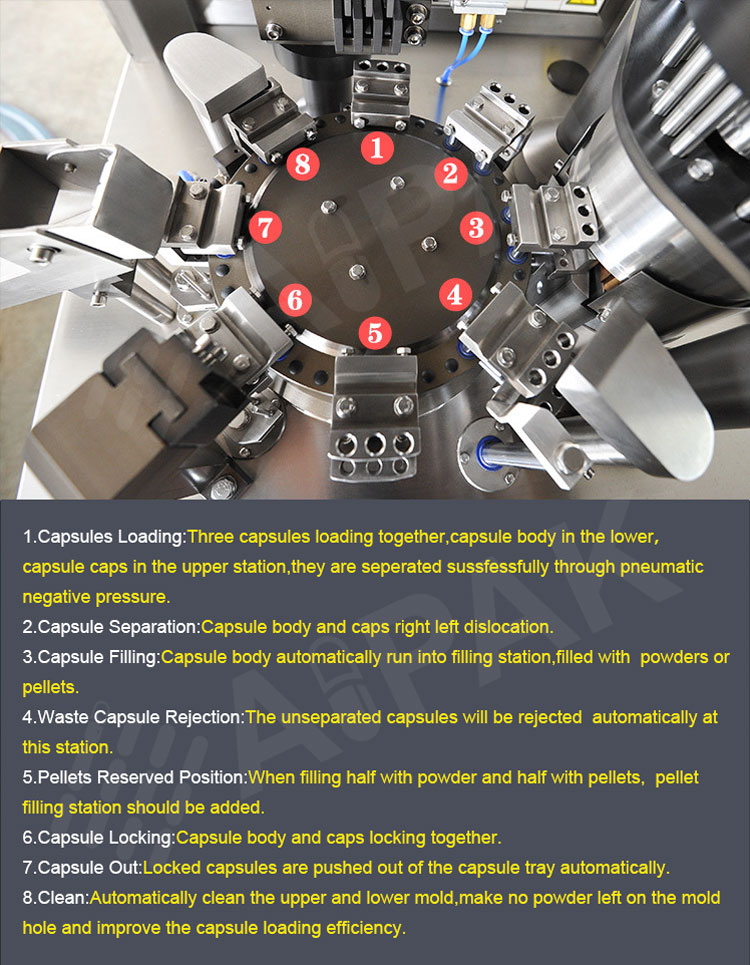

1.Automatic Capsule Filling Machine Working Principle

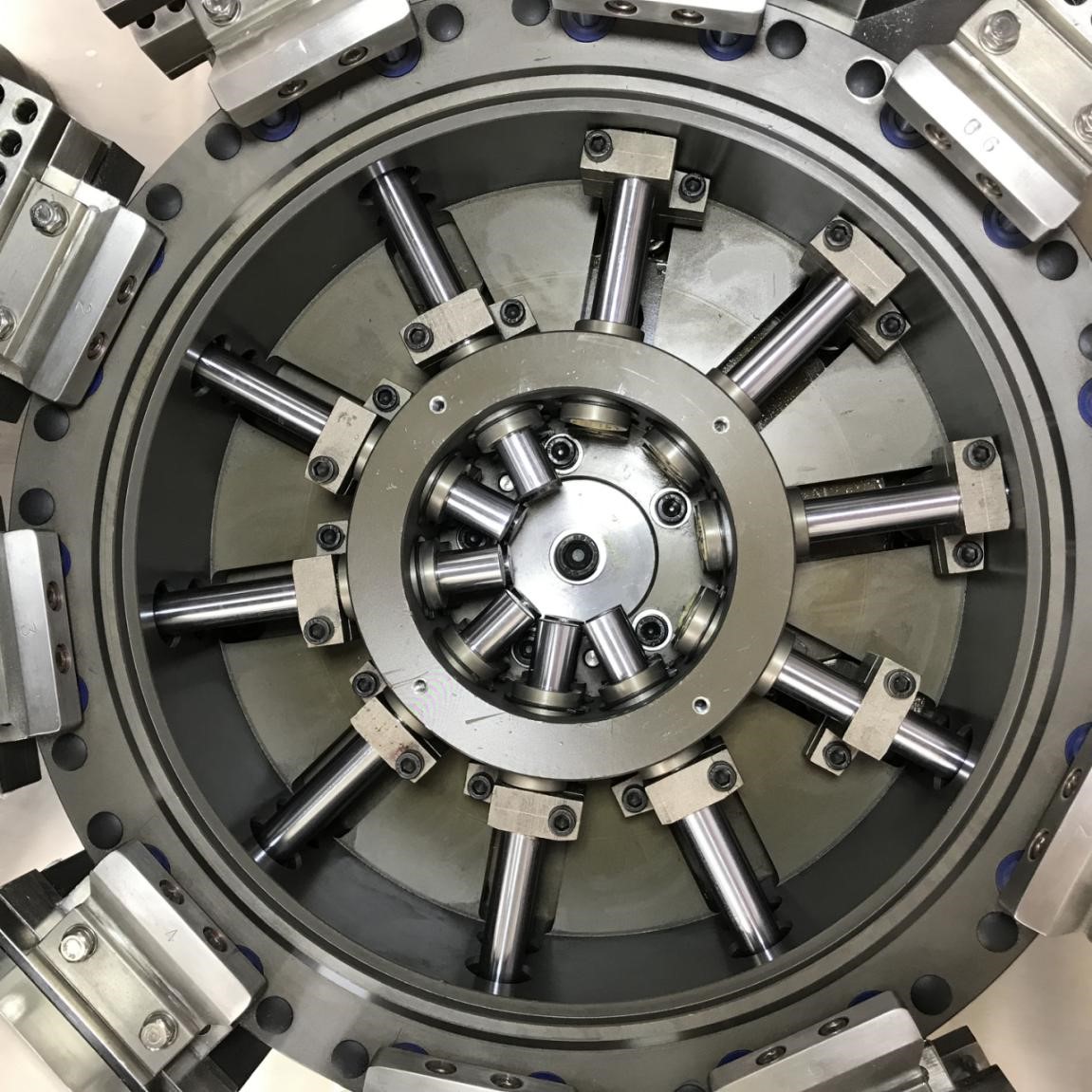

2.Automatic Capsule Filling Station

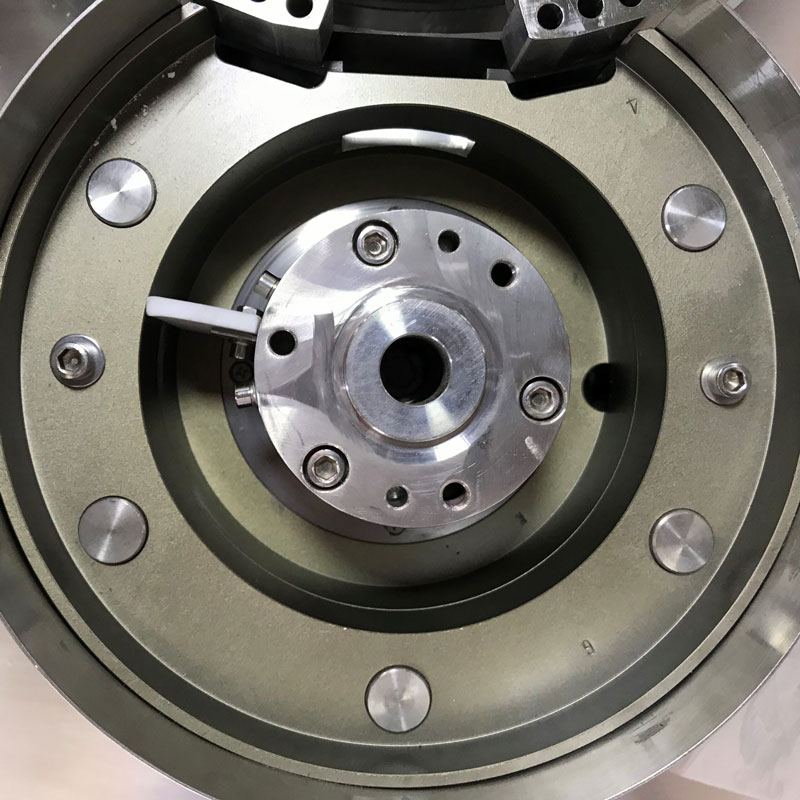

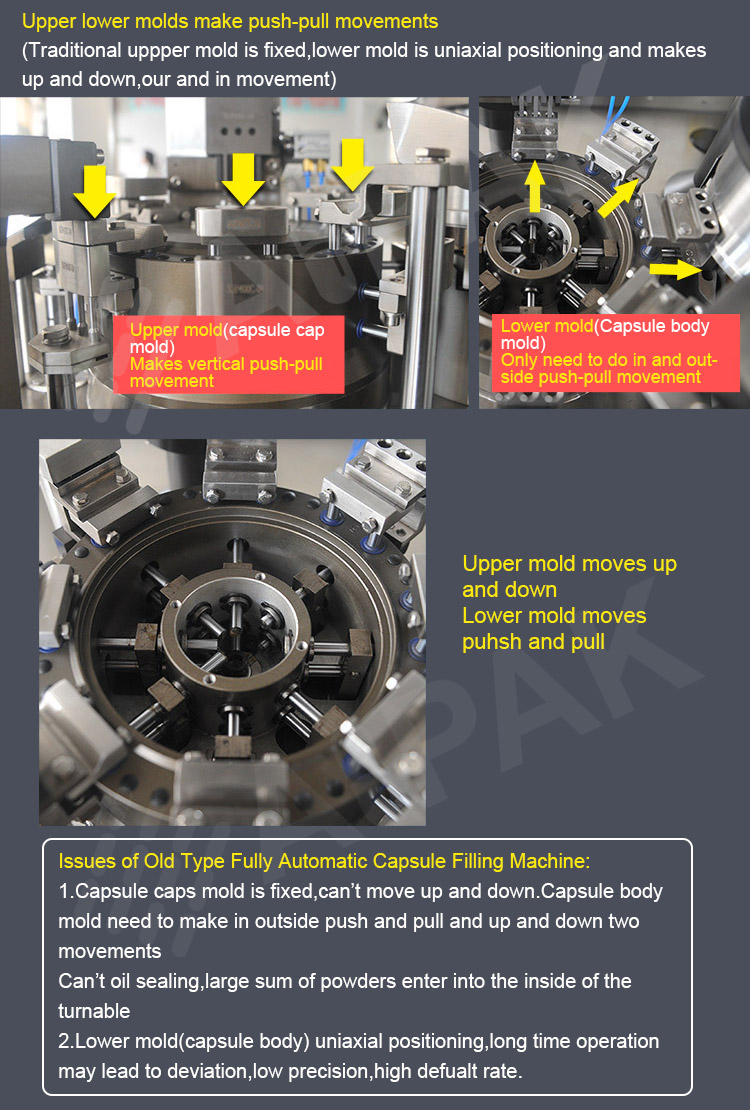

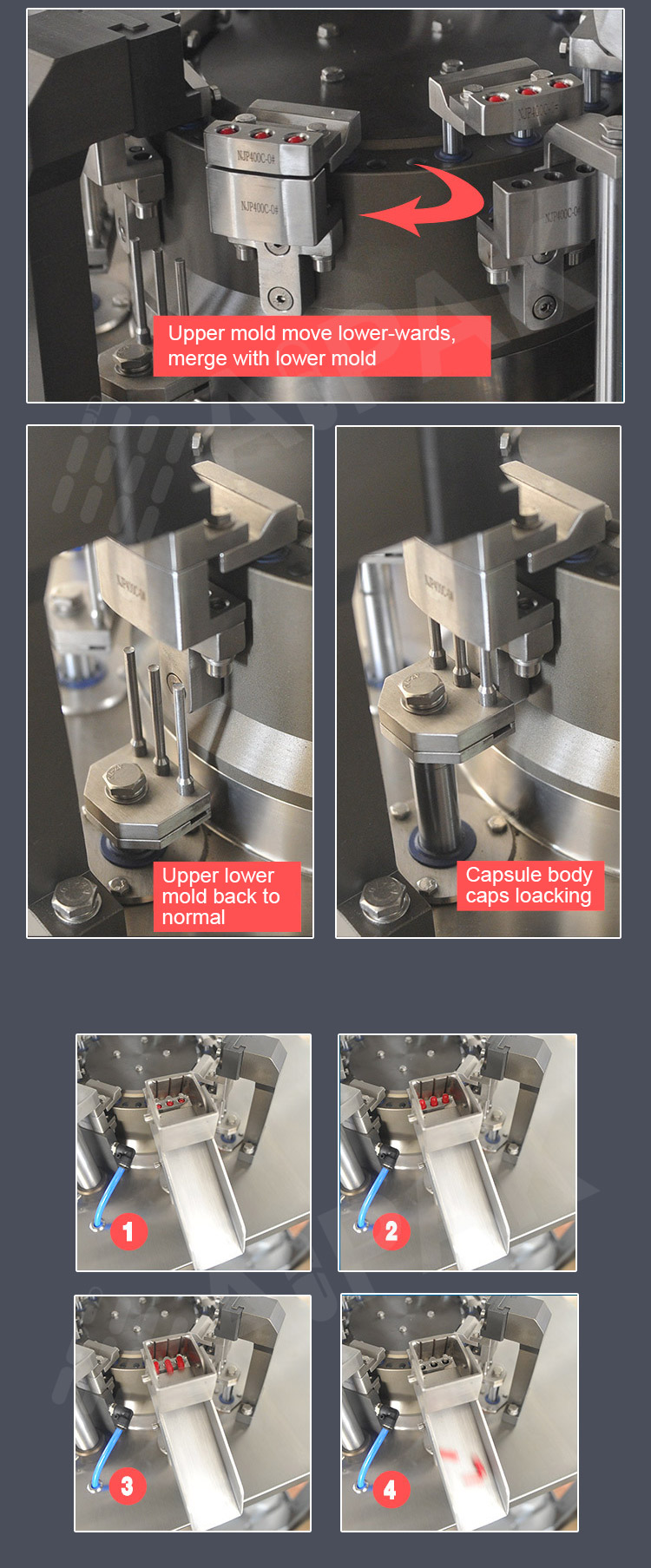

