All Sizes of Capsule Available

High Productivity & Fully Automatic

High Efficient & GMP Standard

Want A Free Consultation

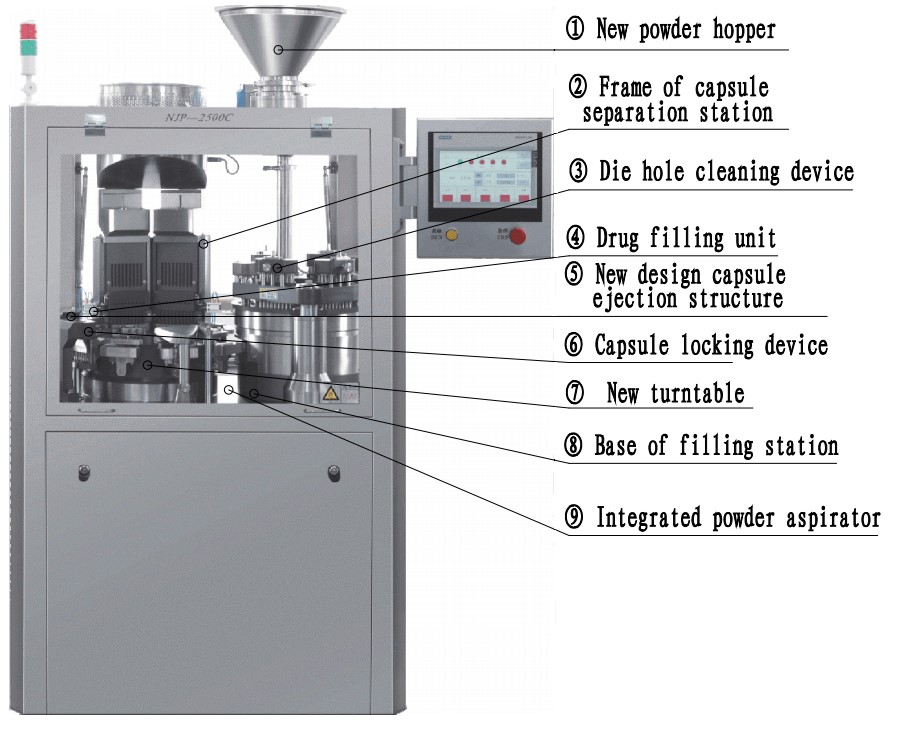

NJP-2500C Automatic Capsule Filling Machine

AIPAK NJP-2500C automatic capsule filling machine produced by our company is the innovative product of the third generation after many times of innovations and improvements. The new product is equipped with advanced technologies and perfect configuration. It not only covers all the functions and effects of the domestic capsule filling machine of the same model, but also has five pieces of innovation, three of which has been issued the utility model patent certificate by the national intellectual property administration, PRC at May 11, 2016. The innovative NJP-1200C automatic capsule filling machine, whose performance and quality has reached the top level in domestic industry, has passed the inspection of related requirements.

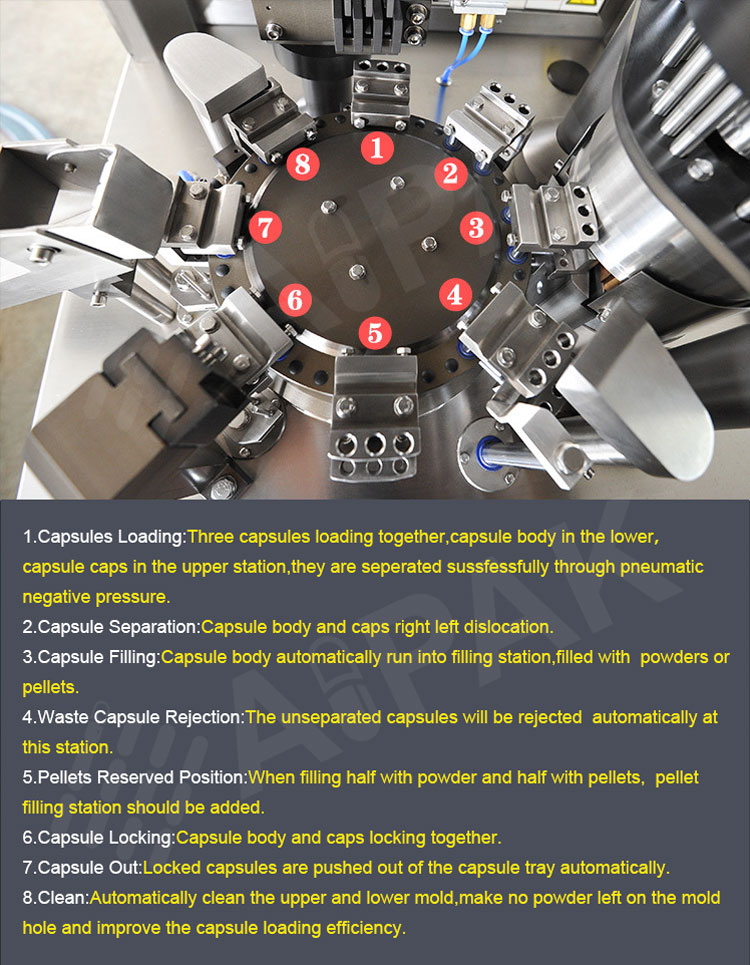

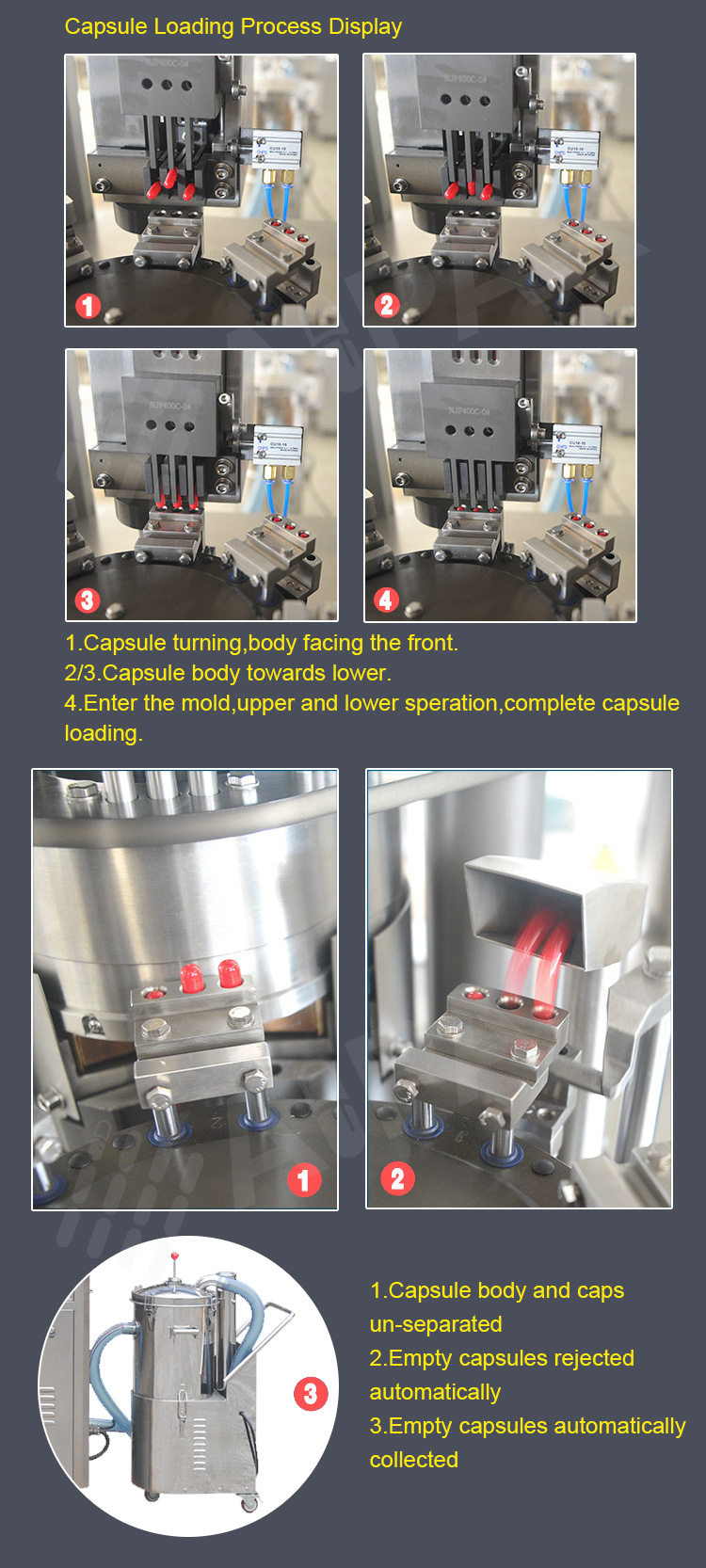

1.Automatic Capsule Filling Machine