Blister Packer: The Complete Buying Guide In 2025

Blister packs were originally developed in 1960’s to encase medicines; the first blisters were used for oral contraceptives and aspirin but now they have a much broader range of applications. From cam shell to pen, from lip balm to calculators and so on and so forth blisters provide safety, security to the product it contains.

Whether you are a student or someone looking to increase their businesses you will find a concise and up to date information in this blog. Bringing you Blister Packer: The complete Buying Guide in 2022. In this blog we will cover blister packs, how are they made? Types of processes and equipment involved in manufacturing blister packs? And much more.

1.What are blister packs and how are they made?

It is the kind of primary packaging fabricated by heating plastic or aluminum film and molding this film into cavities. These cavities fully enclose the consumer goods such as tablets, capsules, pen, batteries etc.

Usually blister packs are manufactured by thermoforming or cold forming processes. In standard blister cardboard paper is present at the back while plastic blister pocket is at the front.

There are different shapes of blister packs available in market; sometimes even possessing unconventional shapes of products.

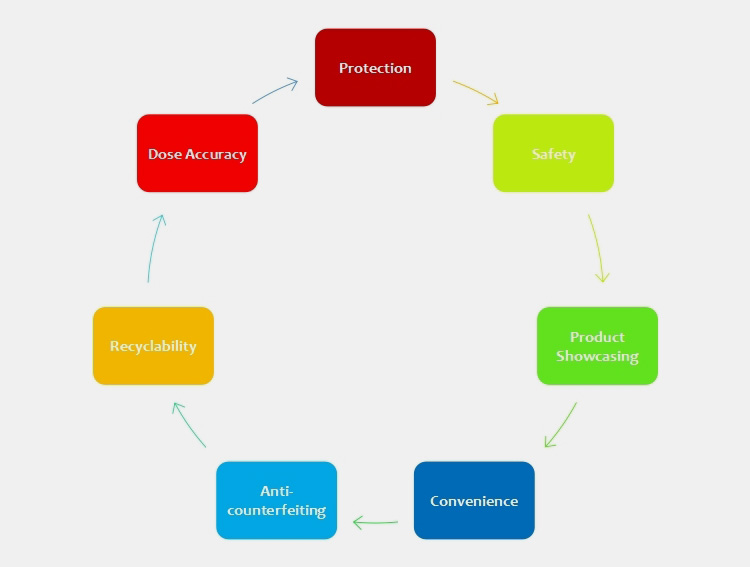

2.What are the advantages of blister packs?

Blister packs are versatile and common form of packaging. These are used for packing almost every kind of consumer goods. They offer some major benefits which include:

Protection

This packaging protects the product from environmental elements. The blister pack assist in stability of the product by providing adequate moisture and microbial control.

Safety

Blister packing aids in immobility of goods. The individual partition in blister packaging prevents movement of delicate items thus reducing their chances of damage.

Product Showcasing

Products in blister packs are self-evident that effortlessly attract the attention of customers thereby increasing the chances of moving from shelves to consumers’ home.

Convenience

Blister packs are easy to hold than bulky pill bottles and occupy small space thus are easily carried around while traveling.

Dose Accuracy

Individual pills are sealed in blister pack which provides visual cues for remembering daily medication dosage thus increasing patient compliance.

Anti-counterfeiting

It protects the merchandise from counterfeiting. Tampered products are easily distinguished by broken seal of blister packs.

Recyclability

These packs are composed of plastic and cardboard that are easily recycled.

3.Blister packs and their applications in various industries.

Almost every industry today, use blister packs for packaging wide ranging kinds of goods. Some applications of blister packs are:

Pharmaceutical Industry

In pharmaceutical industry, capsules (soft gel, hard gel), pills, mini-tablets, are packaged in tamper-proof blister packs for security and protection.

Food Industry

Versatile design blister packs are used for packing food items like chocolate, confectionaries, bakery goods, eggs, etc for preventing their contamination and damage.

Stationery Industry

Different stationery items like pens, inks, paper clips, pencils are packaged inside to avoid their shop lifting.

Technical Industry

Electronic items for instance batteries, headphones, flash drives, cables, nuts, and bolts are sealed inside the blister packs for lowering their damage due to rough handling and transportation.

Chemical Industry

Blister packs are essential in chemical industry for packaging of tube chemicals like adhesives, glues, paints to reduce their tampering.

Personal-care Industry

Full face sealed blister or full card blister are utilized in packing of personal care goods like toothbrushes, tooth paste, dental floss, creams to maximize their visibility.

4.Types of blister packs and the materials used for making them.

Consumer goods are packaged in various kinds of blister packs depending upon safety and security of products. Some kinds of blister packs are:

| Full-face Seal Blister

This blister is formed from plastic sheet and cardboards. This provides additional protection as it not only covers the merchandise but also surrounds the back cardboard. It is manufactured by heat sealing or by sliding extra plastic material on each edge. |

|

| Full Card Blister

The design of full card blister is same as that of full-face seal blister but difference in both these kinds are that the former is made by wrapping of flanges around blister. The card is either slid in place or is stapled to blister. |

|

| Face Seal Blister

It is created by molding of plastic film around objects and then heat sealing to cardboard back. This is used to packing bulk quantities of products. |

|

| Trapped Blister

The design format of this type of blister is similar to that of traditional pack but the blister is packed between two layers of cardboard. The top end has die cut design in order to place blister containing product between two cardboard pieces. |

|

| Clamshell

This does not have cardboard but are formed by two plastic layers that are hinged folded for opening and closing. The construction is somewhat similar to clam shells. |

|

| Mockup Clamshell

It is one part blister in which cardboard is sealed at the back end of blister. It is used for positioning and protecting cardboard. |

|

The most important thing next to type of blisters is the raw materials that are used to make them. Some materials used in creating blister packs are:

Polyvinyl chloride (PVC)

PVC is most commonly used material for fabricating blister packs due to its ease of molding and low price. It is about 0.2 to 0.3 mm in thickness and offers excellent chemical protection.

Polychlorotrifluoroethylene (PCTFE)

It is also known as Aclar film and is often used for its chemical inertness and abrasion resistance. This laminate layer is utilized for forming aseptic blister packaging due to its heat sterility.

Polyvinylidene chloride (PVDC)

PVDC is not itself forming substance but is routinely added to other materials to increase protection characteristics by ten folds. This laminate material augments elegance of product owing to its gloss and transparency.

Polypropylene (PP)

It is a superior alternative to PVC as it has high water impermeability and is recycled without any difficulty. PP does not emit dangerous chemicals upon incineration.

Cyclic Olefin Polymers (COP)

COP is a multi-layered material and has superior barrier against water. It is highly popular due to its exceptional thermoforming features.

5.Difference between blister packs and strip packs.

Both these types of packaging offer protection against harsh environmental conditions as well as aid in reducing damage to the product. But there are some differences in both these packaging:

| Blister Pack | Strip Pack |

|

|

| In blister packs, the plastic or aluminum sheet is heated and molded into pockets or bubble like cavities for placing the products. | In strip packing, the aluminum or paper sheets are heated and then products are enclosed and hermetically sealed between two webs of sheets. There are no pockets in strip packaging. |

| This packaging can have any design: from rectangular to oval; encompassing any shape of enclosed item. | It is available in oval, round or square shapes. |

| It is used for packaging numerous products such as capsules, tablets, toys, batteries, bulbs, pen, etc. | These are generally used for packaging limited items for instance tablets, fertilizers, pH buffers, camphor etc. |

| This packaging has greater patient compliance as individuals can easily see packaged product. Moreover, these are opened simply by pushing the pills. | Strip packaging is not preferred by consumers as opening of these packs require a lot of dexterity and products are not visible that can cause problem in product consumption. |

| Blister packs are less expensive to manufacture. | Strip packs are more costly to produce. |

| Materials used in blister packaging are not easily recycled. | 90% of strip packaging forming materials is recycled and reused. |

6.Are blister packs child resistant?

The blister packing has evolved since its invention i.e. it has gone from simple means of securing medication to fully child proof packaging.

The child resistant blister packaging not only provides safety but has an added benefit of preventing children from getting access to medicine.

Children do not push medication but rather puncture holes in blister by using their small fingers. Different materials such as polyester or polyamide films are used for manufacturing puncture resistant blisters but these blisters are peeled easily by adults.

Some companies used ultrasonic welding for fusing two plastic layers of tablet strips and blister backs- this ensures that tablets are fully locked in and cannot be opened by children of age six or lower.

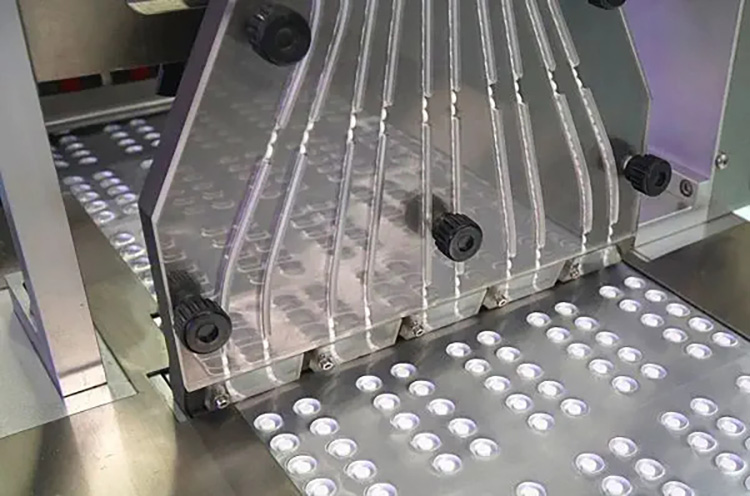

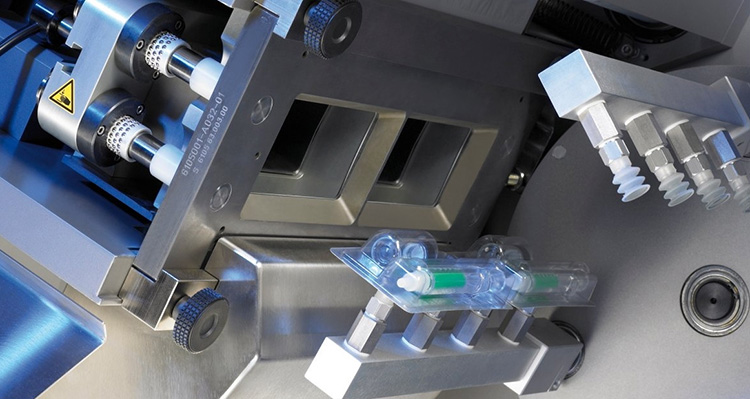

7.What is a blister packer?

Blister packers are mechanical device comprising of mobile and stationary components that work as one for heating and molding of plastic polymers and aluminum foils. These create cavities or bubbles for inserting and sealing the products such as tablets and capsules.

These equipment either use thermoforming or cold forming process for molding the forming materials in desired shapes. They are widely employed in pharmaceutical, food, electronic, and other industries for packaging of goods.

8.Automatic blister packer; a brief overview.

Automatic blister packers are well suited for mass scale productions. These packers have large production capacity and can pack bulk quantities of consumer goods in minimal time.

These are fully automated and are often customized with robotics for loading products, molding plastic sheets, fabricating pocket bubbles, placing products within pockets and sealing the material layers.

Automatic blister packers have PLC touch screen, sensors, alarms for detecting problems in machine functioning and for improving consistency in blister packaging.

9.What Blister packers have to offer? Features and specifications.

Blister packers are versatile machine having several technological advanced features such as:

- These packers are equipped with servomotors for even and precise material unwinding and molding.

- They have compact hygienic stainless steel construction manufactured according to cGMP regulations.

- The machines are furbished with safety lock doors for preventing accidents.

- Vision systems and camera are utilized to inspect the errors in blister formation and packaging.

- Dedicated feeders having large filing capacity and dust exhaust systems are used for loading filling products on machines.

- These equipment have automatic heat control that lowers heat loss and also maintain optimum temperature.

- They have hydraulic gas pressure system for efficient sealing of blisters.

- Touch screen setting minimizes the time for batch changeover.

- The machines are offered with cross punching station that efficiently trims the blister and reduce material wastage.

Some specifications of a standard blister packers are:

| Speed | 15-60 cycles per minute |

| Output | 100-300 blister per minute |

| Net weight | 800-1500 kilogram |

| Dimension | 4000 mm (L) x 650 mm (W) x 1200 mm (H) |

| Lidding material | Aluminum, paper |

| Maximum forming depth | 12-15 millimeter |

| Air pressure | 0.4-0.6MPa |

| Water consumption | 240 liter per hour |

| Reel Diameter | 440 (PVC) |

| Voltage | 220VAC, phase 3 |

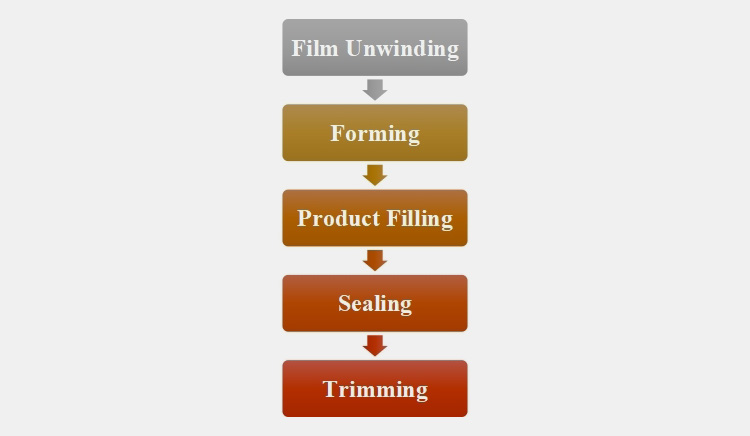

10.What is the working principle of blister packer?

The step by step working of blister packer is given below:

Film Unwinding

First forming film (plastic or aluminum) are put on film reel. The motor powers the bearings that rotate and pass the film across guiding and positioning rollers. The bearings carry the film roll to forming station.

Forming

At forming station, the plastic sheets are heated by heating rods at temperature greater than 130°C that soften plastic which is drawn into molds by vacuum. The molding results in blister of desired shape.

Product Filling

The molded blisters are transferred by servomotor to filling station. The items are filled inside the blister bubbles by feeders. The sensors are used for determining the accuracy of filling.

Sealing

Next step after filling of items in blister is sealing. The sealing of blister is done by heat sealing rollers or plate pressing. Roller and pressing plates have texture on them which is imprinted on aluminum foil after sealing.

High pressure and heat is employed for sealing of blisters.

Trimming

The blisters are transported to trimming station for cutting the corner of blister for creating rounded edge blister. Also, a flimsy mark is thumped on blister for their manual separation.

11.Difference between blister packers and strip packers.

Blister packers and strip packers may have same function and some similar parts but are entirely different machines. Some differences between blister packs and strip packers are as follows:

| Blister packers | Strip packers |

|

|

| Blister packers are the machines that form blister cavities by heating and shaping plastic materials. These machines fill the pockets by items and then sealed them with pressure and high temperature. | Strip packers use crimp rollers for fashioning plastic or paper layers and load the products between two layers. Afterwards, these two layers are sealed by heating device. |

| These equipment have more production efficiency and can form 600 blisters per minute. | These machines are generally slow only producing 250 strips per minute. |

| They use less material for forming blisters. | Strip packers need more raw materials for making strips. |

| These equipment have less running cost. | These instruments have more running expenses. |

12.Major components of a standard blister packer; an insight.

Blister packers consist of various electric and mechanical components that work together as unit for efficient blister packing.

Some important parts in blister packers are:

| Touch screen interface

Touch screen is used for monitoring progress of machine operation, its status, and problem diagnosis. The operational commands and parameter are set on HMI. |

|

| Servo Drives

These provide necessary energy for motion of various parts by transforming electric power into mechanical energy. |

|

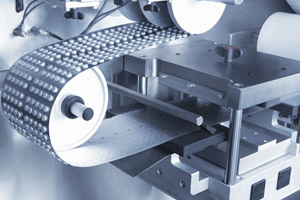

| Feed rollers

The rollers are powered by motors and continuously rotate for driving the plastic forming sheets turning rollers. |

|

| Turning rollers

They exert tension on starting materials and carry them to forming unit. These together with feed roller form feeding system. |

|

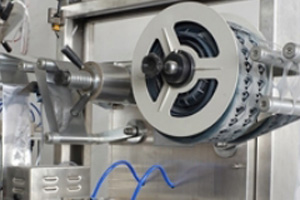

| Blister Forming Unit

Forming rollers in forming station have holes for pressing and molding polymer sheets into desired design. |

|

| Sealing Plates

The sealing plates or rollers are used for sealing the filled blister with lidding material using high pressure and temperature. |

|

| Punch Station

The function of punching station is to eject blister cards from forming and sealing web. This also split the blistered products. |

|

| Product Chute

This is the part which ejects the newly formed blister from the machine. |

|

| Waste Material Collector

It stockpiles the waste of forming and lidding film. |

|

13.Troubleshooting of some common problems.

Every machine operation is filled with problem but these can be easily rectified by knowing your machine and following some guidelines. Given below are some commonly occurring problems and their solutions;

| Problem | Cause | Remedy |

| Blister are struck in the forming station |

|

|

| Forming station does not fully open |

|

|

| Blisters are damaged in sealing unit |

|

|

| Overloading of servomotors |

|

|

| Slippage of forming and lidding materials in punching station |

|

|

| Decrease air pressure |

|

|

14.What are general safety considerations when operating this equipment?

Safety considerations are essential in minimizing the risk of accidents. Few safety considerations while operating blister packers include:

- Install the blister packers away from heated and humid environment.

- Avoid touching hot molding and sealing plates as they may cause serious burns.

- Do not use foreign tools and place hands in moving parts of machine.

- Ensure the voltage settings are appropriate as per machine power specification.

- Safety locks doors should be closed all the times except during routine maintenance.

- The personnel must wear proper clothing and gloves while working to prevent any accident.

- Power off the packer immediately if it produces unusual sounds.

- Ensure that electrical gadgets are not in contact with the equipment for preventing electric incidents.

15.How to maintain your equipment?

Regular maintenance guarantees a healthy and trouble free machine throughout its working life and also saves your repair cost.

Some maintenance hacks for your equipment are:

| Daily | Clean the frame of machine before and after every batch processing.

Regularly inspect thickness mechanism of forming unit to avoid slacking of drive shafts. Lubricate the moving parts to prevent friction buildup. |

| Weekly | Check for leakage in compressed air pipes.

Fasten lose electric connection and cables. Inspect working condition of all buttons and control system. Check heating elements to avoid malfunction. |

| Monthly | Inspect the vibrating coil and replace the worn out springs in coil.

Tighten the loose line connections. Inspect the heat and seal roller, if necessary then replace these old rollers. Check the line sensor in order to ensure proper sensing. |

Conclusion

Blister packers are state of the art equipment designed to make blisters of any size and shape. This machine has extensive application in every aspect of daily life including but not limited to health care sector and food industry. If you require further assistance or need answers to your queries for unique customization of product; you can contact our 24/7 customer care service at Aipak.

Aipak is China’s leading turnkey solution provider bagging over a decade of experience in manufacturing, customizing and installing equipment. Our operations extend to more than 30 countries across 5 continents. We hope to hear from you soon. Happy shopping!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine