Your Premier Effervescent Tablets Packing Machine

No Tube No Filling No Tablets No Capping

100% Accurate

AIPAK Effervescent Tablets Packing Machine

AIPAK effervescent tablets packing machine is suitable for packing effervescent tablets into individual tubes. All of the equipment adopts programmable controller centralized control, optical fiber, photoelectric detection, which has stable performance and reliable operation, and can be operated automatically. When there is no film, bottle shortage, cover shortage and other conditions, it can alarm and stop automatically. The contact part of the equipment and tablet is made of 304 or 316 high quality stainless steel, which is in full compliance with GMP requirements. It is the most ideal equipment for pharmaceutical factory, health care product factory, food factory effervescent tablet packaging and similar packaging.

The Buyer's Guide

Effervescent Tablets Packing Machine:the Complete Buying Guide in 2025

You may have seen effervescent tablets packed in bottles or tubes, the tubes readily catch your attention. Such a delicate type of packaging is done by the use of an Effervescent Tablet Packaging Machine. This machine plays an important role in the pharmaceutical industry. And being in the pharmaceutical industry you surely are in search of this machine too. We welcome you to our website and guarantee you that you have come to the right place for buying Effervescent Tablet Packaging Machine.

In this guide, we will let you know about all the aspects of a high-quality Effervescent Tablet Packaging machine.

1.What is an Effervescent Tablet Packaging Machine?

AIPAK Effervescent Tablet Packing Machine

Effervescent Tablet Packaging Machine is an automated machine that packs the effervescent tablets in the tubes or bottles. The tablets are first compressed and the stacks are made which are then packed into their respective tubes. A tight plastic lid is used for covering the tube. The packaging of effervescent tablets in this way make them safe for human consumption, also there are no chance of damage to the tablets.

Being a fully automatic machine it provides high efficiency and accuracy of its work, there is no chance for the human error. Also machine has a very high speed thus it can pack larger load of tablets in very less time. This machine comes up in many models so you can select the one that suits you best.

2.What are the uses of an Effervescent Tablet Packing Machine?

Following are the highlighted uses of an effervescent tablet packing machine.

- It is the most competent way for the packaging of effervescent tablets.

- It saves you from the cost of human labor.

- It is a practical as well as technical solution for the tiresome process of packaging of effervescent tablets.

- It packs multiple tablets in a single cycle.

- It has a vast impact in the progress of the pharmaceutical industry.

- It is a modern solution for the packaging of effervescent tablets in the safest form.

3. What are the applications of an Effervescent Tablet packing Machine?

Not only in the pharmaceutical industry but this machine plays an important role in nutraceuticals as well as in the food and beverage industry.

Nutraceuticals:

Over the years, nutraceuticals products have gain high attention in health and fitness industry. So, many nutraceutical products are available in the market in the form of food supplements and multivitamins. All these products are packed finely in different tubes with the help of effervescent tablet packaging machine.

Food and Beverage Industry:

This is one of the biggest industry of present age. Food scientists are continuously working to introduce new and improved food products on everyday basis. With this the need of competent packaging of these products has also gain attention. One modern and most effective solution for the packaging of beverage bottles is the use of effervescent packaging machine. It fills the bottles at the required level with great precision.

Pharmaceutical Industry:

It is undoubtedly the most important industry for the use of this machine. With the advancement in the production and use of medicines the packaging of these medicines has also gain the equal attention. It is very clear in today’s scenario that if you want to excel in the pharmaceutical industry you must be equipped with modern tools. This machine is the most effective and reliable tool for the drug manufacturers in the packaging of effervescent tablets.

4.What are the components of the Effervescent Tablet Packing Machine?

It is a fully automated machine made up of a combination of different parts, each part is essential for the proper functioning of the machine. Following are some essential parts of a fully automatic effervescent tablet packing machine.

Cap Vibrating Unit

Tablet Feeding Unit

Tube feeding System

Capping System

Electronic Control System

All these units function in a precise manner to give high-quality results.

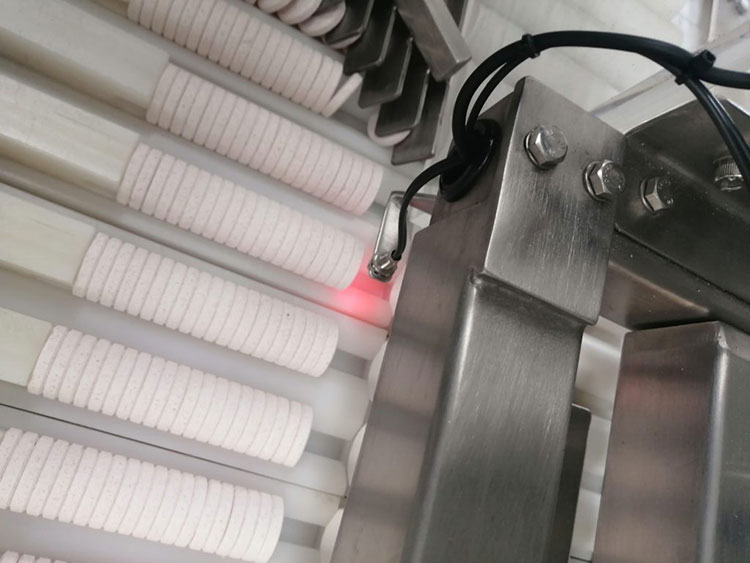

Cap Vibrating Unit:

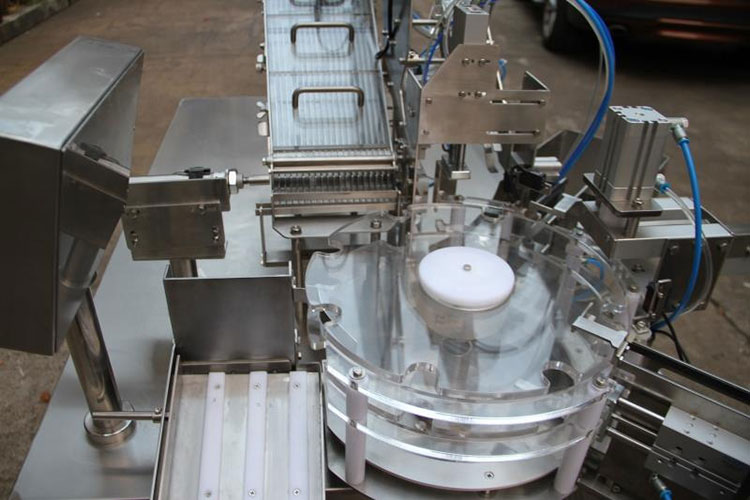

Cap Vibrating Unit

This part of the machine puts the cap manually in an oscillating disc, the hopper is the oscillating disc, and the position of the cap is automatically set by the movement of the hopper. The vibrating system supports the movement of the cap.

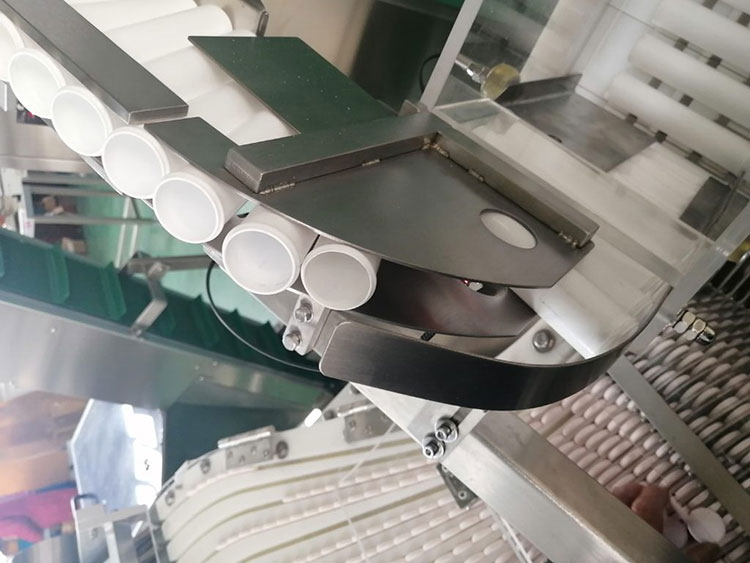

Tablet Feeding Unit:

Tablet Feeding Unit

This part of the machine is responsible for the filling of tablets, the tablets are manually placed in the hopper, from the hopper the tablets will be automatically arranged at their respective filling positions. The bottle for filling is placed at each filling position, the cylinder automatically sends the tablets in the bottles.

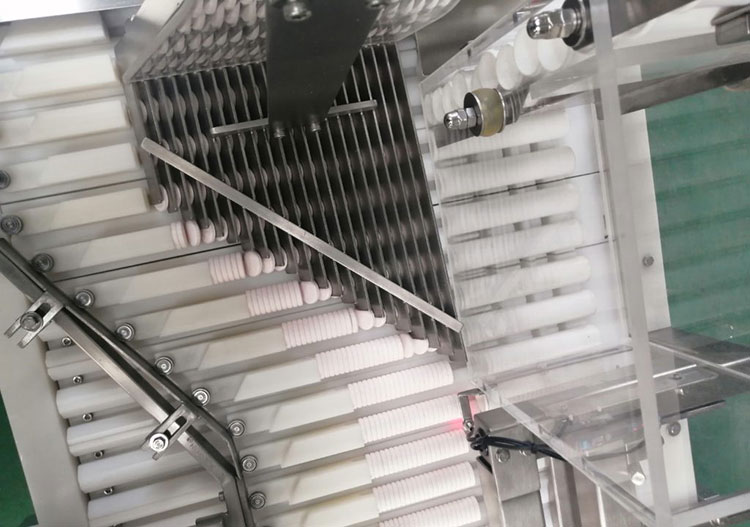

Tube Feeding System:

Tube feeding unit

This unit of machine lines the tubes in the filling direction once they are put in the hopper.

Capping System:

Capping System

Once the filling process is complete the capping unit will automatically fix the caps over the tubes. If there is some problem in the tablet feeding unit the capping unit will not cap the bottle and it will be then rejected by the machine.

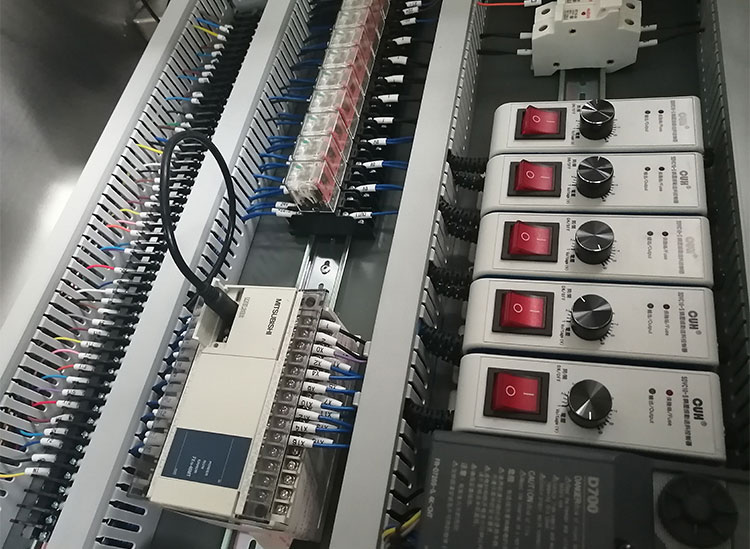

Electronic Control System:

Electronic Control System

The machine is fully automatic and comes along with a PLC control system to control the operations of the machine. The electric system thus assists the machine to perform functions systematically. The machine also has a safety unit attached to it that alarms in case of any harmful changes.

5.How does the Tablet Effervescent Machine work?

To get the maximum benefit from any equipment you need to be completely aware of its working principle. The working principle of a Tablet Effervescent Machine is very simple and is easy to understand. The machine works in four steps.

- Preparation Phase

- Filling Phase

- Inspection Phase

- Capping Phase

Preparation Phase:

Initially, the tubes are loaded in the tube hopper, then the tablets are loaded in the tablet feeder. With the help of a touch screen control panel various parameters like the number of tablets to be filled in each tube, speed of production, and distance among the tubes are adjusted.

Filling Phase:

After the filling of tablets and tubes in the hopper, you will have to switch on the machine through the control panel. The machine will automatically place the tubes at the fixed positions and through the oscillatory action of the hopper, the tablets will be filled in the tubes. This automatic action of loading the tablets help the operator to fill the tablets again when required. The accuracy and quantity of tablets are controlled by a pneumatic system installed in the machine. This helps you to adjust the counting of tablets in odd or even orders.

Inspection Phase:

In this phase, the machine automatically checks if there are the right number of tablets in each tube, also if the tubes are fit for filling and capping. In case of any problem the machine automatically rejects the tube.

Capping Phase:

When the filling of tubes is done as per the requirements the machine will automatically cap the bottles, it has a sensor to check if the tube has a cap or not. And it only allows the tubes with the cap to proceed to the labeling stage.

The operating principle of the machine is very easy and simple, you just need to know about the parameters that are required to enter on the control panel for operating the machine, and afterward, the machine will automatically perform its function.

6. What are the advantages of an Effervescent Tablet packing Machine?

In the modern era, you cannot deny the benefits and ease you get from the effervescent tablet packing machine, so many tasks that were seen to be impossible to do in the past are now carrying out with this and other related machines.

Some benefits of this machine include:

High Productivity:

The machine is fully automatic, it doesn’t need any human labor except a single expert, and this has increased your productivity to the next level. Once you put the machine in a working mood you are free to perform your other tasks side by side. It gives you the highest production of effervescent tablets and fulfills your market demands thus enabling you to stand in the line of competition.

Increased Accuracy:

Being a fully automatic machine it promises you about the efficiency and accuracy of results. As there is no manual operation in the filling process the chances of error are negligible. Its high accuracy and efficiency make it important equipment of the pharmaceutical industry.

Line Integration:

This machine is an all-in-one task performer and thus it gives you the best output in a minimum period. It directly connects the tube filling process to the packing systems and this line integration of the process ensures you about the quality, and accuracy of the whole process.

Filling based on Rotation Principle:

Filling items in tubes is not a piece of cake, it takes your energy, time, and complete focus to carry out the process. This machine inevitably makes this task easy for you. This special rotation principle for the filling of tablets at a very high speed after passing them from different channels. The high speed enables the tablets to slide down the filling tubes most efficiently without breaking down tablets.

Fewer Parts, Easy Adjustment:

The machine is very simple to use as there are fewer parts of the machine that makes the installation, operation, cleaning, and maintenance of the machine very handy. It doesn’t require any formatting of its parts to carry out different functions. Some of the models of the machine come with the option for up-gradation.

All these aspects of the machine have made it an important part of the pharmaceutical industry.

7.Are there any drawbacks of the Effervescent Tablet Packing Machine?

The machine has some minor drawbacks associated with it that need to be addressed to guide you better in making a correct choice.

- In terms of money the machine will costs you little more than the usual, so you need to have a good budget for investing in the machine.

- The working of the machine is limited in terms of filling specific size of tablets. It don’t fills the tablets of small sizes.

- The working operation of the machine is quite complicated and it need a vigilant technician to operate the machine.

- The tablets needs to be packed in a special paper before filling them t=in the bottles, thus the packaging material also costs you some extra money.

8. Which quality standards must be fulfilled by the Effervescent Tablet Packaging Machine?

Following quality standards are essential to be filled by the Effervescent Tablet Counting Machine.

FDA:

This quality assurance standard is very important in terms of the health safety of the medicine for consumer use.

Current Good Manufacturing Practices (cGMP):

This quality control standard gives the confidence to the buyer that the machine is according to current international manufacturing standards and all the parts of the machine are intact and are working in their fullest.

CE to ensure the safety of electric systems:

This is the most important standard. This will give the assurance about the electric supplies and connections of the machine are intact and machine is safe to operate.

ISO certification:

This certification is important for the buyer to prove that machine fulfills all the international rules and regulations.

All these standards are important to increase the value and worth of the machine.

9.What is the features of Effervescent Tablet Packing Machine?

An ideal Effervescent Tablet Packaging Machine will have the following features.

- Automatic Tube Feeder

- Automatic Cap Feeder

- Automatic Cap Presser

- Automatic Checking and Rejection of cap less tubes

- 100% Accuracy in Tablet Counting

- Stopping of the machine on empty tubes or non-capped tubes

- A touch PLC Control System

10. What different types of Effervescent Tablet Packing Machines are available?

There are different types of effervescent tablet packing machines present in the market, each has its operations and specifications. So you can choose the one that fits your requirements and is suitable for you.

The two main types of this machine are:

Semi-Automatic Effervescent Tablet Packing Machine

Fully Automatic Effervescent Tablet Packing Machine

Semi-Automatic Effervescent Tablet Packing Machine:

Semi-Automatic Effervescent Tablet Packing Machine

Semi-Automatic Effervescent Tablet Packing Machine gives you the choice of operating it whether automatically or manually depending on your desire. You can choose to operate some parameters manually and some automatically. Also, not all the parameters of this machine are fully automatic. Although it has all the features of a fully automatic machine.

The main drawback of this machine is that it is not suitable for large-scale production, also the results are not 100% accurate. It can help you with small-scale production.

Fully Automatic Effervescent Tablet Packing Machine:

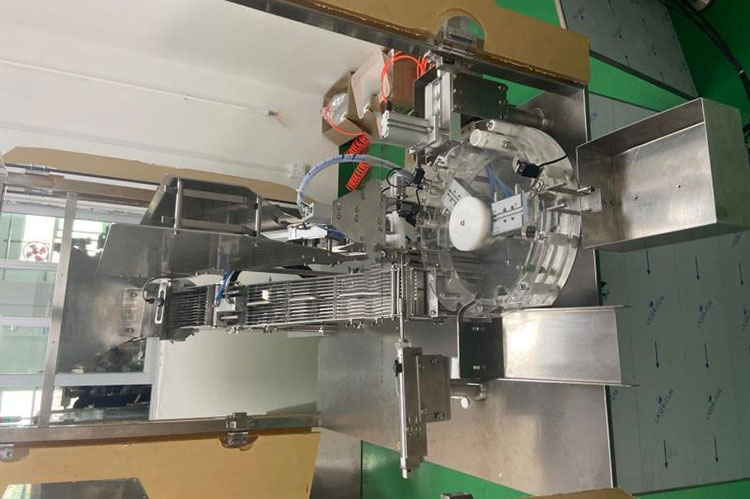

AIPAK full-Automatic Effervescent Tablet Packing Machine

This is the modern type of machine that has become Apple of the eyes of manufacturers. All big-scale industrialists choose this machine because of its fully automatic functions. It performs loading, filling, capping, and labeling of the tube automatically. This machine has sensors to check whether the product fill is according to the requirements or not. If product filling is not up to the mark then it rejects the tube.

The only drawback of this machine is that it needs a highly trained technician to operate it properly.

Now, you are aware of the types of machine you need to be very careful while buying, especially check for the specifications of the model you want to purchase.

11.What are the specifications of an Effervescent Tablet Packing Machine?

There are some factors that will be very helpful for you while purchasing the machine. You must always look for these characters before doing a final decision of purchasing. These characteristics include:

Size of the machine:

The size of the machine matters a lot. You always need to check the size of the machine according to your requirements. A small machine will definitely occupy small space and will be suitable for packaging of small number of tablets, thus it will be best fit in small scale industry. On the other hand a big machine will occur more space at your workplace and will also have high efficiency for packaging of tablets, thus it will be suitable for a large scale industry. Now it will be completely your choice to go for the one that is best fit for you.

Speed of the machine:

The speed of the machine is very important factor to check for before buying. Being a competitive marketer you always prefer the machine with high filling capacity in a minimum time period. Because only in this way you can fulfill the increasing demands of the industry.

Material of the machine:

The machine will be a lifetime investment for your industry, and it should have the ability to withstand the harsh environment changes. In most of the cases manufacturers prefer stainless for the machine. Stainless has high resistant against temperature, water, corrosion and other damages, so ideally it is the best choice for constructing the body of the machine.

Technology of the machine:

The technology of the machine must be advanced with all the latest functions. You must check for the complete automatic operations of the machine with high tech commands. There should be no burden over you in terms of operating the machine. Also the technology must be easy to comprehend and doesn’t bother the operator in any way.

Adjustment of the machine with other equipment:

While working on the packaging of effervescent tablets you need to do multitasking, the whole process work in a coordinated manner from one equipment to the other. Thus, before purchasing the machine always read the user guide book or seek help from the manufacturer regarding the compatibility of the machine with other equipment of the industry.

Technical specifications of the machine:

Always check the following technicalities of the machine before buying.

- Diameter of the tablet

- Speed of filling

- Capacity

- Length of the filling tube

- Weight of the machine

- Thickness of tablets

- Compressor Air

- Power supply

- Size of the machine

- Electricity utilization:

The machine must consume the minimal power for the production of large units. Because if the consumption power of machine is high it will cost you additional charges. Thus check for the latest models that have the power saving options.

Conclusion

Now that you are fully aware of what an ideal effervescent tablet packaging machine is, what benefits you can gain from its use and how much your industry can flourish from this apparatus, so let’s not wait for more and contact us for buying your perfect effervescent tablet packing machine.

Effervescent Tablets Packing Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586