Automatic Popping Boba Machine

AIPAK Popping Boba Machine

Popping Boba is a little juice ball that has become increasingly popular along with the frozen yogurt craze. Popping boba is also known as bursting boba, popping boba and bursting fruit bubbles. The popping boba is a little smaller than the regular tapioca boba, the Popping Juice Boba is filled with fruit juice and and "pop"s when bitten into.

The outside of the popping boba is made of a seaweed extract, creating a thin slightly gelatinous coating and isn't chewy like the traditional boba. In a way, it's more fun with less work. While the inside of the popping boba is also seaweed extract, mixed with real fruit juice and flavors. The Popping Juice Balls are not overly sweet and offers a pleasant variety of flavor. Should you choose to put it on top of your frozen yogurt, shaved snow, or in your drinks, it's a great way to mix and match a unique drink.

Many businesses and consumers alike have been experimenting with different ways to eat Popping Juice Balls, including but not limited to using them in smoothies, blended milk tea drinks, tea drinks and alcoholic beverages. Because of their fun colors and flavors, Popping Juice Boba is quickly rising in popularity and demand.

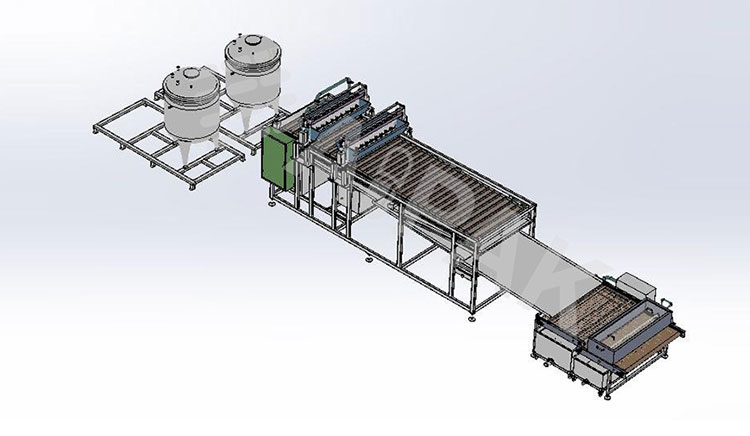

AIPAK Popping Boba Machine production line is mainly made of stainless steel and it is fully complying with the food sanitation standards. The popping boba and agar boa that made by this machine is in beautiful shape and filling can be any taste, bright color and weight without variation.

AIPAK Popping Babo Machine Main Technical Parameters

| MODEL | APK-PB50A | APK-PB50B | APK-PB100 | APK-PB200 | APK-PB400 |

| Capacity | 20-50kg/h | 20-50kg/h | 50-100kg/h | 200-300kg/h | 400-500kg/h |

| Boba weight | According to boba diameter( Customized from 3-30mm or more ) | ||||

| Depositing Speed | 15~25 Strike/min | 15~25 Strike/min | 15~25 Strike/min | 15~25 Strike/min | 15~25 Strike/min |

| Type | Labtory/semi /small | Labtory/semi /small | Automatic | Automatic | Automatic |

Frequently Asked Questions

In many countries,popping boba also can be also called popping pearls,popping balls ,bursting balls, bursting tapioca balls,boba juice balls ,popping juice balls, bursting boba ,juicy boba balls and Juice boba.

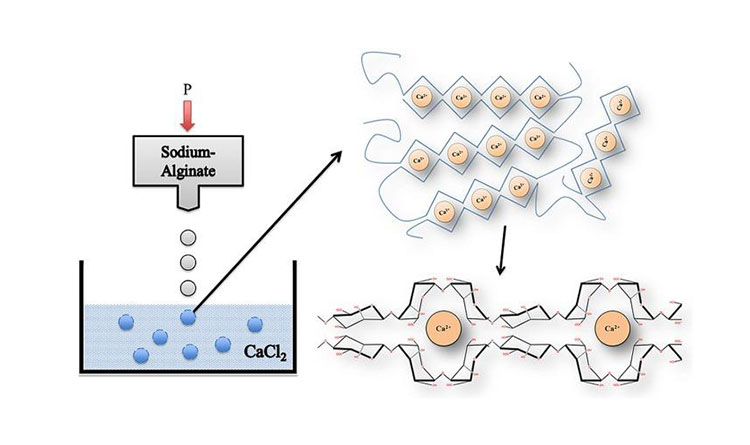

There are two parts for popping boba, shell, and filling.Filling can be any kind of juice or liquid but have to mix with calcium.

When the calcium drop by the machine into shell liquid( sodium alginate ) will have a chemical reaction became popping boba(Outside shell inside juice).

Pls see the below ingredients list for the popping boba making:

Filled juice: (water, glucose syrup, calcium lactate, calcium chloride, guar gum, xanthan gum, juice or chocolate slurry (base on different taste), citric acid, flavor, etc..)

Shell solidification liquid: (water and sodium alginate).

Pretection liquid: (water and fructose)

You need the colloid machine to grind the sodium alginate before dissolving in the cooker (for raw material of the film liquid), because the sodium alginate will be caking when dissolving in the cooker if no milling in advance.

There are two tipping cooker, one is a cooker for cooking film liquid materials and the other one is for cooking filling materials. The mixer is for mixing raw materials when cooking and make it to be heated evenly.

Yes, the depositing machine include the hopper and all equipment required to produce the popping bobas..

If you have steam boiler in your factory and all cooking machine heated by steam, then the total installed power is 3kW/380V/50HZ (or we can use the electrical components according to your local power supply condition).

If you don’t have steam boiler and all electrical heating for cooking machine, then the total power will be 19kW/380V/50HZ.

There is no cooler required in this machine.

This is a small machine about 10-20 square meters is enough.

Yes, the technology transfer include all ingredients ratio, specifications and procedure how to make the popping boba in details. And Of course all details are in English.

