PACKAGES

PRODUCTS

BAG STYLES

Capsules

Capsules have been a very reliable and widely accepted method form of encapsulation for nutraceutical formulas.

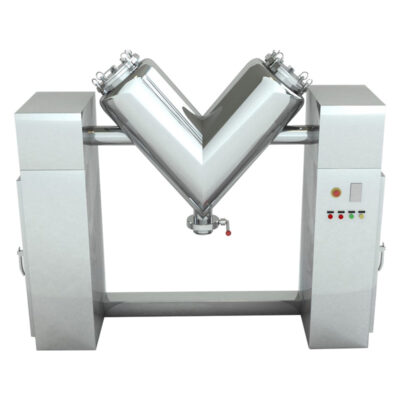

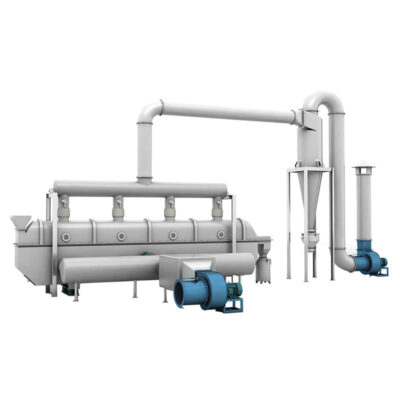

Before encapsulation, your formula must be blended to ensure even distribution of ingredients in each capsule.The powders within the capsules have to be prepared in two ways,wet granulation and dry granulation process.

AIPAK offers a wide range of wet granulation machines,fluid bed dryers,blenders and pharmaceutical dryers for making your formula ready and mixed.

The dry granulation blend is to apply immense pressure and force to make your powder more compact and increase the bulk density.

Once all ingredients in your formula are blended, they are to be filled into empty capsules.

AIPAK has various automatic capsule filling machines for your choice to fill the powder in whatever your gelatin,vegetable or pullulan capsule shells.

After that,each of your capsule will need to be polished of any excess powder for a clean finished look and triple inspected for any defects.

AIPAK has automatic capsule polishing machine or capsule sorter to make your capsule more appealing as well as sorting out the unqualified capsules.

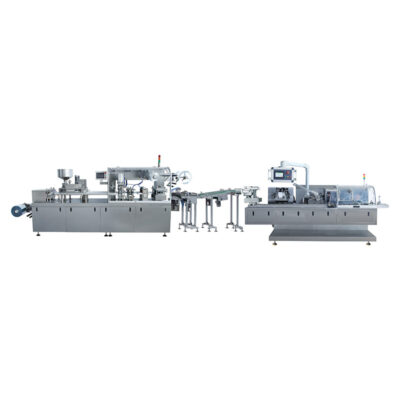

The last step is to pack your filled capsule,at AIPAK,we have first packaging tools-blister packaging machine,to pack your capsules in cavities or pockets made up of thermoformed plastic or cold-formed aluminum film to protect your capsules from mositure or easy to store.

The secondary packaging tools-tablet counting machine and cartoning machine are to count your capsules and make it filled into bottle or make your blister packed capsules cartoning into box.