High Quality Drier Machine

Stable and Simple Operation

Convenient Regulation

Good Fluidity and Solubility

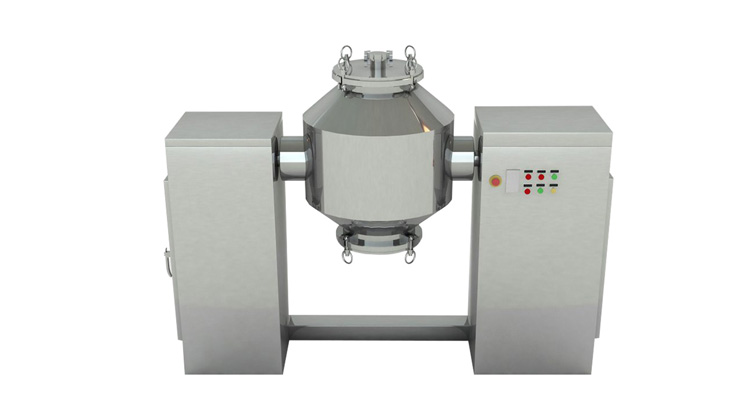

AIPAK Drier Machine

AIPAK Drier Machines are mainly used for drying and mixing of material in pharmaceutical chemical and foodstuff trades etc. Have a good drying and mixing effect on heat sensitive, easy oxidizing, and non-crystalline damage material, solvent recovering material, and strong irritating and toxic material.

All AIPAK drier machines are simple in operation and convenient for cleaning, they are ideal equipment that conforms with the requirements of GMP. The drying speed is fast and the temperature is uniform.

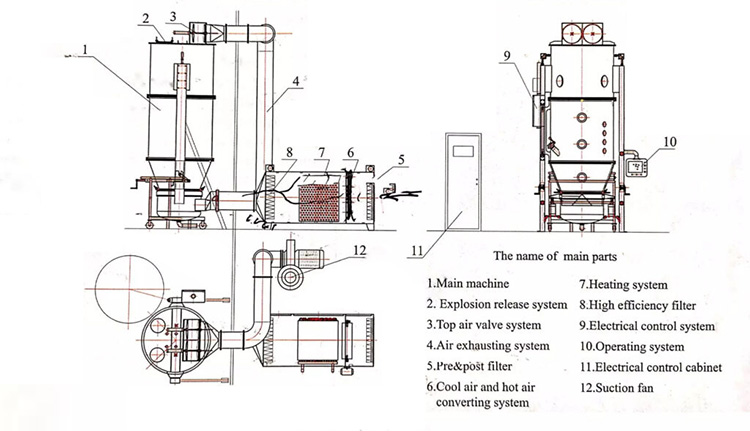

AIPAK Drier Machine Working Principle

The Buyer's Guide

Pharmaceutical Dryer:the Ultimate FAQ Guide in 2024

To produce free-flowing powders for formulation, packaging, storage and transport,you may need a complete drying system.

Now there are many drying technologies available, but do you know the sensitive nature of active pharmaceutical ingredients requires gentle drying?

Today,I will use this guide to give you more information about pharmaceutical dryers to help you find the best drying solution for yourself.

It is important for you to understand the operational needs and capacity requirements before selecting a pharmaceutical dryer.

Let’s go to the subject directly.

1. How many Drying Methods are there in the Pharmaceutical industry?

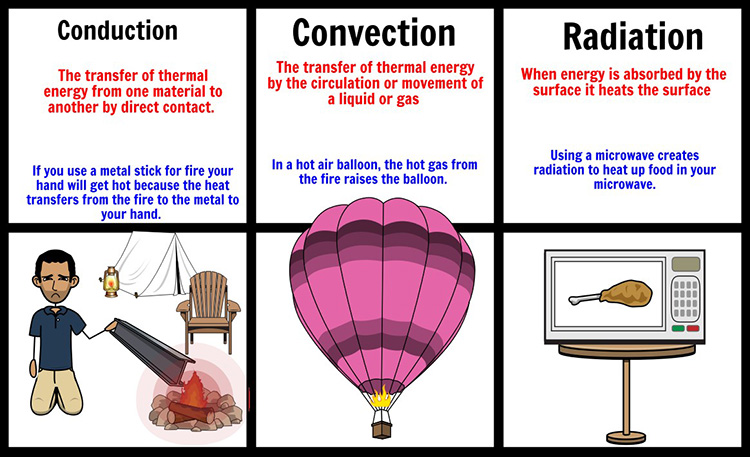

These are the primary sort of heat transfer drying strategies;

1. Convection

At the point when a liquid, for example, air or fluid, is warmed and afterward moves from the source, it conveys the warm energy along. This sort of warmth move is called convection.

2. Conduction

Conduction is how energy is moved (through warming by contact) from a hot body to a cooler one (or from the hot piece of an item to a cooler part).

3. Radiation

Radiation is the emanation or transformation of energy as layers or particles through space or a material medium. This incorporates electromagnetic radiation, for example, radio waves, in the form of microwaves, infrared, obvious light, bright, x-beams, and gamma radiation.

4. Dielectric

Dielectric, is done by insulating a material which is an exceptionally helpless channel of electric flow. At the point when dielectrics are set in an electric field, essentially no flow streams in them because, in contrast to metals, they have no approximately bound, or free, electrons that may float through the material. All things being equal, electric polarization happens.

5. Combined Modes

Heat movement is constantly joined by three methods of warmth movement viz. conduction, convection, and warm radiation.

Conduction, Convection vs Radiation-Photo Credit: Storyboard

2. What is a Pharmaceutical Dryer?

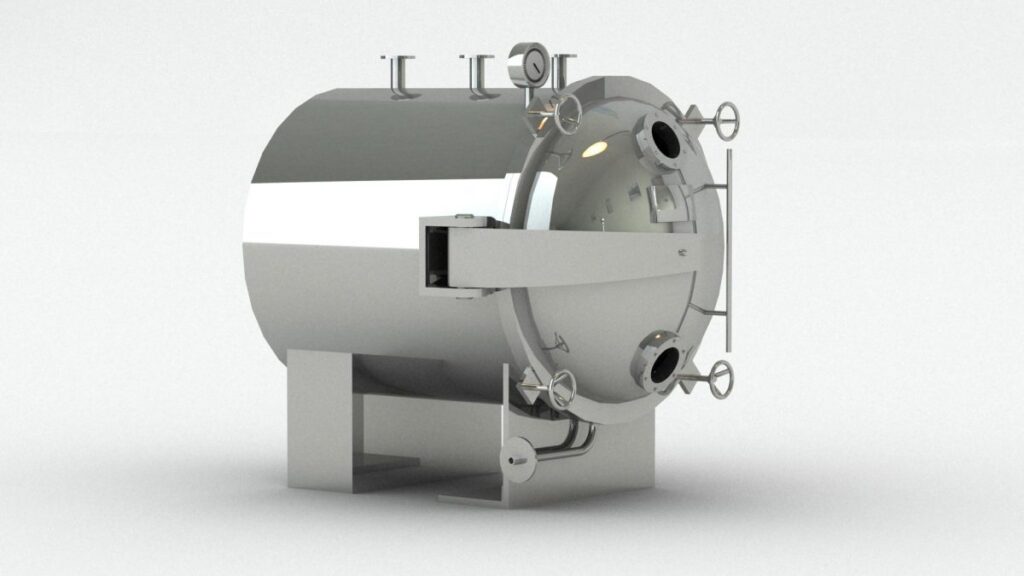

AIPAK Pharmaceutical Dryer

Dryers are utilized in lots of businesses, for example, food preparation, drug, paper, contamination control, and farming areas. Various items should be dried in totally various organizations, for example, researching chemicals and clinical concerns, printing paper, and in the operating of the packaging.

To finish fluids or dampness from mass solids dryers are utilized. It is also used to dry powders, parts, consistent sheets or different fluids by evaporation. There are two types of the dryer: Indirect and direct. Indirect dryers conductive heat an item by contact with a warmed divider. Direct dryers convective (transforming the heat by using the fluid) heat an item by direct contact with warmed air, gas, or a flammable gas item.

3. What is the Purpose of Drying Materials in the Pharmaceutical industry using Pharmaceutical Dryers?

Is it basic to dry powder and granules or would it be advisable for you to utilize them, even when they are as yet wet?

Granules and powder are generally not fit to be utilized in various applications when in their processing form. Powders can't stream easily in their wet form.

In that type of case, it is a must to dry granules in a quite accurate way only possible via a pharmaceutical dryer. In drug, food, chemical, and other significant businesses, for instance, granulation infers adding up to various fundamental powder materials to shape greater granules. These granules will have a more conspicuous thickness, good flow ability, and consistency.

In drug innovation, drying is done for at least one of these reasons:

- To maintain wetness which results in rust and abatement of the item or medication dependability.

- To keep or improve the great properties of a material, for example, Flow ability.

- To lessen the expense of commuting of huge volume of materials ( fluids).

- Bringing the material to these properties where it is simple or more appropriate for dealing with.

- Saving the material for the longtime

- The last phase is Evaporation, Filtration, and Crystallization.

4. What are the Benefits of Pharmaceutical Dryers?

Fluidized Bed Dryer

It requires quite a short duration to finish drying (20-40 mins)

The time required for its handling is also less.

The drying limit goes from 5 to 200 kg for every hour.

The drying holders can be carried to another place, are simple to deal with, and have low work costs.

The warm proficiency is higher than the tray dryer.

It is likewise utilized for blending and its blending effectiveness is high.

Higher drying temperatures can be utilized that are impractical in dryer types like trays.

It encourages the dryness of thermo-labile items as the contact time for the dryness is less.

AIPAK Fluid Bed Dryer

Advantages of the Vacuum dryers

AIPAK Vacuum dryers

Vacuum dryers are proficient.

Materials can be dried in holders or walled-in areas.

The normal drying temperature is a lot lower than standard dryers.

Drying activity turns out to be quicker.

It dries huge dampness when contrasted with ordinary dryers.

The nature of dries material is superior to that of the typical dryers.

Advantages of Spray Dryer

AIPAK Spray Dryer

A shower dryer is utilized for drying drugs like blood items, proteins, antibodies, and so on.

It is utilized in the creation of excipients and co-prepared excipients with more flow capacity, similarity, and tablet-breaking crystals.

To improve drug compressibility and lessen coating tendency in gems.

It is similarly utilized in the mixture of capsules containing drug substances and a biodegradable polymer to get a controlled medication discharge plan.

It is utilized in improving dissolvability and disintegration paces of inadequate solvent medications by a mixture of drug buildings or through the improvement of bioaccessibility.

Tray Dryer

A number of trays increase the territory for drying through the dissemination of hot air.

Valuable for wet granules dryness, powders, unrefined medications, and so forth.

Rotary Dryer

Rotational dryers are less delicate to molecule size.

It can acknowledge the most noteworthy vent gasses of a dryer.

Low support cost; hence affordable.

It has a better limit than a dryer.

Drum Dryers

Drum dryer takes gooey fluids, slurries, suspensions, and glues as info material to be dried and delivers the yield as powders or pieces.

Drum dryers discover applications significantly in Food and Milk, Cheese industry, and Chemical and Pharmaceutical Industries for dryness of different sorts of pasts and slurries by using pharmaceutical dryers.

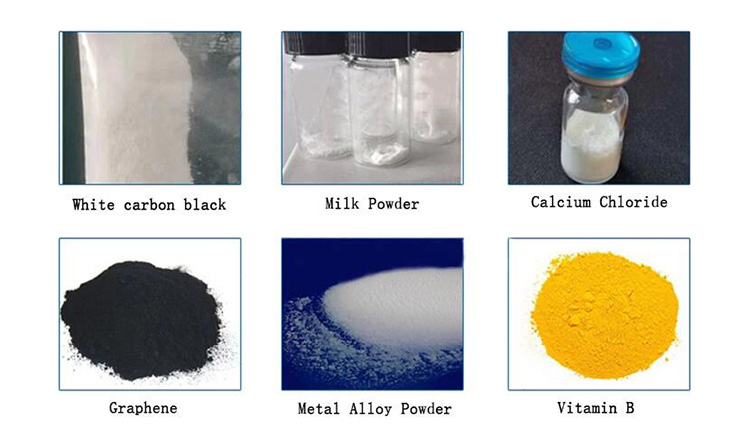

Drum Dryers in Chemical and Pharmaceutical Industries:

Just like many other dryer types, a pharmaceutical dryer drum has some benefits.

Calcium Carbonate

Suspensions Of Zinc Oxide

Sodium Benzoate

Brewer'S Yeast

VIDEO FOR DRYERS USED IN THE PHARMACEUTICAL INDUSTRY:

5. Is there any disadvantages of Pharmaceutical Dryers?

Fluid Bed Dryer Disadvantages

These are a few of the disadvantages of the Fluid bed dryer:

The fluidization cycle may cause issues during turbulence. To stay safe from this kind of phenomenon, utilize the suggested sticking agent.

Handling of the gas framework is required in this system.

Electrostatic charges may be created during the drying cycle. A motivation behind why you should control the fluidized drying framework.

A high-pressure drop may prompt high energy utilization.

Not reasonable for poisonous solids and tacky material.

Spray or Splash dryer disadvantages

Splash/ Spray dryers are heavy and costly to introduce.

It is hard to clean after utilizing the dryer.

Spray dryers are less warm effective a tons of heat is wasted during activity.

Strong items can't be dried utilizing spray dryers.

Item quality reduction or fire danger may result from item deposition in the chamber of drying.

Vacuum dryers disadvantages

Vacuum Drying measure is a batching type drying measure It has low effectiveness.

Vacuum dryers are costly.

Vacuum dryers require talented workers to work with.

Maintenance costs are high.

6. What is a Pharmaceutical Dryer used for?

Dryers are used in a variety of industries,

- Food processing

- Pharmaceutical, paper

- Pollution control

- Agricultural sectors

- Chemicals for research and medical concerns

Eliminate fluids or dampness from mass solids, powders, parts, consistent sheets, or different fluids by dissipation or sublimation.

Food Drying Process-Photo Credit: bakeryandsnacks

7. Which Industries use Fluid Bed Dryers?

This fluid bed dryer can be used in many businesses for extracting humidity from the granules by using this equipment.

Aside from that, after the drying cycle, it will likewise ensure that it cools to the ideal conditions.

Here are the primary businesses where you will require the administration of a liquid or fluid bed dryer.

Fluid Bed Dryer Cut Cross Contamination-Photo Credit: newhopenetwork

Drug Business

You will utilize the FBD or fluid bed dryer in the drug business to play out various roles.

A fluid bed dryer is going to help with disposing of extra dampness in various tablets in the drug business.

It leaves the liquid bed dryer in a dry and strong form for longer conservation/preservation periods just as better transportation.

Aside from that, you can likewise utilize the machine during the time spent blending and granulation of various items.

Furthermore, Other than just drying the items, you can utilize the FBD or fluid bed dryer to cover the materials productively.

Chemical Business

The Fluid bed dryer can offer you services in playing out various roles in the business of chemicals.

It is significant during the cycle for drying various kinds of synthetic particles in the business of chemicals.

You can likewise utilize it for shower granulation for the change of fluids into molds without any dust.

Aside from that, you can likewise utilize it in the crystallization of fluid melts in this specific industry.

Furthermore, it is a significant machine for the reason of re-drying outward wet particles, particularly after mechanical drying out.

Chemical Business

Food Processing Business

You will utilize the fluid bed dryer or FBD in a few roles in the food handling industry.

All things keep in mind, to expand the period of usability of the food you will dry it utilizing the Fluid bed dryer.

Aside from that, you can utilize it for different purposes during the time spent setting up the food.

A portion of the fundamental food process measures that you can perform utilizing a Fluid bed dryer are like:

- Warming of various sorts of food

- Drying of various sorts of food items

- Cooking of various elements or particles for making food

- Disinfection with an end goal of executing microbe from food

- Cooling of various elements for making food

Also, you can utilize the liquid bed dryer in the drying cycle of various sorts of food.

It is liable for making the items that are answerable for shading food.

Fertilizer Business

You will utilize the fluid bed dryer during the fertilizing cycle with a huge scope of inorganic composts.

A portion of the manures that you can have utilizing the fluid bed dryer include:

- Magnesium manures

- Potash inorganic manures

- Nitrate and Calcium manures among different sorts.

The process of production of fertilizer utilizing the FBD or fluid bed dryer is like that of the pharmaceutical industry.

Dairy Industry

You will utilize the dryer machine in handling and drying milk to frame moment milk powder.

It has various parts that it used during the creation of the milk powder industry especially in the instant milk industry.

There are various ventures where you could utilize the administrations of the fluid bed dryer machine.

Dairy Industry -Photo Credit: prediktorinstrument

This includes the colors and the metallurgical enterprises.

8. How many types of Pharmaceutical Dryer are there?

Pharmaceutical Dryer Types

1. Dryers for damp solids

a.Tray Dryer

b.FBD (Fluidized Bed Dryer)

c.Tunnel Dryer

d.Rotary Dryer

e.Vacuum Dryer

2. Dryers for slurries or solutions

a.Drum Dryer

b.Spray Dryer

3. Specialized drying Method

a.Freeze drying

Tray Dryer

The tray dryer has many numbers of trays loaded up with trays and warmers are set on the dryer.

Tray dryers are composed of hard steel and warmed air is pass through all through the trays through fans.

A number of plates are available in the dryer; this is the place where items can be placed to be dried and put over enormous territory.

It is an extremely powerful and mainstream technique for drying.

AIPAK Tray Dryer

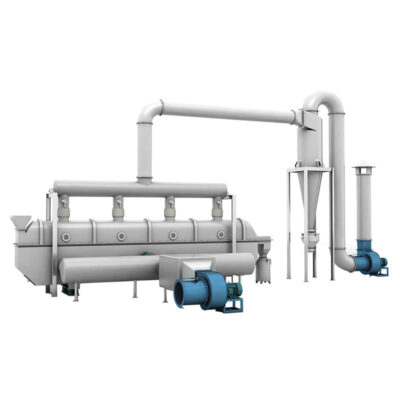

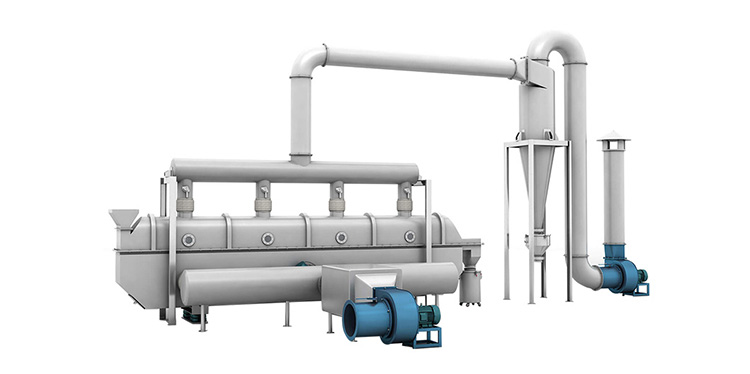

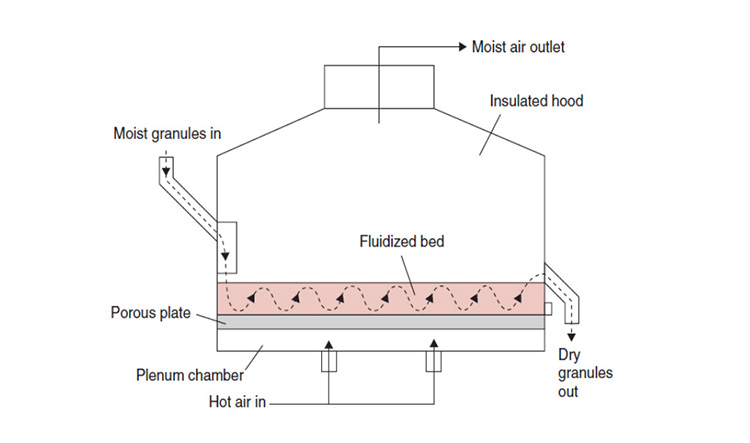

FBD (Fluidized Bed Dryer)

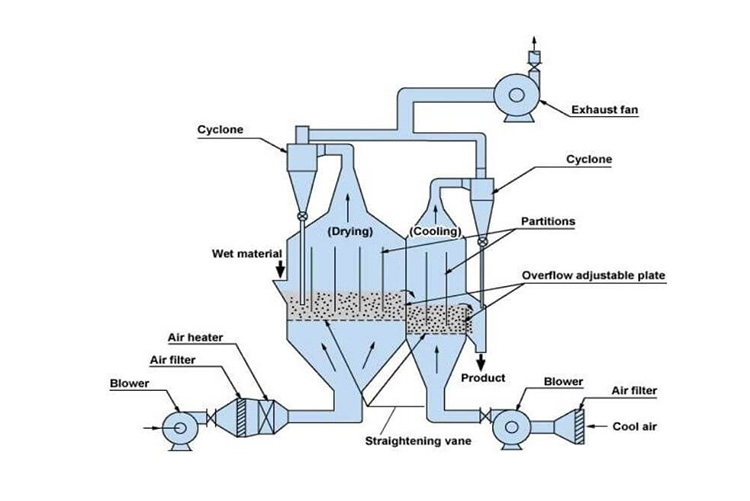

The fluidized bed dryer comprises a removable bowl at the lower part of the dryer for unloading and loading of the wet granules or any other type of material to be dried.

At high pressure, the hot air is circulated through the lower part of the bowl which suspends granules noticeable all around (fluidized state) and dries them.

The temperature of air that is entering for drying and leaving air is checked and filter bags are set over the drying bowl for the recuperation of the fines.

It is composed of hard steel since it directly comes in contact with the item.

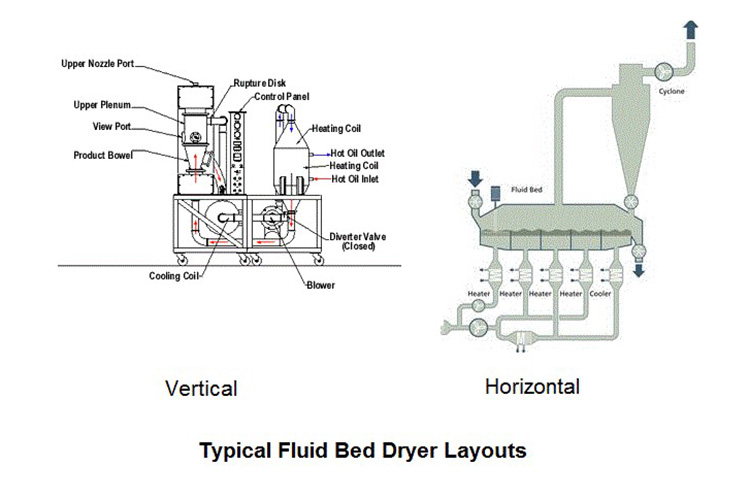

There are either horizontal fluidised bed dryers or vertical fluidised bed dryers.

Tunnel Dryer

The Tunnel is a type of dryer where a holder (tray) loaded up with the material is put on a trolley or the material is stacked on that trolley, and that trolley later on is pushed in from the tunnel chamber entrance. When the material is moved through that chamber in the result of that it dries up.

AIPAK Tunnel Dryer

Different wind current techniques are accessible for the tunnel dryer, such as vertical wind current, horizontal wind stream, and substituting wind current, chosen by elements, for example, the material properties and drying conditions.

Rotational Dryer

The rotating dryer otherwise called a tumbling dryer is a gear utilized to limit the dampness substance of feed materials by getting in contact directly with a warmed gas.

It comprises a slanted long drum or tube-shaped shell regularly fitted with inside lifters or flight; turned gradually upon heading through which the material to be dried stream with a falling activity in simultaneous (for heat-delicate materials) or counter-current stream with the warming gases and air.

The development of items is because of the joint impact of the tendency of the shell to the event and the inside mechanical turnover or tumbling activity.

The idea of the insertion decides the headings of the gas course through the chamber and it is comparative with the strong. This drying gear can likewise perform cluster or unstoppable preparing of the wet feed.

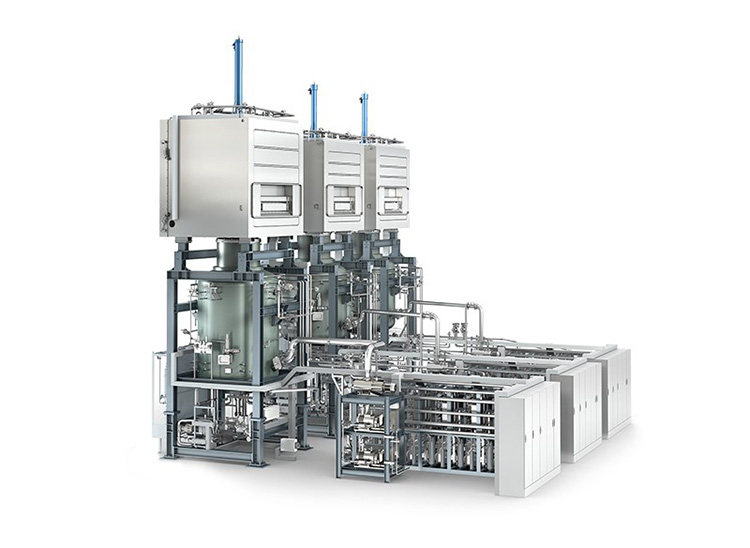

Vacuum drying

There are numerous modern applications where huge volumes of granules or powder should be dried beforehand and they could be bundled or blended in with different fixings.

There are likewise numerous applications in which responsive fixings should be blended in a controlled and weight-tight climate. It does depend upon the application, the ideal powder dryer must have the option to play out a full scope of blending, drying, and responding capacities.

Vacuum dryers, blenders, and reactor frameworks are appropriate for even the most sensitive production method.

Drum dryer

Drum dryers are amazingly reasonable for drying of gooey materials, concentrated arrangements, slurries, or glues by turning steam-warmed drums. Drum dryers are additionally called roller dryers because of their developments.

Typically slurry or sticky material in nature is dried with this dryer, and is scattered with the help of a machine on the two counter-turning drums as a slender sheet, the sheet is later on quickly dried conductively through high warmth that is created inside the drum.

It depends on the items to be dried, we produce different sorts of drum dryers for you, for example, for extremely wet or past containing high dampness level high temperature is accomplished inside the drum, anyway on the opposite side of the materials in profoundly heat delicate low-temperature hot air are moved inside the drums.

Spray Drying

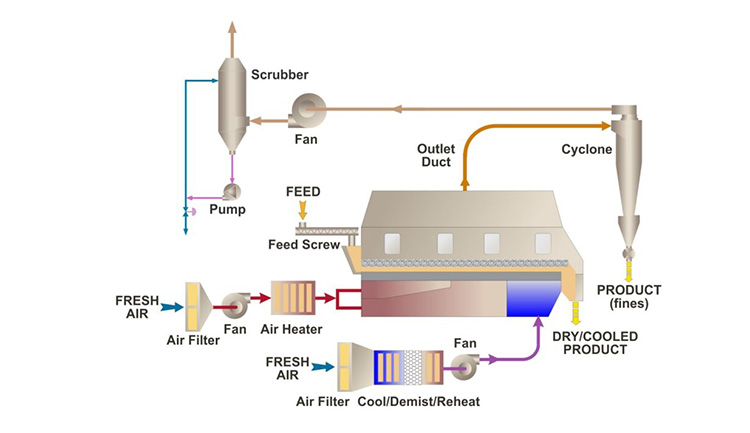

Splash or spray drying is a process of nonstop unit activity that utilizes fluid atomization to deliver beads that are dried to singular particles when moved in a hot vaporous drying medium.

A splash or spray dryer comprises a pump for feeding, an atomizer, an air warmer, an air allocator, a drying chamber, and frameworks for exhaust air cleaning and powder recuperation/separator.

The three phases that happen in a splash dryer before drying is refined include:

- Atomization

- Shower air blending and dampness vanishing.

- Dry item detachment from the left air.

The idea of the result acquired in the wake of drying in a shower dryer relies upon;

- The plan and activity of the splash dryer.

- The physio synthetic properties of the feed.

Drug Freeze Drying

Freeze-drying drugs utilize a cycle called lyophilization to bring down the temperature of the item to under-freezing, and afterward, a high-pressure vacuum is applied to remove the water as a fume.

The fume gathers on a condenser, turns around to ice, and is taken out. At last, a continuous temperature rise removes all leftover 'bound' dampness from the item. This cycle holds the actual structure and jelly the material for capacity or transport.

Drug Freeze Drying-Photo Credit: processingmagzine

9. What are the main differences between various Pharmaceutical Dryers?

| Fluid Bed Dryer | Rotary | |

| Energy Consumption | It does need more energy | It does require less energy |

| Thermal Efficiency | It is more thermal efficient | It is comparatively less efficient |

| Capital Cost | Almost the same | |

| Spatial Footprint | Smaller footprint | Larger footprint |

| Maintenance | Almost the same | |

| Feed Stock Variance | Very sensitive | Less sensitive |

| Industry | Pharmaceutical Industry

Chemical Industry Food Industry |

Raw Material

Minerals Fertilizers |

| Material Consideration | Less Attrition | Some Attrition |

| Operational Consideration | Highly consistent

Operational Consideration |

Easily automatic

Required less skills |

10. What is a Fluid Bed Dryer?

The probability is very high that a normal person might have not heard about that machine.

This is always considered the most vital and role-playing machine in bulk processing.

So what's going on here?

AIPAK Fluid Bed Dryer

It is a machine used in the granulation cycle to dry a particular material in an offer to achieve attractive dampness content in the formulation of the tablet.

Principally, it is generally utilized in the drug area to help in decreasing the degree of dampness content in the powder or drug grains.

This machine is likewise also used in the dyes, dairy, chemicals, food preparation, and other processing industries.

It is accessible in these ventures for a similarly significant stretch attributable to the job that it plays specifically applications.

Regardless, the liquid bed dryers which were regular in the past times have gone through an extensive change.

Coordinating innovative advancement in a few parts of this machine guarantees that the latest versions of these machines offer better quality and high proficiency.

It gives high drying capability given that the granules or particles get totally dry is the most considerable factor about this latest version of the machine.

It consequently shows that you'll wind up accomplishing the best outcomes which is an amazing thing to use as it helps in upgrading production in specific enterprises.

Pharmaceutical fluid bed dryers for the most part deals with the premise of fluidization of the feed materials guideline.

Likewise, keep in mind that this machine fundamentally helps in giving quality items that satisfy the modern guidelines.

What's more, that is the explanation you have to guarantee that you get one that suits every one of your necessities if getting productivity is anything to pass by.

11. What are the main features of Fluid Bed Dryer?

Fastness

Drying times for the fluid bed dryer can go from a few seconds to minutes.

Efficiency and Effectiveness

The Fluid bed dryer offers a better speed of heat transfer in result which makes sure faster and more homogeneous drying than vacuum drying and many other types.

Versatility

Most granular and powder materials can be the most suitable method.

Reproducible Results

Reproducible results are possible through the precise control of the machine.

Ease of Usage

Control is pretty easy as well as manageable and so does the setting of the machine is easy to handle as well.

TEMPERATURE CONTROL

Air is warmed by a 2kW electric warmer and is possible to maintain to any temperature more than 200ºC. The temperature is constrained by a shut circle framework that can accomplish steadiness to inside 1ºC.

Coordinated CYCLE

An underlying advanced clock empowers the drying time to be pre-set and the drying activity to be done unattended. Toward the finish of the process duration, an alert sounds and the unit turns off naturally.

Wind stream

The wind current rate and fluidization speed are vastly factors from 0.4 to 2.4m³/min volume (0.9 to 5 m/sec speed). Ideal levels can be set by noticing the example conduct inside the glass tubs.

Filter BAG MATERIAL

Channel sacks are normally nylon or terylene with different materials accessible to suit more forceful conditions, for example, supported high-temperature drying.

12.What are the Components of Fluid Bed Dryers?

The parts of the liquid or fluid bed dryer are mostly these;

To make sure that the fluid bed dryer functions well, these components of the machine run in a linkage with the other available components in the bid.

You should note that some liquid or fluid bed dryers have fewer parts and on the other hand side, some have more.

This will eventually rely upon the sort and plan of fluid bed dryer you decide to utilize.

Below explained are some of the main components of this machine you need to know about.

Item Container

The item compartment is essential for the fluid bed dryer Powder and Granules must be out in which you want to be dried.

For expanding the durability stainless steel is used in the FBD container.

The best item container or compartment of a liquid bed dryer will accept a cone-like shape for better transferring of material.

Aside from that, the state of the compartment or container will assist better fluidization cycle of the items.

Control Panel

This is the piece of the machine where you will decide all the clear boundaries and activities of the machine.

You will have the option to get and impart all the signs of the drying cycle likewise.

It gives you authority over a scope of angles, for example, to:

- Screen drying boundaries

- Process controlling boundaries

- Essentially, this will guarantee the precision and productivity of the whole cycle.

Fumes Blower

This is the piece of the liquid or bed dryer where the polluted air leaves the FBD machine.

It will permit the liquid bed dryer to infuse in clean air for drying purposes.

You will likewise take in the outside air as it disposes of the polluted air away from the working station.

Air Preparation Unit

The framework is initially answerable for making the nature of air that enters the liquid bed dryer well.

It improves the stream pace of the air bringing about a good execution of the air framework.

It controls all the limits of the wind stream in the liquid bed dryer.

Splashing or Spraying Nozzle

The showering spout is the part that will break the forward motion of the liquid for drying the granules.

It will upgrade the forward motion of the air inside the liquid bed dry in a specific pattern.

You will pick the kind of spout for your machine depending upon the sort of use of the fluid bed dryer or in short form FBD.

They are accessible in various plans hence deciding the general result of the drying cycle.

It is a basic part that will aid the general handling of materials in a liquid/ fluid bed dryer or FBD.

Air Divider

Typically, the air dispersion plate is on the lowest part of the item container.

Among outer and inward parcels, It will aid the correct dispersion of the fluidization.

You will likewise discover the air division plate in various varieties and sizes depending on the machine plan.

Delivery System

You can likewise differentiate it from the fluid-moving arrangement of the consistent fluid bed dryer.

It guarantees the flow of the solution through the atomizer without facing any unseen obstacles.

It comes with a tank of fluid, a pump, and a magnetic filter.

Warming System

Here in this part of the machine liquid or air is warm for the reason to achieve the right temperature in that part of the fluid be dryer.

The liquid will move from the warming framework right to the material tank for proper drying of the particles.

Residue Collector

You will rely upon the residue collector of the machine to gather tidily and lessen wastage and outflows.

It will assist in the removal of residue from the air resulting in improving indoor quality of the air.

It additionally assists in the decrease of outside outflows along these lines lessening contamination of the air.

In the next coming part, we will talk about working with a fluid bed dryer.

13. How does Fluid Bed Dryer work?

Fluid Bed Dryer working

Remember I promised you earlier about discussing the working principle of the fluid bed dryer machine?

When you talk about a detail impossible to finish without writing about the working of that particular machine.

Here is a well-explained part about working with the dryer.

That is part which you want to know about every bit of the detail and want to be aware of every aspect too.

Here, when you say working principle it means the way machines work and function during the process.

It makes sure that pharmaceutical particles, granules, and grains dry up during this process.

Working of Fluid Bed Dryer-Photo Credit: GEA

But first, I want you to watch this video:

Also, keep in mind that this working principle is especially for drying applications.

To be very clear here, bear in mind this type of working principle is for drying only.

Another thing to keep in mind is that it would be more than well to know that working on the machine can also change from one application to the other.

Here in this detail, some of the words will be machine-related and technical to understand.

Lastly, I would make sure I use the easiest possible words to make sure that you understand every detail of it.

Let’s get into the further details now;

The flow of the material is used as the base of the working of a fluid bed dryer.

While this process is being run, hot air or gas is run through the compact particles of the bed.

As the particles have very small spaces in between, the gas passes through them in an upward direction.

Now, speed expands, which thus powers the particles to delay upward to affect the granules at a phase that gets comparable to the power of attraction that is underneath.

It at that point prompts fluidization of the bed which makes it workable for these granules to suspend in the liquid.

The liquid or fluid bed dryer comprises an electric engine which controls the fan inside it.

So as a result of all this the starting point of the cycle begins, the air is sucked from the surrounding by the usage of that fan.

This air gets very hot given that it crosses over through a warming framework in the dryer.

It is this warm drying air that is compelled to flow through the bed which consists of particles put down on a constantly vibrating steel bed.

Continuous fluid bed dryer

Presently, the hot drying air enters the bed with consistent speed and temperature that makes it workable for fluidization of the bed.

After that every particle in the granules comes in contact with hot drying air passing through due to direct contact.

The consistent vibration of the permeable steel bed triggers the bed to convey the particles forward at a moderate movement along the dryer.

The hot air at that point sucks all the dampness present in pulverizes.

From that point onward, it gets into the residue recovery framework where its reusing happens.

In a perfect world, what occurs here is that as the forward motion increments inside the steel bed, the more it broadens and grains start a shaking movement. So the consistent contact makes it workable for the material to get dry.

From that point forward, the air that leaves this machine goes through the channel to take into consideration the assortment of fine granular materials.

It is imagined to control the temperature and velocity of the hot air as it passes on the bed.

What this infers is that this machine can too dry the very wet materials successfully.

The following thing that happens is taking care of the dry material in the cooling zone the cool air brings down the temperature of the material to the particular required condition.

One principal part of the liquid bed dryer worth underlining increasingly more is that it has a high pace of drying items, which likewise takes the most brief time conceivable.

Hence thus, you can accomplish proficient drying of powder or items with the guidance of a liquid bed dryer machine.

In reality, the working is not more than that.

It is not something you will not understand as you attempt to envision. You will note that after using that machine quite a few times.

Ideally, the working process of FBD is easily understandable.

14. What are the differences between various Pharmaceutical Dryer working principles?

Fluid bed dryer vs Pharmaceutical Oven Working

| Fluid Bed Dryer | Pharmaceutical Oven Working |

| The fluidized bed dryer not only eliminates extra dampness, but it also performs granulation of the particles being dried.

In addition, liquid bed dryers perform different activities, for example, covering the particles. In any case, fluidized bed dryers have a source where the air containing the dampness it takes from the particles passes. Furthermore, the FBD or fluid bed dryer typically suspends the particles noticeable all around as it dries up the particles and granules. This is just because it streams at an exceptionally fast speed which prompts the suspension of the particles. |

The other way around, you can't utilize a hot air circulation drug oven during the cycle granulation of particles.

Hot air circulation drug oven or broiler, then again, holds the air inside the oven for additional drying. The hot air flow drug oven circles the air at low speed along these lines with no pause of particles. |

| You will utilize both a fluidized bed dryer and the hot air course drug stove to dry various things.

Aside from that, in the two machines, there is a ceaseless forward motion of hot air over the particles you expect to dry. |

|

Freeze Drying vs Fluidized Bed Drying Working

| Fluidized Bed Drying | Freeze Drying |

| The fluidized bed drying standard includes the use of warmth in the drying cycle.

FBD rule includes the going of hot air over the particles or granules in an offer to dispose of extra dampness. It suspends the particles or granules noticeable all around since the hot air moves at a very high speed. It goes through within the particles. It takes with it the overabundance of dampness from the particles in this manner drying the particles. |

Freeze drying is a low-temperature drying-out cycle including the freezing of various items.

Aside from freezing, it diminishes the weight and afterward eliminates the solidified extra dampness through the sublimation cycle. |

15.What are the Types of Fluid Bed Dryers?

There are two primary kinds of fluid bed dryers for drug preparation.

These two sorts of liquid or fluid bed dryers

- Modified fluid bed dryers

- Conventional fluid bed dryers

Though the two of them are intended to play out a similar role, there are a few contrasts regarding their determinations.

You will take a view at the comparison between the two and will even guide you on the best way to pick the kind of FBD( fluid bed dryer).

Modified or Altered Fluid Bed Dryer

Another sort of fluid bed dryer that you should know about is an altered or modified fluid bed dryer.

In case, you're looking for the extra function on your fluid bed dryer this is where you can have it because conventional fluid dryers do not offer that many of the functions.

What would it be a good idea for you to do?

Here are some of the vital factors highlighted you ought to think about purchasing the best altered or modified bed dryer.

This sort of fluid bed dryer is planned and produced to meet your particular needs.

The majority of the alterations are custom-made to improve the nature of the drug item while at the same time improving the proficiency of the liquid bed dryer.

Altered fluid bed dryers have some particular features that are changed to address the difficulties of the traditional liquid bed dryer.

They have various progressed mechanical components that are intended to disregard a large portion of these difficulties.

From the models, you can undoubtedly tell that some changed liquid bed dryers are intended to play out a specific work in the drug granulation measure.

With the demanded feature, you will get the best outcomes from these liquid bed dryers.

Others are just improved adaptations of the customary liquid dryers.

Altered Fluid Bed Dryer

Conventional Fluid Bed Dryer

The way it is a conventional liquid dryer implies that it has very near-to-no alterations and innovative advances.

It is simply intended to play out its essential role in the drug plant, which is to decrease the dampness content in the granules.

This kind of FBD is successful in playing out the general drying role. In any case, it isn't proper about explicit roles that you may require from a fluid bed dryer.

Even though the conventional liquid bed dryer has various features, one of the most extraordinary is its multi-tasking ability.

A common traditional dryer can do drying, cooling, and sanitization assignments prior. Indeed, every one of these undertakings will be performed by a solitary unit.

You can likewise be certain of the nature of the item that you will get from a conventional dryer. It won't have any sort of distortion.

Another critical part of the traditional liquid bed dryer is its effectiveness in activity.

It is basic and simple to work. You won't need to manage distinctive modern pieces of the dryer.

Because of their ease, this type of FBDs are not hard to maintain. They likewise will in general pull in low support cost.

16. Which quality standards should Pharmaceutical Dryers meet with?

Here are the main quality standards and certifications of the fluid bed dryer machine that need to be considered.

Current Good Manufacturing Practices (cGMP)

Great assembling rehearsals are the practices needed to adjust to the rules suggested by offices that control the approval and permitting of the assembling and offering of food and drinks, beautifiers, pharmaceutical items, dietary enhancements, and clinical gadgets.

Worldwide Standards Organization (ISO) Quality Certification

ISO is the International Organization for Standardization. Its motivation is to encourage and uphold public and global exchange and business by creating principles for that.

Food and Drug Administration Quality Certifications

FDA endorsement is needed for shading added substances utilized in food, medications, beautifying agents, and some clinical gadgets. Certain high-hazard tones additionally require FDA shading bunch confirmation of each cluster. Shading-added substances may just be utilized in consistency with their endorsed uses, details, and limitations.

CE quality affirmation for the electrical machines

CE stamping is a managerial denoting that shows similarity with safety, security, and national insurance guidelines for items sold inside the European Economic Area. The CE stamping is likewise found on items sold external to the EEA that have been made to EEA principles.

17. What is the environmental requirement when Pharmaceutical Dryer drying materials?

The accompanying ecological issues should be considered as a component of a complete appraisal and the board program that tends to extend explicit dangers and possible effects. Potential natural issues related to drugs and biotechnology-producing ventures incorporate these:

- Emission of Air

- Wastage of the Water

- Strong and Risky Squanders

- Risky Materials

- Dangers to Biodiversity

- Bioethics

18. Is Pharmaceutical Dryers Safe?

Every machine comes with a special type of safety features. Just contrary to many other fluid bed dryers comes amazing safety features.

You won't get wounds while using liquid bed dryer machines.

Also, the security features of the machine will help in securing the uprightness of the machine.

Here are the primary safety features of the machine that you should think about prior to making a buy.

- The product bowls of the fluid bed dryer are designed with a special feature and it does have a special interlocking mechanism.

- As you might have noticed above temperature is the most critical factor of the machine for that reason, there is a proper control lead in the machine that tries to maintain the temperature during the whole process.

- In the pharmaceutical dryer, an explosion can be another issue that might occur during the process for that reason, a flap for the explosion has been installed to stop any kind of mishap.

- Earthing is a type of minor electric system that does not cause any problem when you touch it but you feel the shock. An earthing system for static current is available in the machine for safety purposes.

- Just like the temperature in the pharmaceutical dryer air pressure also plays a vital role in the machine. For instance, properly installed air pressure is another must to make sure that pressure remains under control.

- Relay protection in case of an overload

- This is a very common function with almost every machine so does the pharmaceutical dryer they have an emergency stop button. This is to stop the machine in case anything bad happens.

19. What should you consider when choosing the most suitable Pharmaceutical Dryer?

Energy Utilization

You don't need a fluid bed dryer(FBD) that will compel you to spend lots of cash on the power bills. You can make that possible from the very first step by picking an energy-sparing FBD( fluid bed dryer).

This angle will directly affect your business in the event that you limit the expense of energy as you expand the benefits.

Versatile to the Preparing Strategies

Two fundamental techniques are utilized in drug food and compound handling. This can be either continuous or batch processing. The fluid bed dryer should be effectively versatile to various preparation types.

By appropriately embracing your preparation strategy, you won't have to roll out any improvements to the fluid bed dryer. It will likewise be simpler to utilize the fluid bed dryer.

Less Maintenance Required

Maintenance of the machine is a separate thing whereas buying the machine is another thing. You ought to pick a fluid bed dryer that is simple and modest to keep up or maintain. Maintenance or keeping up of a liquid/ fluid bed dryer incorporates things, for example, cleaning and changing of parts.

You ought not to experience any difficulty about getting to the pieces of the dryer. Handling the machine to different parts should likewise be a simple project.

Usefulness

Although fluid bed dryers are intended to dry products and items, they may accompany different roles that you might want to investigate. A multi-useful FBD is equipped for performing various capacities, for example, drying, warming, and in any event, covering.

On the off chance that you would need every one of these undertakings to be executed by a single process, consider purchasing a multi-role fluid bed dryer available to be purchased.

Material of Development

It is critical to know the sort of material that has been utilized for building this machine called fluid bed dryer. Though a large portion of them are made of hardened steel, you should go further to discover the quality and grade of steel for the FBD. The sort of material will decide the solidness of your liquid bed dryer.

20. What are the Common Problems with Fluidized Bed Dryer Principle?

While using the fluid bed dryer you might face some issues during the whole process.

The issue might be because of the machine, the way toward drying, or the materials being dried up.

Some of the problems you might face are these, with their possible solutions.

1) Product Degrading

You may encounter material breakage of items because of high the temperature.

You can fathom or solve this by appropriately dividing the particles and afterward bringing down the temperature.

It is likewise essential to realize accurate drying temperatures for all the items you plan to dry.

2) Longer Drying Time than Usual

You may encounter more drying time that it as a rule takes because of a higher dampness content in the materials.

For this situation, you have to do a pre-drying measure on the granules and powder.

Aside from that, you may choose to receive a twofold drying strategy on the powder or granules.

3) Reduction in Particle Size

You may encounter a decrease in the size of the particles that you are drying because of an expansion in stay time.

You have to decrease the stay time appropriately to sort out this issue.

4)More Moisture in Dry Products

There are circumstances when the dampness in dry items is higher than you anticipate that it should be.

This is a consequence of the inside dissemination of the particles or granules.

You may take care of this issue by lessening the stay timing again inside the liquid bed dryer.

5) Inability of Particles to Fluidize

With all the boundaries considered, you will sometimes understand that the particles don't fluidize by any stretch of the imagination.

This can occur in the fluid bed dryer because of an issue with the electrostatic charges.

You can figure the issue out by productively earthing (Fasting the equipment to earth) the liquid bed dryer.

6) Shrinkage on the Surface

The end-product of the particles or powders may have the correct dampness content however with shrinks on a superficial level.

The principal purpose behind this is high temperatures that surpass the ordinary drying temperatures.

You ought to have the privilege of drying temperatures for each item with the goal that you can keep up a legitimate temperature balance.

21. How to maintain a Pharmaceutical Dryer?

- Switch off the pharmaceutical dryer properly.

- Use a dry duster to remove the dust

- Make sure that all of the dried material has been removed and nothing is clinging to the bowl.

- Check each and every part weekly basis if they are working properly.

- Pay attention to drying time.

Conclusion

These pharmaceutical dryers offer you novel occasions to create covered controlled delivery items. Be that as it may, with different dryer limits you can modify the performance of an item, and at the same time should be analyzed altogether.

It is essential for you to research and comprehend these factors to guarantee a good execution for buying a pharmaceutical dryer.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586