Working Principle

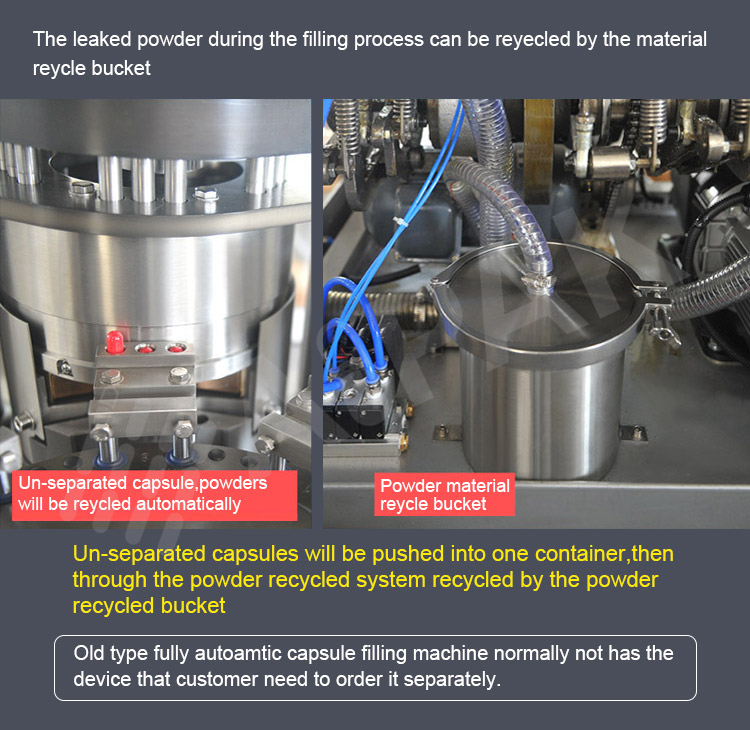

2.Automatic Capsule Filling Station

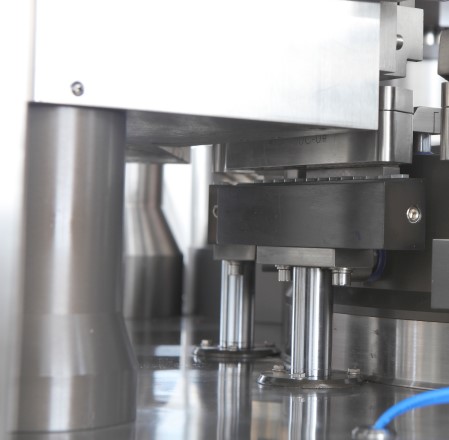

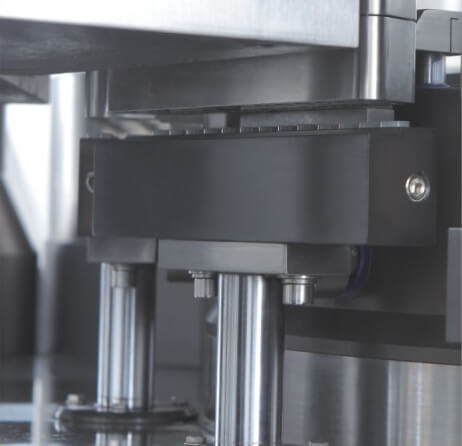

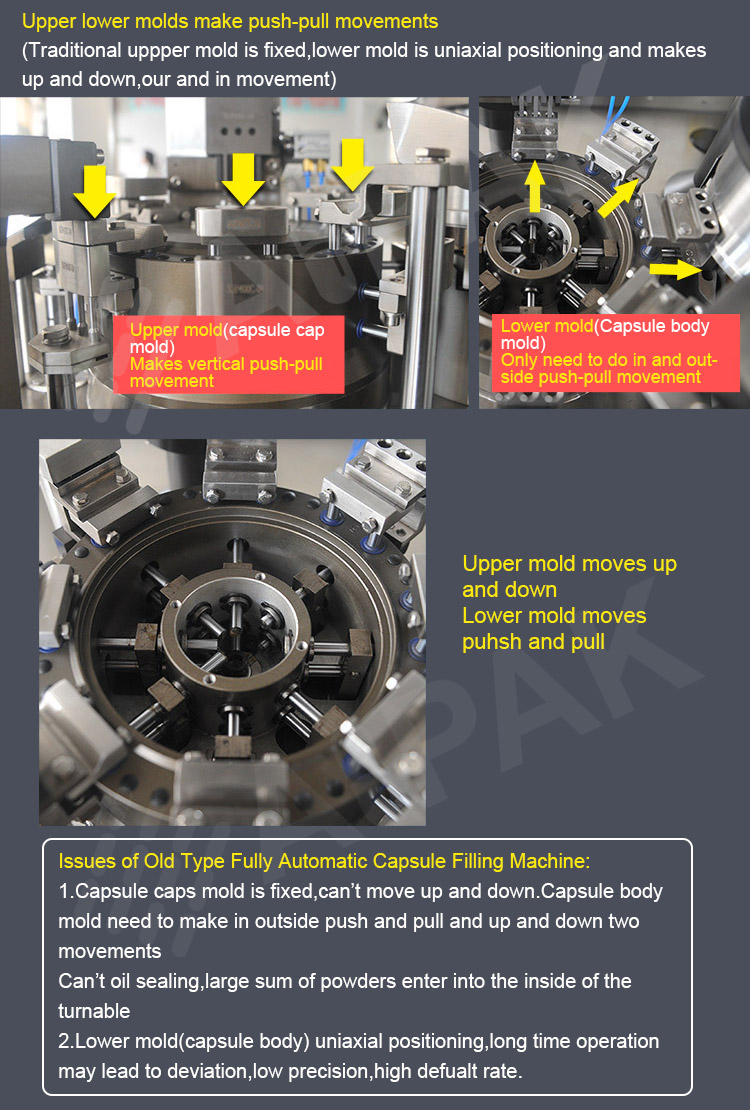

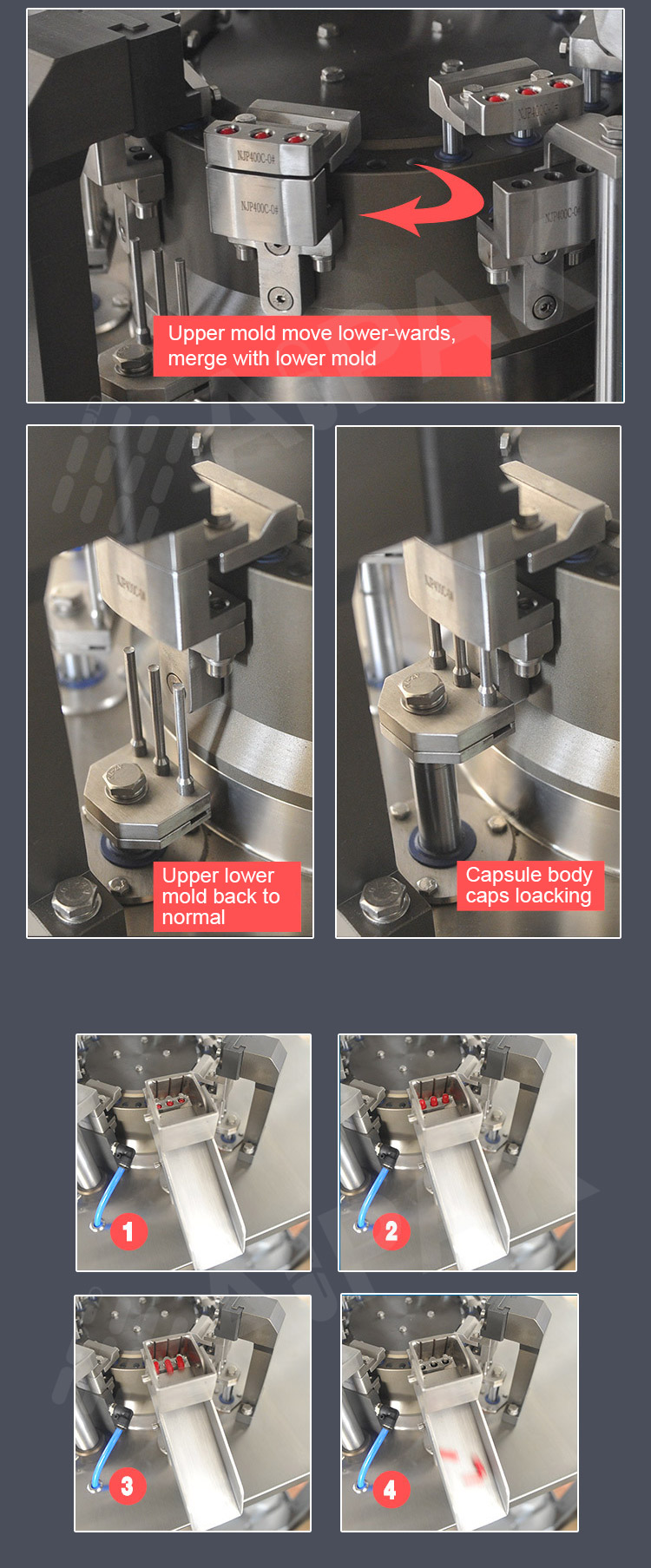

3.Upper Mold Movement

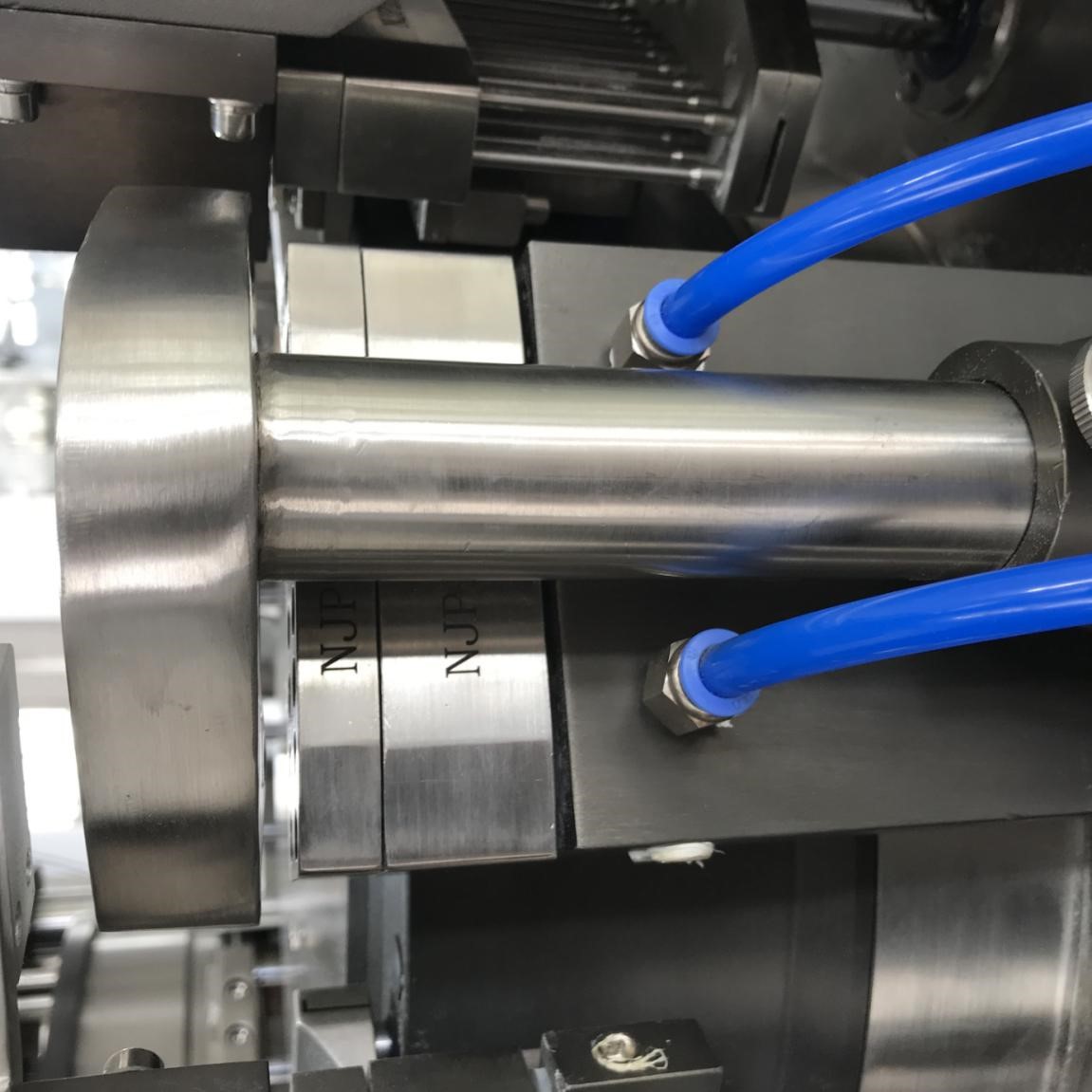

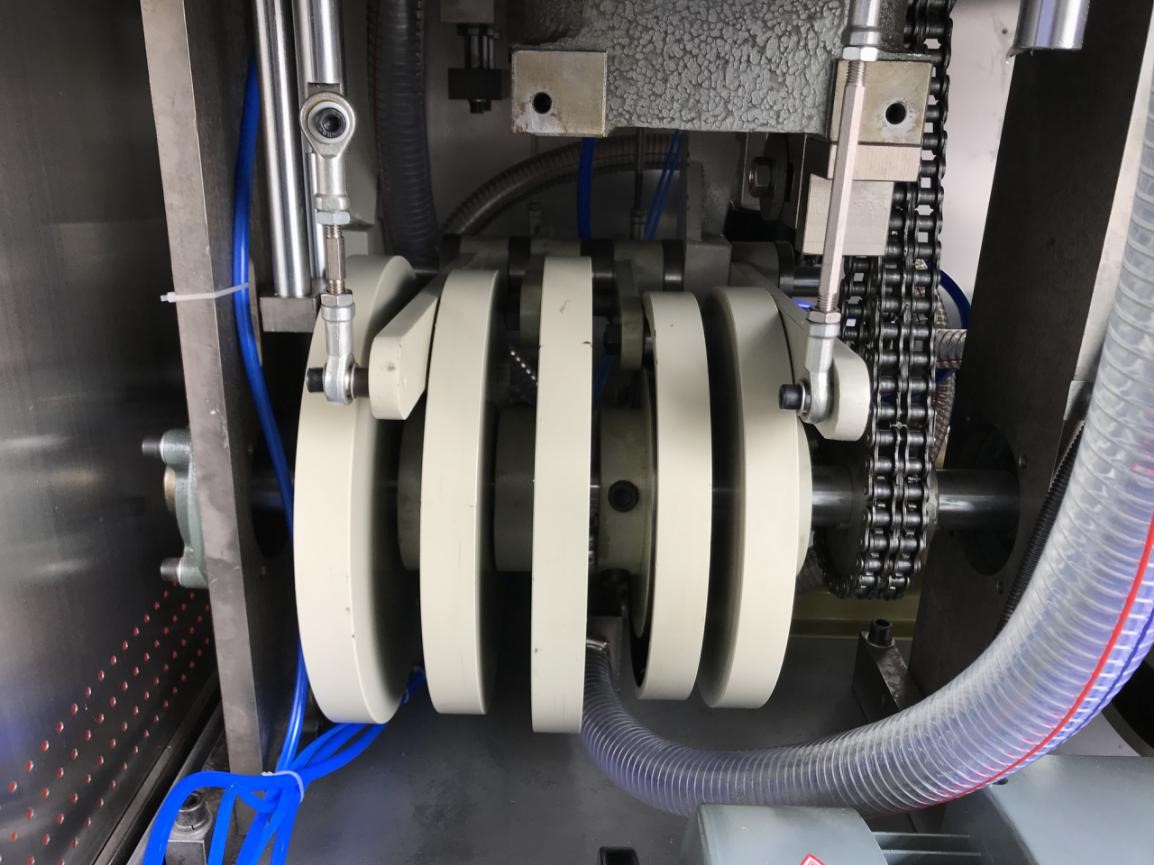

4.Double Shaft Double Oil Sealing

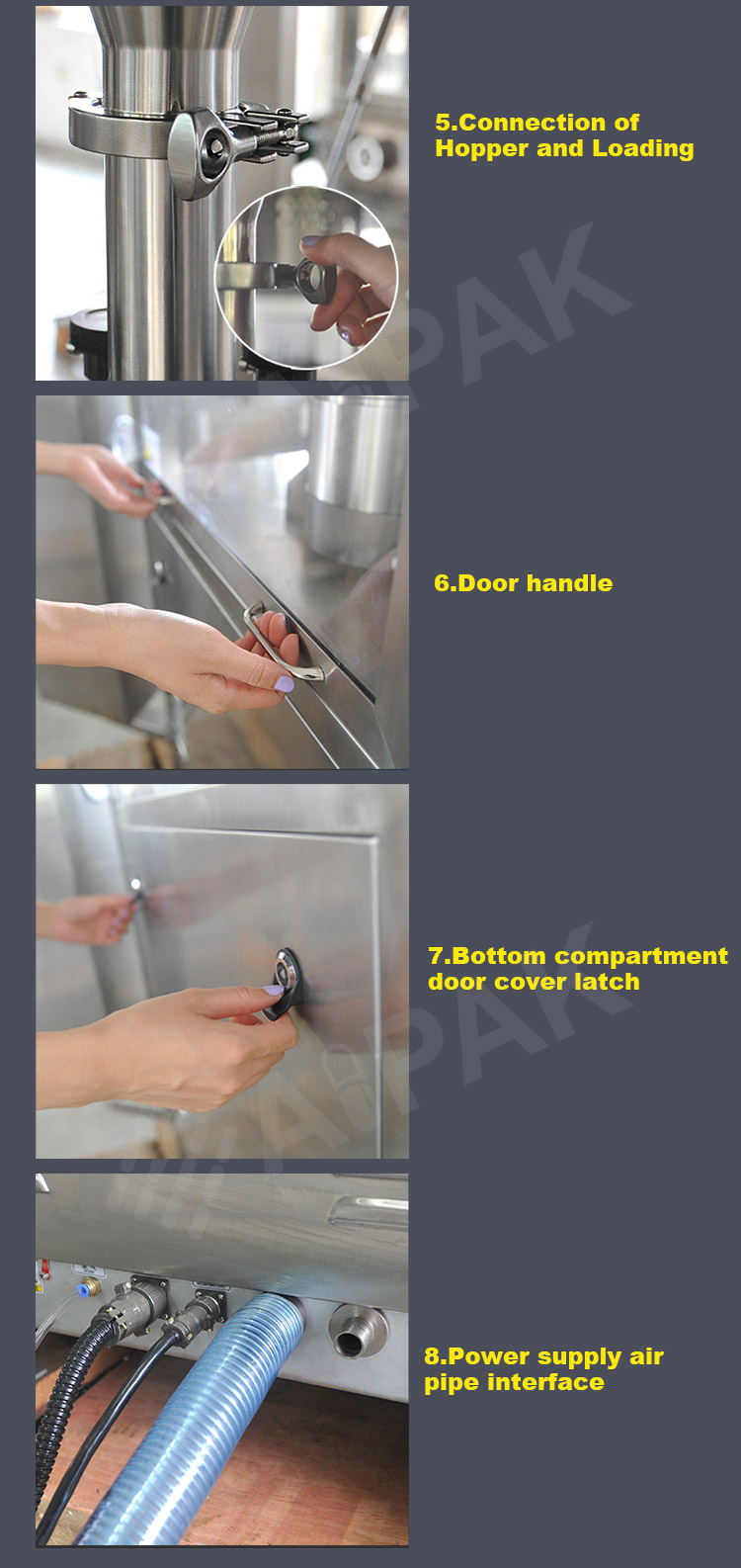

5.Loading Valve

6.Aviation Material

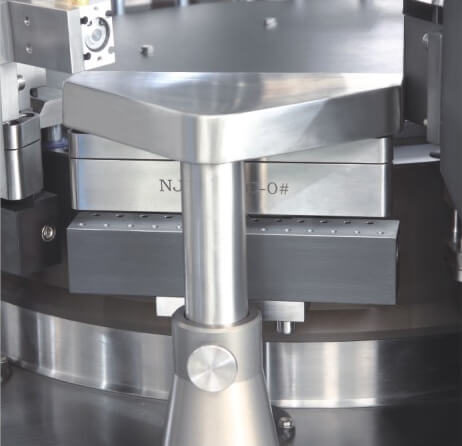

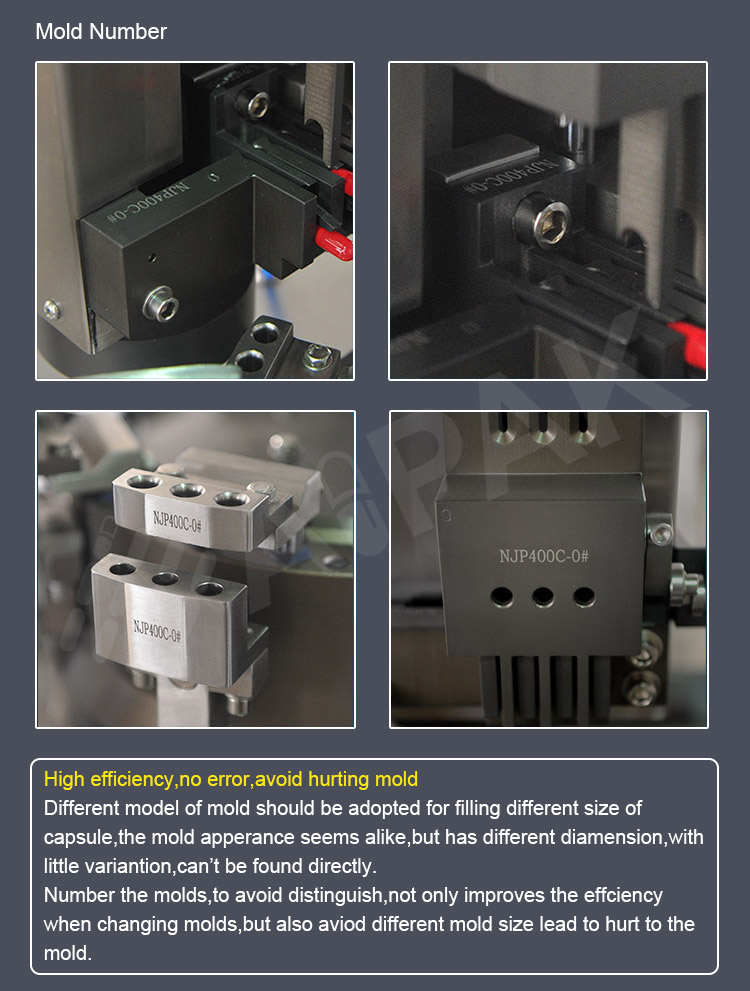

7.Mold No.

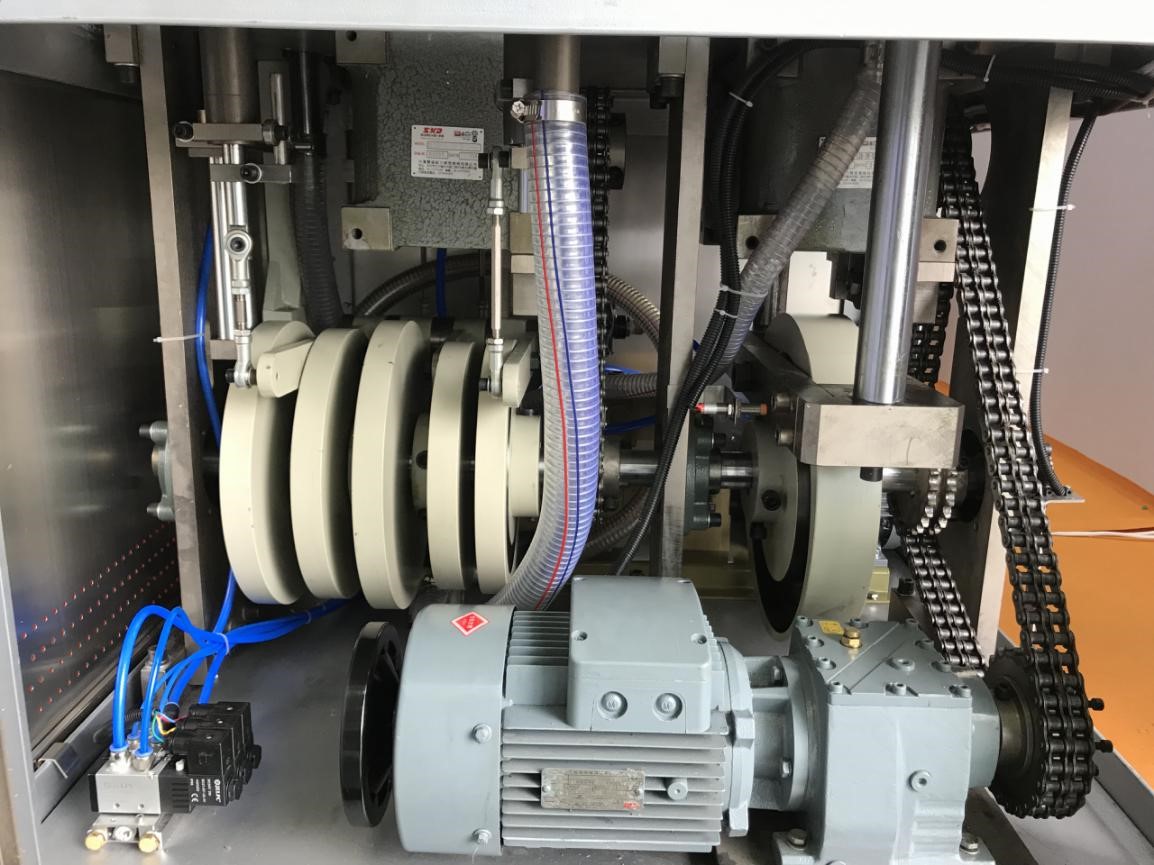

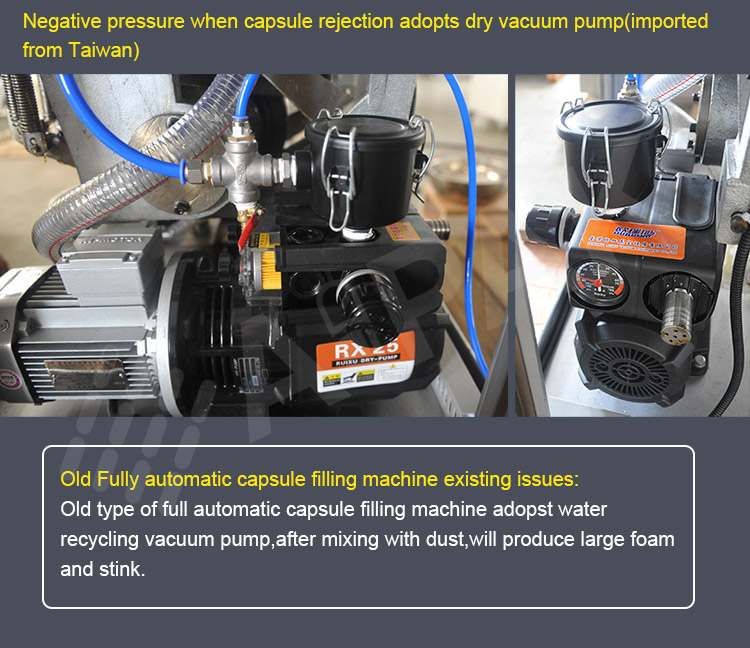

8.Dry Vacuum Pump

9.Safety

10.Specific Details

11.Capsule Filling Complete Process

12.Pellet Filling

13.What AIPAK Automatic Capsule Filling Machine Can

FEATURE

- Opening and locking of capsule can be controlled automatically which is safe and convenient.

- Equipped with inching control system, which makes it easy and convenient for cleaning, loading and unloading of upper and lower dies.

- Equipped with gate control security system and mechanical failure security system, which provides functions of automatic alarm and shutdown.

- Automatic alarm and shutdown will be activated when lacks empty capsule or powder.

- Rich functions designed on the HMI, including counting and displaying functions during the production, and it is able to link with printer, if needed, for printing information including date of production, lot number, quantity, etc.

- The capsule separation chamber is driven by seal guide rail, which can prevent defective capsules and dust from entering into the chamber during spreading capsules, ensuring the stability of operation.

- Shafts of capsule absorbing, pushing, locking, as well as defective capsule rejecting are all sealed with two layers of sealing ring, among which the first sealing adopts Nitrile Butadiene Rubber (NBR) to prevent lubrication from losing, and the second sealing uses imported silicone rubber sealing ring (SIL) to prevent powder from entering bearings, which has effectively solved the problem of bearing damage and shaft jamming because of powder leakage.

- The two horizontal shafts of high-precision fully enclosed turntable adopts PTFE oil-free bearings, which are sealed with imported silicone rubber sealing ring (SIL) for preventing powder from entering the inside room of the turntable, ensuring running accuracy of the turntable, without needing to maintain and add lubrication permanently.

- The plane cams are running in the mode of double rails, where the two axes run out separately. It can improve the operation accuracy and meanwhile eliminate the possibility of collision between the lower die and the dosage disc.

- The high precision cam splitter uses optical dividing head of German Zeiss. The dividing spindle is machined in the CNC all at once, which has ensured accuracy dividing of the turntable and dosage disc while the machine runs fast, thus ensuring the precision of filling. Higher precision of cam splitter also provides the machine longer service life.

- The operating cams are all processed with 20crmoti carburizing and quenching treatment, and then machined in CNC grinding machine all at once, which has ensured the accuracy and unity of the cams and provided a longer service life.

DATA SHEET

|

Model |

NJP-2500C |

|

Filling capacity |

150000pcs per hour |

|

Weight |

1500Kg |

|

Machine size |

1100×1200×2000mm |

|

Power supply |

380/220V 50Hz |

|

Total power |

8KW |

|

Segment bores |

18 holes |

|

Vacuum |

63m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Air compression |

Air consumption 6m3/h Pressure 7-8Kg |

|

Water source |

500L/H 0.2-0.3Mpa |

|

Operating noise |

<75DB(A) |

|

Filling percentage |

Empty capsule 99.9% filled capsule 99.8% |

|

Capsule size |

00,0,1,2,3,4,5# Safety capsule A-E |

|

Filling accuracy |

Western medicine ±3% Chinese medicine ±4% |

|

Suitable for |

Powder, Granule, Pellet, Tablet. |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586