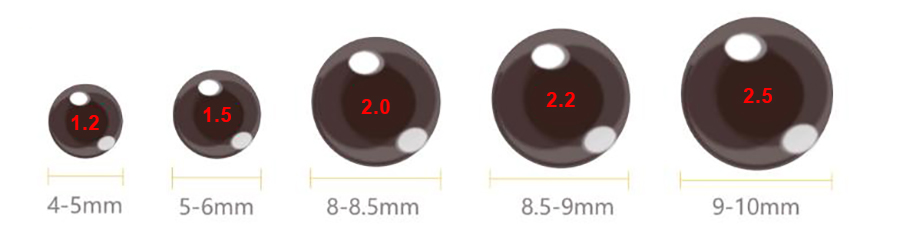

Various Sizes of Popping Boba

Popping boba sample

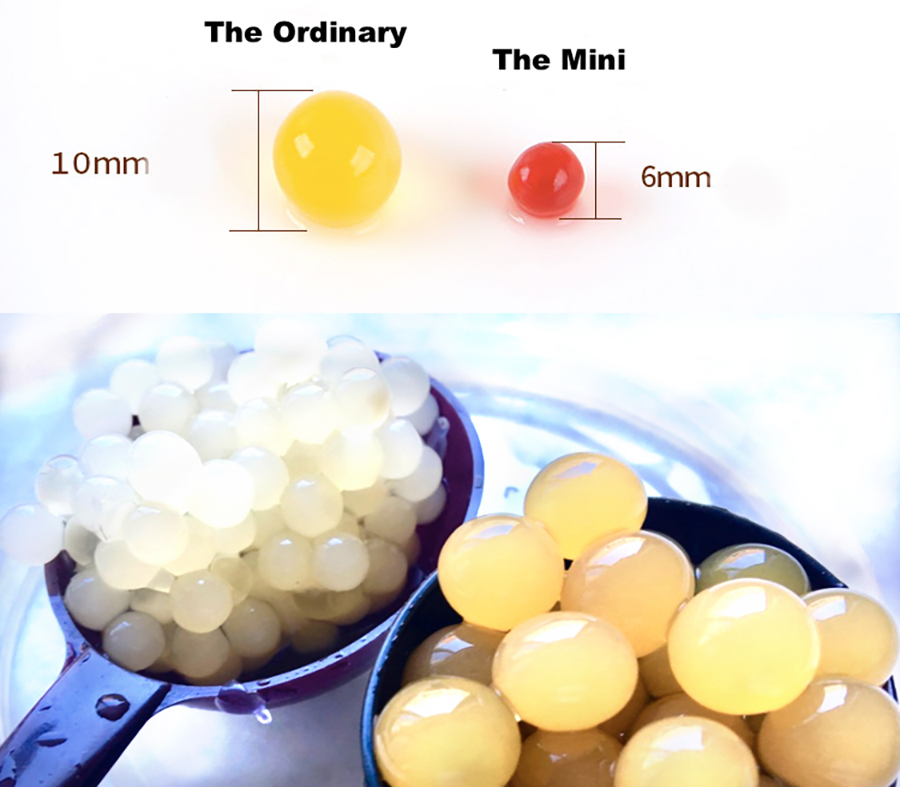

Comparsion of two size of Popping Boba

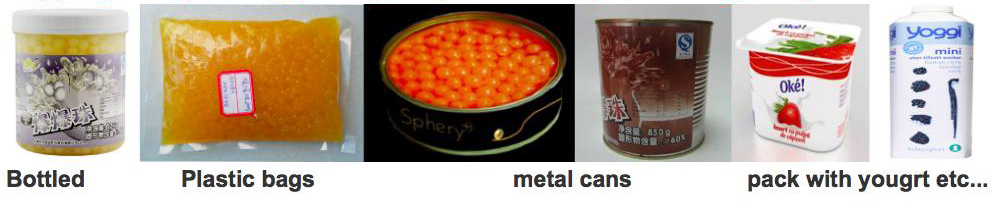

Popping Boba Packing(Can be storaged in production Liquid for long time)

The Buyer's Guide

Popping Boba Machine:The Ultimate Buying Guide In 2025

Except you’re living under a rock, it is not possible to not know popping boba which is a small juicy ball that has becoming progressively more popular with trend of frozen yogurt.

No doubt it is very inspiring to see how this amazing sip of drink has become a full-blown sensation all around the world.

Similarly, when you put popping boba in your mouth you will find flavour juice popping inside. The out layer of popping boba is composed of seaweed extract.

The seaweed is perfect ingredient that retain tasty content until they are ready to pop when beaten.

But do you know how popping boba is made?Read More! To know more about popping boba machines, working principle, components, classification and much more.

This blog will provide a thorough aspects of popping boba machine that you must know before purchasing a popping boba machine.

Let’s get into it!

1)What do you know about a Popping boba?

In 1940s, the spherification was originated by mistaken by the food scientist, since then it was utilized in molecular gastronomy. While scientist calls this process as cross-linking which is a bond formation between two or more polymer.

Chefs uses this spherification process in kitchen to make popping boba which is simply a delicate skin like structure contains juice inside releases upon squeezing. This is also known as ‘bursting boba, poppingboba as well as bursting fruit bubbles that has taken world by a storm due to variety of yummy flavors. For instance, mango, oranges, strawberries and so on.

The popping boba are made from sodium alginate which is added to a flavored liquid. Then you can drop this liquid into a mixture of calcium chloride.

You’ll love the chemistry between calcium chloride and sodium alginate. Because by reacting each other, calcium starts replacing sodium ions ultimately links the polymer chain bonding forms a perfect network which holds the liquid.

So, the popping balls are the wonderful example of an ionic cross links which you love to eat.

2)What is the composition of a popping boba?

A delicious, icy, and unique popping boba make you feel like a real fruit juice when burst in mouth. The popping boba ingredients are composed of the following.

- Water

- Flavor of fruits

- Seaweed extract

- Sugar

- Fruit juices

- Calcium lactate (it is commonly used in beverage industry as a calcium sources for the fortification of fruit juices.)

- Malic acid (it acts like a blending agent which creates a smooth and enhances a natural tasting flavor)

- Potassium sorbate (it is commonly used antimicrobial and preservative agents in food products)

3)What are the basic applications of popping boba?

A ball bursting beverage is capable to use in many ways to enhance the flavor and taste of many products. They are made of real fruit juice that’s why when you put jelly like balls in mouth, they burst and gives you delicious fruity taste. Popping boba is unique and attractive topping which is not only delicious but super-fun also.

It is wonderful addition when you incorporate them with following products:

a)- Ice cream

b)- Smoothies and slushes

c)- Tea, Iced bubble, and bubble tea

d)- Confectionaries

e)- Frozen yogurt

f)- Cocktail drinks

g)- Custard

4)How popping boba is prepared?

- To prepare a popping boba, you need to add popping material in a specified ratio into a jam hopper.

