High Quality Single Punch Tablet Press Machine

Meets GMP Requirement

All Stainless Steel Construction

Reliable Safety Sealing System And Dust-Proof System

High Visibility Isolated Door To Prevent Cross-Contamination

AIPAK Tablet Press Machine

AIPAK tablet press machines have a wide application in the industry of pharmaceutical, chemical, food, electronic, etc. The tablet press machine is mainly for pressing powder or granule stuff into different shapes of the tablet according to production requirements and is also used for compressing biscuits for military and civilian use. Based on their state-of-the-art designs and technological innovations, AIPAK tablet press machines feature mature, stable running, and durable quality. Along with these, they range from effervescent rotary tablet press machines to single-punch tablet press machines and high-speed high-capacity rotary tablet press machines. With interchangeable turrets, producing annular, irregular, or engraved tablets remains within the desired overall equipment efficiency. All AIPAK tablet press machines are GMP compliant and working stable, safe accurate easy to operate, and maintain.

The Buyer's Guide

Tablet Press Machine:the Ultimate Buying Guide in 2024

The tablet is a kind of widely used dosage form and its simple taking and convenient carrying that makes it more and more favored by people nowadays .

While as its “founder”, the tablet press machine can’t be denied.

Yes,as a fundamental equipment in pharmaceutical machinery,tablet press machine has played an integral role in today’s world and been an dispensable device in pharmaceutical,chemical,food,daily goods and other industries.

Some of you may begin to ask what is that magical tablet press machine.

So today I am going to take advantage of this tablet press machine ultimate buying guide to introduce some of the benefits,classifications,parts,working principle,installation and FAQ about this machinery.

You may make your desired pill or become a professional from a beginner by investing in a suitable tablet press machine.

Now,let’s go straight to the main subject of this guide:

1. What is a Tablet Press Machine?

A tablet press machine is also referred to as a tableting machine, tablet compression machine, tablet punching machine, tablet making machine, or pill press machine.

It is a mechanical device that compresses various granular materials into uniform shapes, sizes, and weights of tablets.

While the quantity of active pharmaceutical ingredients (API) and excipients after compression containing are approximately the same.

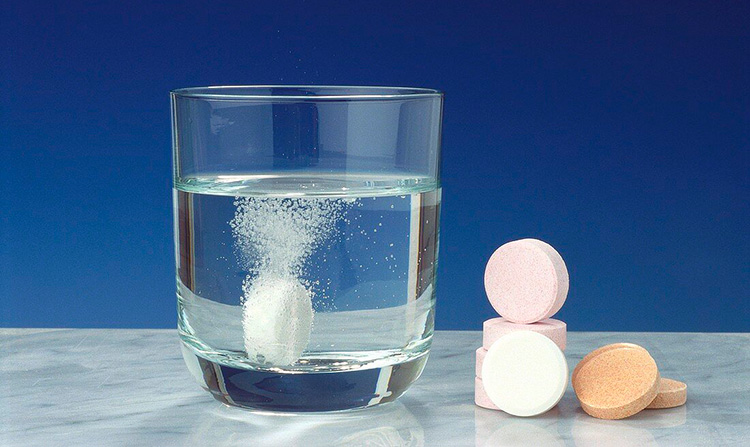

Various compressed tablets

With the technological innovation that makes the development of tablet press machines a continuous process, in the past, we have hand-driven mechanical tablet presses while nowadays it has been modernized to electrically driven tablet presses.

AIPAK Tablet press machine

All tablet press machine owns the same basic principle of compression and its basic unit is tooling consisting of two punches and a die called station.

The upper and lower punches come together in the die making the tablet formulation.

2. What materials can be compressed into tablets using a Tablet Press Machine?

You can compress a wide range of granule or powder materials into tablets using a tablet press machine.

Below you will find the materials you can easily press onto tablets:

- Pharmaceutical Products

- Cosmetic Products

- Cleaning and Sterilizing Products

Chlorine Dioxide Disinfectants Tablets

But you will need to take note of the name of the machine which determines the specific purpose when choosing a tablet press machine.

3. Where are the applications of a Tablet Press Machine?

You can use a tablet press machine to make different shapes of tablets for different purposes.

You will find the various industries include:

1. Pharmaceutical Industry

The pharmaceutical industry is one of the industries related to the national economy and people's livelihood.

Tablet press machine in this industry is used to make different functional medical tablets with different formulations of active ingredients for different disease treatment options.

In addition, you can also use the tablet press machine to make the traditional medicine tablet and western medicine tablet.

2. Food Industry

You can the tablet press machine to make confectionaries, compressed biscuits, and food supplements, like chicken essence blocks, Isatis root blocks, divine tea blocks, etc.

Compressed biscuits

3 . Military Industry

It may be rare to you for the military industry tablet press machine in the military industry is a type of food machinery, which is used to produce compressed biscuits for military and civilian use.

AIPAK compressed biscuit-making machine

Compressed biscuit production involves five main processes, that is, biscuit baking, powdering, mixing, compressing, and packaging.

4 . Chemical Industry

You will easily find some chemical substances in tablets in your daily life like disinfection tablets.

Chlorine dioxide disinfection tablet

You can use a tablet press machine to compress different kinds of chemical granules and powders into tablets, such as camphor pills, health balls, washing blocks, Smurfs blocks, art powder, pesticide tablets, etc.

5 . Cosmetics Industry

The cosmetics industry prefers to use tablet press machines to make tablets for use to enhance beauty.

That is, you will use the tablet press machine to make different sizes, shapes, and colors of beauty tablets.

6. Healthcare Industry

You can use the tablet press machine to produce different forms of healthcare supplement tablets.

Like the pharmaceutical industry, different formulations of active ingredients are been compressed to play the health care function, such as the effervescent vitamin C.

4. What shapes of tablet can you produce using a Tablet Press Machine?

You can produce a wide range of shapes of tablets using a tablet press machine as to the variations of the tooling system, which determines the final shape of the tablet.

Generally, the most common shapes include:

- Round shapes

- Cylindrical shapes

- Spherical shapes

- Concave shapes

- Convex shapes

- Other geometric shapes (such as squares, triangles, ellipses, capsules, etc.) can also be pressed with words, trademarks, and patterns on them.

5. Why need medicine in tablet dosage form?

Everyone knows the pharmaceutical industry is somewhat of a broad industry.

That means people could get different forms of dosage when they are taking various treatments or other similar conditions.

However, from time immemorial, tablet dosage form seems to be favored by people.

Someone is taking tablets-Photo Credits: Healthline

It is one of the significant forms, on the one hand, it is the most popular solid form for drug delivery.

On the other hand, as a mixture of active ingredients and excipients, the essence of the tablet dosage form is to enhance or prompt the treatment plan for a certain condition.

Well, we can see that tablets have a lot of functions especially when reaching a certain dosage.

There are many benefits that tablet dosage forms will bring to you. As for the reasons, I would like to explain in detail.

1. Cover bad taste

A patient will be more accepting and accessible to tablets as they cover the bad taste of drugs.

The situation is to get rid of the bad taste of some substances, some drugs are manufactured to be bitter and generally have a bad taste, while the patients always find it difficult to swallow.

But for compressed tablets, it won’t be as its concentrated ingredients.

2. Accurate measurement

When you are sick, the physician will prescribe medicines for you and will instruct you to take them according to a certain amount, and to get better as soon as possible, you will certainly follow the exact instructions.

That is, in most circumstances, tablets will provide the most precise dosage that contains certain meaningful substances.

3. Easy formulation

Take the same case for example, when you are sick, you may need to take different kinds of medicines at the same time, this is because you may need two or more compounds to act on different functions.

To avoid the many times taking medicines, the manufacturers formulate all the medicines into one substance, of course, there is no conflict for the formulation.

Tablet form

Besides, just like a capsule, drugs in tablet dosage form also help in covering up the flavor of a substance that doesn’t taste good.

4. Easy for identification

You may have heard the cases of the wrong prescription of drugs to patients in the pharmaceutical world.

The main cause of this confusion is that the physicians find it hard to identify the same medicine, let alone the novices.

Sometimes, some different forms of drug dosage may have similar final products or have little variations that make them difficult to distinguish.

Various tablets

Not to mention that some patients need to differentiate the drugs after backing home.

However, the tablets make the drugs easy to identify as they are produced with various color-coated or embossed markings.

5. Stable dosage

Compared with other types of dosage forms, tablet form is relatively stable as its chemical, physical properties are better.

What’s important, you can also manage the dosage of your treatment when you are using this type of dosage.

6. How many types of Tablet Press Machines are there?

Tablet press machines in current use can be classified into:

Single punch press machine

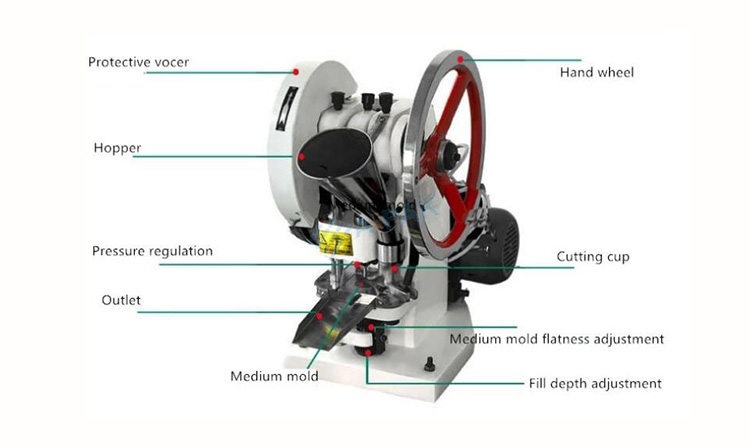

AIPAK single punch tablet press machine

It is also known as a single station press machine which contains a single set of station tooling (a die and a pair of upper and lower punches).

It is the simplest device that manufacturing tablets as it can be either hand-operated or mechanically driven.

It works by the compaction force on the fill material exerted by the upper punch while the lower punch is static.

Such action is equivalent to hammering motion, and as a result, the single punch press is referred to as the stamping process.

The single punch tablet press produces about 60-85 tablets/min, suitable for laboratory and large-scale tablet production.

Muti-station rotary tablet press machine

It is either a mechanical or an electrical device that has several tooling stations which

rotates to compress granules/powder mixture into tablets of uniform size, shape (depending on the punch design), and uniform weight.

It was developed to increase the output of tablets and has a range of types, that can be customized to meet specification production requirements.

AIPAK effervescent rotary tablet press machine

During the working of the rotary press, the compaction force on the fill material is exerted by both the upper and lower punches leaving the powder granules to be compressed in the middle.

This is also the so-called accordion type of compression.

The capacity of a rotary tablet press is determined by the rotation speed of the turret and the number of stations on the press.

As the technological process of the rotary press is continuous, continuous feeding and continuous discharging, and in terms of the whole machine, the force is relatively uniform and stable, it is widely used in formal production.

Flower Basket types tablet press

This machine is used to press medicinal tablets, coffee pills, powder metallurgical parts, electronic components, and various tablets of fertilizer.

It is suitable for small-batch production in laboratories and hospitals.

Flower Basket types tablet press

7. How does a Single Punch Tablet Press Machine work?

The working steps of a single punch tablet press machine can be described as follows:

Filling

1. The upper cam will withdraw the upper punch from the die, the lower punch will be low inside the die cavity to make the granules fall from the hopper and fill the cavity made by the die and the lower punch.

2. You shall adjust the weight of the material to be required by the lower punch and when the lower punch lifts, the excess of powder will be ejected from the die.

Compression

3. The lower punch remains stationary and the upper punch will down to the die to compress the powder into a tablet.

Ejection

4. The upper punch is then withdrawn while the lower punch pushes upwards lifting the formed tablet from the die. The tablet is then removed from the die surface by the surface plate.

5. Then repeat the cycle in the next batch.

During the production, you will need to manually adjust the machine to suit the type of tablet, the material, the compression, and the capacity of material required for each tablet.

While through that step you can also make a check on the appearance, size, and mechanical robustness of the formed tablets.

Once you are satisfied with the quality of the tablet, the mechanical adjustments will be locked into place, and the machine will be ready for automatic production.

So, to maintain the quality and standard of the product, you will need to regularly check the settings especially if you need to make large quantities of tablets.

8. What are the functional parts of a Single Punch Tablet Press Machine?

Hopper

It is connected to the feed shoe and the part where the granules/power mixtures are poured before the compression process.

It can be filled manually or by using mechanical equipment during the subsequent pressing process.

Die cavity

It is the place where the granules/power are compressed into tablets.

While the die cavity also determines three aspects of the tablets, namely:

1. The size of the tablet

2. The diameter of the tablet

3. The thickness of the tablet

Punches

There are the upper and the lower punches that united to compress the powder into tablets of various shapes within the die.

Cam truck

This part is to regulate the position or movement of the upper and lower punch.

Ejection adjuster

It is the part that facilitates the ejection of the tablet from the die cavity after compression.

Tablet adjuster

It is to adjust the volume of the power to be pressed and then determine the weight of the tablets.

9. What are the advantages of using a Single Punch Tablet Press Machine?

Single punch tablet press machine is widely used in pharmacy, chemical, food, hospitals, scientific research units, lab trial production, and small batch production, so you will find its advantages are:

1. It is small with a rational structure that won’t take up too much space and is easy to move.

2. The single punch works at a high utilization ratio and it is easy to operate with all kinds of dies that can be customized and installed.

Easy pressure adjuster of a single punch

3. You can use it to manufacture odd-shaped tablets which will be more attractive to your customers since both the material filling depth and sheet thickness can be adjusted.

4. Each piece made by the single puch is even with the same hardness as the machine utilizes a high amount of pressure to reduce the weight variations between them.

5. It can be hand-cranked even if there is no power supply.

6. It won’t produce too much noise during the compression process.

10. Are there any disadvantages of a Single Punch Tablet Press Machine?

Yes, just like any other machine, a single-punch tablet press machine has its disadvantages in using.

Compared with any other type of tablet press machine, it is slower.

Besides, it is a little hard for you to clean the single-punch tablet press machine some of its parts are exposed to the air.

11. How does a Rotary Tablet Press Machine work?

Like the single punch tablet press machine, a rotary tablet press machine will go through three main steps to make a tablet which include:

Filling

Firstly, you will need to fill up the hopper with granules or compressed raw materials when the machine is running.

Processing the materials

Then the materials will go through various procedures from the hopper that include: granulation, dressing, and other types of processing projects.

Besides, the rotary tablet press machine will also mix the granules to make them become homogenous mixtures.

Compression

The mixed granules will flow into the die cavity from the hopper to be compressed.

Then when the die cavity is filled, you will need to gauge the number of granules by removing the excess of granules, through which the machine will compress the appropriate volume of granules into tablets.

Then the lower and upper punch will begin to work to compress the granules into various shapes and sizes of tablet you want.

Ejection

In this step, the machine will remove the punch from the die cavity by the lower punch, and the upper punch will retract from the die cavity by lifting above the turret.

Then the lower punch will lift upwards by pushing the tablets out from the die cavity.

During this procedure, the eject cam will affect the ejection of the tablets from the die cavity.

Finally, you shall take off the blades and the compressed tablets will be removed from the die cavity for the next process.

12. What are the main components of a Rotary Tablet Press Machine?

A tablet press machine is made by the hopper, dies, punches, cam tracks, and feeding mechanism, while a rotary tablet press machine, consists of more parts than that of the single punch.

Now, let's talk about them in detail.:

1. Hopper

Feeding Hopper

A hopper is the feeding station of the rotary tablet press machine.

From where you will put the granules/power mixture that are to be compressed into tablets.

2. Die cavity

Just like the single punch, the die cavity is the most critical place for the tablet-making process as it is where the granules/power are compressed into tablets.

The shape of the die system is also determined by many factors such as the tablet diameter, size, and thickness, and other features such as logos where necessary.

3. Feeding paddle

This part helps to force the feeding of granules or powder mixture into the dies, especially during quick rotation.

4. Punches

As the single punch, the rotary tablet press machine is also comprised of upper and lower punches, which move within the die bore to compress the granules into tablets.

5. Cam tracks

To guarantee the normal movement of both the upper and the lower punches, there needs the cam tracks.

6. Lower cam track

During the filling stage, the lower cam track will guide the lower punch to make in-time adjustments when the die bore is overfilled.

7. Ejection cam

This part is used to facilitate the ejection of the compressed tablets from the die cavity by guiding the lower punch upwards.

8. Depts of fill/capacity control

It is to ensure the appropriate quantity of granules remains in the die before the compression process by adjusting the lower punch track during the latter section of the filling stage.

9. Pre-compression rollers

There might be an excess of air entrapped in the die, then the pre-compression rollers are to drive the granules to give them a compression force to get rid of this air.

10. Main compression

It is the part that dives into the final compression force needed for the formulation of the tablets.

11. Take-off blade

The blade is located in front of the feeding house and it is for deflecting the compressed tablets down the discharge chute.

12. Discharge chute

This is the place where the compressed tablets pass through for collection after being deflected by the take-off blade.

13. Operation Panel

This part includes the emergency switch and you can use it to control the thickness and pressure during the tablet compression process.

13. What are the advantages of using a Rotary Tablet Press Machine?

The rotary tablet press machine is mainly used in the pharmaceutical industry and the chemical, food, plastics, powder, metallurgy, and electronic industries.

AIPAK rotary tablet press machine

You only need to replace components and add powder-absorbing apparatus which greatly lowers the cost.

While, apart from that, you will also find so many advantages of tablet press machine including:

- You will gain high productivity with a minimal amount of labor and at the same time save money.

- You will have a decrease in waste of valuable substances which will have in non-specific tablets.

Various tablets by the rotary tablet press machine

- You are allowed to control either the weight or hardness independently.

- Your powder-filled cavity can be automatically managed by a moving feeder.

- You will have a large output of up to 9000-234000 pieces per hour which will not only save you time but also meet the high demand of tablet dosage form.

- There is high high-visibility isolated door that helps you prevent cross-contamination.

- The 360°design makes it easy for your observation and cleaning.

14. Are there any disadvantages of using a Rotary Tablet Press Machine?

A rotary tablet press machine has a large output but also has its demerits.

First, a rotary tablet press machine is large and has a heavyweight, which will make it difficult for you to move the machine from one place to another.

The cost of purchasing and installing the machine is much higher, you will need to have large output profits to balance this.

You will also need to train your workers to be familiar with operating the machine which will also add to your cost.

The machine will also lead to environmental pollution as it will release some wastes by some substances through compression.

15. What are the differences between a Single Punch Tablet Press Machine and a Rotary Tablet Press Machine?

There are many variations between a single punch and rotary press machine from the tablet press technological process, and tablet press procedure to the tablet quality, etc.

The tablet is better from the rotary press machine than the single punch while the operation procedures are more complicated.

But the four most important differences you will find are:

1. The single-punch tablet press adopts single-sided compression to make tables while the rotary tablet press utilizes double-sided compression.

2. There is no dwell time during the compression cycles of a single punch tablet press whereas the rotary tablet press uses a punch head flat that enables a dwell time when the punch goes through under the compression roller.

3. The exhaust ability of the single-punch tablet press machine is poorer than that of the rotary tablet press machine after the granules or powder are compressed.

4. The flowability of the granules is not visible to you for a single punch while the rotary press is.

16. What is the tooling in the Tablet Press Machine?

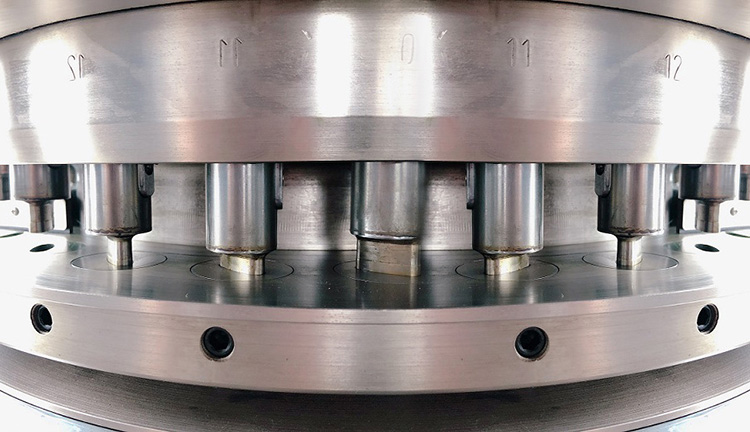

Tooling is the basic mechanical element of whatever tablet press machine.

It is made by the die and its associated punches, which are essential tools in the tablet compression process.

They are also what key elements that determine the design and functions of the tablet press machine.

Besides, these punches and dies are critical to the quality of the tablet produced like the size, shape, and nature.

Generally, a standard punch consists of three parts: the upper punch and the lower punch whose work makes the surface shape of the tablets.

Tooling system of the tablet press machine

The upper and lower punches make the surface shape of the tablets.

According to the structure and shape of the die, it can be divided into circles and special shapes (including polygons and curves).

The shape of the punch can be plane, hypotenuse, shallow concave, deep concave, and comprehensive. While the plane shape and hypotenuse punch are used to press a flat cylindrical tablet, a shallow concave shape is used to press a double convex tablet, a deep concave shape is mainly used to press s coated tablet chip, and a comprehensive shape is mainly used to press special-shaped tablet.

Different shapes of tablets

To identify and take medicine easily, you can also engrave the name, dosage, and vertical and horizontal lines of medicine on the die.

Therefore, you will need to select the appropriate types of tooling to compress different sizes or shapes of tablets.

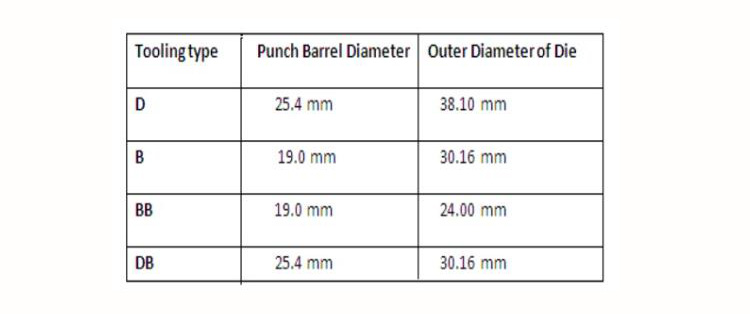

17. What are the commonly used tablet press tooling?

Tablet press tooling can classified into “B”,” D”, “BB”, and” DB” types, you will find the difference in tooling configurations between the four types are:

While the most commonly used types are:

- ”B” type

- ”D” type

They are counted as the majority of tooling configurations used today.

”B” type

From the above image, you can see that the “B” type configuration has a normal punch barrel diameter of 0.750 inches which is 19mm.

It can be used with two types of die or with two different sizes of die that include:

1. Die with a diameter of 1.1875 inches, which is 30.16mm, which is suitable for all sizes of tablets up to the maximum for its “B” punch.

2. Small “B” die that has a diameter of 0.945 inches, that is 24mm, and the die type is suitable for tablets with a diameter up to 9mm or a maximum of 11mm.

”D” type

The “D” type tooling has a larger barrel diameter of 1 inch, which is 25.4mm, and a die diameter of 1.500 inches, which is 38.10mm, which is suitable for tablets with a maximum diameter or maximum length of 25.4mm.

Besides, you will need to know that the “B” and “D” types only can be used separately.

The compression force used in the tablet press machine depends on the type of tooling used.

That is, a tablet press machine with “B” type tooling can exert a maximum compression force of 6.5 tons while the “D” type can exert 10 tons.

Surely, some special machines are designed to exert higher compression force, you can control the size of the punch tip or choose a special design.

Last but not least, you can achieve higher output through the following aspects including:

1. Increase the number of effective punches

2. Increase the number of station

3. Increase the number of compression points.

4. Increase the rate of the compression turret speed.

Of course, they are not absolute and have their limitations and advantages.

18. What aspects do you need to consider for choosing the suitable Tablet Press tooling?

From the above introduction, you may have a general impression that your ideal tablets are determined by the type of tooling system.

While considering all the tooling options and steel types available on the market now, you will be still confused and complicated to choose the most suitable tablet tooling, I would like to give my advice before you make the final decision.

Firstly, you may need to request the supplier to provide a tool and tablet drawing for approval most tooling manufacturers can provide a sample of copper or other special materials made tablets to you.

Secondly, I also would like to give you a guideline list that you need to request the tooling manufacturers to provide to you for further approval to meet the special requirements of your tablet press.

1. The press type, model number, and number of stations.

2. The size, shape, and cup depth of the tablet to be compressed, otherwise a sample tablet or sample tools would be enough.

3. Drawing a number of the tablet if they have a drawing.

4. Historical data on tablet problems such as capping, sticking, picking, high ejection forces, etc..

5. Special options such as tapered dies, domed heads, key type, etc.

6. If have special shipping instructions

19. What do you need to consider when choosing the material for an Effervescent Tablet Press Machine?

An effervescent tablet press machine is a kind of automatic rotating and continuous tablet press machine.

AIPAK Effervescent tablet press machine

It is also a special equipment for chemical, food, electronic, and other industrial enterprises to press granular raw materials into tablets or granules, which is suitable for small batch production.

At present, the effervescent tablet press on the market can press all kinds of special-shaped, circular, and double-color tablets, and can press tablets with trademark, text, and simple figures on both sides.

It is equipped with an overload protection device. When the pressure is overloaded, it can automatically shut down.

This kind of tablet press improves the uniformity of tablet density and reduces the phenomenon of split and loose tablets.

Generally speaking, a reasonable materials selection will achieve satisfactory effect, you will need to pay attention to the following items.

Fluidity

The materials needed for the effervescent tablet should have good fluidity and be easy to flow into the mold hole evenly to fill a certain amount.

At the same time, it also needs to have a certain viscosity, so that the pressure can form a tablet, but it can not be too sticky, or it will be difficult to demould.

Hygroscopicity

The hygroscopicity of materials should not be ignored.

For example, sugar powder is easy to absorbs moisture, which will make the effervescent tablet soft and deliquescent.

Effervescent

Adhesive

The selection of adhesives has a great influence on the quality of finished products.

If the viscosity is not enough or the dosage is too little, the pressed product is easy to loosen and break, but if the viscosity is too strong or the dosage is too much, the particles will be too hard, and the effervescent tablet sugar made is not easy to dissolve or disintegrate. The syrup is a kind of adhesive with strong viscosity, and the sugar tablet is hard.

When you are using dextrin as an adhesive if the amount is too large, the particles will be too hard, and the surface of the extruded sugar tablet often has spots and pockmarks, which will affect the disintegration speed of the effervescent tablet.

Acid and alkali materials

Acid and alkali materials have a certain influence on effervescent effect and production.

There are three things that you need to consider:

First, the proportion of acid and alkali materials plays an important role in the effervescence effect.

Generally, the carbon dioxide content in the finished product is not less than 8%. To make the product moderate in sour and sweet, and ensure that the neutralization effect of bicarbonate or carbonate is complete, the consumption of acid is generally slightly higher than that of alkali by 10%.

Second, if citric acid must be used in the formula, the humidity and temperature of the production workshop must be controlled within the recommended humidity temperature, otherwise, it will stick to the punch.

Third, the citric acid was replaced by tartaric acid or fumaric acid, the effect was better without precipitation.

Tartaric acid instead of citric acid, moisture absorption will be greatly reduced, but the taste is not as good as citric acid.

Magnesium stearate

It is understood that magnesium stearate is mostly used as lubricant in the process of tablet pressing, but all raw materials and auxiliary materials for making vitamin C effervescent tablets should be soluble in water, because magnesium stearate is hydrophobic and insoluble in water, and the use of magnesium stearate in vitamin C effervescent tablets will produce turbidity and precipitation, so it is recommended not to use or use as little as possible.

20. What is the turret of the Tablet Press Machine?

The turret is the key part of a tablet press machine as its holes hold the dies of the machine and ensure the correct alignment of the die packets and the punch guides.

Turret

Generally, the turret in a tablet press machine contains three critical parts.

- Die turret which holds the dies.

- Upper turret which holds the upper punches

- Lower turret which holds the lower punches

21. Which support equipment do you need for the tablet compression?

To make a tablet, except the tablet press machine, you will also need some supporting equipment, they are:

1. A dust collector

It is a dedusting device that helps to get rid of the excess dust from the tablet press machine.

2. High-shear mixer machine

You will need this machine to make the even, quick, and easy mixture of the tablet formulation ingredients.

A high-shear mixer machine

3. A granulator

A granulator will help in the forming of the tablet.

4. A metal detector

This metal detector is to inspect the metal fragments within the compressed tablets.

5. A tablet coating machine

You will need a coating machine to coat the formed tablets.

6. A fluid bed dryer

It is a drying machine that is used to dry the wet granules.

A fluid bed dryer

7. Weight checker

This weight checker is used for weighing the tablets and rejecting tablets that exceed the weight tolerance.

22. What are the GMP requirements for a Tablet Press Machine?

GMP refers to good manufacturing practice, which is a standard requirement that the tablet press machine must meet, as it will guarantee the safety and hygiene of the tablet manufacturing.

But also certifies the machine is made of qualified material that will not contaminate your products.

Besides, a tablet press machine that meets GMP standards will also guarantee your manufacturing is consistent and can be controlled according to required quality standards.

To conclude, meeting the GMP requirement will help you minimize the production risks that can’t be reduced by testing the final product.

Then what are the GMP requirements for the tablet press machine?

Here there is a list.

1. Design requirements for tablet pressing equipment

i.Equipment selection

1) It should have the functions of dust collection and cleaning.

2) The operation is convenient and reliable, and there is a necessary adjustment device. Such as mechanical adjustment devices, filling adjustment devices, pressure adjustment devices, speed adjustment devices, sheet thickness adjustment devices, etc.

3) It should have a reliable safety protection function. Such as pressure overload protection, and current overload protection.

Some equipment with a high degree of automatic control also has the functions of breaking protection, scraping out, fault alarming, automatic weighing and testing, etc.

4) The design of the tablet pressing chamber shall meet the requirements of being airtight (isolated from the outside), having no pollution, no dead angle, easy to observe, easy to clean, easy to assemble and disassemble the mold, etc.

5) It should have a protective device to prevent injury to the human body. Such as grounding devices, over-current breaking protection devices, automatic opening breaking protection devices, etc.

6) The design is beautiful and simple, easy to operate, observe and maintain.

ii. Determination of performance parameters

1) It shall meet with the national or industrial standards.

Formulate enterprise product standards that are stricter than national or industrial standards, and actively promote the adoption of international standards, such as EU standards and IPT standards for tablet dies.

2) Good sealing and isolation measures.

For example, the sealing and isolation between the mechanical components and the tablet pressing chamber, the sealing and isolation between the punch body (the up and down movement guiding role) and the punch top (the part contacting with the material), the sealing and isolation between the upper and lower parts of the turntable (the punch body guiding role) and the middle worktable (the area of material flow and tablet forming), the sealing and isolation between the tablet pressing chamber and the outside, etc.

3) Good mechanical properties.

The transmission is stable, with appropriate accuracy, low noise, no obvious vibration, and abnormal thermal deformation.

iii. Management of technical documents

1) There is a complete set of technical documents and quality records that meet the national standards, and the requirements of equipment manufacturing, installation, and operation combined with the actual situation of the enterprise.

a) In the equipment selection stage: there are documents and records such as information collection, market research, technical investigation, feasibility analysis, development decision-making, etc.

b) In the stage of equipment design: there are documents and records such as product design scheme, technical and economic cost analysis, design calculation, design verification, structure and component design, process design, etc.

2) Establish document control files, standardize management, and ensure the operation quality and traceability of the design system.

2. Manufacturing requirements for tablet pressing equipment

i.Purchase

1) Establish purchasing quality control files, and select qualified and reputable suppliers to ensure purchasing quality.

2) According to the requirements of the procurement documents, purchase the raw materials and all kinds of materials that meet the quality requirements and have the quality assurance certificate or qualification certificate.

3) Carry out necessary material chemical analysis for main key parts and raw materials with GMP requirements.

4) Carry out incoming inspection and quality tracking for important standard parts and accessories.

ii. Manufacturing

1) You can assemble, and debug the parts and manufacturing according to the design drawings, process documents, and relevant standards.

2) Set up processing quality control points for the manufacturing of main key parts and standardize the construction.

3) Strengthen the quality inspection of parts manufacturing with GMP requirements to prevent mixing and knocking.

4) Necessary quality control is carried out for the surface coating process of some parts required by GMP to prevent coating peeling and rusting.

3. Installation requirements of tablet press machine

The manufacturer shall prepare the operation manual of the equipment, including composition and use of the machine; technical parameters; transportation, installation, storage; operation and adjustment; maintenance; catalog of vulnerable parts, and shall be obliged to help and guide the user to install and use the equipment.

You can install the equipment according to the installation method and requirements in the operation manual.

The installation environment of the equipment shall meet the relevant provisions of the pharmaceutical production quality management code (1998 Revision).

Necessary auxiliary facilities shall be provided, such as a power supply, compressed air source, feeding device, dust removal device, etc.

The equipment shall be operated in the air or in a test run to confirm the stability and adjustability of each mechanism function of the equipment, and the reliability and safety of the instrument.

4. Performance requirements of tablet press machine

Select one or several physical test parameters, such as the shape, size, and thickness of the pressed tablet, determine the appropriate rotational speed for physical production, and the quality of the pressed tablet meets the requirements of the finished product and national standards.

The equipment conforms to the design parameters in the simulated production operation or the physical production operation, and there is no abnormal leakage of powder, liquid, or metal chips and particles in the tablet pressing room.

The operation and maintenance are simple, safe, and reasonable, and the disassembly and assembly of mold, feeder, and other parts are convenient.

The equipment is easy to clean without dead angles and leakage.

23. How does the Rotary Tablet Press Machine control the weight of the tablets?

The rotary tablet press machine uses compression force to control the tablet's weight during the compression process.

It is a gap between the rollers exerting pressure that must remain constant to get the uniform tablet weight.

If the compression force does not remain constant, the quantity of the to-be-compressed granules in the punch die cavity will be affected.

Once the tablet thickness and hardness are set, a fixed amount of granules are compressed between the punch at a fixed distance to generate the same amount of compression force on every tablet.

Therefore, you will need to measure the compression force and compare it with the control parameters to know whether the tablet is within the weight tolerance.

24. What specifications do you need to provide to the supplier for customization?

When purchasing a tablet press machine, you may have to choose a supplier who can design, customize, and make dies for you to suit your different production purposes.

At the same time, there is some information about your product that you need to provide to them, they are:

1) Raw material

The supplier may need to know the raw material to analyze its nature or fluidity to know if they are falling from the hopper easily.

2)Size, shape, and yield capacity

They will figure out if their machine can compress and which models will meet your requirements.

25. What is the tablet coating process?

After compression, all tablets need to be further proceeded to make it a real acceptable tablet, which refers to the coating process.

The coating process is to cover up the bad taste, then make it easy to swallow and protect the active ingredients inside to make it functional.

Tablets through the coating process will become smoother, more appealing, and in a word, easier to digest.

Coated tablets

There are coating machines for you to make such a coating process.

26. What should be paid attention to when using a tablet press machine?

You need to pay attention to the following aspects when using a tablet press machine:

1. You shall first read the operation manual and operation procedures of the tablet press, and be familiar with its performance and operation methods of the control part.

2. Before normal use, the die must be checked strictly, without any crack, edge missing, deformation, or other defects. After installation, it should be tightened properly. If it is unqualified, you shall not use it to avoid damaging the equipment.

3 As the granule is an important factor related to the smooth completion of the tablet pressing, the granule quality should be controlled according to the process requirements, otherwise it will affect the tablet quality and the normal operation of the machine.

4. As the tablet pressing speed will affect the tablet quality and the service life of the equipment, so generally, you shall make the tablet press speed slow to press difficult-to-form materials and large-diameter tablets, while fast for easy-to-form small tablets.

5. During idling, you should increase the filling volume to avoid the impact of the upper and lower punches on each other and damage to the shape of the tablets.

6. Note that do not dismantle the machine parts on the equipment at will. In case of large vibration or abnormal sound during use, you should stop the machine for inspection immediately and use it after troubleshooting.

7. It is recommended to clear the tablet pressing room at least once per shift. Some fine powder adhered to the punching rod, punching rod hole and middle die hole will lead to the inflexible rotation of plug punching and punching rod, which will affect the normal operation of the equipment.

8. You shall regularly check and maintain the wearing parts, such as rail guide, pressing wheel, bridge, and die, to prevent the damage of individual parts from affecting the whole machine.

9. The tablet pressing speed shall be reduced as much as possible before shutdown.

10. You shall refuel and maintain the equipment regularly according to the operation manual.

27. Why there is tablet tolerance and how to deal with it?

The excess of tablet weight means that the tablet's tolerance exceeds the limit of Pharmacopoeia.

| Average weight | Weight tolerance limit |

| < 0.3g | ±6 % |

| ≥0.3g | ±4 % |

Weight tolerance standard

You will find the reasons and the solutions below:

1. Due to the uneven distribution of granule size and different flow rates during tablet pressing, leads to the uneven filling up of the die holes.

For example, if there is too much coarse granules, the tablet will be lighter, and if there are more fine granules, the tablet will be heavier.

★ Solution: You should make the granules evenly mixed sieve before compression.

2. The fine powder adheres to the punch which may cause the lifting punch.

★ Solution: At this time, the lower punch will not rotate flexibly, so you will need to check in time, disassemble the die, and clean the lower punch and the die holes.

3. Due to the poor fluidity of the granules, the amount of granules flowing into the die hole is sometimes more and sometimes less.

★ Solution: You will need to granulate again or add suitable fluid aids such as silica gel powder to improve the granule's fluidity.

4.Granules stratification.

★ Solution: You will need to reduce the granule size difference.

5. Use too large granules to make smaller tablets.

★ Solution: You shall select the appropriate size of granules.

6. The hopper is blocked, which often occurs in drugs with strong viscosity or humidity.

★ Solution: You should dredge the hopper, keep the tablet pressing environment dry, and add the flow aid properly.

7. The punch is not in good coincidence with the die hole, for example, a lot of powder is leaked between the outer surface of the lower punch and the die hole, resulting in "astringent punching" and insufficient material filling.

★Solution: You need to replace the punch and die.

8. There is a variance in the length of the lower punch, which leads to an uneven amount of filling.

★Solution: You should make the length tolerance of the lower punch within ± 5 μ M.

9. The damping force adjusted by the damping screw is not good.

★Solution: You shall re-adjust the damping screw.

10. The filling track is worn or the filling mechanism is unstable.

★Solution: You shall replace or stabilize the filling track.

28. How to deal with common problems of single-punch tablet press machines?

When you are using a single punch tablet press machine, you should note below aspects:

1. The single punching machine can only operate in a certain direction, and can not be reversed to avoid damage to the parts.

AIPAK TDP-5 single punch tablet press machine

2. When you are using an electrician-driven single punch tablet press machine, the "handle" on the "big hand wheel" shall be pulled down to avoid personal injury during operation.

3. You need to make the upper punch core rod in the rising position before starting the machine whether it is electrical or mechanical.

If you start the machine when the upper punch is in the down position, it will enter into the die just after the start. At this time, because the rotation speed of the machine has not been up, the inertia is small, and it is easy to cause the situation of carjacking.

4. You can adjust the belt tension through the two adjusting nuts on the electromechanical bottom plate, and note that if they are locked after adjustment.

5. When there is no power supply, you shall remove the triangular belt to reduce resistance and wear. But do not remove the "big pulley", because the "big pulley" has the effect of flywheel labor-saving.

6. Treatment method for carjacking

(1) In case of carjacking during electric tablet pressing, turn off the power immediately to avoid burning the motor.

(2) In case of serious jacking, it is necessary to loosen the connecting rod nut, turn the lower part of the upper punch rod anticlockwise with a wrench to make it rise to reduce the pressure, and then turn the big hand wheel to eject the tablet. Then re-adjust the tablet hardness.

7. You will need to check the quality, weight, hardness, and surface of the tablets frequently and adjust in time.

8. When using, if you find the granules still can not pressed into tablets when the pressure has been adjusted to a considerable extent or the tablets are too loose, delamination, debris, pockmarks, powder falling, etc.,

You should never adjust or increase the pressure which will damage the machine, but you should check the quality of the ingredients.

29. How to solve common problems in the tablet compression process?

There will be several problems arise during the tablet compression process.

You will find the solutions for them are:

1. Capping

Capping refers to the tablet's fractures from its main body during the ejection or handling process.

It is the most common problem when the air is constantly compressed.

And the expansion of the tablets during the ejection will also lead to capping.

At this time, you will need to reduce the tablet pressing speed, clean the punches and dies, reset the punches, and re-adjust the blades to prompt the ejection process.

2. Sticking

That’s when the granules are sticking on the tooling, you will find poor dried or lubricated tablets produced.

Then you need to increase the compression pressure or decrease the turret speed.

But when the issue is still on, you may have to re-polish the tooling of the tablet press machine.

3. Cracking in tablets

The little and fine cracking of the tablets may be the result of the quick expansion of the tablets.

You may need to replace them with flat punch faces as the cracking is usually seen when you are using concave punch faces.

Or you may choose to use a tapper die to solve this kind of problem.

4. Chipping

This phenomenon occurs when the tablets break at the edge after compression or are finished products, which is also led by the machine with incorrect parameter settings.

Facing this issue, you may have to replace or polish the die to correct the parameter setting or polish the punch tips and the concavity of punch faces.

5. Lamination

Lamination refers to the tablets separated into two or various horizontal layers poor ejection or air-entrapment or too high turret speed.

Then you have to use a tapered die or a quick decompression or lastly reduce the turret speed and the compression force.

6. Double impression

It is easy to understand that the double impression is lead by the lower punch not being fixed tightly which makes it drop freely at a small distance creating new markings on the tablets.

It also could be a result of not being restricted to the upper punch that makes it rotate again and make new imprints on the tablet.

At this point, you may have to use the device with an anti-moving function to prevent this kind of issue.

30. How to troubleshoot common problems of tablet press machines?

The common faults of the mechanical part of the tablet press are easy to occur in the guide rail, the pressing wheel, the overload protection, the reducer, and the die of the tablet press.

There are many factors involved, including both the use factors and improper adjustment factors.

So, it is necessary to clean the tablet press room regularly, and regularly check and maintain the working parts that are easy to wear.

Now according to our experience accumulated in the actual use process, I will analyze and solve some common faults and maintenance methods.

1 Worn of the upper guide rail

(1) It may be an oil cut-off and improper oil filling to the upper punch, which causes the stamping punch and wear of the upper guide rail.

To remedy this, you will need to wipe the remaining oil on the upper punch surface with a clean rag, and then brush a little oil with a small brush, evenly apply it on the upper punch hat head and upper punch rod, so that the upper punching can rotate flexibly.

However, the amount of oil should not be too much to prevent oil from penetrating the powder and causing an oil slick.

(2) The oil quality is not good.

Only engine oil can be selected for lubrication between the guide rail and punch rod. 30-gear oil or air compressor oil is recommended.

(3) The pressing material is too fine and there is a lot of dust.

It must be added lightly when feeding to avoid flying dust and abrasion of the upper guide rail.

(4) If the pressing material is too wet and the upper guide rail is worn due to the phenomenon of product hanging or sticking, the material shall be re-dried and lubricant added for rework.

In addition, the process formula shall be improved to control the particle size distribution, fluidity, and compressibility of the material.

2 Worn of the lower guide rail

If the bridge plate of the lower guide rail is worn, you may have to repair it with oilstone on the lighter, and the severely worn one can only be replaced.

(1) If the pressing material is too thin or too damp, it will make the power punch hole or the lower punch skinned, which results in stamping, sticking, and wearing of the lower guide rail.

Then you may need to clean the lower punch hole until it turns to move.

And you shall also pay attention to whether there is any abnormal sound in the process of tablet pressing.

When hearing the abnormal sound, you shall shut down the machine timely, and wipe off the punching holes, the crusts on the punch, or the tablet pressing materials for rework, to avoid serious undercutting and stamping.

(2) The lower punch is not clean, which results in stamping.

Then you may need to brush the lower punch hole.

If the punch hole is skinned, the skinning must be cleaned with a scraper. Especially for products with high viscosity, the punch must be cleaned with alcohol to ensure that the punch can rotate flexibly.

3 Pressing wheel

The pressing wheel is a device to adjusts the pressure of the tablet and increases the protection.

Its common faults include the wearing of the pressing wheel, the lack of oil, or the damage to the bearing of the pressing axle.

If the outer circle of the pressure wheel is seriously worn, the tail resistance of the punch rod will be large, so you need to replace the pressure wheel.

If the inner hole of the pressure wheel and the pressure axle are seriously worn, you shall also replace the pressure wheel or the pressure axle.

Sometimes the fracture of the pressure axle is mainly due to the excessive bearing pressure At this time, you shall replace the pressure asle adjust the material, and re-adjust the pressure.

In addition, you will have to lubricate and maintain the bearing of the compressor shaft

regularly and replaced in time in case of damage.

4 Tablet press die

Punch is an important part of the tablet press. The common faults in use are: the punch rod is worn, which only can be replaced by a new one.

Another problem is punch bending which mostly occurs on the small-diameter punch, which is mainly caused by excessive pressure.

The punch bending will affect the weight difference of the tablet, so replacement is necessary.

5 Hopper is worn or installed improperly

(1) When the bottom surface of the hopper that is close to the plane of the turntable is worn, you will need to adjust the position of the hopper to make the gap between the bottom surface of the feeder and the working surface of the turntable is 0.05-0.1mm.

(2)Both the upper punch stamping, lower punch breaking, lower punch blasting, upper punch hat head fracture, and the part of the punch breaking in the hopper not taken out in time will cause the hopper to wear and even damage the machine.

Then you shall make the pressure not be too large, the machine not be overloaded, and any abnormal situation must be found and handled in time.

In the process of tablet pressing, if an explosive punch or hopper is found, the punch shall be replaced in time.

When you have changed the hopper, the flat surface must be cleaned, and the cleaned powder and the blasted film must be isolated and treated.

(3) The hopper is not installed properly, and there are granule particles on the flat of the turntable.

At this time, you may have to adjust the screw positions on both sides of the hopper and the hopper positions to control the material flow.

6 Tablet weight tolerance

(1) The axial movement of the lifting rod causes inaccurate measurement and the variation of tablet weight.

To remedy this, you shall check if the small turbine is worn and replace the worn parts in time.

(2) It is the improper installation of the hopper that makes the filling volume too small or not stable. Then you may need to adjust the screws on both sides of the hopper to increase the granules flow and be stable.

(3) The lower punch stamping will also affect the filling amount and lead to weight variation, then you may have to brush the lower punch hole or change the punch.

(4) You may have to check whether the die meets the standard and change the unqualified punch.

(5)The granules problem: the granules particle is too thick, and the tablet weight is unstable. Then you should weigh the tablet weight frequently and reintegrate the granules.

7 Vibration of the whole machine

(1) The shock pad compression screw is loose. The shock pad needs to be installed correctly, you can check whether the compression screw is loose. If it is loose, tighten the nut.

(2) The speed of the tablet press is not correct. The speed should be reduced or increased.

31. How to maintain the Single Punch Tablet Press Machine?

You can maintain a single-punch tablet press machine in the following ways:

1. Testing by hand

That is before the starting-up of the single punch tablet press machine, you may have to test its working parts to make sure they are in good condition and if there is no problem, you can open it.

2. Regularly cleaning of the machine

After each use every day, you may have to take out the remaining powder and wipe all parts of the machine.

If the machine is out of service for a long time, you must remove the die and clean the friction surfaces, coat it with anti-rust oil, and cover it with dust-proof clothes.

While the die shall be wiped clean and then immersed in oil for preservation.

3. Lubricating

The lubrication of the friction surface of all moving parts is significant to ensure the normal operation of the machine and extend its service life.

So, if the main moving parts are short of oil, the machine will be damaged quickly and cannot be used.

Therefore, before using the tablet press, you must lubricate all oil cups, oil holes, and friction surfaces and cover the friction surfaces with oil film when running empty, then it can be put into operation.

For every future shift, you shall also refuel on time, but not too much each time, to avoid spillage which will affect the cleaning and contaminate the tablets.

4. Inspection of the machine

You may have to check the parts regularly, at least twice a month.

And before each shift, check whether each screw is loose, and pay attention to checking frequently during the working process.

If it is loose, tighten it immediately to avoid failure.

In addition, the main parts that have screws are punching up fastening nuts, fixing screws of die, lower punch fixing screws, connecting rod lock nuts, connecting rod pin set screws, lifting fork lock nuts, and butterfly screws.

Besides, you must check the quality of the die frequently.

In case of any defect, crack, or serious damage due to deformation, it is necessary to replace the die in time, to prevent the machine and tablet quality from being damaged due to failure.

5. Measuring the Tooling System

You need to regularly measure the tooling system of the tablet press machine to make sure that it keeps the original dimensions.

If there is any change in the size, you will need to replace the tooling system, otherwise, it will affect your production efficiency.

6. Storage of the machine

You should store the machine in cool and dry condition to avoid corrosion of the metallic parts.

32. How do you check the tablet quality?

There are Pharmacopoeial and non-pharmacopoeial tests for you to check the quality of the tablets.

Tablet quality tests

The Pharmacopoeial tests are more official and standard tablet testing which include:

1. Weight variation checking

2. Disintegration time checking

3. Active ingredients checking

4. Dissolution time checking

And the non-Pharmacopoeial tests are non-official tests which include:

- Tablet hardness checking

- Tablet friability checking

- Tablet tensile strength checking

- Tablet Thickness checking

- Tablet porosity checking

33. How to deal with the pressed tablet not disintegrating within the prescribed time limit?

Generally, the disintegrating medium is water or artificial gastric fluid, and its viscosity does not change much, so the four main factors that affect the penetration of disintegrating medium (water) into tablets are:

- The number of capillaries

- The pore diameter of capillaries

- The surface tension of the liquid and the contact angle

The influencing factors of tablet disintegration include:

1. The compressibility of raw and auxiliary materials

It is reported that the raw and auxiliary materials with strong compressibility are prone to plastic deformation when compressed, and the disintegration of tablets is slow.

Some experiments showed that the addition of starch in some tablets could increase the porosity of the tablets, significantly enhance the water absorption of the tablets, and facilitate the rapid disintegration of the tablets.

2. The hardness of granules

When the hardness of granules is small, they are easy to be broken by pressure, and the tablets disintegrate slowly, on the contrary, when it is large, the tablets will disintegrate faster.

3. The compression force

In general, the greater the pressure, the slower the disintegration of tablets.

Therefore, the pressure should be moderate, otherwise the tablet is too hard to disintegrate. However, the disintegration time of some tablets decreases with the increase in pressure, so they need to be treated differently.

4. Lubricants and surfactants

Hydrophobic lubricants commonly used in tablets may also seriously affect the wettability of tablets and accelerate the disintegration of tablets.

When hydrophobic lubricant and particles are mixed for a long time and with a large mixing strength, the surface of granules is completely covered by hydrophobic lubricant.

Therefore, the pore wall of the tablet has strong hydrophobicity, which can significantly prolong the disintegration time.

In addition, tablet disintegration is also affected by other excipients.

For example, the influence of starch, starch can make insoluble or hydrophobic drugs disintegrate quickly, but it has a poor effect on water-soluble drugs.

Besides, the storage conditions of tablets are also very important.

It is understood that the disintegration time of tablets is often prolonged after storage, that is, the temperature and humidity may also affect the disintegration.

The tablets will slowly absorb moisture making the disintegrating agent unable to play its role, which results in the slow disintegration.

When the storage temperature of the sugar-containing tablets is high or the tablets are wet, the disintegration will also be prolonged.

34. What are the prospects of the Tablet Press Machine?

As the production tool of tablets, the tablet press machine has made the tablets more compact, exquisite and aesthetic, convenient to take.

Nowadays, with continuous reform and upgrading of tablet press technology, the tablet press machine industry has been moving towards the direction of high speed and high yield.

With the introduction of the new tablet press, tablet production can reach 375 million tablets per year.

However, the new technology requires the future tablet press machine should not only meet the GMP requirements, but also have the functions of dust collection and cleaning, convenient and reliable operation, and necessary adjustment devices.

Such as mechanical adjustment devices, filling adjustment devices, pressure adjustment devices, speed adjustment devices, sheet thickness adjustment devices, etc.

But also has reliable safety protection functions, such as pressure overload protection and current overload protection, high degree of automation control such as breaking and flushing protection, waste piece removal, fault alarm, automatic weighing and detection, etc.

AIPAK High-speed rotary tablet press machine

Besides, the design of the tablet pressing room shall meet the requirements of airtight (isolated from the outside), pollution-free, easy observation, cleaning, and convenient to assemble and disassemble.

Today tablet press machines with a new stable tablet pressing system preloading, long compression time and small tablet weight variation, double impeller forced feeder, progressive sealed semi-automatic grease lubrication system ensure grease lubrication, special oil proof, dust-proof and noise proof design, the surface of turntable covered with hardening layer to it not easy to wear are all can be prospected.

Tablet Press Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951