3.Upper Mold Movement

4.Double Shaft Double Oil Sealing

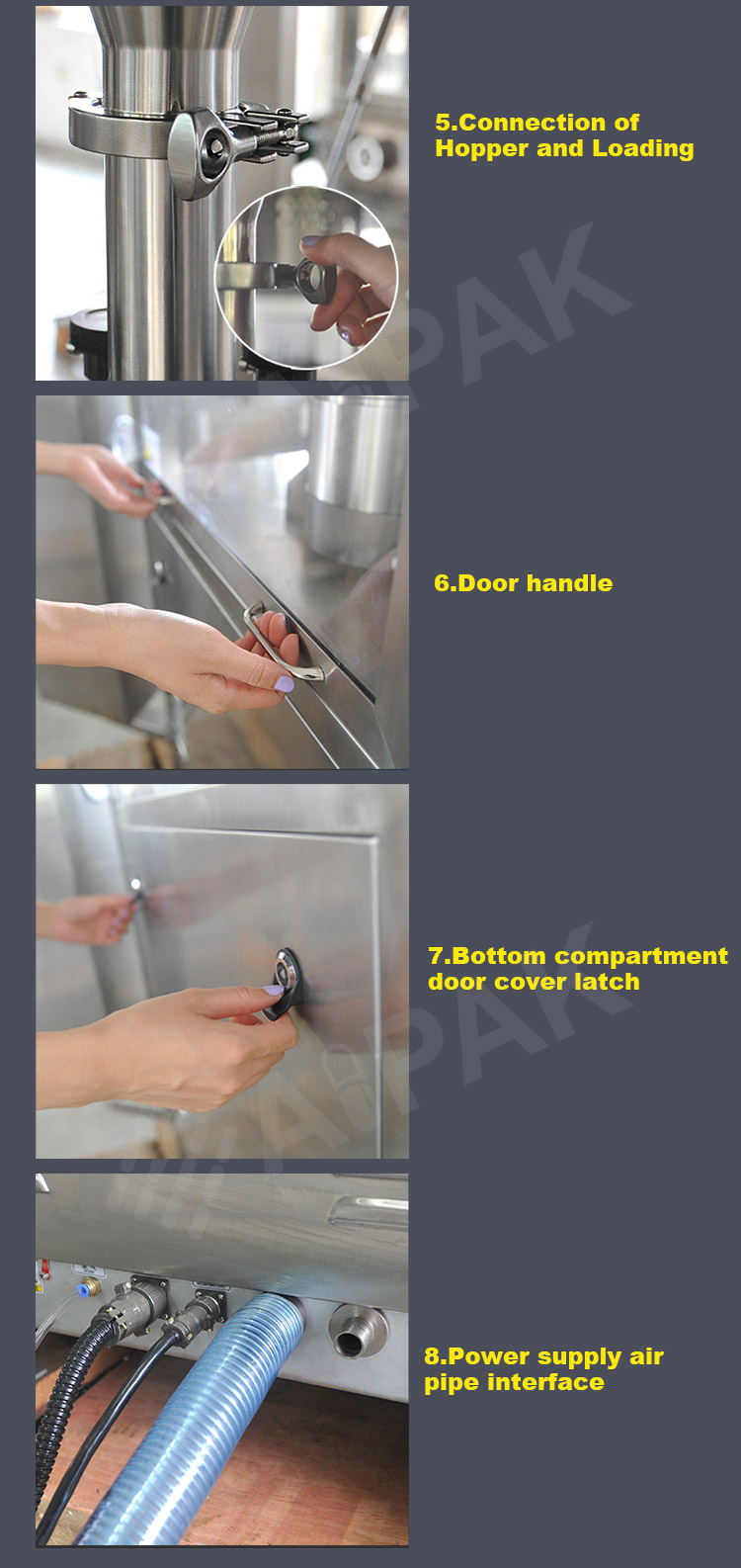

