PLC programming combined with photoelectric detection control

Touch screen man-machine interface operation

Equipped with the overload protection system

Want A Free Consultation

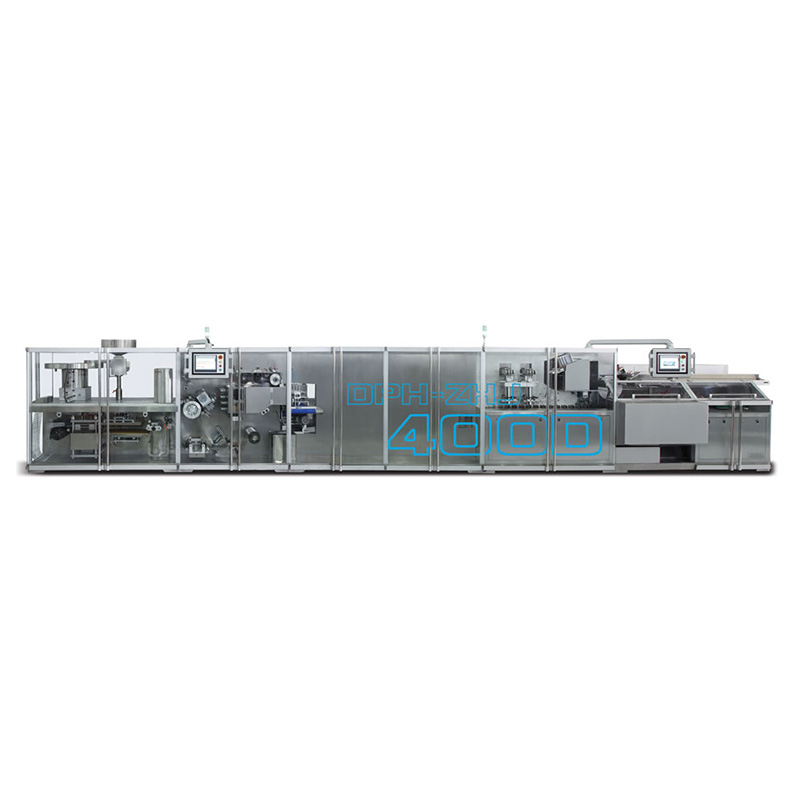

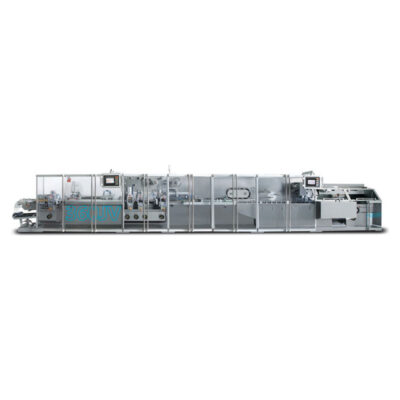

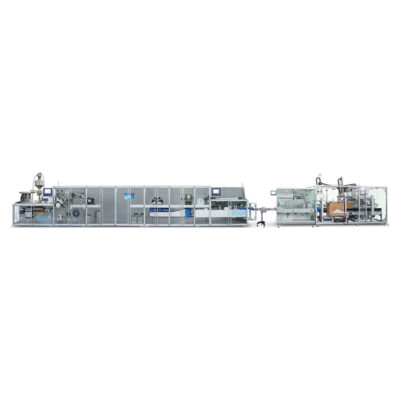

DPH-ZHJ400DHigh-speed ALU PVC blister packing machine and automatic cartoning machine production line

AIPAK DPH-ZHJ400D High speed ALU PVC blister packaging machine and automatic cartoning machine production line is suitable for high speed alu PVC packing of medicines, especially capsules, tablets and sugar-coated tablets. It is equipped with auto vision system and rejection device. Blisters automatically queue to be transmitted to feeder of high speed automatic cartoning machine, then automatic high speed cartoning machine packs blisters and leaflets into cartons and do batching no. The entire process is automatically controlled to save labor and work space. The high automation and high purity also make machine more in line with GMP standard.

FEATURE

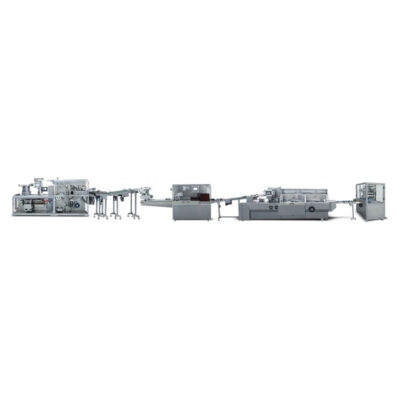

1.This model is suitable for automatic feeding and boxing of various types of blisters, bottles, ointments and other items;

2.On-line material conveying and testing, manual folding (1 to 4 folds) and transmission, manual testing, carton suction forming and transmission, material loading into boxes, embossing batch numbers, paper tongue sealing at both ends of cartons (also applicable to thermal Melt glue) The process of removing missing materials and finished product output is automatically completed; it is the best choice for linkage production and mass production.

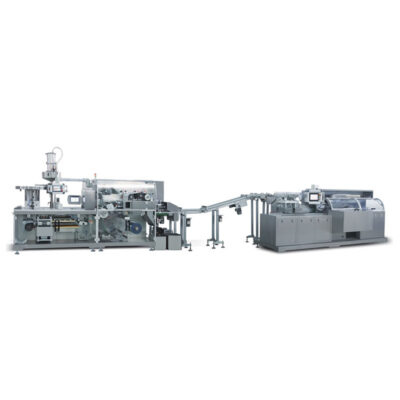

3.The cartoning machine adopts PLC programming, combined with photoelectric detection control, touch screen man-machine interface operation;

4.There are codes and addresses of the actuators and actuators of each sensor in the touch screen, and the consequences caused by damage to the sensors and actuators can be queried.

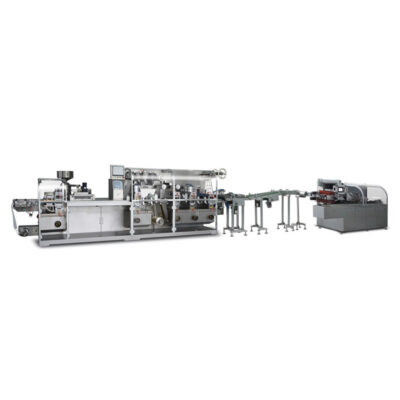

5.Equipped with the overload protection system of the whole machine, the overload protection system of the conveying chain, and the overload protection system of the push handle, it will automatically stop when overload such as jamming occurs, and the overload position will be displayed on the touch screen to reduce damage to the equipment.

DATA SHEET

Main Technical Parameter(High speed blister packing machine)

| Model | DPH-380D | ||

| Punch Frequency | 60-180times/min | ||

| Max. Forming area | 240×370mm | ||

| Max. Forming depth | 13mm | ||

| Traction stroke | Punch:20-120mm Forming:80-250mm | ||

| Blister specification | Standard:80×57、95×65、103×43(Customized allowed) | ||

| Packing material | Cold ALU ALU | 0.14-0.16×380mm | |

| Standard PVC hard sheet | 0.15-0.5×380mm | ||

| Standard PTP Aluminum foi | 0.02-0.035×380mm | ||

| Average hole diameter rofroll | 70-76mm | ||

| Air consumption | ≥30 m3/h (Self-contained) pressure:0.6-0.8Mpa | ||

| Mould Cooling | tap water or recycle water 60L/h | ||

| Total power | 22KW | ||

| Main motor | 3.0KW | ||

| Overall dimension (L×W×H) | 4050×1030×1750mm | ||

| Weight | 3500Kg | ||

Main Technical Parameter (High speed cartoning machine)

| Model | ZHJ-400 |

| Cartoning speed | ≤400(ctns/min) |

| Carton size (L×W×H) | (50-200)×(20-80)×(15-60)mm |

| Leaflet size (L×W) | (100-260)×(100-180)mm |

| Power | 380VAC, 50HZ 5KW |

| Main motor | 2.2Kw |

| Air pressure | 0.6-0.8Mpa |

| Air consumption | ≥5m3/h |

| Overall dimension | 4500×1500×1700 |

| Weight | 4000kg |

VIDEO

CONTACT

Get in touch with an expert

We´re looking forward to find the suitable solution for your product. Please contact:

We´re looking forward to find the suitable solution for your product. Please contact:

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951