Buying your first automatic pharmaceutical equipment must be a tough decision.

If your business comes to a plateau and you are wondering if it’s time to invest in automatic pharmaceutical equipment, we’re here to help.

Popular First-Time Pharmaceutical Equipment

Our first-time buyer’s guide will let you know every aspects of different types of pharmaceutical machineries,acquire the answers to the most commonly asked questions,and provide suggestions and notes when you are considering purchasing the most suitable pharmaceutical machines.

Frequently Asked Questions

In fact,there is no quick answer to this question.Pharmaceutical machinery may vary by supplier,brands,parts,size,productivity,etc.To suit for your various production requirements,the pharmaceutical machines may be assembled with different parts or tools,so it’s not practical to define a “standard price”.

Whatever,you can contact with our expert team to tell us what’s your budge,what your raw material,what effect or productivity do you want to achieve ,we will come up with a complete suitable solution for you.

Anyway,the more complex,customized or high-precision automation work you want ,the more you should expect to pay.

The good news is that as long as your configuration reuqirement to that pharmaceutical equipment is not too complicated or hyper-customized,the equipment will be quite easy to operate!And actually,most AIPAK pharmaceutical machines are equipped operation instruction manual for your reference and operation explanation video for you watch and then practise ,that is,don’t require too much senior technical knowledge to operate.

Besides,modern equipment are more automatic than ever ,there is HIM to guide your operation and tips,warning when your operation goes wrong .

If you still worried about the suitation,you may seek the help of our expert engineer, who will remotely guide your operation.

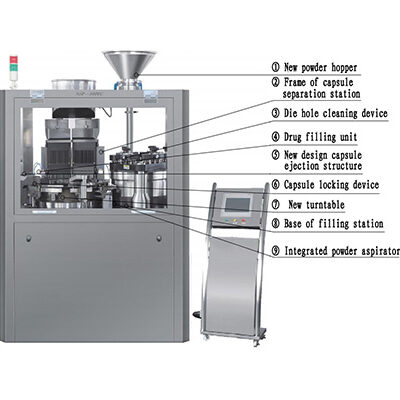

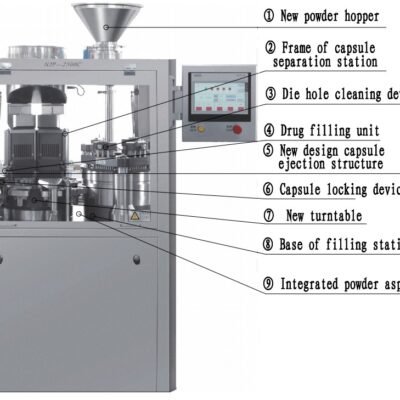

As one of the largest pharmaceutical equipment in China,what AIPAK supplied machines can meet your various material processing requirement .From powder capsule filling,packaging,cartoning,liquid filling,packaging,sealing,granules crushing,granulating,tableting,coating to semisolid processing,etc.

Besides,AIPAK also offers various scale of gummy making machines,that is making your drugs as well as manufacturing your additional nurition.You can use our gummy bear machine to make different shapes,size of jelly,gummy candy or adding different nutritional supplements to making your unique gummies.

Another category of our pharmaceutical equipment is horizontal liquid filling sealing machine and rotary packing machine,with which you can pack your liquid,foodstuff,cosmetic products.

A fully automatic machine stands for machine with high speed high productivity and less or no human operation involvement.A fully automated production line indicates the equipment could all automatically load the products,feed the materials,dishcarge the finished product or keep the whole production line running in order.Of course,automated machines provide a high level of accuracy and stabile performance,that as a result require larger investment.

A semi-automatic machine is half automated that requires human to assist to guarantee normal running.So,a semi-automatic machine is suitable for small scale pharmaceutical factory or who has not too much requirement to the productivity per hour.Semi-autoamtic machine will be your good choice if you are new beginner or if you are not well prepared for the full automation.In fact,some customer may choose a semi-automatic machine and integrates them with other machine to form a fully automated production line.In a word,semi-automatic machine has much lower cost for your beginner but at the same time may has lower generation or accuracy than of fully automated machines.

Generally,the answer is some of “yes”.Most of AIPAK pharmaceutical machines are design with good compatibility,that is ,you may change the mold or adjust the running model to make machine handle various raw materials or change some part of the machine to make it suitable for producing different size of product.

On the other hand,the answer may be “no”,some machines may only handle defined raw material or produce one size of product.That is ,the more different need you require,the more the machine may need to make sense to invest in multiple system that can only generate good result at defined prcess.It can also explained as the machines are optimized to run defined parameter.And if your needs are varied,it may be hard or inefficient to run the machine at the same time.You may prefer a machine that does one thing good other than it has many functions but just Ok doing them.

This answer is yes,since as your equipment gets older,it may require more maintenance to guarantee a stable running performance.Routinely call a maintenance specialist may cost you so much.

By investing in a new pharmaceutical machine,who will give more reliable and desired performance.For the long run,it worth doing and ,you time,money or customer are likely worth more than the hard time reparing the older equipment.

Buying the most up-to-date equipment can benefit you in so many ways,but only with proper usage and training,maintenance.

In most cases,most people may only purchasing the best equipment on the market,only always use it to the same things.In fact,sometimes,investing in traning or learning about that machine can ensure the long term running or make it to its fullest potential,further maximizing your return on investment.

LEARN BUYER’S GUIDE

Good tips to learn various benefits or drawbacks of the machine,try your best to understand the working principle,standard requirements it need to meet with,then get clear what result you really want.

BEFORE REQUESTING QUOTATION

Think it’s time to request a quotation? First,take some time to review what’s your raw material,what’s the result you want,what’s your factory occupyation,your budget for the project,your productivity requirement.

PREPARE YOUR FACILITY

What will it take to get your facility ready for the new pharmaceutical machine?Actually it may more than you think.But take it easy,we have numberous solution for your choice to suitable for your various needs.

THE NUMBERS DON'T LIE

Wandering if your investment worthing?That may take some time,for the long term running,there is no better way to decides if the automated machine is worthing for your business.Let’s do the ROI calculation to think about it in another way.

Learn More About Pharmaceutical Equipment

GET A CONSULATION