5.Loading Valve

6.Aviation Material

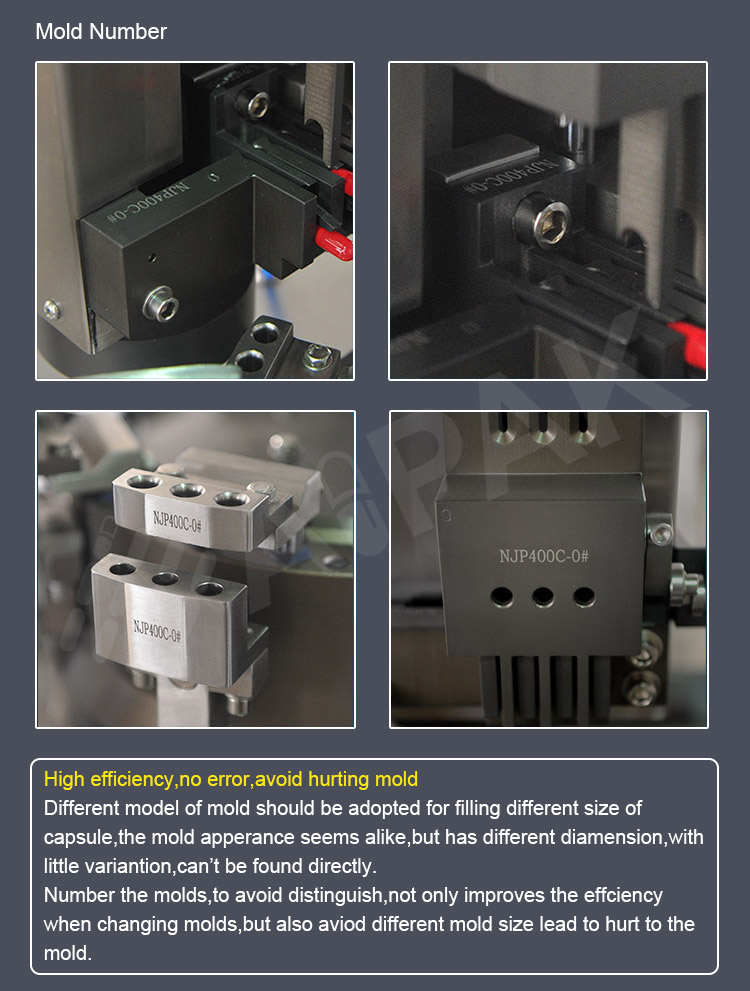

7.Mold No.

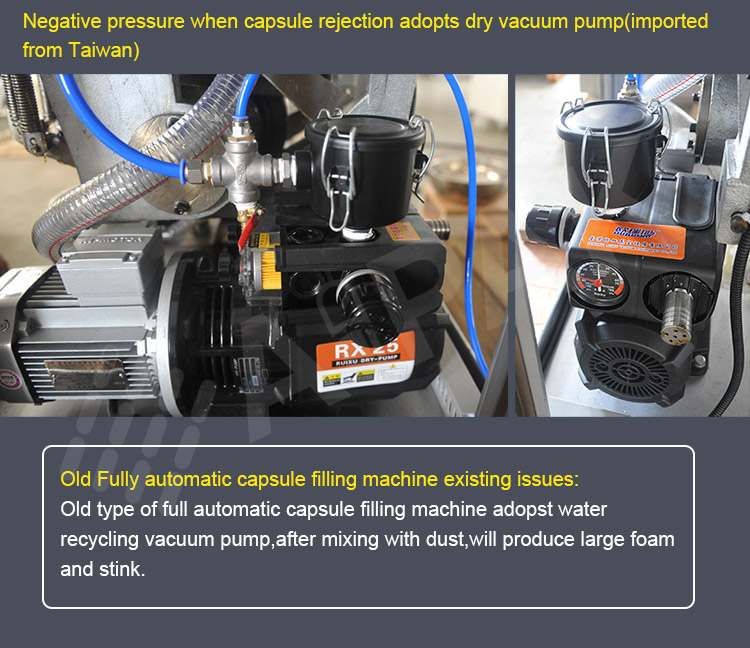

8.Dry Vacuum Pump

9.Safety

10.Specific Details

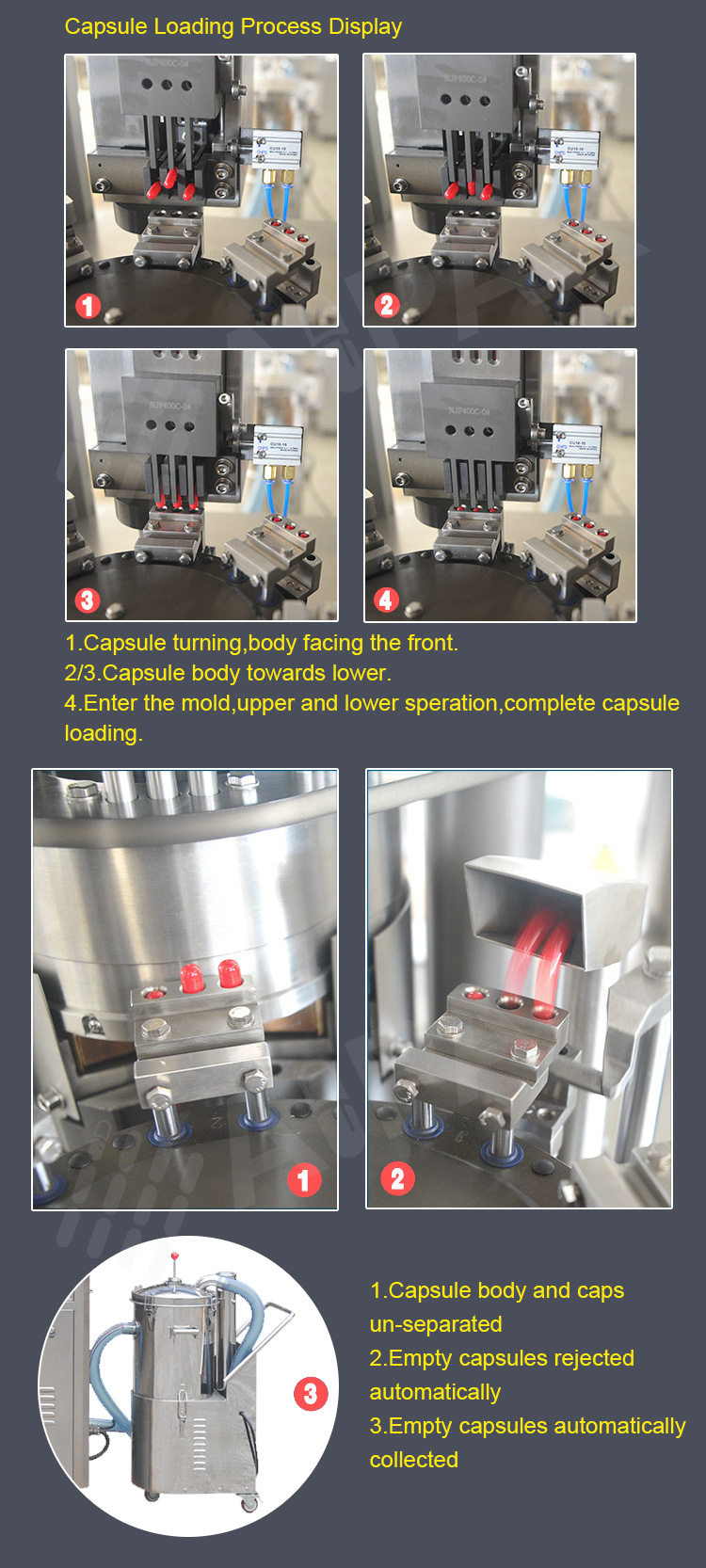

11.Capsule Filling Complete Process

12.Pellet Filling

13.What AIPAK Automatic Capsule Filling Machine Can

FEATURE

- Innovation of turntable mechanism: Patent No. ZL 2015 2 1021530.0 issued by the State Intellectual Property Office on May 11, 2016 (changing the problems of complex structure, poor sealing performance and dust easily entering the turntable of general filling machine). Innovation of turntable mechanism: good stability, regardless of filling speed. How fast, how long the operation time, no dust into the turntable, quick and convenient assembly and disassembly of the mould (15 minutes) to reduce labor intensity, on the original basis to improve the efficacy of three times. The installation of the mould is accurate, the concentricity of the upper and lower die holes is good, there is no deviation, and the capsule has no edge insertion effect.

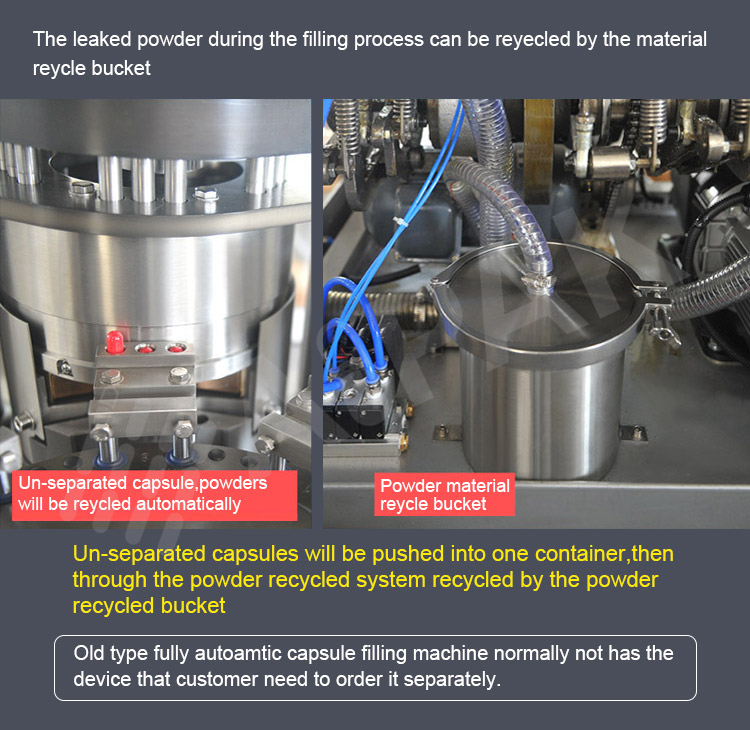

- The filling mechanism has been innovated. On May 11, 2016, the State Intellectual Property Office issued a patent certificate for the use of the new type (patent number: ZL 2015 2 1021519.4). The advantages of the new filling mechanism are: easy installation, disassembly and cleaning, and effective improvement of work efficiency. The gap between the metering plate and the copper gasket can be adjusted conveniently and quickly, which reduces powder leakage and improves the loading accuracy. A new type of tug was used, and an automatic powder recovery structure was installed. The powder leaked from the production filling process was automatically recovered, which increased the economic benefit.

- The separation device of powder and waste capsule was innovated: effective recovery of lost powder. The recovered powder can be filled and used directly, which reduces waste and increases economic benefits.

- Equipped with point control system, it is easy to assemble, disassemble and clean moulds, safe and convenient.

- Automatic control of capsule closing and opening is safe and convenient.

Quick.

- Equipped with an automatic cleaning die system, the upper and lower die holes are automatically cleaned when the upper and lower die is running to the tenth working station. After cleaning, there is no dust in the upper and lower die holes. Effectively improve the seeding effect.

- Equipped with gate control and mechanical failure safety system, automatic alarm and automatic shutdown.

- Automatic alarm and shutdown when the hopper is short of powder.

- Man-machine interface functions are complete, and counting functions can be displayed automatically when production is running. For example, if your hospital needs printers (date of production, batch number of production, quantity of production, etc.)

DATA SHEET

|

Model |

NJP-800C |

|

Filling capacity |

48000pcs per hour |

|

Weight |

900Kg |

|

Dimension |

1100×900×2050mm |

|

Power supply |

380/220V 50Hz |

|

Total power |

5KW |

|

Segment bores |

6 holes |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Air compression |

Air consumption 5m3/h Pressure 5-7Kg |

|

Water source |

500L/h 0.1-0.2Mpa |

|

Operating noise |

<75DB(A) |

|

Filling percentage |

Empty capsule 99.9% filled capsule 99.8% |

|

Capsule size |

00,0,1,2,3,4,5# |

|

Filling accuracy |

Western medicine ±3% Chinese medicine ±4% |

|

Suitable for |

Powder, Granule, Pellet, Tablet. |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951