Syrup Filling Machine

Controlled by Touch Screen

Easy To Clean

No Pollution To The Liquid

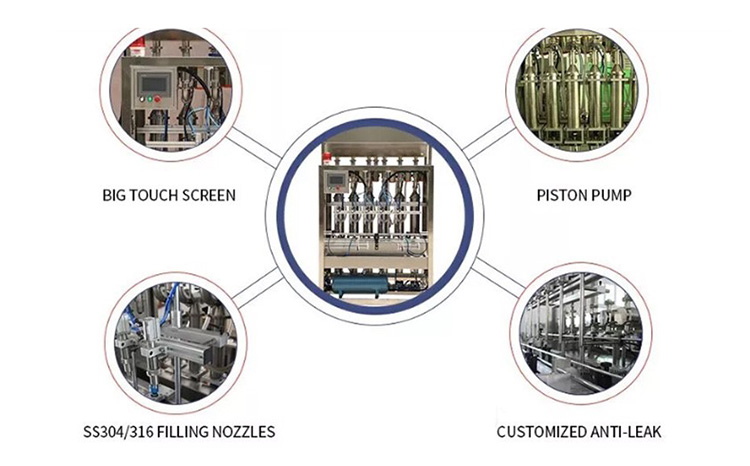

AIPAK Syrup Filling Machine

AIPAK Syrup Filling Machine is suitable for 5-100ml bottle oral liquid washing,drying,filling and capping. The Syrup Filling Line is made up of ultrasonic washing, sterilizing machine, filling & capping machine, which can complete the following functions of ultrasonic washing, flushing, air charging, drying& sterilizing, filling and capping. The machine adopts advanced ultrasonic washing, alternating washing with multiple-head washing with water, air separately and quartz tube ultraviolet hot radiation sterilizing with high temperature, advanced technology of multiple-head filling and sealing, and the whole prodcution line also adopts photoelectric technology and PLC and color touch LCD screen for the control system, with high automation.

The Buyer's Guide

Syrup Filling Machine: The Complete FAQ Guide in 2025

You may have heard that the explosion of population has caused a great increase in the demand for convenient and fast sources of goods.

That is ,automatic filling machines are essential in the modern industrial word.

Actually,this includes the automatic oral liquid syrup filling machine that can help in safe and cost-effective production of goods while reducing unnecessary wastages.

Syrup filling machines are commonly used in many areas like the pharmaceutical and food industry for filling oral liquid syrups or juice,coffee flavorings.

Today,I will use this guide to introduce some of the critical aspects of the syrup filling machine,including classifications,benefits,working principle,main components,troubleshooting and FAQ.

You will get some of the best packaging solutions to pack all your syrup products.

Let’s get started directly.

1.What is A Syrup Filling Machine?

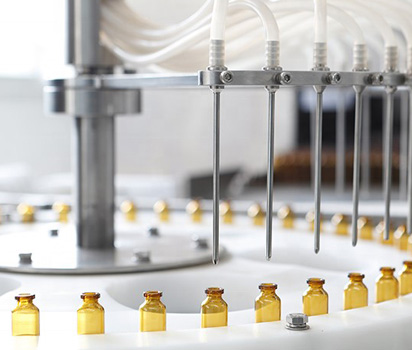

AIPAK Syrup filling machine production line

Syrup Filling Machines or Syrup Fillers are being utilized to move various sorts of syrup items from the tank which has a capacity into the bottle, cans, and such items.

These syrup filling items are filled using a Syrup Filling Machine.

The diverse sort of items that are filled up and the bottles that they fill are distinctive in nature.

There is a huge number of cycles, methods, and machines are utilized for the purpose of filling these products.

Whereas the most advanced versions of Syrup Filling Machines are conservative flexible and encased in the best quality steel.

2.Which Industries are Syrup Filling Machines Used?

There are many liquid industries. However, talking about the syrup filling machine following explained industries use the syrup filling machines in their process.

Food Industry

Syrup In the Food Industry

For instance, chocolate syrup, espresso seasoning, soft drinks, milk, yogurt , sources, squeeze, and wine are bundled by these fluid filling machines.

Other products are caffeinated items, cooking oil, nectar, baby recipe, and fundamental oils.

Construction/Development Industry

Items like superglue, paint, silicone likewise rely upon this innovation for the purpose of the filling.

Cleanser Processing Industry

This machine is utilized in filling fluid cleanser, deodorizers, cleaners for the glasses, floor clean, and wax.

Hand sanitizer, other house cleaning products, and washing cleansers additionally utilize this application.

Agriculture Business can Use This Machine

In the business of agriculture, you do use chemicals for killing the worms and all related things in the crops. The syrup filling machine is fundamental in filling farming synthetic compounds like fluid items like pesticides, fertilizers, and much more.

A major part of the drugs/ pharmaceuticals business

The utilization of this gear is additionally relevant to drug organizations.

The pharmaceutical industry uses it for filling and seal syrups like syrup coughing, hostile to Bacterial cleansers, dental gels, and thick medication like creams.

Natural enhancements are additionally packed utilizing an oral syrup filling machine.

Beauty and Cosmetic Business/Industry

Cosmetic Business/Industry uses it to fill thick creams for facial purging, gels, cleansers, conditioners, facial scouring creams, body moisturizers, and glycerin etc.

Car Industry

Grease, light, and engine oils are additionally filled utilizing this innovation.

Filtered water Companies

Water is filled in the bottles of glass and plastic of the .5, 1, one and a half, and two liters or considerably bigger compartments utilizing these syrup filling machines.

3.How will you Benefit from A Syrup Filling Machine?

Syrup filling machine offers more benefits over the other available machines in the market. There you go, let’s learn about some of them here.

- This aids in rapidly adjusting the filling particulars so you can proceed with the filling cycle. For example, in the event that you need to change the filling rate, filling volume, or a net load of the item being filled.

- The utilization of these machines ensures the cleanliness and security of the items and their administrators.

- Because of decreased human contact with the items, tainting is limited.

- The machines are additionally made so that mishaps during filling are decreased, let's consider it never happens.

- The syrup filling machine not difficult to set, work, clean, and keep up.

- The semi-auto and automatic machine stores data that can be recovered for sometime later.

- As there is a screen panel installed it is not a big deal to maintain the production rate by using this machine.

- This gear has proven an extremely valuable machine in the quick development of the business as well as the economy wherever they are being used.

- Most enterprises preparing fluid items have embraced it for different reasons, despite the fact that it has a few difficulties simply like different machines. Indeed, there have been huge improvements in Automatic/programmed fluid filling line machines.

- It is savvy since human work is decreased, particularly for the automatic syrup filling machine, where the filling is totally on the basics of computer. For the handling and the placing, the machine has various parts.

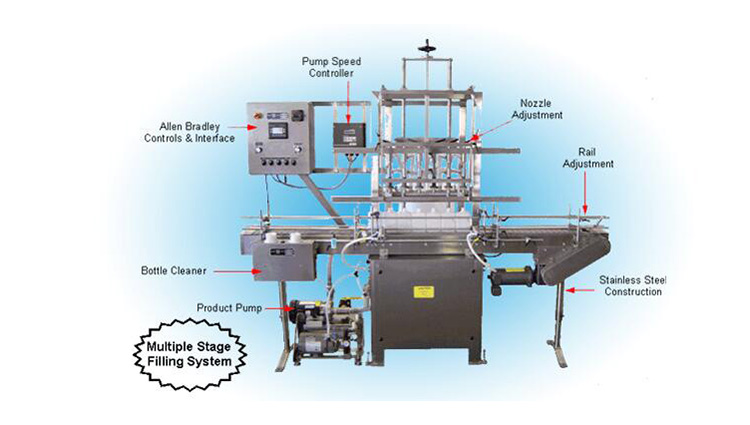

- It additionally has a conveyor belt framework, filling spouts, filling motors, item conveyance framework, and ejector.

- This machine is exceptionally effective and as a result, it assists businesses with completing their process of packing quicker.

- With huge requests, the machine has the ability to fill many bottles to meet the necessary amount of items on the schedule, and result that your order won't be late.

- The vast majority of syrup filling machines can have a simple changing of the breakdown parts, which makes it ideal for use in packing various items. By just altering the head, you can have another filler, and you can continue with filling various items in various amounts.

- As you might have noticed the thickness of the material is very important in this machine. However, with the help of this machine, you can fill very dense, medium dense, and even fully dense material in the bottles.

- It tends to be utilized to fill items going from water to thick oils like engine oils, mobile oil, etc.

- It can function admirably with numerous kinds of compartments like glass, plastic, does not matter if they have squared or round base shapes.

- The filling cycle yields precise amounts as already fixed in the syrup filling machine.

- In this way, there is no extra filling or less filling of liquid once the machine alignment is done effectively.

- At the point when the machine is completely robotized, it has a programmable control framework with a touch screen.

- Stainless Steel is what it is made from.

- The machine does not catch any type of rust, erosion, or stain because of its high-end material as well as matting.

4.Are there Any Disadvantages of A Syrup Filling Machine?

Keeping the pros in the mind we also have bit of the disadvantages of the syrup filling machines.If multiple products are being run the chances of contamination getting in is higher. In such cases real quality does not transfer.

- By using a syrup machine it is not possible to fill up the solid items.

- For the running of this machine you need to be trained enough so, you can perform like an expert.

- The power consumption of the machine is more.

- It is a bit expensive investment too.

5.How many types of Syrup Filling Machine are there in the market now?

AIPAK Syrup Filling Machine

Volume metric Syrup Filling Machine

A self type of pump is used in this type of machine.

There is a moving piston inside this chamber and also that actually hit the length and width of the cylinder that decides the volume while filling the syrup.

Net Weight Syrup Filling Machine

System dependent on gauging the specific weight utilizing a valve that is put over an electronic weight measurement machine.

The scale in the mix with the gauging program controls the valve activity resulting in a process of weight measurement.

Piston Syrup Filling Machine

There are two things in this machine one of them is the pump whereas another one is the main tank of the machine from where it does takes out the material.

The sign triggers the rotating valve to transform so the item may come from the container into the chamber.

Later on, the piston starts to take the item from the container into the chamber until the chamber is full.

When the chamber is almost full, the turning valve changes place which permits the piston of the machine to promote the item through the chamber and spout and into bottles finally.

Fill to Level Syrup Filling Machine

The machine has its own framework for pumping to associate the machine with the primary tank.

The progression of fluid is estimated and changed over into electronic signs being constrained by PLC based hardware. Least change needed to set various limits with the different containers.

The whole range is possible to be determined to a similar machine with no change parts. PLC controlled the most recent innovation with variable formula information.

Clock Based Filling

The pumping framework associate the machine with the fundamental tank. The rotational Gear Pump attracts the fluid which is handled by the clock.

The keypad is used here for the setting of the filling range. By providing a start order the fluid will come from the spout.

When the set volume of fluid lessens the nozzle will close and it would make sure no dripping happens afterward.

Peristaltic Syrup Filling Machine

Pump utilized for little fills for high worth material at high precision.

The filling machine user uses a PC and checks the no. of revolutions of the pump of the Peristaltic head with the goal that it realizes exactly how many items have been conveyed.

At the point when the objective fill volume is fulfilled, the stoppage of the pump happens here and the excess item liquid doesn't trickle out because of pipette activity.

The PC stores all fill limitations in memory for quick changeovers.

6.What is A Gravity Liquid Syrup Filling Machine?

The easiest filling technique is gravity filling.

That simple development and activity of a gravity filling machines need less possible support compared with other machines.

For the fluid which has less thickness you use this machine and it is vital that the fluid thickness don’t change with environment temperatures or item group variety.

7.What are the Advantages of Gravity Liquid Syrup Filling Machine?

Gravity Liquid Syrup Filling Machine always known for its amazing work.

- It is suggested for destructive synthetic compounds like corrosive, which is unsafe to individuals.

- Contact among humans and the item is limited, in this manner lessening the mishap the item may impact the machine administrator.

- Additionally, less spillage during the process lessens the impact of the destructive compound item on the climate.

- It is appropriate for fluids with dainty thickness for example water since these items fill at an extremely high rate.

- It is considered one of the best cost-efficient options when you think about all syrup filling machine.

- It works quicker, with precision, and the least wastage.

- By using this machine all process of the filling becomes less costly and also within the less period of its turns out with the high production.

8.Are there any Limitations of Gravity Liquid Syrup Filling Machine?

There few limitation that you need to know.

Can be utilized by a restricted scope of items as it was.

For instance, it is ideal for thin dense fluids like water yet can't be utilized to fill items as creams.

Liquid path and nozzle/spout activation present unique attributes that normally change over the long run.

Accordingly, the machine administrator should make acclimation to the machine's put away boundaries frequently, dissimilar to in different innovations.

9.What is Gravity Liquid Syrup Filling Machine used to fill?

Filtered water organizations generally utilize this filling machine to fill jugs of various shapes and sizes with drinking water.

Food preparing organizations additionally use it to fill juices, milk, and soft drink in glass and plastic bottles of various sizes.

Fluid cleanser and spectacles cleaners are additionally filled utilizing this machine by cleanser producing organizations.

It is additionally utilized in filling liquor, chemicals, ink, paint, wine, and destructive synthetic substances for example acid.

10.What are the Main parts of Gravity Liquid Syrup Filling Machine?

This Gravity Liquid Syrup Filling Machine has five unique parts.

They incorporate as;

- Bulk Supplying Tank

- Transferring Pump

- Production Tank

- Automatic Touch Screen Panel

- Electric Activated Pneumatic Valve

Each part performs various capacities for the whole syrup filling machines to be fruitful.

You can now analyze every part with its functionalities.

Bulk Supplying Tank

This piece of the machine is the place where the items are stacked in availability for the filling cycle.

The item gets moved to the item tank starting here.

Transferring Pump

When you use the transferring pump it helps in taking the material from the main tank and transfer them into the production tank.

Production Tank

This portion of the syrup filling machine situated over the valve of the pneumatic.

It is the place where the item settles down whenever it has been taken out from the supplying tank.

The item streams downwards to the holder/container by the valve from this piece of the machine.

Automatic Touch Screen Panel

In this portion of the machine specially, pre-defined standards are set about the running of the machine.

Not only this, other than that number of items to be produced as well as rotations are also defined.

The pace of item filling can likewise be checked now of the machine.

Electric Activated Valve of Pneumatic

The item streams into container put beneath it.

Every valve is exclusively coordinated to fill the holder precisely.

This aids in lessening item wastage in the filling cycle.

Oral Syrup Filling Line -Photo Credit:Inline Filling System

11.How does Gravity Liquid Syrup Filling Machine Work?

Working Principles of Gravity Liquid Syrup Filling Machine

1- This machine has a auto touch screen board where machine settings are done before it is run.

2-Items are stacked into the tank of bulk supply, at that point pumps are used o take the material from the tank of production to the items tank situated over the valve of the pneumatic

3- The valves are exclusively coordinated by the filler's PC.

4- This planning guarantees a precise amount of the items streams by gravity in the compartments.

5- When a compartment is loaded up with the ideal amount, the following void holder is passed on underneath the filling valve.

6- The cycle proceeds like this until all compartments are filled as arranged by the controller.

12.What is A Fill to Level Syrup Filling Machine?

This is the most generally utilized kind of machine for filling and covering syrups.

It tends to be utilized to fill fluids with a low and medium thickness.

Also, it can too be utilized in filling fluids with strong particles under 1/16 inches.

13.How will you Benefit from A Fill to Level Syrup Filling Machine?

For the very little bottle, it can be used well.

That machine can manage different extents of feeble for example if a solution has a medium viscosity like flimsy material.

The performance proficiency of the machine is amazing.

As the liquids, it can fill have low to a medium consistently without any problem.

The speeds of filling these things are tolerably high.

It is extremely simple to clean this machine and keep up.

Level to fill up is exceptionally simple to work with.

Indeed this syrup filling machine saves a lot of money.

It has the ability to be controlled to fill and cover different syrup things at an outstandingly insignificant measure of cash.

14.What is Disadvantage of Fill to Level Syrup Filling Machine?

Keep these thing in mind

The machine is not good for the high viscosity products.

If the material thickness is greater than 25k centi poises it is not a good option.

When the particle size is more than 1/16 even then it is not a void option as well.

For the large bottles fill to level syrup filling machine is not a good choice.

15.What are the Main Components of Fill to Level Syrup Filling Machine?

This machine has different sides.

They incorporate the stock side and the returning side back.

From the side where the stock is put pumping is being done.

The abundance items are passed to the returning side and afterward took back to the inventory or the stock side.

These different sides have six unique parts that perform various capacities in the process of filling.

Fill to level Filler Machine Parts

Over Flow tank of the Product Feed

For filling the material this the right place where things are being put to get into the main section by using the pump.

Process of Pumping

This is the reason things come from any section to the main part of the machine.

Main Fold

Before the thing getting into the bottles by using a valve for filling this is the part where things are placed.

Filling amounts are already decided beforehand from the main tank to the pneumatic valve, later on by using a valve directly into the bottles.

Replaceable Transfer Stars

Actually, this is more a type of guide which helps the bottle to follow a track where later they can be filled in the pneumatic jack.

Valve

This part of the machine is specifically designed to feed the bottles with the required material.

This happens either through the power of gravity or under negative tension filling.

Plate Conveyor

By using this part of the machine the bottles are moved to the places where you need them. Mostly, they enter the machine for filling by using this conveyor.

When bottles pass through the conveyor they are kept in the neck.

16.What is the Working Principle of Fill to Level Syrup Filling Machine?

The working principal of this machine goes like this;

Step 1

Bottles are stacked into the replaceable transfer star that assists bottles to the pneumatic valve through a belt.

Step 2

First of all the material is poured into the feeder section, later on, the material is taken into the main fold with the help of the pump.

Step 3

The machine at that point does the filling to an already decided amount into the bottles.

Step 4

The syrup items are siphoned into the bottles through two spouts/nozzles situated at the inventory side of the machine.

Step 5

After the bottle is filled up to the ideal level the abundance syrup is taken out.

The extra items at that point got back to the syrup source in preparation to fill the more bottles.

17.What is Fill to Level Syrup Filling Machine used to fill?

The syrups that regularly utilize this innovation are

- Sauces

- Medication syrups

- Water

- Light gels

- Cleanser

Structure cleaning agents and different synthetics are likewise filled utilizing this machine.

Notwithstanding these oil and vinegar have likewise discovered this machine significant.

18.What is A Volumetric Syrup Filling Machine?

Volumetric syrup filling machines are intended to do the filling of bottles with a exact volume of fluid paying little heed to what the last fill-level resembles in the bottle.

This syrup filling machine fills according to volume and not by using any other scale. It is equipped for filling different items going oils to waters.

Volumetric Syrup Filling Machine

They have 2 options in the machine;

- Auto volumetric syrup filling machine

- Semi Auto volumetric syrup filling machine

19.What are the Advantages and Disadvantages of Volumetric Syrup Filling Machine?

The more advantages and machine offer the more are the chance you can benefit from it.

Benefits of Volumetric Syrup Filling Machine

It does have the ability to fill up different types of material in terms of thickness like low, medium, and high.

The working of this at a moderately fast than fill up by weight instrument and is hence utilized by numerous ventures. It can fill up to a limit of 20,000 bottles every hour.

Does not matter if you are filling the glass or plastic bottles it is suitable for everything.

It gives the exact filling of fluids filling into the bottles hence decreasing item wastage. This outcome in great returns for the business.

The items are protected from defilement since human contact with the items is limited.

This machine is not difficult to clean, work, and keep up.

Disadvantages of Volumetric Syrup Filling Machine

The machine is expensive to purchase, posing a challenge to small scale liquid producers.

It might have issues when used for the small scale production.

20.What are the Main Parts of Volumetric Syrup Filling Machine?

Let’s did more and know about the parts of the machine.

Portions of Volumetric Syrup Filling Machine

It has six unique parts, which include: item tank, PLC and contact screen board, a machine stage, a spout, and an alert. Allow us to perceive how each part capacities.

Item tank

This is the tank that gets the fluid prior to filling starts.

PLC and Touch screen

This is the interface for machine adjustment. It shows all the item filling settings.

The touch screen is the place where all the settings are entered.

The item is filled by the volumes or weight pre-decided on the screen.

Machine stage

This is the place where compartments to be filled are set just underneath the spout.

In an engine worked framework where needles fill the ideal volumes into the compartments, there is an arrangement of jug manage.

This aids in guaranteeing that the compartment is at the focal point of the spout to stay away from item wastage.

Spout/Nozzle

This is the part through which the items are filled into the compartments.

Caution

It alarms the administrator about any deficiencies during the filling cycle so s/he can stop the machine.

21.How does Volumetric Syrup Filling Machine Work?

1-The cycle begins when you physically place the compartments beneath the spout/nozzle.

2-In some cases, whenever this syrup filling machine is mechanized, the engine worked framework manages the containers to be set at the middle of the spout.

3-The items are stacked into the item tank and the machine is changed on the touch screen.

4-Make sure to balance and check settings for example the volume and filling speed on the screen panel before you start the filling cycle.

5-When turned on, the item will move from the tank to the holders/container through the nozzle/spout.

22.What is Volumetric Syrup Filling Machine used to fill?

Shampoo Bottles Filling By using volumertic syrup filling machine

Following written products can be filled by using this volumertic syrup filling machine.

- Shampoo and Lotion

- Wine and Liquid

- Juice and Grease

- Liquor and Cleaning agent

- Milk and Cooking Oil

- Water and Medicines

23.What is A Peristaltic Syrup Filling Machine?

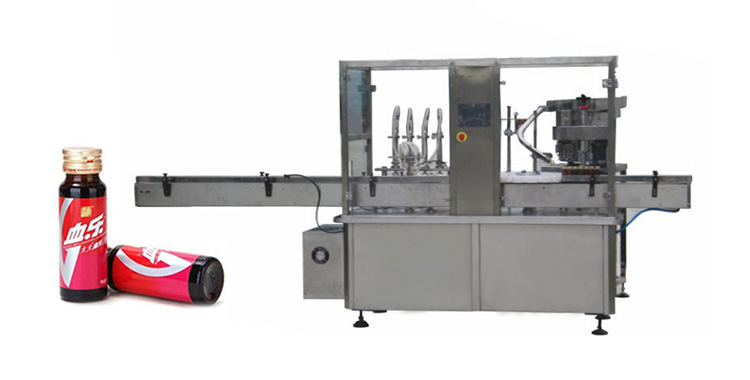

The machines like peristaltic syrup filling machine is utilized in filling little volumes at a fast rate.

It is enthusiastically suggested for watery and fluids with light consistency.

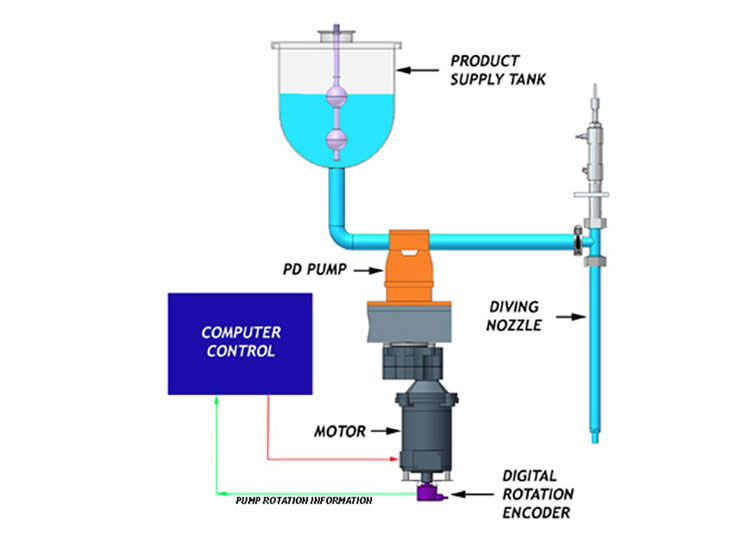

It is comprised of an item supply tank, a pump, engine, tubing surgical, and a computerized turn encoder.

The number of bottles which has gone on the conveyor belt is also measured in the machine by using a PC.

This PC likewise stores all the filling boundaries to make ease in the process changeover.

Pharmaceuticals organizations these days are in demand of this machine.

24.How will you Benefit from A Peristaltic Syrup Filling Machine?

For volumes rate under 1 ml, it is conceivable to accomplish a precision within ±0.5 – 1%.

The liquid path is capable of disposing of and another set up if there is a requirement of that.

The machine is known for its quality at a given scale.

25.What is Disadvantage of Peristaltic Syrup Filling Machine?

Exactness may not be accomplished with fluids of volumes above 1ml.

More volume cannot be a good choice.

10-500 ml Peristaltic Syrup Filling Machine

26.What are the Main Components of Peristaltic Syrup Filling Machine?

Knowing a machines component means the better control on the machine.

Item supply tank

This is where the items are set in availability for filling into holders.

Peristaltic siphons

It is a siphon that prompts the power that promotes the item through to the tubing into the conveyance territory.

Careful/item tubing

The item goes through it to the spout where filling happens into the compartments.

PC regulator

It has a program introduced in it that guides in following the number of revolutions.

The PC can likewise store all the boundaries in the memory for a simple and quick change-over.

Engine

It produces the power that drives the whole machine to work as wanted.

Computerized turn encoder

This part helps in changing the machine activity data like speed and pressure starting with one organization then onto the next.

The change of this data is critical to make it simple for the PC to comprehend and utilize.

27.How does Peristaltic Syrup Filling Machine Work?

Working Principles of Peristaltic Syrup Filling Machine

1-The item is stacked into the inventory tank and the machine settings changed likewise.

2-At the point when turned on, the engine gives turning to the machines and the advanced encoder shows the revolutions in numbers.

3-It connects with the external pieces of the careful/item tubing.

4-The item stays in contact with within part of the tubing as filling happens into the compartment.

5-The PC regulator assists with following the rotation number.

6-This causes the administrator to decide the amount of the items previously conveyed into compartments.

28.What is Peristaltic Syrup Filling Machine used to fill?

Peristaltic Syrup Filling Machine is used for the filling the cough syrup, flu syrup and fever syrup too.

More things that is possible to be filled using this is;

- Fragrances

- Essential oils

- Inks and dyes

- Special Chemicals

Perfume Filling Process

29.What is A Piston Syrup Filling Machine?

This is quite possibly the most praised and long-lasting machine of all types of syrup filling machines for you.

Piston is actually core for the running of this machine.

You should get this machine because different types of business have been using this machine for a while now.

Most of them are packing companies who fill the liquid.

This machine is ideal for thick velvety or stout items with enormous particles.

Piston Syrup Filling Machine

30.What are the Advantages and Disadvantages of Piston Syrup Filling Machine?

Everything comes with the pros as well as cons. So, below listed are some advantage and disadvantages of the Piston Syrup Filling Machine.

Piston Syrup Filling Machine Advantages

It is more affordable when contrasted with other available syrup filling machines within the market place.

It is proficient even with genuinely thick items.

Every cylinder filling machine has the ability to work with numerous chambers of various sizes.

This is on the basis that it can handle diverse holder volumes.

That machine is produced using treated steel which fulfills the required chemicals and food norms.

It is in this way impervious to pitting and consumption.

The items are additionally protected when bundled utilizing it.

Regardless of whether manual or mechanized cylinder filling machine, they are on the whole simple to work, clean, and keep up.

Piston Syrup Filling Machine Disadvantages

This innovation is gradually disappearing because of the available more developed version of servo positive uprooting fillers.

That machine is a bit costly to buy.

Putting everything aside from a more extended effort to do the cleaning and changing parts is also tricky.

31.What are the Main Components of Piston Syrup Filling Machine?

Below defined are the parts of the Piston Syrup filling machine.

Cylinder/Chamber

The items are stacked in this piece of the machine so they can be driven into the rotating valve.

Pistoning Part

That is the portion that when moved back/ like turned on, the item is sucked in the chamber.

At the point when it is drawn out of the chamber, the items are being pushed down the spout/nozzle into the holder underneath.

Rotational valve

The rotational valve changes its place with the goal that the items are pushed out of the spout into the holder.

The valve shuts the route to the spout when the pistoning is brought into the chamber.

At the point when the cylinder is drawn apparently from the chamber, it gives a path for the item to pass to the compartment.

Nozzle/Spout

The spout is the part through which the items are conveyed into the compartments.

It helps in filling of the items.

32.What is the Working Principle of Piston Syrup Filling Machine?

Working Principles of Piston Syrup Filling Machine

1-In this process, sucking is done mainly, for the sucking of the material piston is being used.

2-The way toward sucking the items into the chamber prompts the moving of the revolving valve's position.

3-The rotational valve shuts the path to the Nozzle/spout whenever the piston is brought into the chamber.

4-Yet, the rotational valve gives away actually the piston has to be drawn into the chamber/cylinder.

5-The item at that point gets the occasion to go through the spout into the compartment beneath it.

33.What is the Application of Piston Syrup Filling Machine?

Cylinder syrup filling machine is generally utilized for packing

- Hefty sources

- Cosmetic creams

- Weighty cleanser

- Gels

- Conditioners

Products filled by the Piston Syrup Filling Machine

Other than these they are also used;

- Glue cleaners

- Waxes cement

- Substantial oils

- Greases

34.What is A Net Weight Syrup Filling Machine?

This machine the Net Weight Syrup Filling Machine is used on the basis of the net weight of the products.

A weighting scale is being used in the machine to monitor the bottles filled in the process.

Just like many other machines it also have two types automatic and semi automatic weight syrup filling machine.

This machine is pertinent for items that are bring sold when named by measurement of the weight.

Net Weight Syrup Filling Machine

35.What are the Advantages and Disadvantages of Net Weight Syrup Filling Machine?

It is appropriate for filling huge holders like gallons and 20-liter bottle.

The machine is easy to use and can undoubtedly be dominated by administrators.

This gear has a crisis stop press button that can be utilized to stop the machine in the event that deficiencies are recognized.

Disadvantages of Net Weight Syrup Filling Machine

Can't be utilized for filling little compartments.

This sort of filling machine is expensive per filling head.

The machine gives a generally more slow strategy for filling in contrast with different sorts of filling machines.

36.What are the Main Components of Net Weight Syrup Filling Machine?

Portions of Net Weight Syrup Filling Machine

Mass stock tank

This is the place where the fluid is stacked.

Item tank

The fluid is pumping here anticipating the filling cycle into the holders.

Pneumatic Valve

The item streams to the holder put beneath it through this part.

37.How does Net Weight Syrup Filling Machine Work?

This is how this machine works,

1-Put all of the items into the mass supply/stockpile tank.

2- Utilizing a PLC contact screen, make the filling interface to decide the filing points of this syrup filling machine.

3- Every holder utilizes its very own pre-defined weight.

4- You would now be able to be pumping the item up into the holding tank over the pneumatically working valve.

5- This cycle prompts the starts of the valve of the pneumatic.

6- The machine administrator screens genuine weight data until it accomplishes the objective weight.

At the point when the objective weight is accomplished for a holder, it moves from the central place of the valve.

This gives an occasion for the following holder to be introduced under the valve to go through a similar cycle.

7- The exactness of a filling occurs with various mass and spill techniques in the filling cycle.

This aids in overfilling avoidance into the compartments.

38.What is Net Weight Syrup Filling Machine used to fill?

The net volume syrup filling machine is the best fit for items that require mass filling into large holders like gallons of buckets and twenty liters.

Instances of such items are;

- Water

- Shampoo

- Solvents

- Alcohol

- Paints

- Ink

Alcohol Filled in the Machine

Some of the time, items that have exceptionally high fabricated worth likewise discover this machine helpful.

For instance, for synthetic compounds and destructive synthetic substances like corrosive and fade.

It's energetically prescribed for fluid expected has to be filled into see able compartments since it advances equivalent holder level filling.

39.What Auxiliary Equipment are needed to form a Complete Syrup Filling Machine Production Line?

Air compressor

This is equipment must connected, otherwise the production can not work.

Air compressor is a device which is used to change power into the potential energy with the help of gasoline engine or electric motor. This air compressor store more and more in the tank which increase the pressure of the air which is also called compressed air.

Closing station

Closing station is used for screw capping of the vails. In this closing station there is a PVC screen control panel where you can adjust the force that you want to use for the capping of the vails.

This machine is used to print and apply the label on the product. This machine is used for printing and applying the label on plastic, fiber drums, and glass. Labeling machine used in many industries.

Ink Jet Coding Machine

Ink jet coding machine are used to print important data on the product. In the syrup filling process you may use it to print the manufacturing date and expiry date of the products.

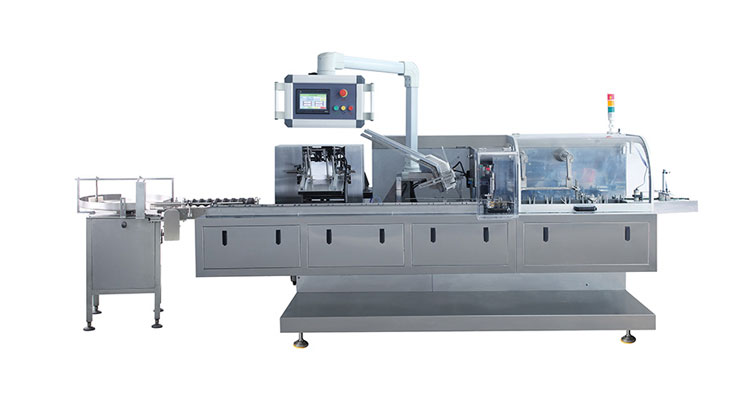

Cartoning machine is the type of packaging machine which is used make the cartons and put the product in these cartons and after this sealing the cartons.

AIPAK Cartoning Machine

40.Are there any Environment Requirements for the Syrup Filling Machine Filling Process?

Temperature needs to be maintained

Temperature is key in the pharmaceutical business so does in the syrup filling process. It must be taken care of.

Environmental Cleaning Procedure

Environmental Cleaning Procedure is important so does the syrups filling machine.

Microbial Count

Microorganisms checking is the vital pointers in the field of the syrup filling industry. It demonstrates how many microorganisms are available in an example. Checking the absolute microbes tally is essential, on the grounds that the number of the microorganisms shouldn't surpass certain guide esteems.

Microbial Counting

41.What are the Applicable Specifications of Syrup Filling Machine?

Technical Data

| Product Number | APKGZ-4 | APKGZ-8 | APKGZ-16 |

| Applicable specification | 5-25 ml | 5-25 ml | 5-25 ml |

| Production Speed | 60-80 bottle per min | 150-220 per min | 300-330 per min |

| Filling Error | ±1~2% | ±1~2% | ±1~2% |

| Water pressure and water consumption | 0.25-0.35MPa,0.5m³/h | 0.25-0.35MPa,0.5m³/h | 0.25-0.35MPa,0.5m³/h |

| Power supply | 380/220v,42.5KW | 380/220v,45KW | 380/220v,45KW |

| Purify compressed air pressure and air consumption | 0.3-0.5MPa,5~10m³/h | 0.3-0.5MPa,10~15m³/h | 0.3-0.5MPa,10~45m³/h |

| Weight | 650kg | 3000 kg | 7500 kg |

| Dimension | 4000*1300*1500mm | 1000*1800*2000mm | 12000*2500*2400mm |

42.Are there any Differences between Oral Liquid Syrup Filling Machine Production Line and Plastic Bottle Filling Production Line?

| Oral Liquid Syrup Filling Machine Production Line | Plastic Bottle Filling Production Line |

| As this machine is oral it has the high filling requirements | Whereas plastic bottle filling production line is less demanding |

| Environmental requirements for this machine are higher like cleaning of the premises. | Environmental requirements for this machine is less. |

| Oral Liquid Syrup Filling Machine Production Line is a long procedure. | Plastic Bottle Filling Production Line is a short procedure. |

| It requires, washing, drying, stanilized, filling and then capping. | It requires, unscrambling, filling, and then capping. |

| The one process ink jet coating and labeling are available here. | The process ink jet coating and labeling are available here too. |

43.What Quality Standards should Syrup Filling Machine Conform to?

Quality Compliance of Liquid Syrup Filling Machine

The because necessities are;

- Current Good Manufacturing Practices Quality Standards, cGMP

- International Standards Organization Quality Standards, ISO

- Food and Drugs Admin Quality Standards, FDA

- Electronics Quality Standards CE

Lastly, the equipment should be made from stainless steel and should be easy to operate, clean and maintain.

44.Which Factors should you consider when Buying A Syrup Filling Machine?

These are 5 points to be considered;

Notwithstanding these, we will likewise take a deep look at how auto innovation impacts the acquisition of the machines.

Automation Technology

For this situation, you may either have an auto and semi-auto syrup filling machine.

These will likewise in an incredible manner to decide the production rate at which a machine attempts to fill a distinctive bottle size.

Syrup's Viscosity

It is imperative to know what type of the product you are making.

It is important to know because that's what helps you with picking up the correct filler machine that may pack it productively and precisely.

The Medication of the Syrup

A few of the products are watery, semi-thick, very thick, or even weighty thick in terms of viscosity.

The various attributes of the fluids cause them to have requirements for various syrup filling machines.

The item thickness decides the framework type which you will be using, like fill rate and other essential factors during the production process.

AIPAK Syrup filling machine

Sort of Filling Bottles

As most of the machines fill various kinds of bottles, for example, plastic and glass, you need to take a further look at the sizes of the bottles.

Suggesting that your decision of holder size will decide the kind of machine that you will buy.

Syrup Filling Rate

For this situation, you should keep in mind how quickly you need your production will be.

Fluid syrup filling machines have various degrees of paces which will decide the pace of syrup filling.

You should, accordingly, pick the correct sort of machine that will agree with your filling necessities.

Syrup Filling Technology

It is critical to pick the latest sort of fluid syrup filling innovation to try not to have an old innovation.

There are particular sorts of innovations that are gradually growing dim and leaving space for new innovation.

Syrup Filling Machine-Photo credit:Pharmaceutical Online

45.How to Troubleshoot Common Problems of Syrup Filling Machine?

There are various methods of investigating your fluid filling machine, contingent upon the issue.

Serious issues include:

Force Issues

Force issues can go from loss of capacity to electrical breakdown of the wires.

You can forestall this by continually guaranteeing there is a reserve generator in the event of intensity blackouts.

If there may be an occurrence of electrical wire issues, consistently do standard support on the machine to guarantee everything is fit as a fiddle.

Frothing and Dripping

The reason for this issue is as a rule in the utilization of wrong seals.

This causes loss of liquid, which can build the general expense of working the machine.

You can rapidly tackle this by fixing the seals of your machine and watching that the valves are not spilling.

A mistake in Filling Timing and Levels

The mistake in filling timing and level causes a great waste and builds the general running expense of the machine.

The reason for this can be the utilization of an awful seal, which you need to supplant before additional activity.

On the off chance that the dilemma is off base planning, you can rapidly mind the setting and change the time.

This guarantees the liquid occupies at the set time.

Conclusion

I am pretty hopeful with the given details in this guide about the syrup filling machine you can choose the best products for you.

For further information and quotation you can reach our teams of experts at AIPAK.

Syrup Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586