5 Questions To Answer Before Requesting A Capsule Filling Machine

Presently, a capsule filling machine gives you as many as 200,000 capsules/hour. Thanks to modern science and technology that promotes better types of machinery, better control, and a better understanding of customers’ needs. If you’re planning to buy, we have designed basic 5 questions to answer before requesting a capsule filling machine.

This informative review gives you common questions that your vendor may ask about capsule filling machine. So, let’s get started.

Table of Contents

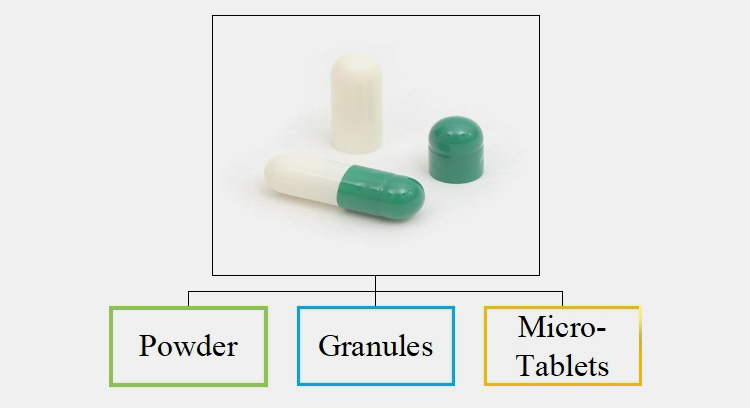

Ⅰ.What Material You Are Going To Fill-in? Powder, Granule, or Liquid?

In general, any type of formulation is required to be dosed into hard gelatin capsules either powder, granules, coated beads, micro- tablets, small capsules, or various combinations of any mentioned form; a hard gelatin capsule is an acceptable way of drug delivery.

So, what would be the recommendation for capsules filled with liquid?

You must know that due to the presence of plasticizers in the capsule shell, conventional hard gelatin capsules have high moisture content in them e.g. 13-16%. Due to this reason, formulations with hygroscopic content can be prone to absorb moisture from hard gelatin capsules resulting in brittle, and breakage of the capsule under mechanical stress.

To deal with such a situation capsule liquid filling and sealing machine is significantly important. You will be recommended to use HPMC capsules or capsules with little moisture content. A capsule liquid filling and sealing machine is convenient for filling concepts (solution, suspension, and micro-emulsion) and is frequently used in pharmaceuticals, health, and cosmetic industries.

Ⅱ.What Production Capacity Do You Require?

Before consulting a vendor; you must do with an initial assessment of production capacity. This can be achieved by simple math. For that, you can estimate the capsule filling requirements for each minute to an hour to the whole shift (8 hours).

This information may help your supplier to adjust the filling rate and try to offer the best option that can increase your production rate. In the end, the necessary quantity of capsules filled each would be a fairly simple task. However, many customers hope for and expect high growth without doing proper analysis before adding new equipment may find it a little difficult.

So, what type of machine can fulfill your requirement?

By knowing the production rate, your vendor would be able to suggest the type of machine according to its automation.

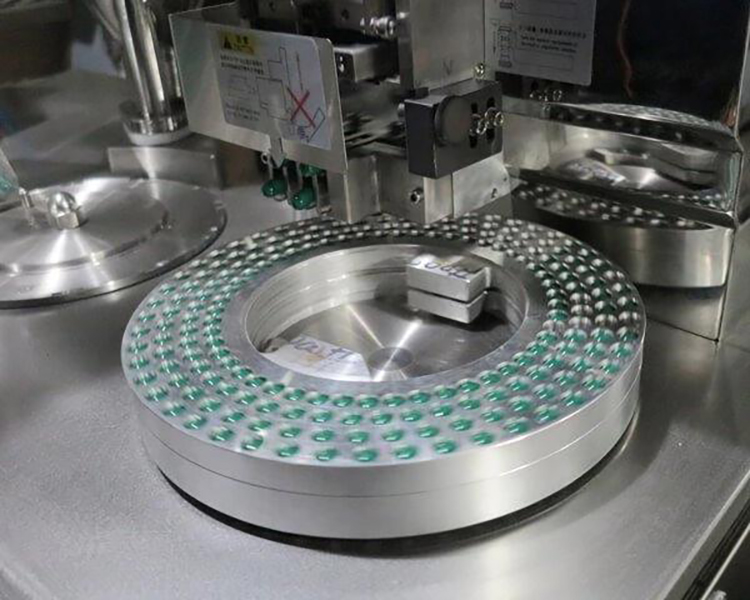

AUTOMATIC CAPSULE FILLING MACHINE

Automatic Capsule Filling Machine

An automatic capsule filling machine is capable of filling thousands (average 200,000 to 400,000) of capsules each hour. In each eight hours workday, it equates up to lacs individual capsules produced ultimately over a week it can reach you to million.

The automatic capsule filling machine automates the production line from start to end. It orients, separates, loads the two halves with the intended formulation, and then closes it.

Your vendor might suggest you an automatic capsule filling machine due to many reasons where this kind of unit would be proven as most relevant. For instance, pharmaceutical manufacturing processes, Multiple production lines that are handled by your team where you cannot give time to each batch, or operating facilities meet extremely high- production requirement

SEMI-AUTOMATIC CAPSULE FILLING MACHINE

Semi-Automatic Capsule Filling Machine

This machine has combined elements of both automatic and manual machines to streamline production while allowing a significant amount of manual operation. If you have a comparatively large or small production line with a limited budget then your vendor might suggest this option to pick. Why?

Because you will be pleased with the smooth operation of semi-automatic units as it allows you to fill your capsules quickly with professional results. But it requires the technician to assist with production by conveying the filling plates between the various production stages.

This line is equipped with an automatic capsule conveying unit that transport finished capsules to integrated units where it is needed. The average production capacity of a semi-automatic capsule filling machine varies from 25000 to 47000 per hour (depending on the brand to the brand).

MANUAL OR HAND-HELD CAPSULE FILLING MACHINE

Manual Capsule Filling Machine

This machine requires the participation of the operator to form a completed product. Unlike an automatic machine, it is difficult to get a precise rate of capsules per hour. So, it is up to your speed and production requirement as well as the size of the capsule that drives the production capacity.

This machine is suitable for small batches where an operator can adjust the bottom halves of capsules in the tray’s holes. The bottoms are filled with the intended formulation then the operator can press the tray to close the bottom halves and tightens them to create a seal. This unit requires more and more attention than an automatic version. The average production capacity of manual capsule fillers varies from one hundred to a thousand per hour.

Ⅲ.What Is Your Capsule Size? Why Are You Required To Determine It?

Figuring production rates for the present production is fairly simple but trying to determine the growth and ensuring that a capsule filling machine can handle an increased production in the future is somewhat difficult.

For this, you can't ignore capsule size and weight if planning for buying a new capsule filling machine.

Why are you required to determine the capsule size and fill weight?

The choice of capsule size and filling is accompanied by unit dose requirement and type of formulation used. If you have developed a formula and the weight to be dispensed is known; then it is easy to define an appropriate capsule size.

Moreover, the capsule’s body has a defined volume itself too; knowing the density of the filling mixture may help you to establish the volume to be occupied and filled in each capsule.

| Powder & Granulate

|

When your formulation is composed of powder or granulate, then you must assess its tapped density ensure to determine a suitable capsule size. Tapped Density: is an increased bulk density that is attained after mechanically tapping a container or graduated cylinder filled with powder or granulate. |

| Micro-Beads or Pellets

|

When the formulation is composed of micro-beads or pellets, then there is no possibility of compaction or tapping. But it is essential to assess the bulk density. Bulk Density: this is an essential parameter in the pharmaceutical sector. It is used to determine the amount of substance that can fit into the assigned space (inter particulate void volume). Furthermore, all capsule filling machine vendors will supply you capsule size chart to help you in assessing the choice of capsule size. |

CAPSULE SIZE CHART

Be aware of when capsule size you want to produce in your capsule filling machine. You need to observe the swallowing parameters if you choose the largest size. Generally capsule size ranges from 000 to 5. Typically, preferred capsule sizes are 00-2 as they are smaller, versatile, and ensure easy swallowing.

Mentioned below is a capsule size guidance chart showing basic measurements and weights used for various capsule sizes.

EMPTY CAPSULE SIZE

| Capsule Size | 0 | 00E | 0 | 0E | 0 | 1 | 2 | 3 | 4 | 5 |

EMPTY CAPSULE WEIGHT

| Average Weight (mg) | 158 | 143 | 123 | 107 | 99 | 78 | 61 | 48 | 38 | 28 |

| Tolerance | ±10 | ±10 | ±7 | ±7 | ±6 | ±5 | ±4 | ±3 | ±3 | ±2 |

EMPTY CAPSULE VOLUME CAPACITY (ml)

| Capacity | 1.37 | 1 | 0.9 | 0.78 | 0.68 | 0.48 | 0.36 | 0.27 | 0.2 | 0.13 |

FORMULATION DENSITY

| Formulation Density | ||||||||||

| 0.6g/ml | 822 | 600 | 540 | 468 | 408 | 288 | 216 | 162 | 120 | 78 |

| 0.8g/ml | 1096 | 800 | 720 | 624 | 544 | 384 | 288 | 216 | 160 | 104 |

| 1.0g/ml | 1370 | 1000 | 900 | 780 | 680 | 480 | 360 | 270 | 200 | 130 |

| 1.2g/ml | 1644 | 1200 | 1080 | 936 | 816 | 576 | 432 | 324 | 240 | 156 |

ANTICIPATED RECOMMENDATION FROM YOUR PRODUCTION CAPACITY

By knowing production capacity and goal, your vendor can help you to suggest the right model and featured machine suitable for your production line.

Ⅳ.What Is Your Financial Estimation For The Capsule Filling Machine?

Those manufacturers who make health and nutritional products are under constant pressure as a ‘cost-leader’ to run the system under a leaner budget side by side producing new products quickly and economically satisfying according to consumer channels and outperforming the competition.

Your financial budget is the most important aspect when shopping for a capsule filling machine. Traditionally, your vendor may help to trim margin by assessing your cost. But it may lead to affect the machine’s quality as you deserve. It is not surprising that following this approach can come with some unwanted downsides. Hence, your supplier might have offered you some costly but good performance equipment that can bring better outcomes.

Ⅴ.Do You Have Any Other Requirements For A Capsule Filling Machine?

Not all machines will automate every aspect of capsule filling at one time. Once the capsule filling machine is chosen, ensure that equipment will integrate with existing operational units or with purchased in the future. Many automatic capsule filling machine is capable to roll up to any existing unit such as

- Capsule counting machine

- Capsule polishing

- Conveyor

- And a bottle filling machine

However, a semi-automatic capsule filling machine may not be versatile. Ensure that the machine chosen must be capable enough to work well with other required machines.

Conclusion

A capsule filling machine is what every good manufacturing company is looking for. 5 questions to answer before requesting a capsule filling machine is a comprehensive effort that encompasses the entire system. Aipak Pharmaceutical lays the foundation for a smooth capsule filling production process for all customers. The company ensures the highest quality machines that can handle hard gelatin and HPMC,ensures no liquid or powder leakage from capsules.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine