Liquid Filling Production Line

Liquid Filling Machine : The Complete Importing Guide in 2025

Whether you are new to the world of liquid filling machines or you are already an user of this machine and just want to update or make some changes to your production line,searching online to find a most suitable machine would be a tricky work.

Vial or syrup filling machine? Automatic, semi-automatic or manual? Hot or cold-filling?

Fortunately,there should be so many choices for you to find the ideal equipment-however,there should require a lot of homework beforehand .

So,today,to simplify the process,I have made a conclusion from benefits,classification,working principle,main components and FAQ about this liquid filling machine that will help you narrow down your search and focus only on those systems that meet your objectives.

Let’s get started directly.

1.What is A Liquid Filling Machine?

AIPAK oral liquid filling machine

It is a machine which is used to fill liquid in the containers. It is very easy and precise to fill liquid in the machine using a liquid filling machine.

It is used in the drugs industry, cosmetic and for beverages. It is a multitasking machine which can do filling, capping, and wrapping. It can fill different sizes of container. There are many types of liquid fillers. It can fill up to 1000 bottle per minute.

2.What are the Special Uses of Liquid Filling Machines in the Pharmaceutical Industry?

These are the some of the uses of liquid filling machine in the pharmaceutical industry

- It is used to fill the liquid form of drug in the vail and it is very accurate in filling the exact amount of dose.

- It is used because it is accurate once you set the amount of medicine you want to put in any container there is no chance of error.

- It is used in the pharmaceutical industry to fill syrups, eye drops and different veils.

- It is used because it does not waste any material during the filling process.

- It is used because it is a multi-tasking machine. It can do filling, capping, and labeling etc.

3.How will you Benefit from A Liquid Filling Machine?

AIPAK Eye Drop Liquid Filling Machine

These are some of the benefits of the liquid filling machine

- It reduces the production cost because there is no human labor required in the automatic machine. where the filling is completely motorized. The machine has various parts for bottle taking care of and situating.

- It has a transport framework, filling spouts, filling motors, ejector, and transportation framework.

- This machine is structured, it assists different companies with completing their bundling quicker.

- The machine can fill numerous vessels to meet the necessary number of items on the schedule.

- A large portion of these filling machines can have a simple changeover, which makes them ideal for use in bundling various items. By changing the head, you have another filling machine, and you can continue with filling various items in various amounts.

- It is a very ideal machine for filling high, medium, and low consistency fluids.

- It may very well be utilized to fill items going from water to thick oils like engine and ointment oils.

- It can function admirably with numerous sorts of compartments like glass, plastic, which have either round or squared base shapes.

- The filling cycle yields exact amounts as it is set in the machine. Then, there is no above-filling or below-filling of items once the machine adjustment is done accurately.

- At the point when the machine is completely automatic, it has a programmable control framework with a touch screen. which makes everything very easy.

- This aids in rapidly changing the filling details so you can proceed with the filling cycle. Like you can change the rate of filling, or the filling volume.

- The utilization of these machines ensures the cleanliness and well being of the items and their administrators.

- Because of decreased human contact with the items, defilement is limited.

- The machines are likewise made so that mishaps during filling are diminished to a simple least assuming any.

- This machine is not difficult to set, work, clean, and keep up.

- The semi-automatic and automatic machines store data that can be recovered sometime later.

- It is not difficult to screen the filling pace of an item through the screen as the filling cycle proceeds.

- It helps you to decide that how much liquid can be filling in the designated time

- This makes it ideal for the wrapping of numerous items like food items.

- The machine is safe from stain and rust because it is made by the stainless steel.

4.Are there any Drawbacks of Liquid Filling Machine?

Now, some of the main disadvantages of liquid filling machines include:

You are well aware that there are many advantages of liquid filling machine. However, some drawbacks are also there:

A- It is not quite possible for you get help in filling solid items with the liquid filling machine.

Similarly, as the name recommends, fluid/liquid filling machines must be utilized in the fluid filling.

Inferring, they can't be of any utilization in organizations that produce non-fluid items.

This demonstrates a test to most pharmaceutical businesses.

If you are a company that is producing fluid as well as nonfluid products need to buy both machines.

In such a case, you got to go with 2 machines one for the liquid filling and another one for solids.

B- There is always some training and expert opinion required for the machine.

Just like some other machine, fluid filling machines need some specialized skill to work.

If any human is operating something it is not very hard to process though.

Whatever, any apprehension in the process of the machine can convert into colossal misfortunes.

You need to prepare your representatives on the best way to utilize the machine.

That is a bit of the requirement you need to fulfill for the liquid filling machine.

5.How many Types of Liquid Filling Machine are there in the market now?

Liquid filling machine has many these are some of them:

Manual Liquid Filling Machine

Semi-automatic Liquid Filling Machine

Fully Automatic Liquid Filling Machine

Inline Liquid Filling Machine

Rotary Liquid Filling Machine

Manual Liquid Filling Machine

Manual liquid filling machine -Photo credit:purplecitrus

It is a filling machine, as it is shown by the name you must do all work by yourself, and there is no need for power in this machine. It is very good for wrapping liquid-like gel, cream, shampoo different items with medium consistency.

It is suitable for producing small batches like a local manufacturer. It can fill 15 to 500 vails per hour depending on the size of the vail.

Semi-automatic Liquid Filling Machine

Semi-automatic Liquid Filling Machine-Photo credit:machpackprocess

It is fast, accurate and precise the manual liquid filler. It is a filling machine that requires power and you also must do some work by hand when you are using this machine.

It is suitable for the medium scale organization and it can also be used for large-scale production. It normally comes with needle, cylinder, and spout parts to keep zero-dribble activity.

It is ideal for the wrapping of different liquids like dairy, drugs, and agricultural items. It is appropriate for different liquid glue and liquid that have particles.

Fully automatic Liquid Filling Machine

AIPAK full automatic oral liquid filling machine

It is a liquid filler which is faster than manual and semi-automatic liquid fillers. There is no human effort required when you are using this liquid filler. It is used in large organizations and it can fill the liquid which has a high consistency.

It is an upgradable machine where you can add the filling nozzle to increase the production capacity of the machine and it has a transportation system to transfer the containers. It can fill the container from 5ml to 10 liters.

Inline liquid Filling machine

Inline liquid filling-Photo credit:mdpackaging

It is used for filling liquid in the container that is arranged one by one on the conveyor belt. This kind of filling machine can fill fluid, semi-fluid, low and high-thickness stuff in various sizes and states of compartments.

Inline fillers are appropriate for small and medium-sized organizations, yet a few models are adaptable, permitting makers to add topping heads to increase the creation speed. Inline filling machines can be utilized in food, dairy, and beauty products

Rotary Liquid Filling Machine

Rotary Liquid Filling Machine-Photo credit:penglaichina

It is a liquid filler that consists of a conveyor belt that moves the vails in a circular direction where there are all the stations like filling and capping. It is used in the food, drink, and automotive industry.

Liquid Fillers are fundamental in the assembling cycle. Being part of the item mechanical production system framework, fluid filling hardware advances speed, exactness, and productivity of the sequential construction system, which as a result will permit makers to meet their creation targets.

6.What Liquid Filling Machine can you Import from AIPAK?

AIPAK gives you the variety of the options for the liquid filling machine.

We have multiple filling machines for you, and they go like

Syrup Filling Machine

AIPAK syrup filler or syrup filling machine is used for filling the mixture of the solutions in bottles and other type of the containers.

Like syrups for the pharmaceuticals are filled by this.

Vial Filling Machine

AIPAK Vial Filling Machine

As vial are sealed in a different manner, they demand a different machine for the filling too.

Spray Filling Machine

AIPAK spray filling machine

Do you wonder how sprays are placed in those bottles well this is a machine that helps them.

Gel Filling Machine

Gel Filling Machine-Photo credit:liquidbottlingplant

Gel filling is a developed machine and it has been used a lot recently for filling sanitizer filling as it has been used during this corona-virus/covid-19.

Oral Liquid Filling Machine

AIPAK oral liquid filling machine

These machines are completely auto with a conservative plan planned to fill different sort of fluid in glass or plastic compartments with various filing volumes.

7.What are the Main Components of Liquid Filling Machine?

As you know every machine is made up of different components & those components assist the machine to deliver a quality production.

Here are the main components of the Liquid Filling Machine.

Start Pedal

Start pedal in liquid filling machine

When the machine is not in the running process this component of the machine helps to start the machine. You can say that it is a start button of the machine which helps you to perform the operations on the machine.

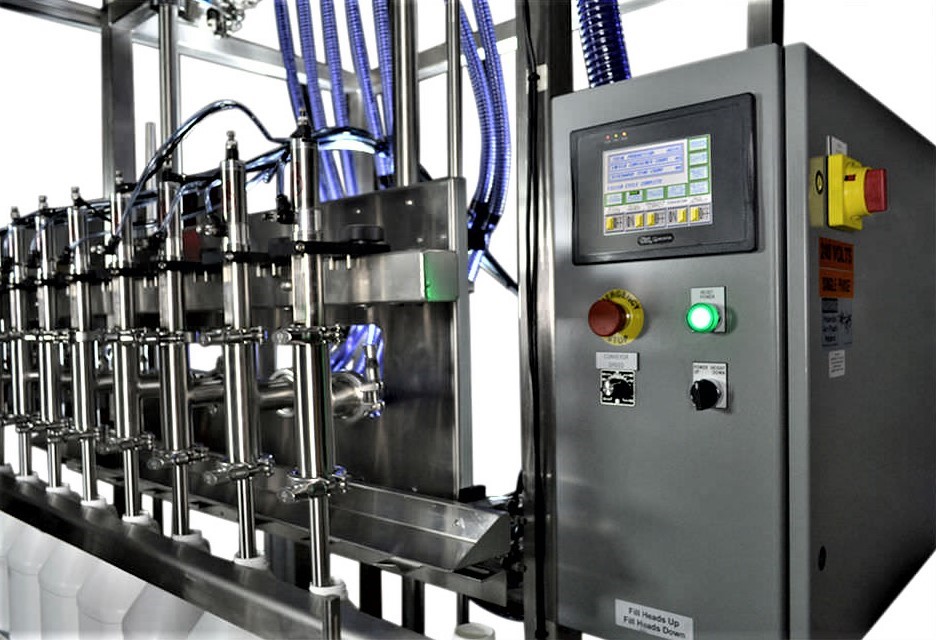

Control Panel

Control Panel in liquid filling machine-Picture Credits: Directindustry

As you know by the name this part of the machine is used for the intersection between the machine and human being for giving different types of commands.

This part of the machine provides you the flexibility to easily operate all the functionalities of the machine & start your production line.

Supporting Tray

When the bottles are set to be filled inside the machine this part of the machine called the bottle holder tray is used for holding the bottles on which the filling is done.

It helps to hold the bottles at their specific position so that filling is done properly & filling material not get wasted.

Liquid Tank

Liquid tank in semi-automatic liquid filling machine -Picture Credits: Karmelle

This is one of the major parts of the machine which is used for filling the bottles. The liquid that is going to be filled in the bottles present is present in the tank.

This is the holding component of the machine that holds every type of liquid for filling.

Filler Tap

Usually, a tap is used for discharging the liquid but in the Liquid Filling Machine, this filler tap is used to fill the bottles up to the given level.

This part of the machine fills the bottles with an accurate amount of liquid.

Base/Pivot Wheels

Wheels are used for the movement of the machine & these pivot wheels in the machine are also used for placing the machine from one place to another according to your working area.

Inlet Valve

Inlet valve

When the bottles are placed in the desired position for liquid filling and filling material started to flow from the filler tap the liquid which is coming from the tap has been controlled with the help of the solenoid valve.

The liquid pressure and flow rate are controlled with the help of this machine.

Corking Unit

When the bottles are filled they must be moved away for further processing after the filling is done and the rotation of the corking unit helps the machine to do so.

When the filling is done bottles are sent forward for this purpose the rotation of the corking unit must not be stopped.

Start Levers

Start lever on right side of small size semi-automatic machine

Bottles when placed into the tray this lever help the tray to be set in the desired position & when the filling is done levers help to remove the bottles from the tray & again set the tray onto the desired position for new bottles filling.

Tray Lifting Cylinders

Tray lifting cylinders in liquid filling machine

When the filling is done the corking unit must rotate so that the production line move on for further processing & these Pneumatical cylinders assist the corking unit & other parts of the machine to work properly.

8.What is the Working Principle of Liquid Filling Machine?

Many sorts of Liquid Filling Machines are there for you in the market with different automation levels & they had different working principles.

There are three types of filling that is possible to be done with the assistance of the Liquid Filling Machine according to its type.

The first one is an ordinary filler which works through the gravity filling, the second one is vacuum filler which works through the vacuum pressure for filling, and the third one is pressure filling in which filling is done with the help of air pressure.

Here is the basic working of the Liquid Filling Machine.

Step-1

First of all you need to start the machine with the assistance of a start pedal & you just need to give 5-10 minutes to the machine so that every component of the machine comes into its idle state.

When the machine is started the bottles are set into the sorting tray this can be done manually by the person as well as automatically by the machine.

The moving tray move the bottles towards the supporting tray for filling.

Step-2

When the placement of the vials/bottles is done in the supporting tray it holds the bottle for filling and then the positioning tray assists the supporting tray to set the bottles on to the specific position for filling.

When the bottles are placed in the specific position the filler tap fills the bottles up to the desired level & this is done according to the working principle of the machine-like, air pressure, vacuum pressure, and gravity force.

Step-3

When the bottles are filled the corking unit makes the rotation for removing the bottles from the positioning tray for further processing.

Liquids that are dense in quality require more filling time because their density makes them slow to flow from the liquid tank to the filler cap.

The movement of the corking unit is so continuous for moving the bottles away from one position to another.

Step-4

When the filling is done bottles are moved into the discharging tray for further processing. You will see that every bottle is filled with the right amount of filling material with the best air pressure.

So, that is the basic working principle of the Liquid Filling Machine. You will get uniform production & accurate filling with the help of this machine.

9.What Quality Standards should Liquid Filling Machine Conform to?

The manufacturing of your machine must come through some quality standards that are set by some European & other unions. These are the quality standards that your machine must fulfill during its manufacturing.

CGMP

The production material that is used for the manufacturing of the machine must be approved by the FDA and is of quality standard.

The raw material which is used for the manufacturing of this machine must be of good quality and standard. The material that is used in making the machine will define the life of your machine that how much your Liquid Filling Machine is going to survive.

ISO

Before making the machine all your requirements must be listened to and noted. And this standardization helps you to tell every requirement about the machine according to your production.

The manufacturer must design & develop the machine according to your requirements and needs.

CCC

A Chinese quality standardization that tells you about the inner raw material of the machine is made up of quality standards & safe for you to use in any type of environment.

The work rate & production is defined with the help of this standardization because if the material is good in the quality you will get accurate production.

EN

This standardization ensures that the machine that you are going to operate is reliable in every kind of environment & safe to operate.

It is an economical standardization which is set by the European Union which also tells you about the production cost of the machine & how much you have to invest.

CE

This standardization tells you about the working specifications & in which environment you can operate the machine with what restrictions. Is it easy and reliable for you to use in your working area or not?

After the production of the machine is done then it is tested in different levels & stats to know about any reaction. A lot of practices are made on the machine before delivering it to you.

ROHS

As you know the production that you are going to get from the Liquid Filling Machine will make interact with different parts of the machine so this quality standardization makes sure that no hazardous substance is used in making this machine.

The safety of your product and labor makes sure. Restrictions are made on some materials like mercury and led that a manufacturing firm can not use for the production of the machine because these are very reactive substances.

ASTM

Global standardization defines that many practices are made when the production of the liquid filling machine is done. If there is any kind of defect in the machine that must be solved before delivering it to the customer.

10.Which Auxiliary Equipment are Commonly Used to Cooperate with the Liquid Filling Machine?

There is a complete production line that contains auxiliary equipments from filling to packing & these equipments complete your production line by working with your main machine.

Filling Machine

AIPAK Eye Drop liquid filling machine

First of all the filling on the medicine vials is done with the help of a Pharmaceutical Filling Machine.

You can fill different types of material in the bottles with the help of this machine.

When the filling is done the auxiliary equipments came into action for further processing.

Sealing Machine

When the filling is done the first auxiliary equipment that comes into the action is a sealing machine which makes sure that the bottles are made leakage-proof & air tighten.

With the help of this auxiliary equipment, your product is made secure for traveling.

Capping Machine

If the sealing is not done perfectly then with the help of this auxiliary equipment the sealing is made perfect in terms of capping. Medicine in your bottles is made secure with the help of capping.

All the vials/bottles are sealed perfectly with the help of capping.

Labeling Machine

AIPAK Automatic Labeling Machine

After the filling and sealing is done then you mention the details about the filled product present inside your bottles and the printing machine helps you to do so.

The label on the bottle is made with the help of a printing machine that tells you about the product and its use.

Packing Machine

When your production is completed then the packing of the products is done with this machine. The packing can be done in the form of boxes or any other type of packing.

Cartoning Machine

In the last step when everything is done the cartons are made of the packing products with the help of this machine and they are set for the traveling process.

So, that is the complete production line of the Liquid Filling Machine that contains auxiliary equipment.

11.How to Troubleshoot Common Problems of Liquid Filling Machine?

During the filling, some common errors and problems may count on you during operating the machine. Here are these problems that can occur & the solution to these problems as well.

Dripping & Foaming

Foaming in a liquid bottle -Picture Credits: Today show

During the filling when the bottles are not placed in the specific position for filling then your filling material may get wasted. This often happens when the inadequate seals are not tightened up properly.

If the bottles are not sealed properly your filling material will also drip from the bottle. And when it comes to the foaming of the liquid this often happens because of the liquid material that you are using.

- Solution

The solution to solve the dripping during the liquid filling can be done by making sure that all the seals are tight up to the maximum level and the valves are made leakage-proof.

A nozzle which is called the diving nozzle can solve the foaming problem happening to your product during the filling. Because this nozzle can go into the bottom of the vial for filling.

Different Filling Levels & Timing

Different filling levels -Picture Credits: Mathworks

This is one of the main problems that can occur during the filling. You will find level changes in the bottles during the filling process like some bottles may be filled with more filling material from the estimation level & some of the bottles may fill with less amount of material from the approximate level.

Filling time can also change according to the size of the bottle & filling material that you are using. Larger size bottles will take more time as compared to the small size bottles.

- Solution

To solve the inaccurate filling of the bottles you just need to make sure that your seal is air-tight & leakage-proof.

So, that your material does not get wasted after the filling and an accurate amount of the filling material remains the bottles up to the right level.

If the air pressure does not remain constant during the filling your sales may not remain with the bottle head so try to provide the right amount of air pressure.

Power Problems

Power supply control-Picture Credits: Dr. Meter

The power consumption of every machine is different and when the level of the power changes it may cause damage to your equipment & your production may also get affected by the short supply of power.

Power problems can cause harmful reactions in different parts of the Liquid Filling Machine.

- Solution

To troubleshoot the power problem that may occur during the filling process you need to have a backup plan if the power supply goes out start the generator and switch the power consumption supply so that your machine remains in fine form & your product may not get wasted.

Regular Maintenance

You know that maintenance of the machine is very important for long the long run of the machine.

If you maintain your machine by utilizing some energy on the daily basis then it will be best for you to avoid these problems that may occur during the process of filling.

Clear and lubricate the necessary parts of the Liquid Filling Machine for better working & quality production

12.What Should You Consider When Buying Liquid Filling Machine?

There are few important factors you need to keep in mind when you want to buy a liquid filling machine.

1.Consistency with Machine

When you fill the bottles or whatever using the filling machine there might be some inconsistencies while filling the right amount into the bottles. In a pharmaceutical business, you cannot afford any type of inconsistencies while filling the bottle.

The liquid filling machine makes sure that it has no error while filling the pharmaceutical bottles. The chances of the error are very less with this machine.

There are different precision machine on the types like;

- Volume

- Weight

- Level

It has these filling input setups.

Precision is the real demand of the business.

2.Production Speed is Good

Vials Filled

As there are different sorts of filling machine. You can fill it with the manual system whereas the manual system is very slow. The production velocity of the liquid filling machine is better and it makes your whole system fast.

However, the velocity of the liquid filling machine depends upon the thickness of the liquid and also on the machine's head.

Normally, it does the 100+ bottles/min with the normal sixteen heads.

3.Simple Operating Systems

Mechanical fluid fillers may appear to be hard to work from the outset, yet they accompany working frameworks that can be handily scholarly over the long haul.

Some packaging machines regularly just require basic acclimation to transform one container to another.

Different models, for example, those from producers like AIPAK are furnished with rotative fillers for less difficult and programmed activity.

Filling machines have input settings, for example, ordering times, occupy times, and siphon speeds.

4.Long Term Usage

Modern filling machines are worked to keep going for longer creations without wearing out.

This guarantees that you can keep your business running for a more drawn out time.

With a legitimate month to month support checks and a couple of laborers close by the cycle, you can save money on everyday expenses on schedule and energy.

5.Filling Flexibility

Filling machines don't simply fill up a similar sort of item in a similar sort of compartment.

At the point when settings are changed, these bottle filling machines can fill any sort of bottles.

Filling machines can fill both thin and thick fluids, which benefits organizations with numerous lines of creation searching for this modern flexibility.

6.Production Scale-ability

At the point when you need heavier help in production as the business develops, bottle filling machines may be updated without supplanting machine.

Relying upon the model, most modern filling machines start with either 6 or 4 heads.

You will have the ability to add up to 16 according to your production requirements.

Putting resources into machines for your business might be expensive toward the beginning.

Be that as it may, you will get a profit for speculations by the time you will start the production.

13.How to Maintain a Liquid Filling Machine?

Appropriate support is fundamental for the powerful working of a filling machine.

Through upkeep, you can recognize the defective parts and fix them.

You are additionally in a situation to grease up the moving parts and fix broken parts.

This guarantees your machine works at an ideal level.

These are some guiding headlines for you to follow for the maintenance of the liquid filling machine;

1- Check for each and every part and it must not be rusty.

2- If there is any part is rusty make sure you grease up them properly.

3- Check for the power cable as well as the different button on the machine. The wire should be properly covered and shouldn’t have any chance for electric shock.

4- When checking for the buttons make sure they are fine.

5- You need make sure that lubricate the machine properly and if some parts are not working properly replace then on time. So, they don’t affect on the production.

6- You need to be certain that filling heads are in best working conditions.

7- The machine in the creation cycle, opportune eliminate the fluid or glass trash.

8- Clean the outside of the machine once prior to leaving and add the spotless chemicals.

9- The places where it is hard to clean use a blower.

10- Keep the Ambiance clean.

14.What is the Future Prospect of Liquid Filling Machine?

The future of the filling machine is expected to have:

- Indexing System (Moving Semi Auto Machines to Auto)

- Quick Conversion

- Multi-functional Machines

- Delivery Time will be Shorter

- Additional Filling Head is Expected

- According to the research gate, the advancement space of the filling machine industry will just develop bigger and the market potential is perpetual.

However, it actually needs the creating endeavors to truly try sincerely and cooperate to constantly improve the specialized level to accomplish a decent and stable advancement in the worldwide market.

The momentum objective of the filling machine industry is still to supplant the conventional method of aimlessly presenting and replicating with mechanical advancement autonomous innovative work.