10 Best Capsule Filling Machine And 20 Production Capacity Increasing Ideas

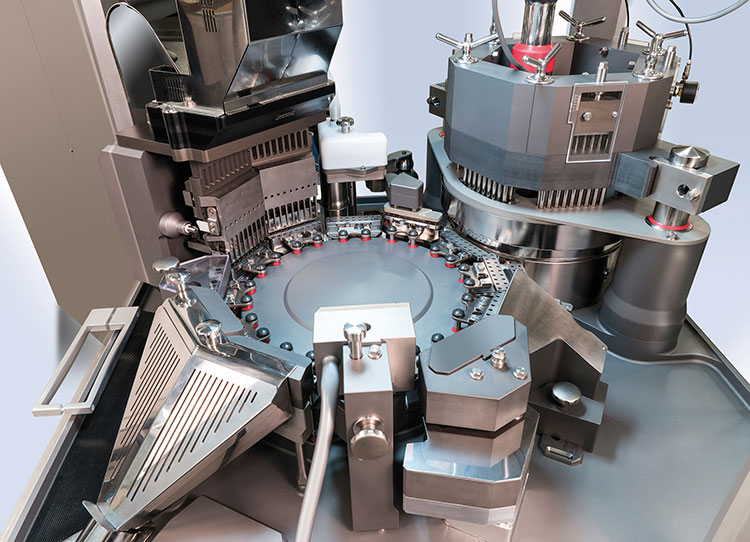

Back in 1950s capsules filling machines were only used for filling readily soluble powder ingredient in capsules. The need for encapsulating low dose and poorly soluble drug ingredients has revolutionized capsule filling equipments in 1960s and 1970s. Now these automations are employed for variety of solid and liquid dose materials such as pellets, micro-tablets, granules, etc.

If you are novice in capsule filling machines or are in need for upgrade your existing instrument then you should going through this guide “10 Best Capsule Filling Machine and 20 Production Capacity Increasing Ideas”. So you can learn about various capsule filling machines in market and also how should you increase your existing production capacity. Let’s delve into topic.

10 Best Capsule Filling Machine

1.Vacuum Wheel Dose

The best capsule filling equipment is furbished with a vacuum wheel dosing system for highly accurate filling of dry powder inhalation (DPI) and drug ingredients. This micro-dosing technology is employed to load extremely small quantities i-e 500 µg of active ingredients.

Drugs are filled inside capsules with great care to avoid agglomeration with a vacuum wheel dosing system. Furthermore, this dosing system generates minimal material waste while offering a high yield.

2.Liquid Filling/ Volumetric Filling

An ideal capsule filling machine has a liquid filling or volumetric station for encapsulating various kinds of liquids such as hydrophilic or thixotropic. These filling units are fitted with heaters to acquire the optimum viscosity of liquids during filling.

The function of volumetric dosing pumps is to dispense a precise and accurate volume of liquids in capsules by the movement of the pump.

3.Flexible Designing

Flexibility in designing is an essential feature of capsule fillers. These innovations accommodate both latest and traditional technologies and are easily furbished with various feeders, hoppers, and dosing systems to encapsulate a variety of products from mini-tablets to liquids.

4.Automatic High Precision Working

Capsule filling machines are equipped with high-tech innovation systems that provide automatic high precision dosing and filling. This built-in feature guarantees the quality and excellence of capsules. For ensuring the accuracy of encapsulation, the systems simply detect the height of the powder bed.

High-precision technology such as sensors and weighing systems also identifies faults in end products like deformity, denting, popping, brittleness, etc.

5.Stainless Steel Frame

Stainless steel construction holds several advantages for capsule filling automation. This alloy provides durability to capsule fillers and protection against corrosion resistance. Stainless steel equipment can withstand fire and heat.

This hygienic frame of capsule fillers is easily cleaned and sanitized. Accumulation of bacteria and dust on capsule fillers is prevented due to the smooth polish of the stainless steel exterior.

6.Safety System

Containment of filling area in paramount quality capsule filling equipment is all about the protection of the workforce. This protective barrier that separates product station from the operator work area is essential in preventing contamination of products.

These safety systems are vital in the aseptic processing of capsules and also put off operator exposure to severely harmful active drug ingredients.

7.Modular Assembly

This attribute of capsule filling machines is ideal for processing several batches per day. A modular assembly consisting of a quick change of parts offers high production capacity in considerably less time. These quick lever components are dismantled without needing tools.

Furthermore, this reconfigurable modular construction is cleaned in minimal time resulting in quick batch processing.

8.Capsule Hopper & Sensor Level

Superior quality capsule fillers are equipped with a capsule hopper having built-in level sensor for ensuring that level of empty capsules remains at programmed threshold in hopper. These sensors control the flow of capsules to the filling station and reduce the wastage of empty capsules.

9.Capsule Filling With Different Sizes

The filling of various-sized capsule is key attribute of capsule filling machine. This contributes to the versatility and flexibility of the equipment. Drug ingredients as large as 1370 mg and as small as 60 mg are conveniently encapsulated in 8 different sized which are 000, 00, 1, 2, 3, 4, and 5 by the automation.

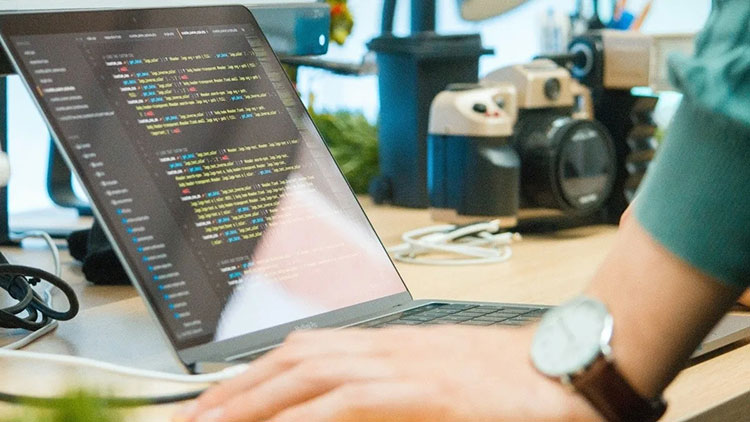

10.PLC Programming Software

Capsule fillers are equipped with futuristic PLC computerized systems that aid in better machine control and management. PLC allows monitoring the entire filling process and also assists in self-diagnosis and troubleshooting.

This high-tech software cut down production expenses and increases data security.

B.20 Production Capacity Increasing Ideas

1.Invest in New Instrument

If your wallet allows then consider replacing old capsule fillers with the latest tech capsule filling machines. This will significantly elevate your manufacturing capacity. New machines are fabricated with sophisticated components like large hoppers, filling stations and sealing systems that have capability to process large batches of capsules in small time period.

2.Purchase Management

This problem prohibits your capsule fillers from giving their maximum production efficiency. If you experience late shipment of equipment or vendors send you the wrong machine or damaged equipment that slows down the capsule filling process.

To avoid these issues find the right supplier who will of service at any time.

3.Use of Floor Space

Floor space matters a lot as capsule filling machines need clearance space for the workforce for accessing and maintaining equipment. Cluttering causes work hazards and lower your machine efficiency. So if you have limited floor space then invest in capsule filling machines having a smaller footprint.

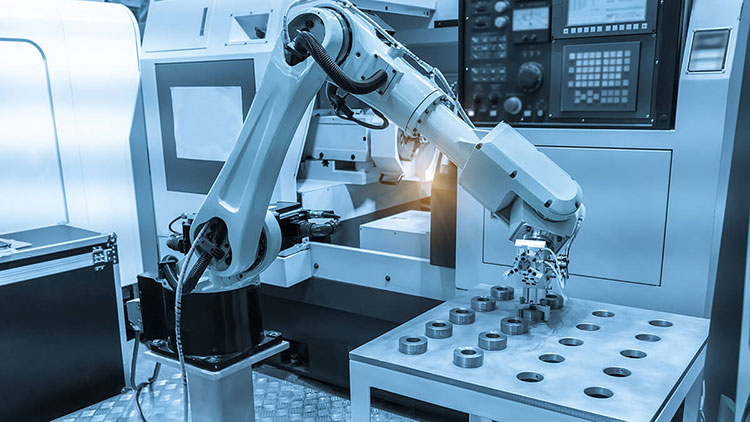

4.Automation

Increasing automation of capsule filling machines can boost their encapsulation efficiency and assist in short lead times. Switching manually operated components with self-automated parts and robotic technology capacity assist to achieve consistency in filling procedure.

5.Outsourcing Production

Sometimes it is quite difficult to meet consumer demand of filled capsule even after running capsule fillers at their optimal capacity. So it is best to sub-contract some burden to other manufacturer in order to attain required amount of product in short term.

6.Reduction in Downtimes

Downtime is the biggest hurdle in achieving the highest production capacity and results in critical revenue loss. You can lower the rate of downtime by monitoring entire capsule filling process.

Production monitoring software can display real-time performance of capsule fillers and also allows you to detect and resolve imminent machine failure before time

7.Customization

Designing a capsule filling machine according to your exact specifications is a common approach for expanding your equipment capacity. Selecting machine according to your fill material and fill principle is a way of customizing your automation.

Accessorizing these equipments with various add-ons such as capsule polisher, empty capsule sorter, etc is another approach for tailor designing instruments.

8.Robotics and Sensors

By equipping the machine with high-tech sophisticated robotics and sensors you can enhance your existing capsule filler performance. Robotics is precise in filling and loading materials. While advanced sensor and camera vision systems can identify filling or sealing errors in capsules consequently leading to minimal product waste.

9.Regular Maintenance

Proactive and regular maintenance of capsule fillers can boost their performance. Setting maintenance alerts can inform you about scheduled machine upkeep. This ensures that capsule filling machines are running at optimum capacity during production time.

10.Investing in CIP Systems

CIP system comprising of chemical sanitizers and water pumps is an effective method for getting rid of drug dust and debris that can otherwise cause jamming and freezing of capsule filler equipment sequentially reducing production capacity.

11.Quick Changeovers

Fast format change increases the versatility of capsule fillers which in turn increases their production efficiency. Replacing gear by servomotors, purchasing lightweight components, and easy opening locking systems speed up the change of parts while cutting down machine outage.

12.Adding More Shifts

The production capacity of capsule fillers is increased by adding more shifts in a day. A different group of operators makes sure that filling equipment operates for a longer period thus filling more capsule per day.

13.Training Workforce

There is a direct correlation between training the workforce and the productivity of machine. When operators are skilled in handling capsule filling machines then there is decreased chance of error while operating equipment.

Training increases the work efficiency of laborers and helps them to safely repair machines.

14.Bottleneck Identification

Efficiency is lowered when capsule filling equipment is not working to its full ability. Some components face bottlenecks and limit the entire filling process. Various computerized diagnostic tools aid you in identifying wait time and throughput of different components.

15.Flexibility

Flexibility in capsule fillers facilitates meeting real-time manufacturing requirements. Different-sized capsules could be conveniently filled by investing in parts that fill different volume ingredients in capsules with HMI reprogramming.

You can also improve the flexibility of your fillers by purchasing feeders that handle various fill materials such as pellets, micro-tablets, powders, and granules.

16.Integration

The efficiency of capsule fillers can be increased by integrating it with various other machines such as mixers, capsule manufacturing equipment, capsule inspection equipment, etc.

The packaging integrator assists you in designing your capsule manufacturing line.

17.Layout Improvement

Improving your in-house layout aids you in using your capsule filling machines to the fullest. Rearranging your production line will allow you to better utilization of raw fill material for filling capsules and in managing product waste more efficiently.

18.Adequate Raw Materials

Managing inventory of fill materials and ensuring an adequate supply of empty capsule is the failsafe means to boost the production efficiency of capsule fillers. With longer shipment time, it is best to store raw materials on site for avoiding unnecessary delays in capsule filling process.

19.Improve Quality

The efficiency of capsule filling machine is negatively impacted by poor quality of capsules. These flawed capsules are usually thrown away causing the loss of yield. The quality of filling process is improved by decreasing human error and optimizing encapsulation workflow.

20.Safety and Security

Safe handling and data security are necessary for increasing the capacity of capsule filling machine. Safety reduces the risk of operator injury and machine damage. Security of machinery ensures that authorized personnel programs HMI and access data recipes for preventing deceptive machine manipulation.

Conclusion

Best capsule filling machines are endowed with several handy attributes as mentioned above to give you the best outcomes. By going through this guide, hope you have got various ideas for boosting your capsule filling business. If you have any questions regarding capsule filling equipment, purchasing, or buying a guidance program; Our Hi-Tech Experts Welcome You For Free Assistance!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours