Your Best Softgel Encapsulation Machine

GMP standards

Superior performance

Compact structure

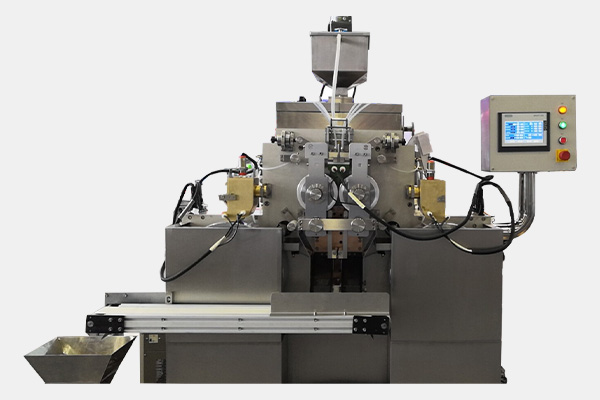

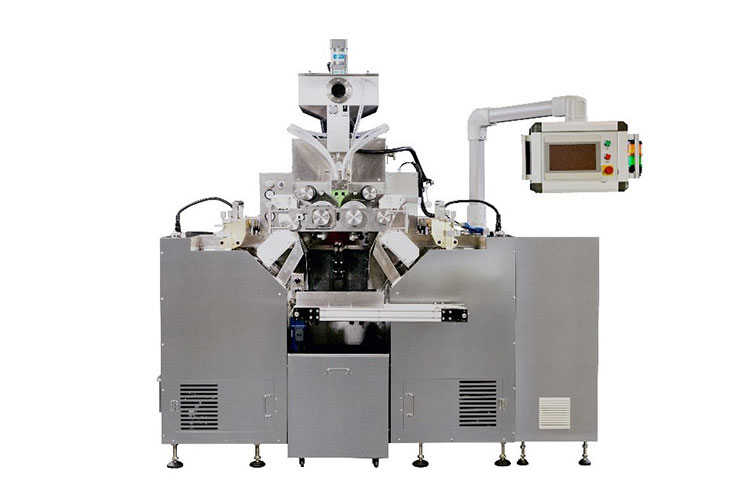

AIPAK Softgel Encapsulation Machine

AIPAK softgel encapsulation machine is designed to produce softgels from either animal gelatin or plant starch(tapioca).All AIPAK softgel capsule machine can quantificationally inject the oil, mix suspension and pasty mass into the capsule to form all kinds of soft capsules with different size, shape and color,such as egg, fish, cylinder, ball, calabash shape.With compact structure, easy operation, simple maintenance, stable performance, high production and low consumption,all AIPAK softgel encapsulation machines are widely used in pharmaceutical, cosmetic, health food and pesticide industry ,etc. Softgels are very popular especially in the fast-growing nutriceutical industry, take this chance to skyrocket your business!

Softgel Encapsulation Machine Details

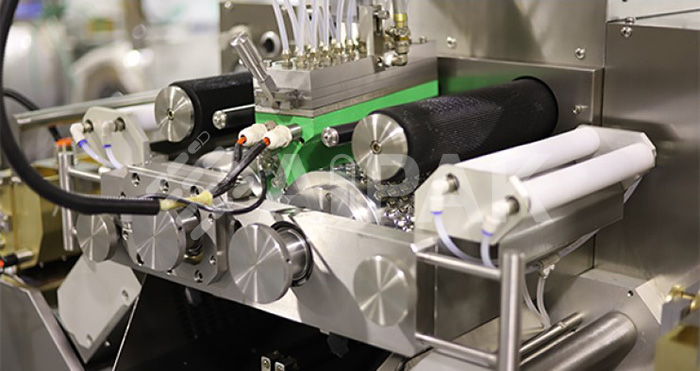

Patented die roll shaft support base structure with higher precision and longer MTBF.

Gelatin liquid level in the gelatin box is controlled by capacitive proximity switch, non-contact, stable and reliable.

The patented symmetrical loading structure of feed pump ensures the stability of dosage and the adaptability of materials.

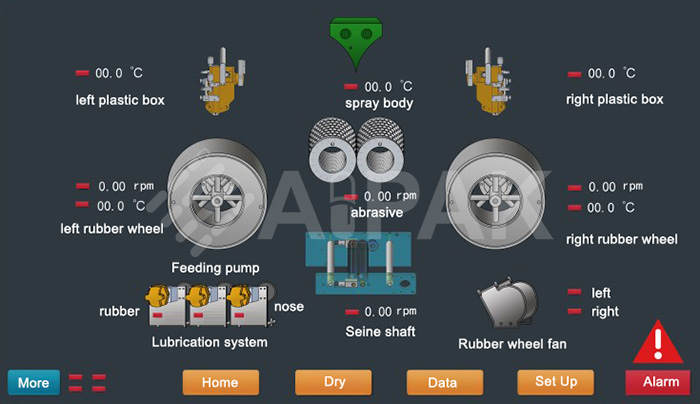

Operation interface design is more humanized, simple and intuitive, easy to learn and understand.

Patented wedge lifting mechanism, mechanical position limit structure, to prevent accidents.

Patented cold air technology of die roll can improve production efficiency and yield when encapsulating special materials (optional).

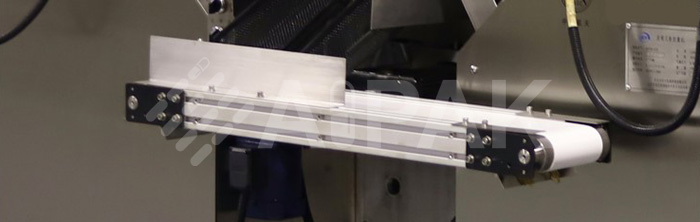

Light conveyor, small volume, light weight, convenient disassembly and cleaning.

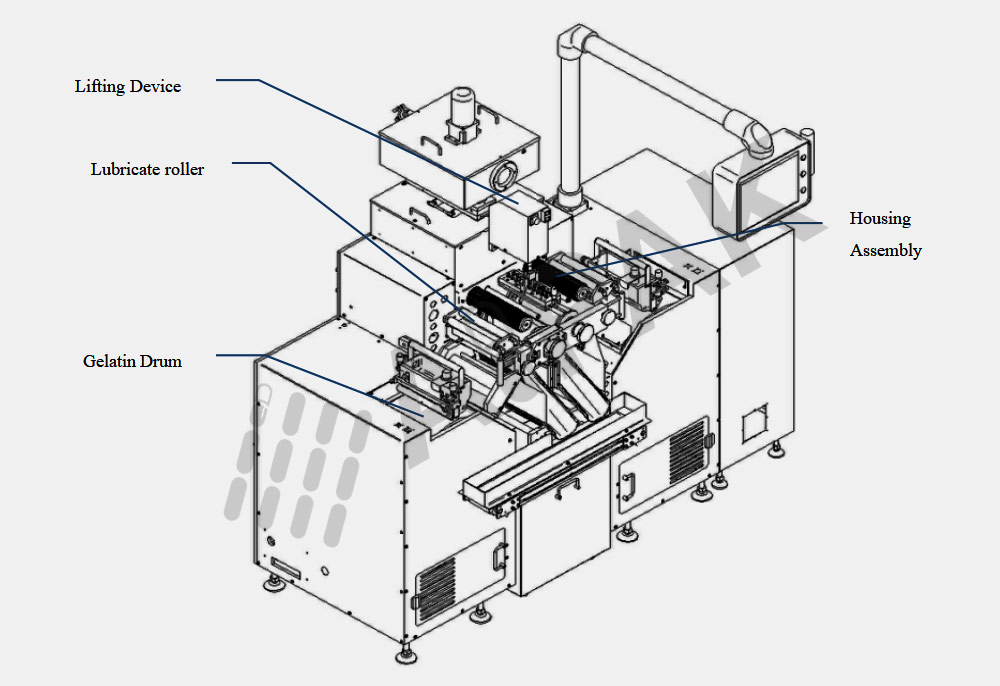

Softgel Encapsulation Machine Part Details

Softgel Encapsulation Machine Production Line Accessories

Main Machine

Prepare Tank

Gelatine Melting Tank

Colloid Mill

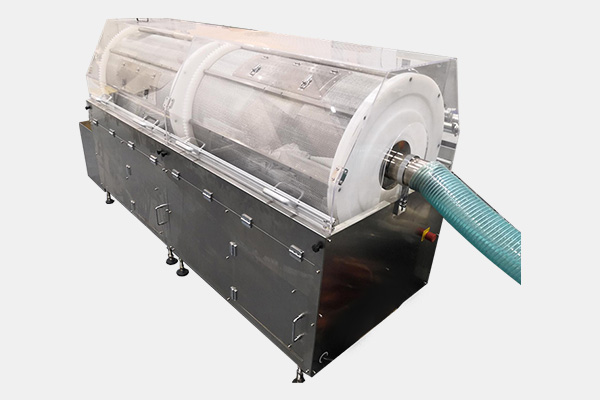

Tumble Dryer

Vacuum Pump

PVC Tray

Light Inspection Table

Drying Car

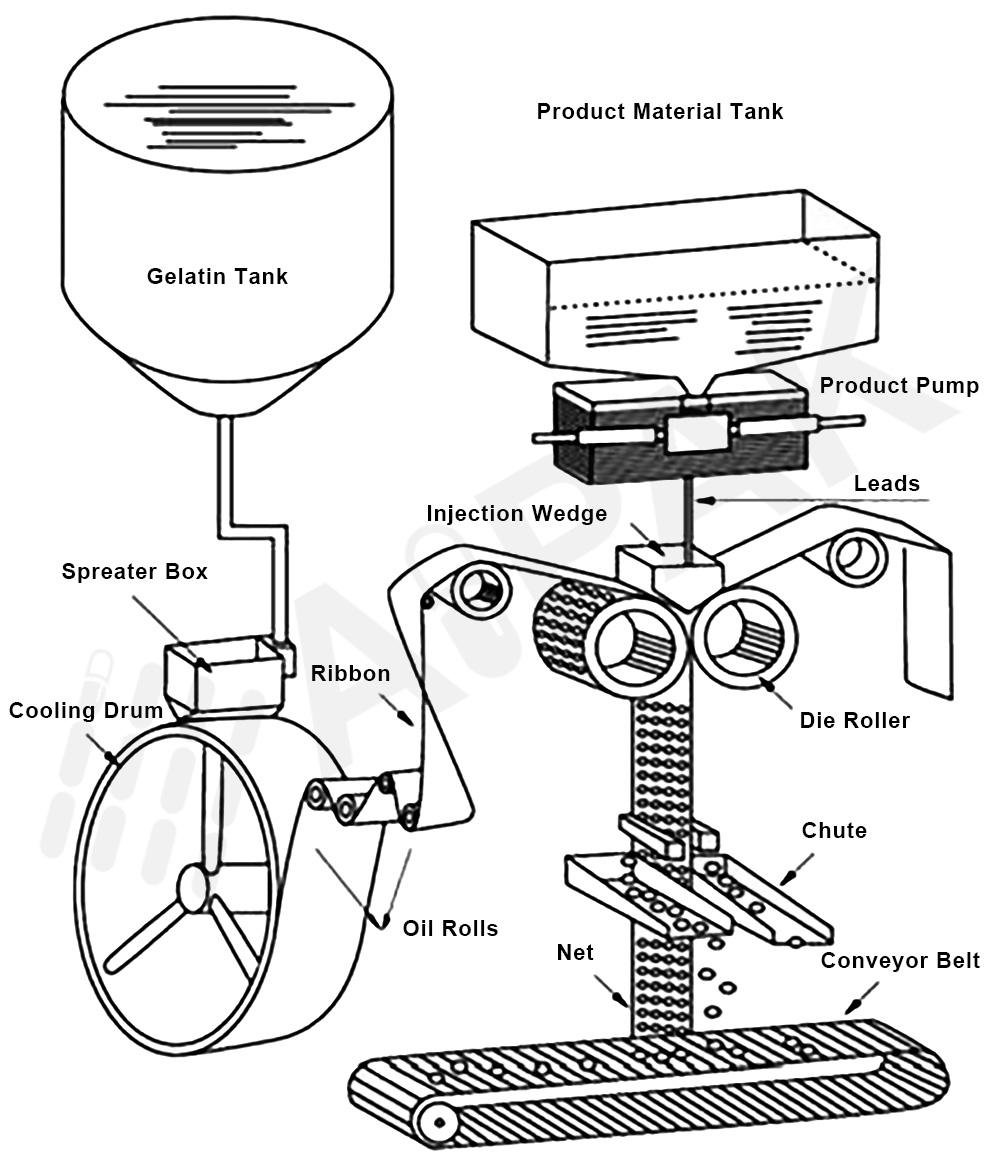

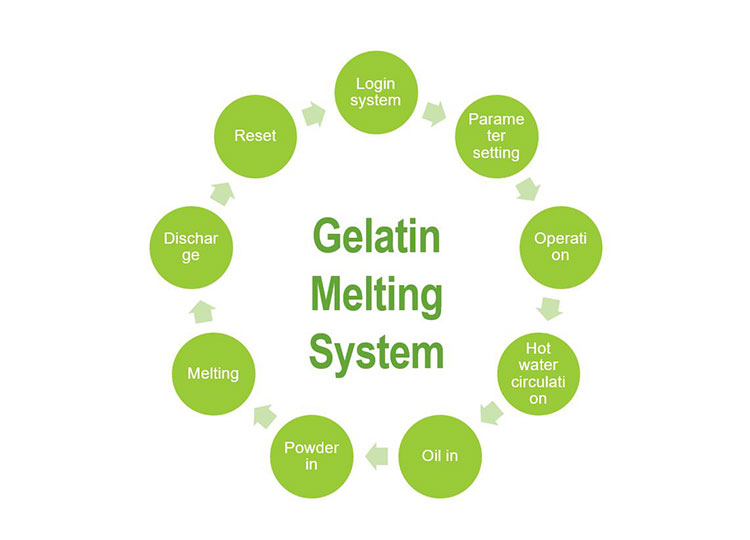

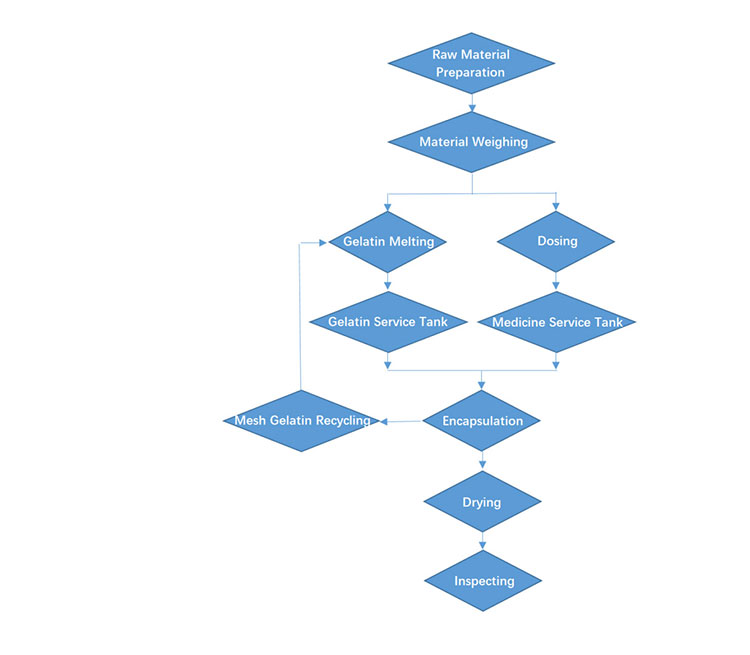

Softgel Encapsulation Machine Working Process

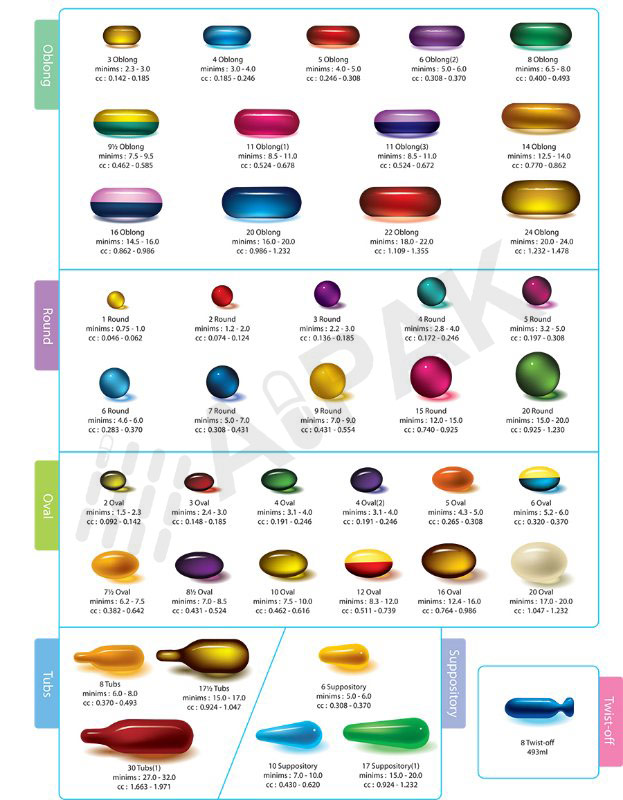

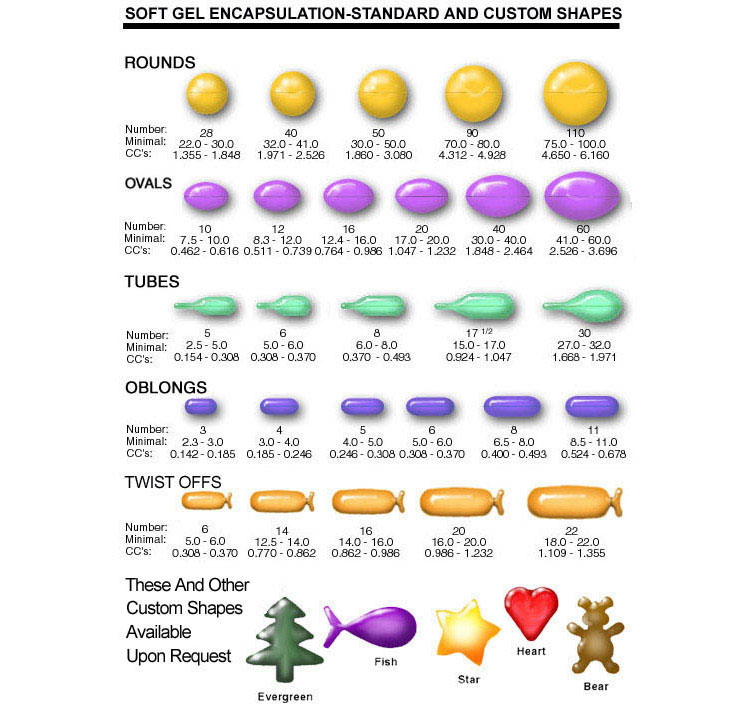

Softgel Size Chart

The Buyer's Guide

Softgel Encapsulation Machine:the Ultimate Importing Guide in 2024

Whatever you are engaged in the pharmaceutical industry ,nutraceutical industry ,cosmetic industry or leisure industry,you may not commonly see softgel as it is not only elegant in appearance but also a good protection for your active ingredients’ oral dosage potency and shelf-life.

While it is the softgel encapsulation machine that produces this magic softgel.

Today,I am going to use this article to introduce some of the most important aspects of this softgel encapsulation machine.Reading through,you will get everything you need to know about this machinery .

Now,let get started directly:

1.What is Softgel?

Softgel is a kind of sealed soft capsule with different sizes and shapes by quantitatively injecting oil, suspension, paste or powder into the capsule shell.

The softgel shell is made of gelatin, glycerin or other suitable pharmaceutical excipients that has certain strength and toughness.

Softgel

2.What is the advantage of Softgel?

You may begin to wonder why we should take the softgels,in fact,through many years’ developing and testing,we have found there are a lot of benefits of softgel.

Below you will get a list of them.

.Good protection for oral dosage potency and shelf-life.

As you know,the softgel is sealed shell wall and filled with oil and liquid,or solution.Its shell will give an unique strength and durability to it,which protects the inner material from oxidation in the air that gives good protection for the oral dosage in terms of potency and shelf-life.

.Easier swallow

Softgel is available to be made into different shapes ,colours and sizes,you will have more options to your industry and make your products more appealing .

Apart from that, softgel is suitable for consumers of all ages and makes the dosage pill easier to swallow.

.Convenient for transportation

With the sealing,softgels are also well protected from light and oxygen,and its inside ingredients are stable and well kept,so it has better performance against heat and temperature change and will be quite convenient for transportation and storage.

.Improved bioavailability

Since softgel can be filled with liquid,it has improved the bioavailability of poorly absorbed or soluble nutrients.

.Easy and flexible formulation

Softgel will allow you to make your own nutrients as its filling materials have flexible formulation.

And now more and more vegetarians prefer the vegan softgel as they can use carrageenan or starch/tapioca powder as their own preference.

3.Is there any disadvantage of Softgel?

Yes,there is some disadvantages of the softgel like:

.The gelatin can be dissolved by aqueous solution or enol solution of some medicine, so it can not be made into softgel.

.The softgel is easy to decompose in case of high temperature and heat.

4.What is the difference between Softgel and Capsule?

A softgel is a kind of capsule,both softgel and capsule consist of a gelatin based shell surrounding a liquid filling.

Capsules

While,for the capsules,their shell of gelatin can come from a variety of sources.

A softgel is easier to swallow than tablets and it is the first choice for filling oils and other liquid ingredients.

5.Which drugs are suitable for making Softgel Capsules?

Drugs suitable for making to softgel capsules are as follows:

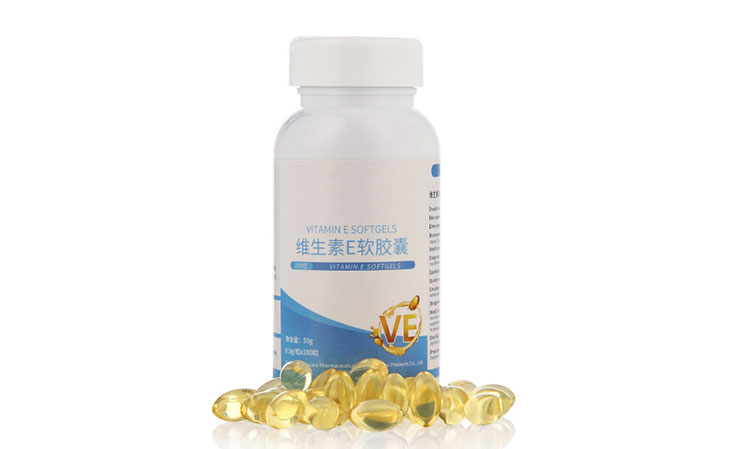

1.Oily drugs or low melting point drugs such as VE and volatile components

VE softgel capsules

This kind of medicine is liquid or semi-solid at room temperature.

When it is made into other preparations, absorption, solidification and other technologies are often used.

If the excipients such as absorbent are added, the volume of the dosage form will be increased. If the preparation is heated and dried, the drug is easy to leak out from the excipients such as the absorbent, resulting in the loss of the main drug and affecting the curative effect.

Softgel capsule is to fill oil-based drugs and low-point drugs with fat soluble solvent or made into emulsion for filling, without absorbing excipients, reducing the dosage form volume, avoiding drug exudation and improving bioavailability. It is the most suitable for this kind of drugs.

2.Hydrophobic drugs with poor bioavailability, such as NPE, are difficult to dissolve in water, with low bioavailability and unstable when exposed to light.

Like the CPE,who has poor water solubility, it can greatly improve its bioavailability if it is made into microemulsion with oily cutting body and then put into softgel capsules.

If other solid preparations are used, it is difficult to reach the effective blood concentration of CPE.

3.Drugs with bad smell and trace active drugs

Softgel capsule can cover up the bad smell of drugs.

Some trace active drugs, such as CAL (0.25ug per capsule), should be made into softgel capsules.

4.Drugs that are unstable in light, humidity and heat and easy to oxidize

In particular the vitamins which are easily affected by temperature, oxygen, heavy metals and so on.

While by mixing with oil, its stability can be increased by wrapping the surface with oil.

And in order to prevent photosensitive drugs from decomposing when exposed to light, titanium dioxide or other light shielding materials can be added to the wrapping materials.

Vitamin

The ancient and tested prescriptions of traditional Chinese medicine can also be made into softgel capsules with definite curative effect, less formula ingredients and less dosage.

The extracts of traditional Chinese medicine such as Acanthopanax senticosus, Gynostemma pentaphyllum, royal jelly, Hypericum perforatum, Panax notoginseng, wheat germ oil, perilla oil and so on are also suitable for making to softgel capsule.

6.How to make Softgel Capsules?

You can make softgel capsules through two ways:

1.Pressing Method

This way you should first prepare the gelatin solution.

As per formulation,you should first immerse the gelatin in the distilled water to make it expand.Then after the gelatin was dissolved, you should add other material to make them uniform mix.

The second step is to make film.

Take out the prepared glue solution and apply it on the flat surface of the board to make the thickness uniform.

Then heat it at about 90 ℃ to evaporate the water on the surface to form a soft film with certain toughness and elasticity.

The third step is to press the softgel capsule. In small batch production, it is pressed by hand with pressure shot mould; in mass production, it is often produced by automatic softgel encapsulation machine.

2.Dropping method

The dropping method is completed by a dropping pill machine with double drippers.

The gelatin based softgel capsule material and medicine liquid flow out at different speed in the outer layer and inner layer of the double-layer dripper respectively, so that the quantitative glue will wrap the quantitative liquid and drop into the coolant which is immiscible with the glue liquid.

Due to the surface tension, it will form a sphere, and gradually cool and solidify into softgel capsules, such as common cod liver oil capsules.

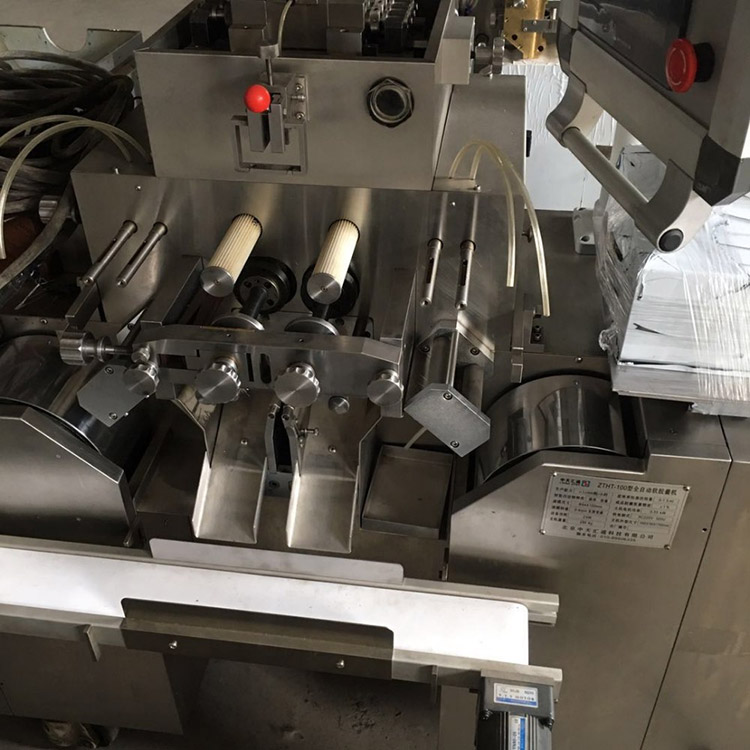

7.What is a Softgel Encapsulation Machine?

A softgel encapsulation machine is an equipment that you can use to make different kinds of softgel capsules.

It is also known as a softgel encapsulator ,a soft gel capsule machine orsoftgel machine,softgel filling machine .

You can use the softgel encapsulation machine to directly encapsulate a certain amount of liquid medicine or seal the solution, suspension, emulsion or semisolid made by the dissolved or dispersed solid medicine in suitable excipients to the spherical or oval shape of soft capsules.

AIPAK Softgel Encapsulation Machine

8.Which Indutry is the Softgel Encapsulation Machine used?

Nowadays,with the rapid development of the softgel capsule technology,as a new type of machine,the softgel encapsulation machine is more and more favored by people.

Below you will find the various industries that the softgel encapsulation machine has been widely used.

.Pharmaceutical Industry

Pharmaceutical softgel capsule

Softgel encapsulation machine has been widely used in pharmaceutical industry for the softgel capsules it has made is neat and beautiful in appearance and has the advantage of fast disintegration,high bioavailability, easy to swallow, easy to store and carry comparing with that of tablet.

Apart from that,softgel capsules by the softgel capsule machine can also cover the unpleasant taste of some drugs.

And you can also make quick acting, sustained-release, enteric coated, stomach soluble softgel capsules by the machine.

Besides,in pharmaceutical industry,some drugs with high oil content in the dosage form that are not easy to be made into tablets or pills can be made into softgel capsules,or difficult to dissolve in water and difficult to be absorbed in the digestive tract can be dissolved in appropriate oil and then made into softgel capsules.

The most common seen products through the softgel encapsulation machine in the pharmaceutical industry include: cod liver oil, health cream, bee queen, pollen, etc.

.Healthcare Industry

The widely use of softgel encapsulation machine is that nowadays,people’s awareness of health is strengthened,more and more food is made into health care soft capsules to promote health.Like the propolis, deep sea fish oil, garlic, seabuckthorn oil, soybean isoflavone, sheep placenta softgel capsules.

Fish oil softgel capsules

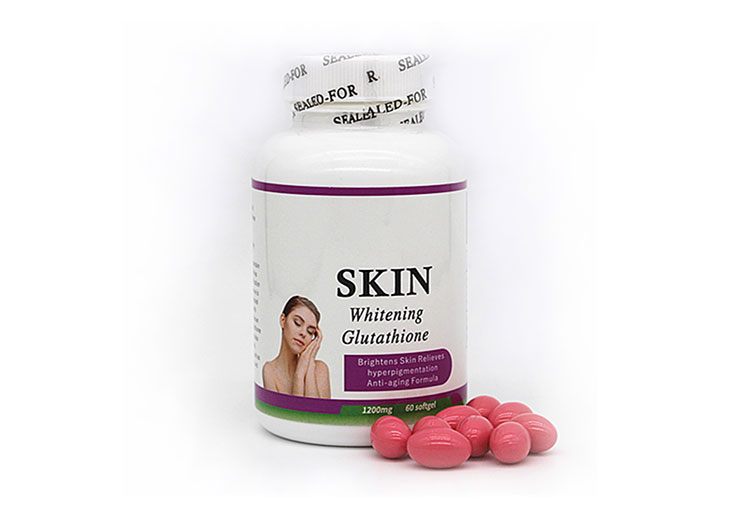

Cosmetic Industry

As easy to carry, beautiful and elegant,some ingredients with cosmetic effect are made into softgel capsules.

Thus making the softgel encapsulation machine becoming more and more popular in the cosmetics industry.

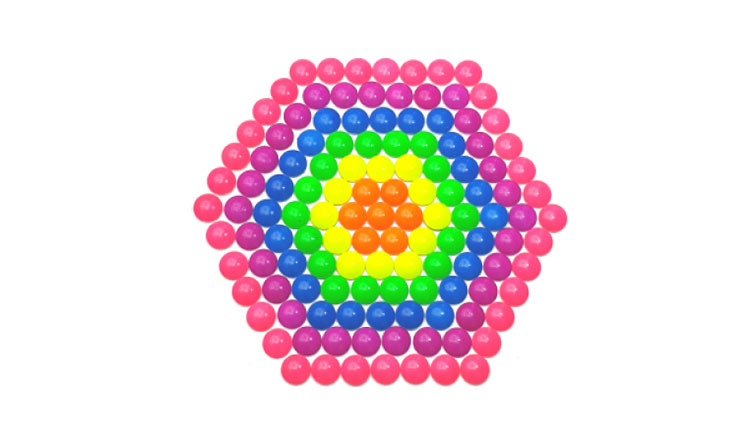

.Entertainment Industry

In entertainment industry,softgel encapsulation machine has been used to make paintball for people to shoot with it.

Paintball

Paintball shooting is a kind of movement that people confront and imitate combat / war.

It is the use of paintball to carry out person to person confrontation shooting. After hitting the human body, the paintball will be broken and leave color marks, so that the participants can not only experience and appreciate the feeling of "real gun and live ammunition" and "battlefield tearing", but also absolutely safe and reliable.

Why is paintball shooting so popular?

Because it is not only an entertainment sport, but also can exercise the physical fitness of the participants; let the participants feel its deeper significance, "shopping malls are like battlefields", how to plan to win, how to cooperate with each other in the team, how to use limited resources, and so on, which is very helpful for the promotion of individual will and the exertion of potential, and its connotation is far beyond that of other sports .

.Food Industry

In the food industry,softgel encapsulation machines has been used to make gel candies.

Gel candy

The main characteristics of gel candy are transparent, smooth, soft, sticky, and elastic. Its state system is relatively stable colloid dispersion system, and the water content is high. Gelatin candy varieties include modified starch soft sweets, gelatin soft sweets, carrageenan soft sweets, agar soft sweets, pectin soft sweets, gum gum and so on.

In fact,food products through the softgel encapsulation machine also include:dairy products, chuckles, soy sauce, soy sauce, peanut butter, cream drinks, etc.

.Chemical Education Industry

Products produced by the softgel encapsulation machine in the chemical education industry include:pigment, smooth oil, odorant, dye, emulsified asphalt, emulsified rubber, catalyst, paint, etc.

Pigment softgel

Apart from that,softgel encapsulation machine has also been widely used in other industry include the construction industry, paper industry, plastic industry, battery industry, etc

9.How many types of Softgel Encapsulation Machine are there?

There are many types of softgel encapsulation machines in the market now you can choose from.

In fact,there are many factors you can distinguish them,below you will find the lists of distinguishing ways and its respective classification.

1.Production Capacity

You can choose the softgel encapsulation machine according to its production capacity to fully meet your manufacturing requirements.They are:

.Small scale softgel encapsulation machine

.Medium scale softgel encapsulation machine

.Large scale softgel encapsulation machine

2.Automation Level

There are

.Semi-automatic softgel encapsulation machine

.Full automatic softgel encapsulation machine

You may choose as your actual production requirements,as a semi-automatic softgel encapsulation machine need to involve the human hands while the full automatic softgel encapsulation machine will not engage any extra labor.

3.Final Product

For your various products or industry,you may choose different types of softgel encapsulation machine like:

.Oil softgel encapsulation machine

.Paintball softgel encapsulation machine

10.How does Softgel Encapsulation Machine compare to Capsule Filling Machine?

You may ask what is the difference between the softgel encapsulation machine and the capsule filling machine.

In fact,there are many points that we can distinguish a softgel encapsulation machine from a capsule filling machine.

AIPAK Automatic capsule filling machine

1.You can use an automatic capsule filling machine to fill empty capsules with powders,pallets,granules or tablets.

While you can only use a softgel encapsulation machine to fill liquids,semi-liquids or suspensions.

2.You can use an automatic capsule filling machine to fill hard gelatin capsules while using a softgel encapsulation machine to fill softgel capsules.

3.In terms of cost,you will spend more purchasing a softgel encapsulation machine but low cost in buying an automatic capsule filling machine.

11.What shape and size of capsule do Softgel Encapsulation Machine make?

You can make different shapes and sizes of capsules with the softgel encapsulation machine through changing the tooling system.

Various softgel shapes -Photo Credit:Nelsonpaintball

From above,you can see that you will make different shapes of softgel using the softgel encapsulation machine,such as:

- Round softgel

- Oval softgel

- Tube softgel

- Oblong softgel

- Twist off softgel

- Other customized softgel

And softgels size made by the soft encapsulation machine can vary from #000 to #5.

12.What will you benefit from the Softgel Encapsulation Machine?

As a softgel capsules liker,there are many reasons why you should buy a softgel encapsulation machine as you will benefit a lot.

Below you will find a list of them.

A softgel encapsulation machine will allow you to produce more easier to swallow softgel other than the hard gelatin capsule or the tablets.

You will have your ingredients well preserved with the softgel capsules by the softgel encapsulation machine.

.A softgel encapsulation machine will be available for you to customize your softgel capsule size,shape or colour or even print your logo.

You will get accurate dosage filling by the softgel encapsulation machine as its filling accuracy is high.

You will have high productivity as the machine has fast working speed.

It will reduce your labor cost since the machine is fully automatic that you will no need too much work to operate it.

You will have better consumer confidence as the softgel capsule produced by the machine will guarantee the bioavailability of the ingredients you are using.

13.Are there any disadvantages of Softgel Encapsulation Machine?

Yes,there are some disadvantages of the softgel encapsulation machine.

On one hand,a softgel encapsulation machine may require higher investment than that of a capsule filling machine,and your will also spend more to install the machine.

On the other hand,you will have to hire people with richful experience and profession to guide the production or make maintenance for the machine.

Another one is that a softgel encapsulation machine is a machine with heavy weight and large volume,so you will not be easy to move it from one place to another.

14.What are the Main Parts of Softgel Encapsulation Machine?

Softgel encapsulation machine is an indispensable mechanical device that is commonly used to produce softgel capsules and paintballs.

Below you will find a list of their major components of softgel encapsulation machine and their respective functions.

It is of great impotance that you need to know every parts of the machine in case that you can stay calm when ordering the machine.

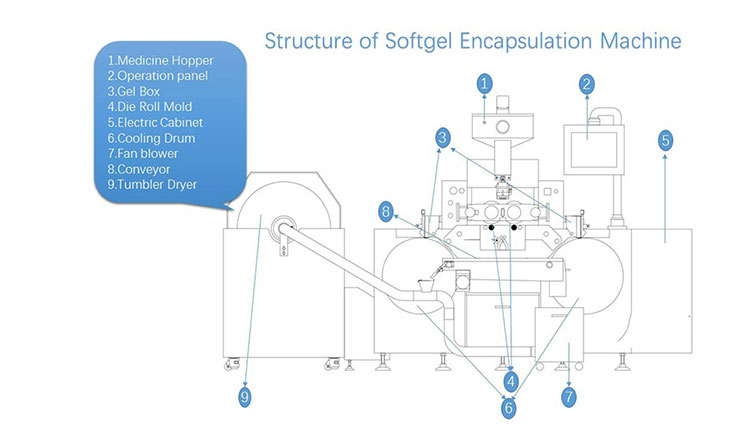

1.Medicine Hopper

You can also call this part the medicine pump or the material feeding pump,it is on the upper side of the machine and above the machine frame.

It is made of stainless steel that is stable and robust.

Here you can make the medicine hopper hold your filling medicine the capsule content that goes into the soft capsules.

Here you will find the the medicine hopper is built with a hot water jacket to offer the heat preservation function,keeping the material even solution,avoiding sediment and performing the liquid level detection functions.

Actually,the customized circulating jacket is available for you.

And when the softgel encapsulation machine is in process,you are recommeded to load at least 5 kilograms of filling material into the medicine hopper since a little filling material may cause the machine to plunge emptily.

Besides,the filtering is indispensable for the filling process,or it may cause a blockage when large or hard particles entering into the pump.

Theoretically, suitable filtering sizes are around 60-80mes though the finer particles the better.

2.Operation Panel

Now most softgel encapsulation machine adopts touch screen and PLC system,which are availabel for you to combine all the setting parameters into the PLC (programmed Logic Controller) for your easily manual setting and controlling.

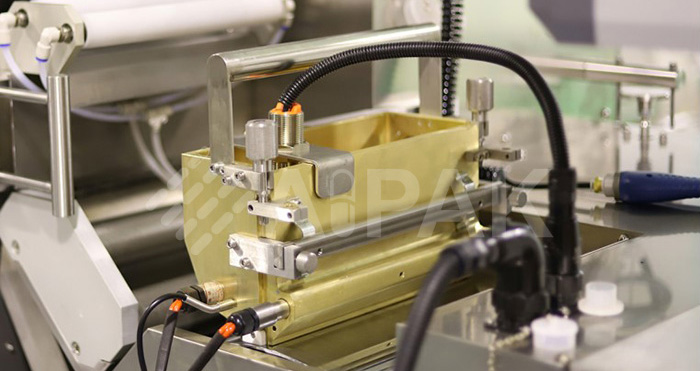

3.Gel Box

This part is used for holding the gelatin solution,and also performs the heating and liquid level detection function to guarantees the height and the fluidity of the gelatin solution.

Here you can also adjust the gelatin ribbon thickness to improve the afficiency of the machine.

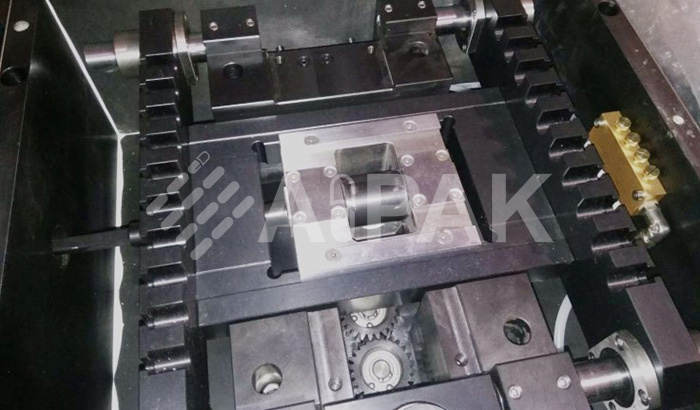

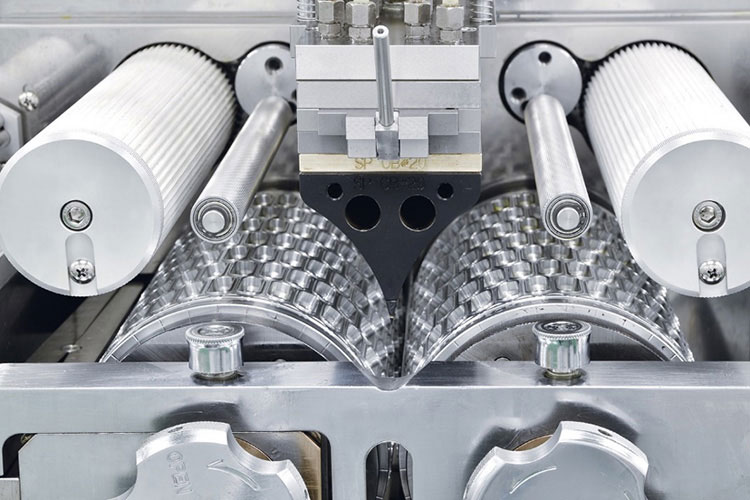

4.Die Roll Mold

Here you can also call it the softgel dies as it is a vital and precise part of the encapsulation system that determines the softgel shape,size,sealing and cutting.

Most importantly,you must know that the softgel die will alos affact the finished product’s appearance and quality.

5.Electric Cabinet

The electric cabinet is made of stainless steel that it is a box you can fit all electric components inside.

For example:the breaker,the relays,the contactors,the fuses,the terminals and etc.

As this part is the critical section that related with electric that you must pay attention that only electrician is allowed to maintain it.

6.Cooling Drum

This cooling drum can be also called gelatin ribbon drum,you will find it is locate under the gelatin box.

It is responsible for spreading the gelatin solution into the gelatin ribbon.

After from that,the cooling drum will also cool down the gelatin liuqid quickly to form a gelatin film.

And you must know that the cooling system runs through the softgel encapsulation machine to cool down the drum and the softgel dies.

7.Fan Blower

Here you may wonder what is function of this part?

It is after the softgel capsules rolling down from the encapsulation part,they will go into the tumble dryer for the next procedure cooling,however,there is a height difference between the conveyor and the tumbler dryer inlet.

Then here comes the fan blower to solve this problem by blowing the capsules up into the cooling baskets.

8.Conveyor

The conveyor is to convey the softgel capsules to the discharge part where it connects to the tumbler dryer,and it you can move it back and forth.

And the direction of the conveyor is controlled by the PLC.

9.Tumble Dryer

This section is to dry the softgel capsules after its production process.

It will drive the medicine material to the drying trays,then the drying trays will completely dry the softgel capsules once they arrive from the tumble.

And you need to know that the tumble dryers can be customized as different softgel encapsulation machine may have various size and weight of tumble dryers.

Besides,different sizes of tumble dryer may have different power consumption,you must take it into consideration when buying a softgel encapsulation.

Other parts on the softgel encapsulation machine including:

10.Air Compressor

It is contacted with the gelatin melting machine and main machine,the air compressor makes the speed of gelatin and contents uniform.

11.Gelatin Melting Tank

This gelatin melting tank is for you to add and blend all the medicine material to make the gelatin shells.

It is made by stainless steel and will make homogenous mixture for all the ingredients to make good gelatin shells.

12.Water Chiller

You will find connecting with the cooling drum ,there is the water chiller.

This water chiller helps to keep the temperature of gelatin when it pressed and filled in main machine.

It is connected with the compression moulding of the main machine.

13.Lubrication System

Just like all other pharmaceutical equipment,a softgel encapsulation machine has a lubrication system that provide lubrication to the softgel encapsulation machine where needed.

Of course,they are adjustable,you will apply this system according to your actual production requirements.

15.What is the working principle of Softgel Encapsulation Machine?

After getting all the detailed parts of the softgel encapsulation machine,you may want to know how that machine works,how to make the softgel capsules.

Here you will find the step by step procedure of the whole process of softgel encapsulation.

It can be split into 7 main steps that you will find the detailed explanation below.

Step 1:Softgel Gelatin Melting

As you know the main ingredients of gelatin are gelatin powder,water and glycerin and the softgel capsule shells are made of gelatin,plasticizer,water and optionally colorants.

Gelatin is served as the gelling agent in the capsules shell as its feature to dissolve in hot water and forms a softgel when cooling down.

Then to make the gelatin melt,you will need to firstly place the plasticizer and the solvent purified water into the tank.

Secondly,you have to add the gelatin granulates and stir the mixture under 65 – 75 °C until the granulates are dissolved completely.

While during the mixing process,there may be bubbles coming into the mixture,so the deaeration process is needed before mass softgel encapsulation.

Besides,you will also need to add extra water after the deaeration process since there may be some water loss during the process.

Then when the gelatin has good viscosity and elegant appearance,such as transparent,free of bubbles,it will be conveyed to the gelatin holding tanks through a sieve for the next process encapsulation under temperature of 60℃.

Furthermore,you can add colorant after the gelatin are discharged into the holding tank.

The plasticizers can be glycerol 85%, glycerol 99.5%, non-crystallizing sorbitol solutions, sorbitol sorbitan solution, propylene glycol.

Last but not the least,you will have to check all the well-melted gelatin liquid,heat it to a certain temperature,get rid of bubble and make it well prepared for the next process.

Step 2:Filling Medicine Preparation

This step you will need to preparate the filling material that will be filled into the softgel capsules.

The filling material can be liquid,semi liquid ,suspensions or other solutions.

You may use certain medicine to fill the softgel capsule such as the fish oil or other cosmetic powders.

Then you can place all these well prepared filling medicines into the medicine hopper.

Step 3:Gelatin and Filling Medicine Holding Process

This step you will have to transfer the gelatin and the filling medicine from the first two steps into the gelatin melting tank and get rid of the air inside the material.

The gelatin solution will have to be loaded into the gel box by the compressed air and the filling medicine has to feed up to the medicine hopper.

Step 4:Softgel Capsules Encapsulation Process

You must get it clear as this step is the most important among all the processes.

When the gelatin solution is transferred into the gel box through a silica tube by the impact of compressed air.

Here, the flowing gelatin solution will become a thin film which is also known as gelatin ribbon.

Then the gelatin ribbon will roll along with the cooling drum and cool down.

Remember that during this process,the gelatin liquid will lose some water but get more flexibility,it is important to the whole filling process because the strong flexibility the gelatin ribbon has,the better sealing the softgel will be.

When the gelatin ribbon has run a circle on the cooling drum,it will leave and go to the next rolling rod where there is a lubrication system who will lubricate to reduce the friction between the gelatin ribbon and parts of the softgel encapsulation machine.

Here,you must pay attention that no gelatin is sticking to the machine,or it will not run smoothly.

Next,the symmetric softgel molds will make the gelatin ribbon press each other,and the lower side of the softgel capsule will be sealed at first.

And at the same time,the plunge start to inject the medicine material into the formed gelatin.

And at the end of the injection,the upper side of rim of the softgel will be sealed,too.

So,here forms the softgel capsule.

Therefore,you will find the sealing of the gelatin shell rim and the filling of the medicine are happening at the same time.

Step 5:Softgel Cooling

When the softgel capsules are dropping out from the encapsulation machine,they are still wet,soft and fragile.

So here this step may involve one device:the softgel tumbler dryer .

It mainly relies on its fan and rotation function to dry the softgel to get rid of excess of moisture.

Step 6:Softgel Final Drying

This step,you need the drying tray to hold all softgel capsules.

How long will it take to cool down depends on the material you are using,noramlly 1-2 days.

Step 7:Further Treatment

Finally,after the above 6 steps,you will get the softgel capsules,but they are not ready for the final packing.

You will have to check and sort out the defective softge capsules to guarantee the best quality selling to the market.

First,you will need to use a cotton cloth to get rid of the oil if you find the softgel capsules are too oily on the surface.

Then you may need the capsule polishing machine to polish or sort out the defective capsules.

16.Which ancillary equipment do you need for the Softgel Encapsulation Process?

Softgel encapsulation technology-Photo Credit:Jspharma

From above ,you can see the whole softgel encapsulation process,to achieve this process,you will need some ancillary equipment to corporate to form a complete production line.

Here is a list for them.

1.Gelatin Meltin

You will need this equipment to mix all the ingredients like the gelatin to make the softgel gelatin shell.

And you will use it to mix through stirring,heating and melting to make the even mixture.

2.Filling Material Tank

You will need to use the filling material tank to preparate the inner filling materials,normally,they are liquids,semi-liquids,suspensions or solutions.

3.Gelatin/Medicine Service Tank

It is optional for you to choose a gelatin or medicine tank with a heat insulation coater,which has the heating capabilities.

It is useful for you to store the gelatin syrup as it will keep a stable temperature level.

4.PP Trays

You will need a PP trays to hold the soft gelatin capsules before you transfer them to the cooling tunnels or the tumble dryers.

5.Colloid Mill

This colloid mill is for you to grind the different kinds of substance or medicine ingredients to make the softgel capsules.

6.Tumble Dryer

A tumbler dryer will help you to make your softgel capsule get rid of the excess moisture,you just need to place them under it for a while.

7.Softgel Polishing Machine

Pan Softgel Polisher-Photo credits:Secsoftgel

To get rid of the excess debris from the formed softgel capsule,you will need to use a softgel polishing machine ,which will not only help you make your softgel more cleaning,but also will help you sort out the defective ones.

8.Softgel Inspection Machine

After the whole production process,you will need a softgel inspection machine to have all the softgel capsule checked before going for packaging.

Inspection items include the soft hardness,abnormal shape and size,defects on the surface, too greasy and non-smooth,adhesion,bubbles abnormal seam, and foreign objects.

Actually,there are other supporting equipment for the whole encapsulation process,like the like the hot water exchanger, vacuum condenser, vacuum pump, hot water pump, valves, pipes,which are optional but meaningful to guarantee high quality softgel capsules.

17.What is the environment requirement for the Softgel Encapsulation Process?

Production environment requirement for the softgel encapsulation process should include:

The temperature of the air conditioner should be kept constant humidity and constant temperature in the production workshop.

The indoor temperature of the mixing room of the softgel capsule equipment should also be kept at 20-28 ℃.

For the RH60%, the room temperature for the drying room should be 24-30 ℃, and the RH40% should be below.

For the pressure pill room,the inside temperature should be controlled at 21 ~ 24 ℃ and Rh should be between 40% ~ 55%.

For the pill picking workshop of softgel capsule production, the indoor temperature should also be 20 ~ 28 ℃, RH should be below 60%.

18.How to operate the Softgel Encapsulation Machine?

There are eight steps for you to operate the softgel encapsulation machine,namely:

- Press the green button in the "switch" to turn on the power.

- Slowly adjust the "vibration intensity adjustment knob" and turn it clockwise. At this time, the finishing disc integrated with the "vibration support" starts to vibrate. Then touch the plate with your hand and adjust it to a certain vibration intensity by feeling.

- Put the emty softgel capsule shells into the feeding hopper, here you just need to put about 300 capsules each time.

Put the softgel capsule caps into the "capsule cap finishing plate", about 300 capsules each time.

The finishing plate is made of plexiglass plate. There are many funnel-shaped holes drilled on it. The diameter of round hole is corresponding to the diameter of softgel capsule size.

- After about 30 seconds, the capsule shell and capsule cap will fall into the round hole with the opening upward.

- In case of individual capsule cap opening downward, you can gently press them down.

- Horizontally hold the powder loaded capsule shell connecting plate ,push the lower part of the sorting plate inward slightly, and the powder loaded capsule shell in the sorting plate will fall down into the round hole of the connecting plate, and then take out the connecting plate. In the same way, take out the capsule cap with the capsule cap connecting plate.

- You shall prepare a powder square plate with bottom area of 500 × 500mm2 and height of about 10 mm on four sides in advance.

Then you will have to place the empty softgel capsule shell connecting plate in the square plate.

Then cover the randomly equipped plexiglass frame on the powder loading capsule connecting plate, put the powder into the box with a small bucket, scrape the edge of the frame to fill the powder, and scrape off the excess powder.

- Place the softgel capsule cap plate on its connecting plate with the alignment hole,

- Then turn the capsule cap cover connecting plate toi make the capsule opening downward, to make it cover on the powder loaded capsule shell connecting plate that loaded with medicine powder. There are also alignment holes, so it is easy to fit.

- Put the assembled capsule plate into the cavity under the "capsule cap forming plate", pull the "pressure bar" downward by hand and put it in place.

There is no need to worry about excessive force because there is a positioning mechanism to control the pressing height.

Last take out the softgel capsule board and pour out the softgel capsules.

19.What Documents do you need for the Softgel Encapsulation Machine?

AIPAK Softgel encapsulation machine

When buying a softgel encapsulation machine,you will have to ask your supplier for these documentns for the safety and normal running condition of the machine.

At AIPAK,we can provide below documents to you,namely:

FAT

We will provide the FAT certificate to you to guarantee the machine is in good working condition.

IQ

This IQ document is to certificate that the machine has passed the qualfied inspection and will work well after installtion.

OQ

This document is also to guarantee the good working condition of the softgel encapsulation machine.

Its full meaning word is operation qualification ,that is to say,it must meet with the production specification .

Of course,at AIPAK,we will also provide other standard documents include the machine standard operation, cleaning, and maintenance SOP.

20.How to make different shapes and colors of softgel capsules?

You know that the softgel capsules have many different shapes and sizes and a softgel encapsulation machine can be used to manufacturing all that via changing the rotary rolling dies.

While before you start the production of a new shape,you should realize that the softgel capsule mold size is the same as the machine is still the same.

In other words,the cavity quantity in the mold is limited and bigger softgel size or special shape will occupy more space but less cavity number on the softgel die.

That is to say,the mold runs a cycle,the softgel capsules formed will be less.While the production time keeps the same and the gelatin will be more,which will add to your production cost.

Normally,the most common softgel capsule are 500mg Oval shape and 1000mg Oblong shape

And to make colourful softgel capsules,you will need the pigment grinding and gelatin coloring machine.

21.Which factors will affect the Softgel Encapsulation process?

Have known all the working process of the softgel encapsulation process,you must have understood there are some factors that may affect it.

Actually,apart from the machine itself,the environment condition,there are other factors that may also affect the production efficiency.

Getting to know them and taking into consideration when considering to buy one,you will have your production improved and eliminated extra cost.

Of course,the machine is fully automatic that will alert you whenever any condition happens.

1.Gelatin Formulation

The gelatin formulation will affect the softgel encapsulation process that you must make sure you use the right ingredients and proportion in making the gelatin formulation.

2.Speed

The higher speed of the softgel encapsulation machine means the higher production capacity and efficiency.

That you must determine as your actual production requirement to choose the speed of the machine.

3.Drying Process

Different products may involve different drying process and drying machine that means you must determine to choose the right machine according to your actual products needs.

4.Quality

Anyone knows better quality machine means better efficiency and better encapsulation process.

So you must choose a softgel encapsulation machine with qualified quality.

5.Auxiliary Equipment

A complete softgel encapsulation line must involve some auxiliary equipment,which will also affect the efficiency of the encapsulation process.

To have best efficiency,you must consider to choose better auxiliary equipment.

6.Operator proficiency

That means you must hire or train your operator with necessory knowledge of the softgel encapsulation machine before make it run.

This will save your time or improve your machine efficiency.

7.Inpection Assessment

You must have standard inspection assessment to inspect all the final softgel capsules to make them qualified to be sold on the market.

22.What Basic knowledge should you get before operating the Softgel Encapsulation Machine?

As you know the softgel encapsulation machine has been widely used, in order to better use it, you need to have a certain understanding of its operation knowledge before use, let's have a detailed understanding.

Can the equipment produce high viscosity products

You should know whether the equipment can produce high viscosity products since viscous liquid with high viscosity is easier to press and even suitable for paste materials.

The spray body is designed with rectangular straight nozzle, which makes the formation of the capsule more beautiful.

In addition, the decrease of spraying speed can also reduce leakage.

The heating system should be checked frequently at the feeding hopper

According to the process requirements, the ground feeding bucket and hopper should adopt

insulation design, and the gelatin box should be designed as an automatic constant temperature control system for heat preservation and electric heating.

Glue feeding system

Automatic glue supply and feeding system engineering is adopted to reduce the labor intensity of workers and improve the working environment, which is more in line with GMP requirements.

Control the agitator and liquid level in the hopper

For the agitator in the hopper and liquid level control.

Liquid medicine hopper agitator is a screw agitator. There are two ways to measure and control the liquid level.

One is the floating ball sensor, which is suitable for the materials with good fluidity, and the other is the capacitive column sensor, which uses the liquid conductivity to measure the liquid level, which is suitable for the viscous materials.

Types of lubricating oil system of equipment and rolling die

The micro oil supply technology is adopted for rubber and rolling die lubrication.

The amount of lubricating oil can be adjusted according to the needs, so that the consumption of lubricating oil can be reduced to a low level.

The liquid paraffin oil on the surface of the soft capsule is very few that will make the clean more easier.

Type of conveyor belt

At the outlet, the conveyor belt should adopt PLC automatic control speed, 316L stainless steel mesh belt conveyor.

How to control the thickness of rubber

It provides a professional "formula" function, which can store multiple groups of formula data. The speed of each rubber roller and spindle is separately controlled by frequency conversion, and can be adjusted according to the requirements.

Rubber lubrication

The rubber lubrication should adopt micro oil supply technology to reduce oil consumption.

If you use vegetable oil lubrication, you do not need to wash pills (without printing).

Pelletizing device

The pelletizing device should be non-toxic, non sticky and easy to clean.

Water cooling system

Advanced water cooling system can avoid air pollution.

It is necessary to have optimized design of die, aviation alloy materials, high-precision CNC machining, special surface treatment to ensure the service life of the mold.

23.How can you make uniform softgel capsules with the Softgel Encapsulation Machine?

For large scale softgel manufacturing,it is important to guarantee the uniform of the softgel capsules.

In fact,there are ways for the softgel encapsulation machine to control.

First of all,you should have finalized the specification at the beginning of the production.

Secondly,you may guarantee the even mixing and melting of all the gelatin shells and the filling medicine material substances as can a uniform mixture guarantees the maximum utilization of them.

Then you may have to make correct setting for the tooling system to acquire uniform for the softgel capsule sizes and shapes.

Apart from that,make the best and maximum use of the softgel encapsulation machines can also guarantee the uniform of the softgel capsules.

That refers to ,for example,the feeding hopper or the liquid loading hopper that ensures the accurate filling process of the softgel capsules.

Finally,regularly maintenance for the softgel encapsulation machine will also can guarantee the uniform,or regularly inspect or replace the easily worn parts like the sealing system,the tooling system or the valves.

24.How can you print on the Softgel Capsules?

You may want to print your logo or some special meaningful words on the softgel capsules,actually,there are a ways you can use to make the printing on the softgel capsules.

1.Mold printing

This way needs a hard mold with engraved patterns or letters.

First you may put the softgel capsules in the mold,then the printing ink will tap the capsule surface quickly.

Of course,the ink used to print is food grade.

This kind of mold printing is a little easy that you can only print one color one time or can’t print too many letters or too complicated patterns one time.

Printing on the softgel capsules

2.Laser Printing

You may use this laser printing to engrave whatever you like on the surface of the softgel capsules,and the font finess can be 0.005mm.

3.Inkjet Printing

This method printing one the softgel capsules need the printer works with a computer LCD panel display,that is where you input your favorite words or patterns through the keyboard.

Once the photoelectric sensor finds the softgel capsules passing by,it will shoot certain amount of food-grade ink to the surface of the softgel capsules.

This inkjet printing is a very effective and easy to operate way of printing,it is more accurate than that of the mold printing.

25.How to troubleshoot common problems of Softgel Encapsulation Machine?

You may encounter some problems when operating the softgel encapsulation machine.

Below I have summarized some experience in solving problems that may happen during the encapsulating process and possible situations that may occur.

The capsule and shell could not be separated

The capsule shell needs to be replaced due to its own reason.

The vacuum is too small, as can be seen from the vacuum gauge.

There are many reasons why the vacuum is too small. If the vacuum pump is due to its own reason, you should ask the maintenance personnel to repair or replace the vacuum pump.

If the air pipe separated from the vacuum pump connecting the capsule shell is broken, you should replace the air pipe .

If the filter membrane of vacuum pump is blocked ,you should clean it.

There are also other reasons such as water flow is too small, the you should replace with larger water flow pipeline.

You will have to check if the gap between the module and the capsule separator is too large, the you should either adjust the the height of the capsule shell separator, or check if the module or the telescopic rod in the module has problems.

Or if the powder is too fine to stick.

Check if the module is not well placed.Then adjust the module with the debugging lever until it is automatically positioned.

If the powder is too sticky to block the module,you should clean the module.

The head and tail of the capsule are concave

1.Sometimes there is a problem with the capsule itself. I have encountered a lot of this before, and it will be solved by replacing the capsule shell.

2.Another is to check whether the height of the thimble needs to be adjusted. Sometimes it can be solved by increasing the stress area of the bursa.

The softgel capsule's seal is split

This is a headache, and it is often encountered. It needs to be treated carefully. This phenomenon is generally due to the following reasons:

The difference between capsule cap and capsule body is too large. Then you should replace the capsule shell.

It is maybe too much powder remains on the module. Then you should clean the modules.

When installing the module, the upper and lower die are not well aligned, and you can re align the module until the debugging rod automatically set down.

In fact, it is also related to the particle size of the powder.

If there is such a reason, this item should be added in the verification to see whether the particle size can lead to wedge phenomenon.

If it is confirmed that this phenomenon does occur, you should consider to replace the powder during the whole granulation.

Check whether the thimble is too high at the lock of capsule shell and cap.

To solve the problem, there is a way to try to shorten the distance between the upper mold and the top plate.

Of course, the distance could not be too short.

Too big difference of loading capacity

There is no fixed method for this problem.

You should readjust the filling rod.

As it is directly related to the powder.For the consideration of the equipment, you should refuse to fill directly and ask granulating post to rework.

The distance between the powder scraper and the dose plate should be 0.5 mm, as long as the dose plate is not touched.

If the distance is adjusted higher or shorter, the loading capacity will be directly affected. Sometimes the loading capacity is low, you can try to increase the distance. If the filling rod is not pressurized at a short distance and the loading capacity is too high, please ask the granulating post to rework directly.

The bearings at the outlet of the finished product, the locking position, and the removal of the waste bag are blocked.

It is basically because the powder appears after the powder enters.

So you should clean the bearing in time and apply appropriate amount of oil.

It is better to add butter in these places than to machine oil.

After cleaning, make sure that the bearing has been dried, otherwise, it will be blocked immediately.

Last,remember the bearing should be removed for cleaning and oiling each time.

26.How to maintain Softgel Encapsulation Machine?

Softgel capsule is an ideal medicine packaging process in the field of medicine and pharmacy.

As a softgel encapsulation machine, it has a very close relationship with the development and technical progress of softgel capsule.

Softgel capsule is a kind of economical and practical equipment for filling capsule drugs in pharmaceutical industry because of its sensitive operation, accurate filling dose, novel structure, beautiful appearance and convenient operation.

So how should you maintain it in normal use?

Next, I'd like to give you a brief introduction:

1.As the softgel encapsulation machine belongs to the vibration machinery, you should always check the fastening of the screws in each part, if loose,you should be tighten them in time to prevent failure and damage.

2.The plexiglass parts (worktable plate and drug plate) shall be kept away from direct sunlight and close to high temperature, and heavy objects shall not be placed.

The medicine plate must be placed vertically or horizontally to avoid deformation and damage.

3.The electrical shell and body must be grounded to ensure safety, cut off the power supply after work.

4.At the end of each day, you should clean the residual drugs on the machine and in the mold hole to keep the whole machine clean and hygienic, and avoid washing the host machine with water.

If the mould on the machine needs to be cleaned, the fixing screw can be loosened, and the installation is convenient.

5.Generally speaking, the temperature of the air conditioner should be kept constant humidity and constant temperature for the application of softgel encapsulation machine in the production workshop.

Secondly, the indoor temperature of the mixing room of the softgel encapsulation machine should also be kept at 20-28 ℃.

For the RH60%, the room temperature for the drying room should be 24-30 ℃, and the RH40% should be below.

Moreover, the pelleting room is special important,the temperature should be controlled at 21-24 ℃ and RH should be 40% - 55%.

For the pill picking workshop of softgel capsule production, the indoor temperature should be 20-28 ℃, and RH should be below 60%.

27.What do you need to consider when buying a Softgel Encapsulation Machine?

As buying a softgel encapsulation machine will be high cost of your budget,there are some factor you should consider.

First you should be aware of your production needs,how many softgel capsules do you need to be produced every day?How many shifts do you have?How long is your working time?

That means your daily production quantity should be your per hour quantity multiply your working time and your total shifts.

Then you may consider the failure rate on the actual manufacturing,and choose a softgel encapsulation machine with a capacity 10-15% higher than your real production requirements.

Secondly, you should be aware of how many auxiliary equipment do you need to corporate with your actual production and how does the size of the auxiliary equipment should be.

For example,if your softgel encapsulation machine continuous working for 20 hours,it will use up twice material than that continuous working for 10 hours,so when you are choosing the gelatin melting tank and medicine preparation tank,the size of them should match with that and the quantity of tumble dryers should also be accordingly.

Thirdly,the biggest factors you are considering when buying a softgel encapsulation machine is the price.

AIPAK Softgel Encapsulation machine

You may wonder why there is so big a difference between different softgel encapsulation machine supplier and how to choose a most suitable price for your own.

Actually,it is different machines offered by different suppliers may have different design and configuration,which make various quality and price.

Then you may need to negotiate with the supplier to get all the necessary information about the machine and make the final choice.

Forthly,when you have got clear production capacity about the machine,you may also need to know the actual size of the machine to plan enough cleanroom to hold these softgel encapsulation machine and its auxiliary equipment.

Fifthly,you should also consider the installation and other details,like if your factory corridors and doors are wide enough to let all the devices pass by.

The cleanroom,actually can be made after the softgel encapsulation machine entering to your factory in case any unnecessary things happen.

And you may consult with the supplier for the installation to see if they have onsite installation service or training or installation video for your reference.

Or if there is installation space and maintenance space difference than the actual machine space.

Finally,it is critical for you to negotiate with the supplier to get clear about the wiring and piping things as for a senior and professional supplier,they will reminder you about such things and for using a softgel production line will involve the clean water,hot water,vacuum,compressed air and power.

You have to know all the details like what size the pipes should be,what is the power consumption,where should assemble the water supply .

It is better these details should be included in documents for your buying or have detailed video of explanation.

28.What is the Future Prospect of Softgel Encapsulation Machine industry?

Nowadays,the market of softgel encapsulation machines has become more and more large.

The production technology of softgel encapsulation technology has caught up with or even surpassed the counterparts abroad.

As a result, China has added some weights to the international market, softgel capsule health food is gradually becoming a better position in the health food packaging industry with its irresistible advantages.

In the fields of medicine, health care products and cosmetics at home and abroad, the softgel capsule is becoming a new trend of packaging.

However, from the current domestic market point of view, whatever in terms of variety, quantity, use, appearance and other aspects ,softgel capsules are far from meeting the market demand, and the development space is still quite huge.

Softgel capsule with its sealing, attractive appearance and easy to carry is active in the packaging market of medicine and health products.

AIPAK Softgel Encapsulation machine

With the increasing improvement of people's living standards, the market demand for various softgel capsule preparations is also growing.

Nowadays, the continuous increase of oily drugs, health products and other products, as well as the redevelopment of traditional Chinese medicine products in recent years, the vigorous promotion of the modernization of traditional Chinese medicine, the demand for softgel capsules, and the rise of domestic soft capsule equipment manufacturers have further expanded the market prospect of soft capsule production.

The influence of traditional Chinese medicine (TCM) is growing with the popularity of natural products and the rise of natural therapy.

Nowadays, the health care and therapeutic effects of traditional Chinese medicine are gradually recognized by European and American consumers.

Due to the strict control of prescription drugs in Europe and the United States, and the relatively easy import of over-the-counter drugs and medicated health products with non obvious therapeutic motivation, this has become a breakthrough for China's pharmaceutical industry to enter the western pharmaceutical market after its entry into the GATT, among which traditional Chinese medicine preparations can be called the most Competitive direction.

However, the traditional Chinese medicine is mostly in the form of decoction, pill and paste. Its appearance and taste are difficult for ordinary people to accept, and the dosage is not convenient to use and carry.

While when traditional Chinese medicine uses soft capsule preparation, it just makes up for the above shortcomings.

The Chinese medicine and nourishing nutrition products produced by the softgel encapsulation machine are especially welcomed by users at home and abroad.

Therefore, the softgel encapsulation machine will become a new bright spot in the packaging of drugs, health care products and household chemicals in the future.

Softgel Encapsulation Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951