9 Questions To Answer Before Requesting A Blister Packaging Machine

From time to time, you will find advance variations in blister packaging machines with unique performance and features. This is because every manufacturer focuses on different aspects of blister packaging. Most consumers consider several factors that can be effective from both a marketing and an economic standpoint.

Here are 9-Questions to Answer Before Requesting a Blister Packaging Machine that you must keep in mind when assessing the type of blister packaging right for your product.

Table of Contents

I.What are you going to pack?

This is the most important aspect when contacting a vendor. Since blister packaging machine is associated with a broad packaging classification, therefore, it is beneficial to provide thorough details about your requirement. If you are looking to add a new machine it is recommended to communicate supplier and inform them what product you’re going to pack.

For example:

Are you looking to pack pharmaceutical products? Tablets, capsules, pills, suppositories. Or other products e.g., toys, automobiles, stationery, cosmetics, kitchen, home, and décor?

The entire aim is to protect them against hot, and humid conditions with extra protection levels, and easy transportation. Maintaining communication linkage with suppliers, marketing, engineering, and technicians ensures 100% best procurement solution.

Ⅱ.What dimension do you require?

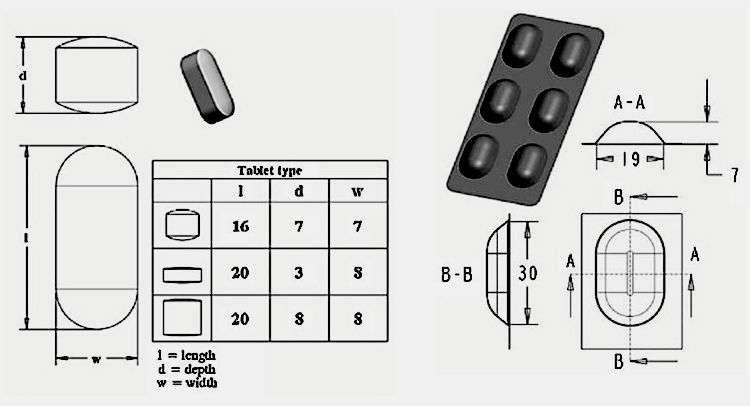

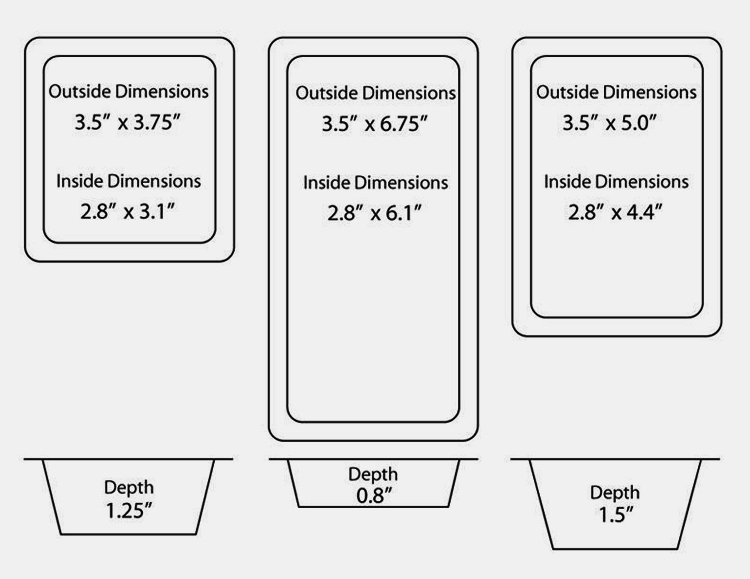

Every product has unique dimensions and packaging types. Once you decide to add a blister packaging machine for its packing; then you must need to do some little research to finalize the respective required dimensions. Always remember, a proper workout is very crucial than making rough guesses. By doing this, your vendor can accurately suggest you the right options (through proper calculation).

Providing technical specifications of the product allows the vendor to assess the best fit options for your production line. You should mention the required packaging size, length, width, depth, outside dimension, inside dimensions, depth of blister pockets, blister covering., etc.

For example: commonly used forming depth varies from product to product such as 16mm, 22mm, 25mm, and so on.,

Furthermore, you just need to inform your vendor what type of age group you’re concerned with, for instance, if your product is associated with an old population then you must assess the age group and type of dimension suitable for them to enhance patient compliance and easy handling.

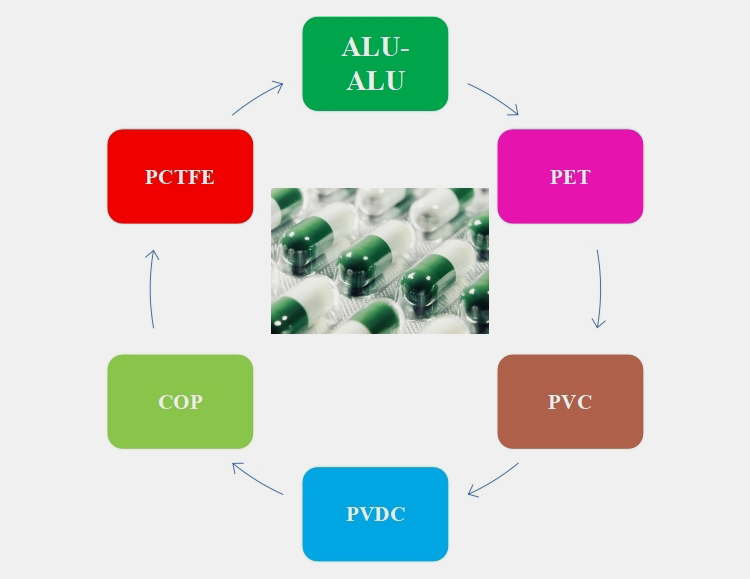

III.Which packaging material do you require?

For blister packaging machines, the following types of material are frequently used to improve your product’s integrity and shelf life. For instance:

ALU-ALU

This form is blister packaging is considered highly excellent as it forms a multi-layer structure designed around sensitive pharmaceuticals and generic medicines that are hygroscopic in nature or prone to photo-degradation.

Polyethylene terephthalate (PET)

Polyethylene terephthalate, also known as PET. It is also used as blister plastic clamshell packaging and more. PET is a lightweight packaging solution that is cost-effective, impact-resistant, and clear material. Apart from blister packaging, you can also use PET for plastic bottles.

Polyvinyl chloride (PVC)

This form of blister packaging material is highly popular for packing because it is very inexpensive. They are basically formed by using 0.25mm or 0.3mm PVC sheets. For such blister packaging, a backing is covered by paperboard, aluminum foil, or plastic sheet.

Polyvinylidene chloride (PVDC)

PVDC is used in combination with PVC to form a blister packaging. It ensures extra layer protection for adequate sealing of products against oxygen and humidity.

Polychlorotrifluoroethylene (PCTFE)

This is a type of laminated blister packaging required to form a moisture barrier around your product. By comparing to other polymers, PCTFE blister packaging has a lesser water vapor permeability.

Cyclic olefin polymers (COP)

COP is commonly combined with other polymers like polypropylene and polyethylene to form a blister packaging with a deep cavity to firmly hold items. This is commonly used to form blister packs to hold pharmaceutical medicines.

IV.Do you require how to make the blister packaging?

Blister packaging is all about protecting your product. Before finalizing the quotation, your product consultant might be asking to know the making of blister packaging you require. There are certain formats that you must know:

HEAT SEAL BLISTER

A heat seal blister has two parts; a single piece board and a blister. A blister plastic is bonded over the paper board with the help of heat and pressure.

| Face Seal Blister | Full Face Seal Blister | Full Card Blister |

| This type of blister has been sealed on the flange while the remaining card stays uncovered. This is less expensive and a cleared form of blister packaging. This type of packaging is commonly used for cosmetics and electronic products. |

This type of blister packaging surrounds the entire product along with the card’s backing. A plastic covering is either heat-sealed or slid via an additional plastic piece over each side. This packaging makes packing stronger and better looking. |

This is the same as a full-face blister but rather than a heat-sealed card; it has flanges that wrap the full card. A card’s slid is sometime firmed and stapled together. |

TRAPPED BLISTER

A trapped blister is similar to traditional blister packaging but the plastic sheet that sticks to the cardboard has another section of cardboard in front of it where it fits around the format of the blister. A plastic is trapped between two sections of cardboard.

DOUBLE-SIDED BLISTER/CLAMSHELL

A clamshell packaging, clam packaging, or double-sided blister packaging does not have a cardboard-like traditional packaging. But it has a plastic backing that is hinged to the front packaging or at the side of the base.

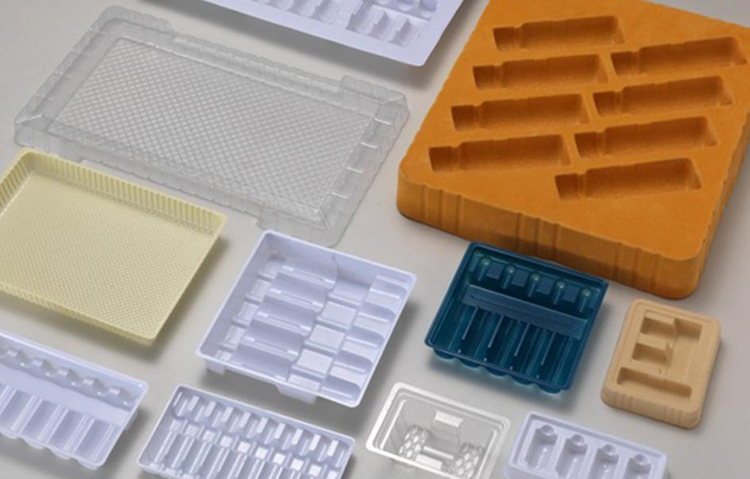

BLISTER TRAYS

This is an important form of blister packaging required for pharmaceutical products like injections, ampoules, vials, etc., It has a pre-formed plastic tray where machines create cavities or pockets from a plastic sheet using heat or pressure.

Ⅴ.How many pieces for each blister packaging?

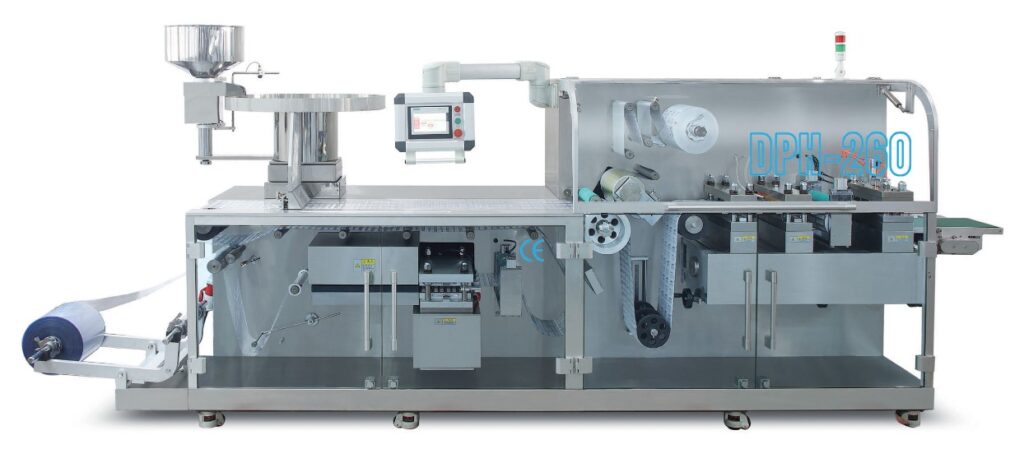

A blister packaging machine automatically fills blister pockets by using a vibratory feeding mechanism and spring chute. Day by day, modern science and technology have improved with more innovations that ensure to achieve your target goal. Today, the competency level of blister packaging machines is higher which is why you’ll be offered various versatile options.

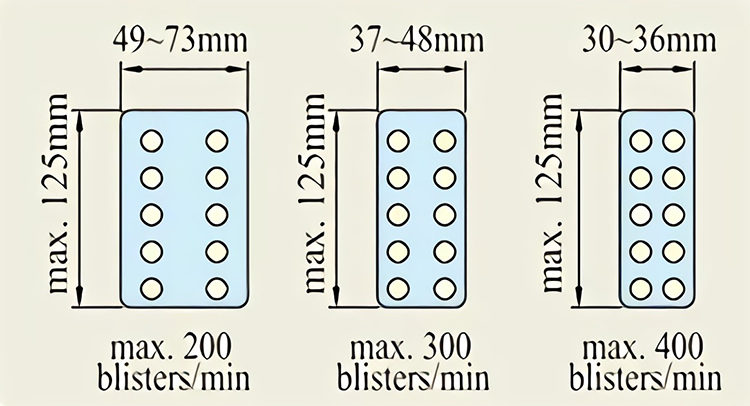

You must assess and inform the equipment manufacturer about the required pieces for each blister packaging. For instance, 10 blisters/strip, 12packet/minute, or 100 blisters/minute, etc.,

Ⅵ.What is your production requirement?

A blister packaging machine serves for various levels of production batches that are not intended for the same users such as from pharmaceutical to agriculture, from automobile to cosmetics, etc.

Considering small to moderate production lines; or bulk/retail packaging, blister packaging plays a crucial role in the broad sector. Consequently, you should properly discuss all the parameters with your vendor to get a suitable machine. For instance:

- Size of Production (small, moderate, or large batches)

- Weight of Your Product

- Automation Requirement (Semi-Automatic, Automatic Blister Packaging Machine)

- Facility Production Shifts (blister pack plates/hour)

- Forming Depth

- Punch Frequency

- Standard Plate Size

- Overall Dimensions

Ⅶ.What is your budget?

Your budget is key to driving the entire decision behind purchasing a new one. You must not hesitate when discussing your financial plans with a product supplier. After evaluating cost estimation, your vendor may be capable enough to offer the list of blister packaging lines with significant operational values, more production capacity, controlled waste management, and reduced downtime. Always keep in mind that buying a new blister packaging machine is not an overnight decision. So, if you are considering your budget, side by side your vendor strives to explore a turnkey solution for that.

Ⅷ.When do you want to put it into production?

When you decide to add a blister packaging machine to your production line; you must inform your vendor about certain requirements.

- Time and date to run the operation

- Availability of space for blister packaging machine installation

- Your production capacity

- Requirement of all validation documents; IQ, OQ, PQ, etc.,

- Test Run

- Technician Training

- Demos

- Delivery and customer support program.

Ⅸ.If you purchased for your own factory or trade?

Your supplying vendor believes in building a positive relationship with you and your partners to ensure the best services. For your ease and offering a one-stop solution; the manufacturer seeks if you’re looking to use the machine for yourself or for trading purposes. Indeed, for local factories or regular visitors, a procedure like a shipment, installation, test demos, training, and equipment guide program is simple.

Whereas, if you are using it for trade purposes, it is worth mentioning as you can establish a distribution agreement with your vendor. For this, the vendor may train you, supply relevant documents required for trading and most importantly virtual post-sale support can also be offered.

Conclusion

The blister packaging machine is an innovative packaging solution that offers an optimum solution with excellent features to protect and promote your product. 9-Questions to Answer Before Requesting a Blister Packaging Machine has highlighted the basic parameters that your manufacturer may ask before offering solution. For more queries and guidance, feel free to contact us. We are here to assist you 24/7/365.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours