Various Tablet Packing Machines:the Complete Comparison Guide in 2024

Are you looking for a machine to pack your tablets or capsules? Or are you having a headache of finding the best way of packing your tablets or capsules?

In fact,there are various tablet packing machines used to pack tablets or capsules nowadays,in the pharmaceutical industry .

And the packing of tablets or capsules is as equally important as producing them whose composition should have no errors,and bad packing may lead to horrible results and make your effort wonder.

Now,you have come to the right place as today I will use 6 chapters to explain every detail of the tablet packing method and tablet packing machines.

Chapter 1.What are Types of Tablet Packing Machines?

There are some following Tablet packing machines that are used for packing tablets with different working method and they are these also sub categorized as well.

1.Strip Packing Machine

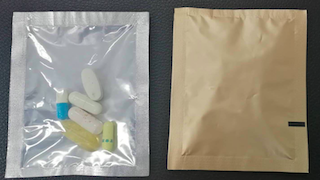

Tablet Strip Packing

A strip packing machine is designed and composed on different working parts to perform high quality accurate packing on different types of tablets and capsules.

It works through controlling the temperature to give specific heat during the packing and also controls the pressure that is used by the rollers for sealing purpose.

Those products that can be sealed with the heat are dealt with this machine like polymer coated type of aluminum foil, coated paper of polymer type, and cellophone.

There are some following key features that Strip Packing Machine can give.

- Easy for you to change and replace all the parts of the machine if they get damage or not performing accurately.

- With the change of product for packing you can easily adjust the production parts according to the size and type of production.

- Sealing is done very precisely as the rollers work very smoothly and effectively.

- As there is no heavy work to do with the packing so, the strip packing machine works very smoothly and noise free.

- Size of the machine is moderate so, it can be fit easily in a small space of area.

There is another type of Strip Packing Machine called High speed strip machine for tablets.

a.High Speed Strip Packing Machine

Tablet packed by high speed strip packing machine

High speed strip machine is a sub type of strip packing machine with fully automation level and provides insane work rate like a working horse with every type of product having different size and type.

When it comes to the working performance in bulk quantity then this machine is highly recommended to you.

It is easy for you to set the required working parts as per your demand so, this machine provides flexibility to work with different type of products.

Here are some of the key features of High Speed Strip Packing Machine.

- Teflon of plated type is used to give perfect sealing to the tablets as this Teflon is also heat resistance to give you pollution free environment for packing.

- As the machine is covered completely with the glass give ease and protection to your worker during the packing process.

- To get the sealing perfectly the temperature is set sensitively and easy for you to adjust according to the product type.

- Working with different type of products is easy as there is no need to set the working modules manually because the machine is fully automatic.

- You can set High Speed Strip Packing machine with your production line to achieve the production.

- Safety of the products made sure as the cutter works in a protective way.

b.Double Aluminum Strip Soft Packing Machine

Double Aluminum Foil tablet packing

This is one of the Strip Packing Machine type used for packing double aluminum based foil sheets like different candies, tablets, and other small size pills.

Sensitive products like jelly based candies and stuff like that which can be melted in light due to heat is packed with Double aluminum strip packing machine operating without the light.

Some of the features of this machine are following.

- Useful in pharma industry to pack sensitive products.

- PLC system makes it easy to control all the parts easily.

- Help you to make your product look more presentable with packing and also increase the life of your product.

- Products that require plastic to plastic based sealing can also be done with the help of this machine.

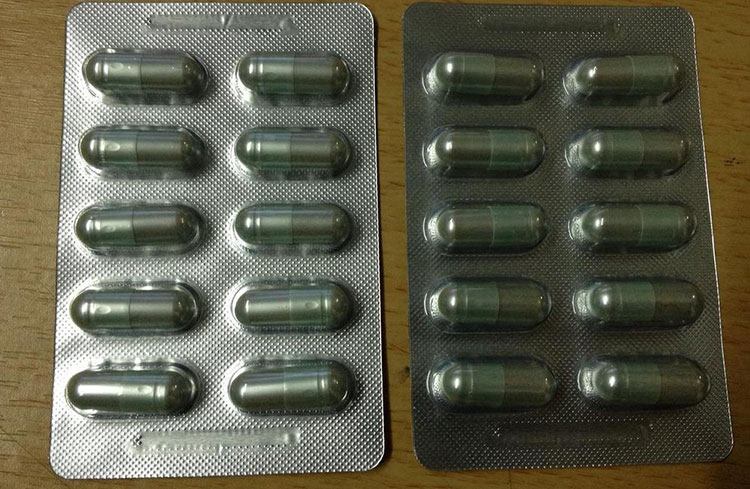

2.Blister packing Machine

This is one of the packing machine type used for blister packaging of the products. Most of the use of this machine is done in medical industry for packing the tablets in blister stuff.

a.Auto Blister Packing Machine

Automatic rotary blister packing

Auto blister packing machine is one of the sub types of blister packing machine use for the packing of capsules and tablets into strips.

A feeder that vibrates is used to remove the extra dosage of powder and other content from inside of the remedy.

Perforation of packing is done horizontally to make the packing tight and air proof.

When the packing is done it sets the batch number automatically on the packet to dispatch.

Heating press cam can be adjusted from 110-140mm of diameter.

b.PVC Packing of Blister

PVC blister packing is also a type of blister packing machine can work to pack both solid and liquid products including capsules and tablets.

You can use this machine for bulk production of two different type of products or you can also use it for single type of product.

Work in a close environment to protect your product from any kind of air dust and humidity.

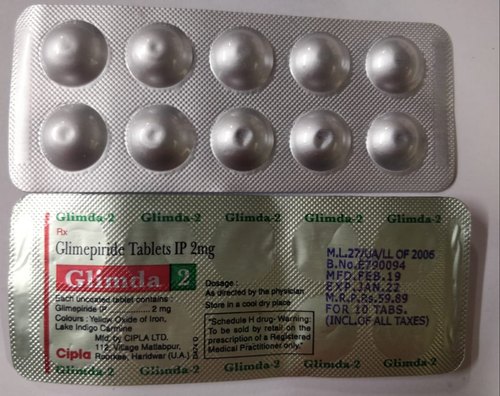

3.Aluminium Foil Packing Machine

Aluminum tablet packing

Aluminum foil packing machine is used for packing tablets and other products with the help of different ways like by heat sealing, and forming.

Different variations of plate size make it more useful for different size of products packing accuracy of Aluminum foil tablet packing machine is very precise.

It gives some of the following features for you.

- You can easily change the moulds as per the demands.

- Sealing is done effectively with 100% guarantee.

- Sealing is done with the help of heat in a compressed manner as the pattern of the net shown in a clear way.

- Medication that requires special attention in terms of heat can be packed with Aluminum foil packing machine.

a.Double Aluminum Packing Machine

Aluminium tablet packaging

Double side packing of tablets is done with this machine as it is based on latest technology and offers you high quality content with noise free environment.

It is easy for you work with this machine and maintenance is also very easy.

It gives you some following key features.

- PLC system enables you to perform the required tasks in a simple way with the help of touch screen without making any effort.

- Like other tablet packing machines double side aluminum packing machine is not limited to some products.

- It can pack multi type of products like food items, candles packing as well as capsule and tablets.

- You can obtain heat sealing, printing and filling at the same time with double side aluminum packing machine.

- Speed packing in a convenient way can be gained with double aluminum tablet packing machine.

4.Tablet Counting Machine

AIPAK Tablet counting machine

Tablet counting and packing machine is a horizontal based packing machine ideal for pharmaceutical products including tablets, capsules and other medical products as well.

Some of the following important features that you can get through this tablet packing machine are there.

- Basic designed structure of the machine makes it easy for you to replace the working components.

- Stainless steel nozzles present inside of it make the counting and packing continuously.

- Dust free process as the inner device works to remove any kind of dust residue from the container.

- As the machine based on stainless steel components so, that your product remain in good shape and quality.

- You can pack 2000 tablets in 1 minute or 1000 capsules in 1 minute with the use of tablet counting and packing machine.

5.Automatic Pouch Packing Machine

Tablet counting & pouch packing

As the name of the machine tells it is fully automatic for packing tablets with the help of sealing form to make a pouch of products after the packing.

Many of the industries use this machine for their product packing like pharmaceutical industry, food industry and chemical industry.

Auto pouch packing machine can pack multi type of products like tablets, liquid tablets, semi liquid products and other hard material products.

Here are some of the following features that Automatic pouch tablet packing machine.

- Sealing device present in the machine works independently and make sure the sealing is done precisely to make the seal leakage proof with a look of pouch.

- Filling of two products at the same time and making a pouch of it after the filling can be done with this machine.

- Computerized based technology to handle the production in bulk amount with maximum speed and quality outcome.

- Stainless steel body structure to make the life longer.

6.Vertical Packing Machine

Small size Vertical tablet packing

Vertical packing machine is used for the packing of sugar coated pharma products like capsules & tablets that require special care along with some other products as well like buttons packing, coffee beans packing.

Vertical tablet packing machine is very appealing in terms of giving you noise free environment with its compact design and structure completing the whole packing process desirably as per the needs.

Chapter 2.How Will You Benefit From Various Tablet Packing Machines?

Different types of Tablet packing machines provide different types of benefits to the users working with the packing in different industries.

Here are some of the following advantages of tablet packing machines.

Tablet packing

- Packing of the product make your product secure.

- Versatility of the product increases with the help of packing.

- Precision in filling the product with required amount of dosage.

- Bulk amount of tablets and capsules can be packed to reach the market level.

- Easy to adjust the working components of the tablet packing machine give you stability to pack different size of products.

- Blister tablet packing machine can help to increase the life of product after packing and make sure that your product remains fresh.

- Easy handling of the control system as the machine operates through the PLC system.

- Packing of the product made them more portable during the transfer from one place to another.

- Pollution free packing made your product fresh in appearance as well as in good quality.

- As the most of packing machines came in a moderate size like blister packing machine so, it is easy for you to adjust it in a small space of area.

- You can set up the tablet packing machine with your production line to make the production quick and fast.

- It will help you to save your time as well as labor cost only one or two persons will require for performing the operation on this machine.

- Packing of the machine is very efficient and affective to save your product in any kind of weather condition.

- Leakage proof sealing is done with the help of automatic tablet packing machine.

- It is easy for you to keep the machine in good shape with easy maintenance.

- Utility ratio of the machine is peak with giving the maximum output.

- Different type of material is used in different type of machines for packing the tablets and capsules like blister is used by the blister packing machine.

- Multi size of tablets and other materials can be packed within the range of the machine.

- Different types of packing can be gained as the machines works in different ways to seal the product like heat sealing, heat pressure sealing etc.

- Aluminum foil tablet packing machine can give you double side packing of the product.

Chapter 3.What are the Applications of Various Tablet Packing Machines?

Many of the tablet packing machines are used in different industries for packing different type of items.

Food Industry

Candies in blister packing

In food industry tablet packing machine is used for packing different products like sugar candies, gum based candies, chocolate beans, coffee beans and other food items like this.

So, the tablet packing machine is not limited to pack pharma products it can be used in other industries as well.

There are some of the tablet packing machines that can be used in food industry for packing various food items.

- Auto double strip aluminum packing machine.

- AI Foil strip aluminum packing machine.

- Strip tablet packing machine of high quality.

- Auto Pouch packing machine.

Pharmaceutical Industry

Tablets & capsules in packing-Photo Credits: Pharma Online

Major use of tablet packing machine is done in this industry as lots of pharma products are packed with the use of this machine.

Different size of tablets and capsules are sealed precisely with this machine to make them secure and safe for any kind of condition.

There are many tablet packing machines that are used in packing the pharmaceutical products with different types of packing material.

Blister packing machine uses the blister for the packing purpose.

Aluminum strip tablet packing machines uses the aluminum strip for packing purpose.

Different types of plastic materials are used for packing purpose like transparent plastic material is also used in blister packing machine.

Rotary kind tablet packing machine is used packing the bulk amount of tablets and capsules in boxes.

Chemical Industry

Mitsui based chemicals-Photo Credits: Japan Chemical Daily

In chemical industry different sorts of chemicals are packed with the help of tablet packing machines of different types.

Small size pills containing chemicals are packed with the tablet packing machine.

Every type of liquid, semi liquid, solid and dry chemical product can be packed with the help of Pouch packing machine with full automation.

As the chemicals are sensitive materials they can be exploited when leave in a hot sunny day without a cover so, for this purpose packing is done with aluminum foil tablet packing machine to make the product secure and safe to travel.

Pouch packing tablet machine is also useful in packing gel based chemicals or other solid and dry granules containing chemicals inside.

As I told you before the use of tablet packing machine is not limited to one or two industries it can be used in many sorts of industries for packing different kind of products.

Chapter 4.What are the Main Components of Tablet Packing Machines?

As the various types of tablet packing machines are present in market they all work differently having different working parts let me explain to you some of the common parts that are almost available in every type of packing machine.

Capsules in Blister Packing-Photo Credits: Wikipedia

- Feeding Unit

Feeding unit with product container

A feeding unit holds two type of material first of all the material that is going to be used for packing is selected like aluminum foil or polyvinyl paper or some other stuff.

On the other hand the product that is going to be packed is hold inside the container that is present on the upper side of the feeding unit. This container holds the material like tablets, capsules and other stuff.

You can provide the feeding material to the feeding unit by yourself or it can get the feeding material automatically depending upon the automation level of the tablet packing machine.

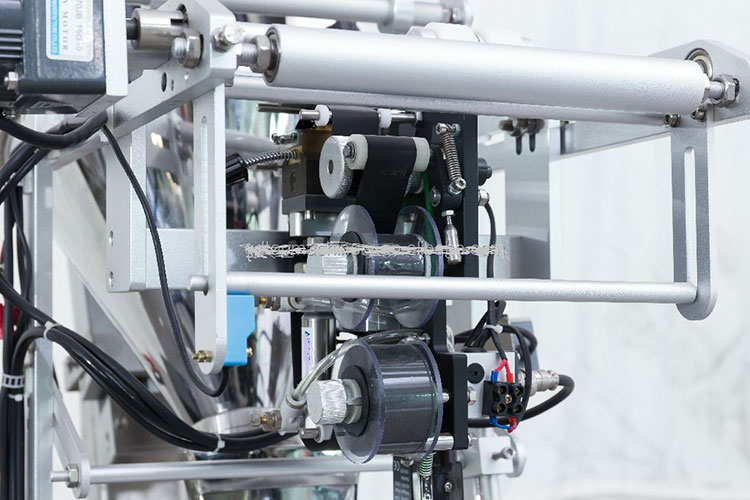

- Driving Component

Driving component with rollers

This component of the machine helps to move the packing material from one part to another like from feeding unit to the productive part.

In this part the driving unit contains rollers in opposite sides of each other to move the material for packing purpose.

- Foil/Plastic material Holder

Tablets in aluminum packing-Photo Credits: Huale Machinery

This component of the tablet packing machine is used for holding and rolling the packing material towards the other productive parts.

- Product Cutter

This cutter is used for cutting the sealed product towards the packing unit for further processing. Whenever tablets are sealed or packed the cutting unit cut them into a specific amount of tablets making a tray type production.

- Batch Printer or Simple Printer

Batch Printer-Photo Credits: Gwear Batches

Printer in the tablet packing machine does the printing stuff to print the products batch number on the back of the foil paper.

Ink present in the small size pins makes contact with the paper for printing purpose to mention about product and its manufacturing date etc.

- Control System

HMI screen

According to the automation level of tablet packing machine this component comes in PLC system or as a simple electric box type to control the working of the machine.

It is essential for operating the machine according to the product type.

- Sealing Heater

Sealing is done with amount of heat along with pressure applied on the tablets pack to make the product leakage proof and air tighten.

Sealing heater make the packing of the product more secure between two packing materials.

- Waste Collector/Assembly

During the packing of the product some of the product get wasted or failed to get packed so, for this purpose collector is used in the tablet packing machine from saving the wastage of product.

- Sliding Chute

When the products get packed then they are move towards this part called sliding chute which makes the product move forward towards the collecting tray.

This component of the tablet packing machine helps the machine to make the packing production fast.

- Product Counter

Tablet counting machine

When the product is sealed then counter unit perfectly count the number of products that are packed before the tablets send towards the box packing.

It helps you maintain the record about the production and help you to calculate the production rate as per the required time.

Working parts in Blister Packing Machine

Blister packing machine holds different working parts because of its different working method using blister for packing purpose.

AIPAK Blister tablet packing machine

- Blister Feeder

Blister feeding component is used to feed the blister paper to the machine for packing the tablets into the blister paper.

- Blister Tool Pack

This component in blister tablet packing machine holds variety of other forming structure parts that include forming film maker and this forming component can generate different types of forming including thermoforming, cool forming and continuous forming.

- Rollers

Rollers present in the blister tablet packing machine are used to turn the blister paper from one place to the other.

Rollers

- Heat Box for Sealing

Heat box contain heating effect to make the sealing perfect by applying some heat pressure on the packing material.

- Guiding Rale

Rales work as moving tray in the machine to transfer the products after the packing for further boxing it runs with the help of belts.

Working parts in Strip Tablet Packing Machine

Strip packing machine works to pack the products in the form of strips and it has its own working components to perform the packaging process.

- Strip Holder

Strip holder in the strip tablet packing machine works as holder for holding the strip papers in the feeding rollers to move it further forward.

- Running Shaft

Forming of aluminum

A rotationally moving component of the machine consists on small moving rollers that help to move the packing material from feeding unit towards productive parts.

- Strip Brushes

All the electrical control from the machine to the packing surface is controlled with the help of these brushes like controlling the flow of heat from heating unit to the surface of the packing material is controlled with these brushes.

- Moving Hopper

Double Aluminum strip packing machine

All the production before and after the packing is transferred from one productive component to the other with the help of hopper to make the production flawless and bug free.

Some other small components are also present in the strip tablet packing machine which makes the strip packing more perfect and accurate.

Chapter 5.What are the Working Principles of Various Tablet Packing Machines?

Every machine has its own working principle according to his running parts and production mechanism.

Let me explain to you the working of some tablet packing machines including Blister tablet packing machine, Strip tablet packing machine and Aluminum tablet packing machine.

Working of Blister Tablet Packing Machine

There are two main types of blister packing machine and both of these machines Alu Alu & PVC blister packing machine work in the same way.

Blister tablet packing

- Step 1

In the beginning all the parts of the blister packing machine are initialized like you turn on the power button and check the motion of every moving component to start its first motion to get in rhythm.

- Step 2

Feeding box holds the packing material and the product which is going to be packed in the feeding chamber and when the process of packing starts the packing material released by the feeder with the help of moving rollers.

- Step 3

Capsules in blister packing-Photo Credits: Pharma Co

When the material used for packing is released from the feeder then it comes into the forming system where the forming of the material is done forming of any type can be made according to the machine manufacturing level.

- Step 4

After the forming the product is released into that forming shape to get settle inside the forming material and sent forward for further processing.

In blister tablet packing machine blister material is used to seal with the forming material and this seal is done with the help of a sealing box that provides heat.

- Step 5

Parts of Tablet Packing machine

When the product is packed then the printing of batch number and other details is done on the tablet pack with the help of a printer.

Printing can be done in two ways either with the ink or on the tablet sheet with the help of nozzle by forming the material that you selected for forming purpose.

And in this way the process of packing is done in the blister tablet packing machine and final product is ready to deliver after the boxing.

Working of Strip Packing Machine

Strip tablet packing machine

Strip tablet packing machine is known as strip machine for packing different sorts of tablets and capsules.

This machine is designed differently from blister tablet packing machine but the process of packing is almost same like blister tablet packing machine.

Strip tablet packing machine can use different sorts of papers for packing purpose for strip packing like PET foil, cold & heat forming material and other back paper foil.

Strip machine works on the air pressure methodology and heat pressing principle to seal the product perfectly.

Different tablets in packing

From forming to printing this machine works in the same way as the other common tablet packing machines do but the packing of the tablets and other products is made in the form of strips.

The main difference in the working of this machine as compared to the others is this when the sealing on the back paper is done with the forming material it is done with the principle of thermal heat to fix the papers and protect the inner product.

When the heat is provided in the form of thermal then pressing on the both ends is done with this machine.

That’s the working function of strip tablet packing machine.

Working of Aluminum tablet Packing Machine

Aluminum packed tablets

Two side aluminum tablet packing machine use the aluminum paper for packing purpose and the functionality of this machine is also as same as the others.

Aluminum paper is used for packing the tablets and capsules the material that is used for forming is a hard type aluminum foil paper that make the form with the pre heating component of the machine.

Tablet strip blister packing

The forming plate uses the hard aluminum foil for product filling and the back paper used for packing is also a foil with light density to make the double sealing of aluminum.

You can use this machine for other product packing as well like those products which require special care and made up of sensitive material.

These are some of the common tablet packing machines that work on their own for packing different kind of products.

Chapter 6.What Should You Consider When Importing the Most Suitable Tablet Packing Machines?

Buying a machine need a huge amount of money to be invest to get the specific type of product that you want according to the needs.

So, when you buy the machine keep in mind some of the key points while purchasing the machine.

Manufacturing Standards

GMP standard logo-Photo Credits: Photo Editors

A product design and manufacturing must be done according to the quality standardization of GMP, ISO and other standardization.

These quality standards help you to know about the product design and its manufacturing environment. It helps you to define the way of using the machine and what type of production you are going to achieve with the use of tablet packing machine.

It also tells you that what type of environment is suitable for you to operate the tablet packing machines and what you should avoid during the packing purpose to get the bug free production.

Production Speed & Quality

Capsules packing-Photo Credits: Pharma Inc

Whenever you are buying the tablet packing machine always remember that how much production a specific machine can give you in how much time.

A normal automatic tablet packing machine can give you 2000 tablet packing in one minute so, select the machine of your choice by going all around the market and ask about the production speed.

You can compromise on quantity but never ever compromise on the quality of your production as it will help you to reach new customers and help you to gain the customers trust about your production.

Quality tablet packing will make your tablet safe and secure for travelling purpose and also make sure that your product reaches your customers at its best.

Product Type & Packing Material

Different products packing with tablet packing machine

You must need to sure that what is your product type and what do you want to gain with the tablet packing machine.

Type of your product mainly depends on the industry type like you are going to use food products or what?

Always choose the type of machine according to your product type most of the tablet packing machines are used for packing different sorts of pharmaceutical products and some other types of tablet packing machines are also used for packing food products and other chemical products.

Maintenance of Machine

Maintenance of the machine must be easy and affordable for you to avoid any kind of extra investment. And you can easy replace the damage parts of the tablet packing machine when needed.

Good maintenance of the machine will help you to get the quality product just like the new machine. Make sure to clean and lubricate your machine if not on daily basis then at least on weekly basis to maintain its good shape.

Tablet packing machine if maintained in good shape then your production will remain ideal and your production speed will also remain as it is.

That’s all about tablet packing machine hope you understand all the information that I provide you in this guide.

Blister Packaging Machine Related Products

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine