Alu-Alu Packaging VS PVC Packaging: What Are the Differences

When you buy medicines at a drug store, you may find that different medicines may be packaged in different ways, such as alu-alu packaging or PVC packaging. Are you wondering why these two different packaging methods are used?

Alu-Alu Packaging VS PVC Packaging-sourced: csptechnologies

How do these two packaging methods protect the contents? What is their cost of use? Read the following article "Alu-Alu Packaging VS PVC Packaging: What Are the Differences" and you will understand the differences.

1.What Is Alu-Alu Packaging and PVC Packaging?

When you mention about the pharmaceutical packaging, alu-alu packaging and PVC packaging are definitely your choice. Here are the explanation of the alu-alu packaging and PVC packaging:

Alu-Alu Packaging

Alu-Alu Packaging-sourced: aluminumblisterfoil

The alu-alu packaging refers to the packaging that both the bottom and lid are made of aluminum-based film. It uses cold forming technology, where the laminate is pressed into a mold without heating, using forming pins to create the product cavity, and then the packaging is sealed with an aluminum lid material.

Products using alu-alu packaging are generally effervescent tablets or high-value, high-potency drugs.

PVC Packaging

PVC Packaging-sourced: csptechnologies

The PVC packaging, also known as PVC-alu packaging, uses aluminum foil material on one side and transparent materials such as PVC (PVC/PVDC, PVC/PE/PVDC) on the other side to package different products. Most of the tablets and capsules such as paracetamol tablets, amoxicillin capsules, etc. are packed in this type of packaging.

2.What Are The Application Of Alu-Alu Packaging and PVC Packaging?

The alu-alu packaging and PVC packaging are widely used in various industries such as food, pharmaceuticals, supplements, accessories and cosmetics industry.

Pharmaceutical Industry

Pharmaceutical Industry-sourced: healthcarepackaging

The alu-alu packaging and PVC packaging are the most important packaging methods in the pharmaceutical industry. It is widely used in the packaging of capsules, oral tablets, hard and soft gelatin, and ampoule.

In addition, they can also be used for composite sealing packaging of medical devices and professional equipment. It has a wide range of markets around the world.

Supplements Industry

Supplements Industry-sourced: thedieline

The improvement of production and living standards has increased residents' attention to health. Many capsules and tablets are packaged with functional supplements, such as vitamins, probiotics, fish oil, antioxidant, creatine and other health products.

Food Industry

Food Industry-sourced: nassaucandy

For foods that are easily affected by light, temperature or bacteria, alu-alu packaging and PVC packaging can be used. For example, cheese, butter, cheese, fruits, various meats, tea, whole grains, seasonings, etc. These two types of packaging can not only protect the food, but also extend the shelf life of the food.

Accessories Industry

Accessories Industry-sourced: clamshell

Various plastic toys, batteries, handicrafts, data cables, headphones, power banks, gadgets, mobile phones, various small electronic products, etc. often use PVC packaging. It can effectively protect the appearance of the product from damage, and can effectively facilitate transportation.

Cosmetics Industry

Cosmetics Industry-sourced: szblisterpackaging

Various lipsticks, lipsticks, hand creams, makeup tools, nail polish, mascara, eyeliner, eyebrow pencils, blush, liquid foundation, etc. will be packaged using PVC packaging. Not only can it save costs, but it can also facilitate transportation and protect product integrity.

3.How To Make Alu-Alu Packaging and PVC Packaging?

The process of making alu-alu packaging also called as the cold-forming blister formation, and the PVC packaging also called as thermoforming blister formation:

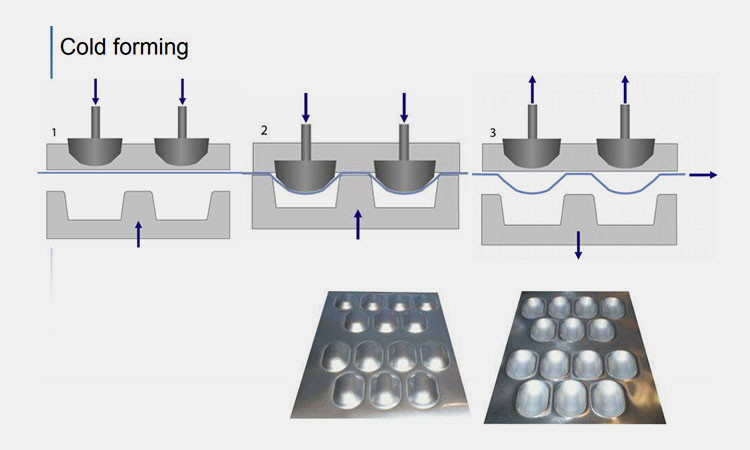

Alu-alu Packaging: Cold-forming Blister Formation

Alu-alu Packaging: Cold-forming Blister Formation-sourced: researchgate

Compared to the thermoforming process, the cold-forming blister formation does not use heat to shape the film. It undergoes plastic deformation by pressing the film into a mold. Therefore, this forming method is a physical and mechanical change process.

The film cannot form an angle close to 90 degrees when it is pressed into the cavity mold. This will increase the draft angle of the bubble size, thereby increasing the production cost of cold-forming blister formation.

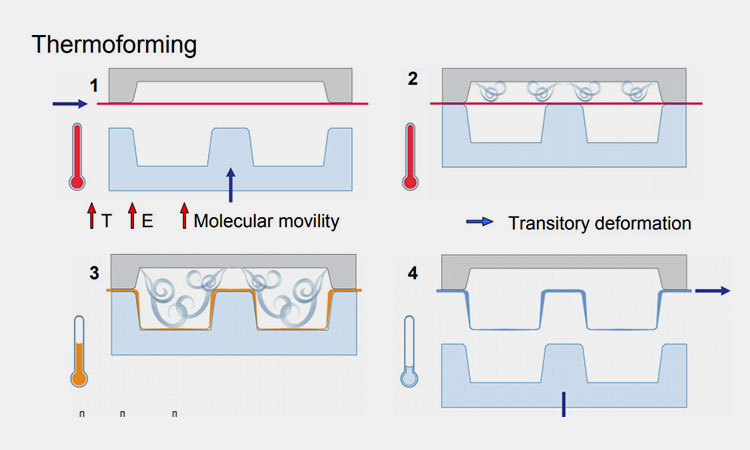

The PVC Packaging: Thermoforming Blister Formation

The PVC Packaging: Thermoforming Blister Formation-sourced: researchgate

The thermoforming blister formation is a process in which PVC film is heated to forming temperature and stretched on a mold to form. You first need to feed the PVC film into a preheating station and heat it to just above the glass transition temperature of the plastic.

The softened plastic is later sent to a forming station. Press the mold onto the sheet. This is the most common forming method for blister packaging.

4.What Are The Differences Between Alu-Alu Packaging and PVC Packaging?

Below, by comparing the differences between alu-alu packaging and PVC packaging, we can understand their characteristics:

| Alu-Alu Packaging | PVC Packaging | |

| Images |

Alu-Alu Packaging-sourced: nutra |

PVC Packaging-sourced: nutra |

| Application | Pharmaceutical industry; | Pharmaceutical, food, supplements, cosmetics, hardware, accessories industry; |

| Cost | l High;

l Alu-Alu blister Packaging is the most expensive packaging, and the packaging cost is about 50% higher than PVC blister packaging; |

l Low

l The cost of PVC Packaging is lower. However, because one side is made of plastic transparent material, its barrier properties against ultraviolet rays, oxygen, and temperature are weak; |

| Materials Used | OPA Films

OPA Films-sourced: wisenano |

PVC Films

PVC Films-sourced: chinapackfilm |

| Features | l Able to provide the best barrier protection for products;