- Add rich quantity specified water in a rectangular stainless tank (SUS-PAN). With the help of high stirring equipped machine, these ingredients are evenly mixed in the tank.

- Add rich quantity of purified water in rest of integrated sink of machine.

- Transfer the juice into the metering channels of the machine.

- Compute the set up using Operating panel, switch ON the machine and switch ON the quantitative funnel to initiate the production.

- With the help of integrated sieve network produced beads are easily removed. They are again incorporated automatically into sink for washing via auto cleaning and collecting process.

- Before long, you can get juicy beads ready for eating or drinking.

5)What are the benefits of popping boba?

1)Diversified Flavors

Popping boba is a diversified food product available in number of flavors such as strawberries, mangoes, oranges, lychee and much more.

2)Low Calories

If you are health conscious, then there is good news for all popping boba lovers because consuming popping boba will give you a low-calorie intake which is only 30.

3)Great Addition to Your Food

There is uncountable way to delight in popping boba. Some people love to take them in an icy texture by simply letting the popping balls in mouth and burst with an expansion of fun and flavor.

Popping boba is no doubt an amazing supplement to dessert and drinks. You can have it in fruit cocktails, frozen yogurt, juices even salads.

There is no limit when it comes to serve popping boba in your food.

4)No Cooking Required

Popping boba do not required cooking or high temperature processing. This product is simple to prepare and does not require so many preparatory steps before serving.

Once it prepares do not forget to seal and refrigerate it for its longer life.

5)Unique and Attractive

Popping boba are unique with a gummy texture. They are seeming to be cleared and transparent and their gummy texture is due to seaweed extracts. Due to their unique colors, they bring colors to your dessert and drinks.

6)What is the difference between popping boba and tapioca boba?

Popping boba and tapioca boba are more like siblings. They should not consider as same. Although just like siblings, they are originated from same region, having an identity apart from one and other, but used for food and drink topping.

The phenomena of topping in making bubbling tea have taken markets of US by storm.

The tapioca boba is a traditional drink which is chewy and incorporated with sugar and honey to produce a sweetened taste. As it is produced from tapioca, so it has own sweetened taste when eaten without sweeteners.

The tapioca boba is often incorporated into milk, smoothies, bubble tea and frozen drinks.

Whereas, popping boba is prepared from seaweed extract having fruit juice inside upon beating it pops. Popping boba has gained a large popularity due to emergence of frozen yogurt. Due to variety of flavour, there is much room of available for customization and flavors.

1)Cooking

There is no cooking required for preparing the popping boba whereas, tapioca boba required cooking.

2)Texture

Popping Boba and Tapioca possesses two different textures. Popping boba quickly pops and capable to mix with other. Tapioca is chewy and soft have remnants of honey that will come by each sip.

3)Temperature

With temperature the flavor and texture of these drink keeps changes. It basically depends upon how long it has exposed to temperature or customer finishes their dessert or drink.

A popping boba is versatile as it does not cause any variation upon temperature as its wont dissolve when you provide warm circumstances.

Always keep in mind! It acts like a gelatin forming more liquid or soft texture over time. It efficiently works with iced or frozen products and giving more resistance without difficult to pop

Whereas tapioca is made from starch, and they respond well upon heating. Tapioca boba taste well when taken with iced milk tea but in smoothies or frozen products they become hard and not easy to chew.

4)Flavors

A popping boba is available in a wide range of flavors. For instance, from green apple to traditional flavors such as lychee. There are many choices as it does not offer just neutral flavors. More flavors more choices.

Tapioca boba have neutral flavors which can virtually pair with anything.

People who love to enjoy singular or focused flavor may eat boba for their smoothness and chewy fun.

7)What is popping boba machine?

A Popping Boba Machine

A popping boba machine helps in the production of popping boba. The filling material dribbled down via nozzle into the tank.

Inside the tank, you will find a reaction liquid, which initiate a chemical reaction and accumulate the covering material in a ball.

Popping boba machines are available in different sizes, with mode of actions such as, manual, semi-automatic or fully automatic popping boba machines.

The entire structure of popping boba machine is constructed by stainless steel that assures food safety.

A popping boba machine are incorporating three liquid systems.

- a) Juices: Juices are the main ingredients which includes water, glucose, sugars, jelly, syrups and much more.

- b) Sodium Alginate: You can call sodium alginate as a solidification liquid which include water and sodium alginate. It is also helpful in making of outer shell of popping boba which is quickly burst upon applying pressure.

- c) Protection Liquid: the protection liquid includes water and fructose. It provides protection to popping boba when in packing box.

8)What are the advantages of using popping boba machine?

a)- A popping boba machines are highly compact equipment that can perform manufacturing tasks efficiently.

b)- A popping boba machines are designed with a well-acknowledge structure. All parts of this machines are associated from German’s standard available with sandblasting surface coat (sandblast coat easily removes rust or corrosive particles).

c)- A syrup storage in popping boba machines is treated with high vacuum system. The vacuum treatment allows to facilitate a seamless flow of syrup with no air bubbles.

d)- A popping boba machines is designed in such a way which allows various adjustable sizes for preparing boba.

e)- A popping boba machine is comprised of three layers of convey systems which allows the flowing of popping boba. The prime advantages of these layers to make boba smooth and round.

f)- The entire structure of popping boba machine is fully welded and washable which encourages you to frequently clean and wash the machine.

g)- A popping boba machine is comprised of well-maintained sanitary liquid recycling system.

9)What are the basic types of popping boba machines?

1) A Small Semi-Automatic Popping Boba Machine

A semi-automatic popping boba machine is a pneumatic control unit and with a semi-automatic design.

A Small Semi-Automatic Popping Boba Machine

Entire working process is carried out with the help of process operator. A popping boba is prepared by adding raw material in hopper. Hopper pour a mixed raw material into a tank containing calcium chloride solution.

You can manually shake the popping boba and rinse it in clear water.

Lets'have a look.

a) Receiving of boba from jam hopper.

b)After receiving they are mixed with calcium chloride to start the reaction. During this time, you should constantly allow the shaking of popping boba.

This shaking will help to form a smooth, round, and seamless shape of boba.

c)After acquiring the desirable shape you can drip the popping boba in water to rinse them.

d)You can now examine the quality of popping boba. This is a simple process that yield high quality popping boba in lesser time.

The entire speed and pouring process is controlled automatically via feeding up the desirable protocol.

2)Fully Automatic Popping Machine

A fully automatic popping machine is an extensive and larger machine that works on a larger scale preferred by many foods and beverage industry.

a) Jacketed Cooker

They contain large jacket mainly used to cook the fruit juices. It practices scraping-edge stirrer to prevent dead ends. Both steam and electric heating are accessible. The capacity of these jacketed cookers is approximately 500ml. They work under a high vacuum pressure to reduce the probability of air bubble formation.

A jacketed cooker

b) Storage Tank

There is a storage tank integrated with a popping boba machine employed for storing liquid raw material temporarily. The storing capacity of the storage tank is approximately 500ml.

A storage tank of popping boba machine

c) A PLC Unit

A popping boba machine has a unified PLC unit that helps in computing the entire set up of popping boba manufacturing process.

As mentioned earlier this is considered as a heart of machine mandatory for a flexible and error free manufacturing process.

You can monitor the entire system with the help of PLC unit.

A PLC unit of popping boba machine

d) Hopper

It has a huge hopper which move up and down to drop the raw material into movable trays filled with calcium chloride solution.

A hopper of automatic popping boba machine

e) Circulation System

A popping boba machine have number of movable tray channels filled with solution. A filling of solution in trays are highly controllable circulatory process that moves across the hopper to receive the specific quantity of dripping popping boba.

A controllable circulation system

Soon after dripping of popping boba, they move horizontally and gently to transfer into a larger tray.

d) Auto-Filtration

An auto-filtration process takes place when running popping boba trays inverts the material over movable filtration unit.

10)What is difference between fully automatic and semi-automatic popping boba machine?

- Fully automatic popping boba machine is a large-scale unit while semi-automatic popping boba machine is a smaller machine in comparison to automatic one.

- Fully automatic popping boba machine has larger production capacity whereas the production capacity of semi-automatic is comparatively lower.

- Entire manufacturing process is carried out by computed functions using PLC system whereas, semi-automatic popping boba machine requires manual handling for manufacturing popping boba.

- Automatic popping boba machine is integrated with movable auto-filtration unit, whereas semi-automatic popping boba machine works with manual filtration.

- Automatic popping boba machine do not required operating experts. whereas semi-automatic popping boba machines requires full time operating specialist.

- Automatic popping boba machine is a high-budget machine whereas semi-automatic popping boba machine is low budget machine require for small manufacturing units.

11)What are the important components of popping boba machines?

A popping boba machine is a bigger set up which have many components involved in the manufacturing of popping boba.

For instance:

- a) Jam hopper

- b) SUS pan

- c) Flushing system

- d) Cleaning

- e) Feeder

- f) Operating Panel

12)What is the production line composition of popping boba machine?

The production line composition of popping boba is mentioned below:

a) Colloid mill

A colloid mill is utilized for intricately grinding of a variety of semi-fluid materials. Because of colloidal mill grinded particles can easily and evenly dissolved.

In this case, the sodium alginate is dissolved in rich quantity of water and improves the dissolution rate.

This is an adjustable process, the teeth of colloidal mill can be fixed and rotated according to requirements

A colloidal Unit

b) Cooking System

This unit is sub-categorized into three basic parts.

- Kettle: Vertical kettle with or without stirrer provides a temperature range of 0-1500 Available in both electrical and steam heating unit fruit juice and other liquid are cooked in this kettle. It has a capacity of 400L and uses a 1.5KW motor.

- Cooling tank. Processed liquids are temporarily stored in a cooling tank. The cooling tank is equipped with a 1.5KW motor and has a capacity of storing 500L. Its main purpose is to drop the temperature of the freshly cooked liquid.

- Transfer pump: Liquid is transferred to and fro with the help of a pump. The pump can transfer liquid at a flow rate of 55L/min over a pressure of 0.32MPa. Entirely made of steel body the pump is equipped with a 1.1KW that has a speed of 1420 revolutions/min.

c) Forming Unit

A forming unit is comprised of many integrated systems such as:

- Depositing system

- Material tray conveying system

- A sodium alginate circulation system

- Filtration system

- Cleaning

- system

c) Electrical Unit

An electrical unit is composed of PLC control system with touch screen device that simultaneously allow you to feed the data and approaches the operation of process extensively. An electrical unit is specially designed for efficient industrial work with great automation and computing solution. Moreover, it is easy for manufacturer to trace the error.

13)What material is utilized in the making of popping boba machines?

The popping boba machine is highly durable device which is made up of stainless steel. All parts of this machine are easily washable to maintain the sanitization and cleaning process. So, you must confidently apply all principal of sanitation without worrying for the corrosion.

14)Does popping boba machine conform with quality standards?

The international quality standards entail all relevant requirement, specifications, products services, and their characteristic of popping boba machines should consistently meets to assure their quality is matching with expected purpose.to meet all sets of international bodies which assigned for food equipment's.

Similarly, when it comes to food manufacturing machine, it is mandatory

Given below are the following product certification that popping boba machine comply with.

1.CE Mark of Quality Standards

CE mark is mandatory to ensure the manufacturing machine meets all essential parameter of health and safety needed for machine. A CE mark also indicates all the parts of popping boba machine are well-documented.

2.Food and Drug Administration Standards

An FDA certification regulates the quality standard of every pharmaceutical/food industry which ensuring the pharmaceutical/food quality is complies with FDA objectives and they’re safe and effective.

3.cGMP Standards

cGMP is the main regulatory standard mandatory for every pharmaceutical and food industry which ensures a safe quality practice of Current Good Manufacturing Practice complies quality standard for human consumption.

4.ISO Certifications

An ISO certification verifies that following management or manufacturing process has all mandatory requirement of quality assurance and standardization.

Each certification has independent standards and benchmarks that is classified numerically.

15)How to maintain a popping boba machine?

A syrup dispensing machine requires a deep cleaning for every 2-3 weeks while general cleaning after manufacturing process. This involved the rinsing out of entire important parts syrup dispensing machine with hot water to avoid microbial contamination. Furthermore, every time you need to ensure that machine does not have any extra remnants of previous manufacturing ingredient.

All movable parts of popping boba machine requires an annual treatment with lubricants. This is helpful in preventing corrosion, wear, and tear.

After each manufacturing session, press ‘Continue’ button to rinsing entire parts of machine with a hot warm and drainage.

After cleaning dryness is mandatory which is accompanied by using an absorbent paper or dry cloth to clean the left over.

Popping Boba Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586