l Can completely block the entry of water vapor, oxygen and light; |

Can block most moisture, light and air; |

| Advantages | l Almost complete barrier to water, light and oxygen;

l Extended the validity period of the product; |

l Easy to operate;

l Product can be inspected visually through clear plastic; l The most basic material of forming mesh is PVC, which is low cost and easy to thermoforming; |

| Disadvantages | l The material of aluminum film is more expensive than PVC;

l The production process is complex and slow; l Blister cards are larger in size, which increases secondary packaging costs; l The lack of transparency in packaging makes it more difficult for inspection systems to eliminate faults; |

l Poor moisture-proof;

l Oxygen-proof barrier properties and poor protective performance; |

| Forming Method | l Belongs to cold forming blister packaging;

Alu-alu Packaging: Coldforming Blister Formation-sourced: researchgate |

l Belongs to thermoforming blister packaging;

The PVC Packaging: Thermoforming Blister Formation-sourced: researchgate |

| Production Method | l With cold forming technology, the laminate is pressed into a mold without heat, forming pins are used to create the product cavity, and the package is then sealed with an aluminum lid material; | l PVC packaging requires the plastic to be plasticized at high temperatures to achieve the required shape in the aluminum-plastic blister machine; |

| Reason for Use | l Stability of active pharmaceutical ingredients;

l Can enhance the protection and stability of sensitive drugs; l Ensure that the active ingredients of the drug will not be destroyed; l Thermal degradation, oxidation, UV light, microorganisms, or hydrolysis may compromise the stability of active pharmaceutical ingredients; |

l Costs can be well controlled;

l Can be applied to many fields; l Convenient packaging, transportation and storage; l Very useful for products that are not sensitive to light or heat; |

5.What Are The Pros and Cons Of Alu-Alu Packaging and PVC Packaging?

Alu-alu packaging and PVC packaging each have their own advantages and disadvantages, and it is not necessarily who is better between them. You can decide which packaging method is more suitable for your product by comparing their advantages and disadvantages.

Pros Of Alu-Alu Packaging

Strong Stability

Strong Stability-sourced: hanlin

Due to the use of OPA-aluminum-PVC laminate packaging materials, it almost completely eliminates water vapor permeability and the entry of oxygen and light. It also can enhance the stability of packaged products.

Strong Protection

Strong Protection-sourced: hanlin

Due to its strong sealing, it can enhance the protection and stability of sensitive drugs, so that the active ingredients in the drugs will not be affected and destroyed. Extended shelf life of medicines. Enhanced protection against highly sensitive drugs.

Cons Of Alu-Alu Packaging

High Cost

High Cost-sourced: stock

The packaging material cost of the OPA-aluminum-PVC laminate used by alu-alu packaging is higher than that of PVC, and for the same number and size of tablets or capsules, cold-formed blisters require more packaging than thermoformed blisters material.

Complex Process

Cold-forming Blister Formation-sourced: researchgate

The alu-alu packaging is a cold forming process. It uses pins to press the cavity geometry into a thin sheet of aluminum. Because aluminum cannot form angles close to 90 degrees, resulting in cavities and blister cards that are larger than necessary. Therefore, the production process is more complicated.

Takes More Time To Make

Takes More Time To Make-sourced: avantisystems

The alu-alu packaging is slow to make and requires professional feeders. Because the board of alu-alu packaging is opaque, it increases the complexity of inspection. Therefore, it takes longer to make.

Pros Of PVC Packaging

Low Cost

Low Cost-sourced: formilla

PVC packaging uses PVC material that is easy to form and cheap. The cost of subsequent secondary packaging is also very low. Therefore, costs can be well controlled.

Simple Process

Thermoforming Blister Formation-sourced: researchgate

PVC packaging is easy to operate and the process is simple. And the product can be inspected visually through the transparent plastic. PVC material is easy to thermoform and is very convenient to make.

Cons Of PVC Packaging

Not Suitable for Photosensitive Drugs

Not Suitable for Photosensitive Drugs-sourced: sepha

PVC packaging uses transparent material, so it is not suitable for packaging photosensitive drugs.

Low Moisture and Oxygen Resistance

Low Moisture and Oxygen Resistance-sourced: versaperm

PVC packaging has low moisture-proof and oxygen-proof properties and is not suitable for packaging such as effervescent tablets or highly active pharmaceutical packaging. Packaging cannot match CFF blister protection.

Poor Stability

Poor Stability-sourced: nationofchange

The permeability of plastic molded films for PVC packaging usually increases with temperature, making the drug susceptible to the effects of temperature, resulting in poor stability.

6.What Are The Machines Applied For The Alu-Alu Packaging and PVC Packaging?

There are different types of machine can be applied for the alu-alu packaging and PVC packaging. They are:

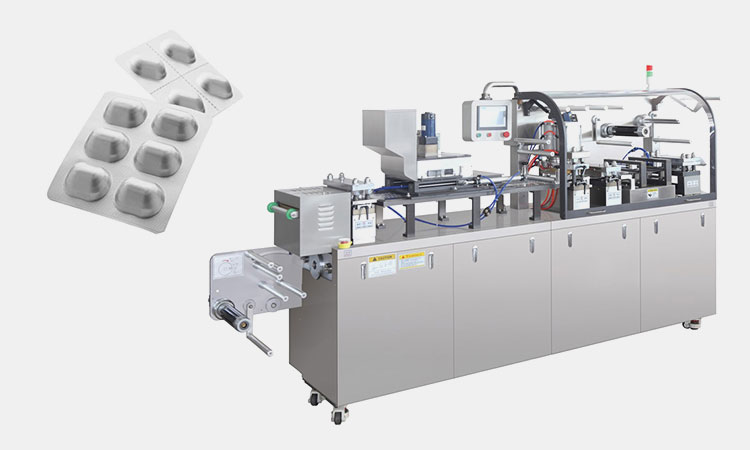

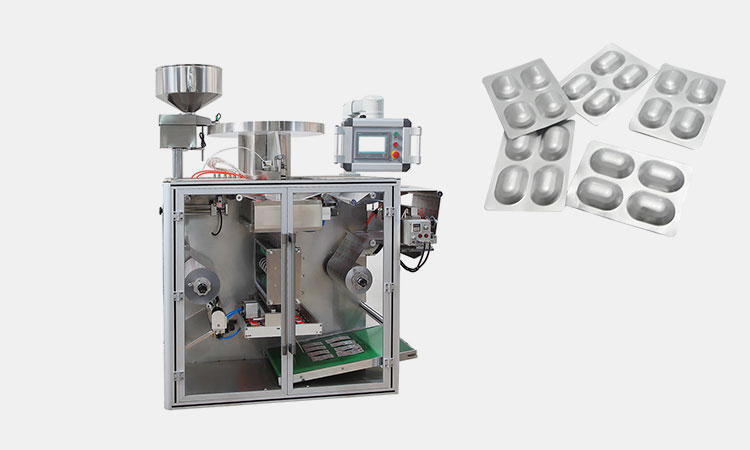

Alu-alu Blister Packaging Machine

Alu-alu Blister Packaging Machine-sourced: AIPAK

The alu-alu blister packaging machine is suitable for both cold forming designed blister packaging and thermoforming PVC blister packaging. It can automatically pack capsules, tablets, others into the alu-alu or pvc-alu blister packs. The machine is suitable for high-volume production in the pharmaceutical industry.

Features Of Alu-alu Blister Packaging Machine:

- The process is complex, time-consuming, and difficult to inspect;

- Can be used for all types of capsules, tablets, soft capsules, injection packaging, etc.;

- With cold forming technology, the laminate is pressed into a mold without heat, forming pins are used to create the product cavity, and the package is then sealed with an aluminum lid material.

PVC Blister Packaging Machine

PVC Blister Packaging Machine-sourced: AIPAK

The PVC blister packaging can automatically complete blister packaging of tablets and capsules. Typically a PVC film is used as the base film and aluminum foil with a heat seal coating is used as the cover film. The blister cavity is formed on a PVC/PVDC film mesh using a vacuum process.

Features Of PVC-alu Blister Packaging Machine:

- Seal patterns that provide tamper resistance;

- Equipped with light level control and vibrator to ensure correct filling of blister;

- Use an integrated water cooling device to maintain the correct working temperature for the machine;

- Fully automatic and using the principle of continuous motion to complete high-speed and efficient product packaging and production;

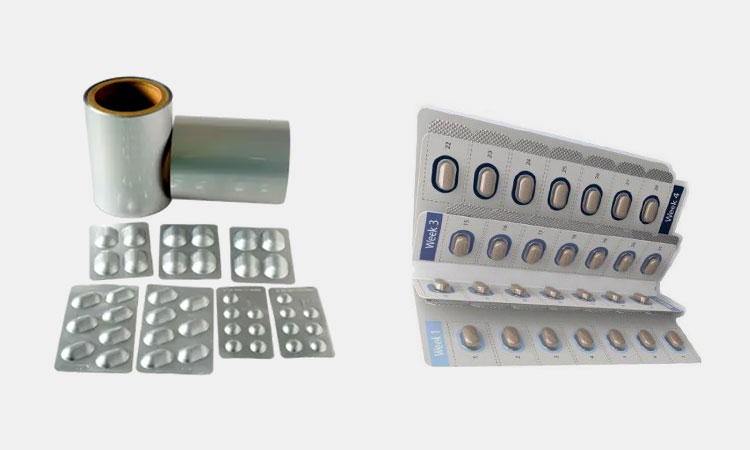

Alu-alu Strip Packing Machine

Alu-alu Strip Packing Machine-sourced: AIPAK

The strip packing machine is suitable for heat sealing packaging of alu-alu or alu-pvc materials. It is often used in tablet, candy, pill packaging, and is suitable for pharmaceutical, health care products, chemical, food and other industries. Such strip packaging can meet the requirements of product sealing and light protection.

Features Of Alu-alu Strip Packing Machine:

- Adopts PLC programmable controller and equipped with frequency converter;

- Advanced structure, high efficiency, low noise, easy operation, etc.;

- It can automatically complete vibration feeding, broken parts filtering, counting, vertical and horizontal imprinting, trimming waste, batch number printing, etc.;

7.Which One Is The Best Choice For You Alu-Alu Packaging Or PVC Packaging?

Nowadays, many medications are usually delivered in oral solid dosage forms such as capsules, tablets, or chewable tablets. Therefore, alu-alu packaging and PVC packaging are needed to package products for this delivery method. Which one is the best choice for you? Check the below:

Why alu-alu packaging solutions?

Why alu-alu packaging solutions-sourced: hanlin

- Advanced product protection that tightly controls humidity, oxygen and reactive impurities;

- Can be integrated into existing blister packaging production lines;

- Eliminate residual solvents that may release gases and interact with drug products;

Why PVC packaging solutions?

Why PVC packaging solutions-sourced: kefaichina

- Hot melt, adhesive-free and cost-effective;

- The process is simple and samples can be delivered quickly;

- The dose is visualized and the blister footprint is reduced by 40-60%;

- PVC packaging can adapt to tablets or capsules of any size and is securely fixed to the lid using hot melt technology;

- Reduce packaging complexity. It enables controlled internal head-space without the need for nitrogen flushing, secondary packaging or refrigeration;

Conclusion:

Pharmaceutical packaging continues to change and update over time. Through this post "Alu-alu packaging VS PVC packaging: what are the differences?", you may already have a preliminary understanding of these two packagings. If you have any new questions about these two types of packaging, you are welcome to consult us at any time. Take action now!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours