Types Of Capsule Filling Machines For Pharmacy

In the pharmacy, it is essential to have the right type of capsule filling machine to perform specific encapsulation jobs. Commercially, you can call them ‘Capsule Fillers’.

In the past few years, capsule filling machines have become very popular across the globe. It includes: R&D, pharmaceuticals, and hospital set ups for small as well as large batches.

Learn more about ‘Types of Capsule Filling Machines for Pharmacy’ in this informative blog.

Table of Contents

Ⅰ.What are the types of capsule filling machines for pharmacy?

Capsule filling machinery is split up into 3 main types, manual, semi-automatic and fully automatic.

Manual Capsule Filling Machine

A manual capsule filling machine is an exceptional and cost-saving solution to create products. This form of filling unit is suitable for two categories: business, entrepreneurs, R&D unit, and individual use. You can implement a manual capsule filling machine without spending thousands on equipment. Furthermore, this machine allows you to deal matter into your own hands and know exactly what formulations are going into it, thus you can save a large amount of money.

Semi-Automatic Capsule Filling Machines

A semi-automatic capsule machine produces greater economical solution in upfront expenditure; however, it has more interaction with the operator. Whenever a company decides on a new business, they merely begin with semi-automatic capsule filling machines to prove their concepts. Here, operator performance is required throughout the leading steps to assist production.

Fully Automatic Capsule Filling Machines

This machine will need monitoring like every industrial machinery that runs a large production batch. The machine requires less interaction of operator as compared to semi-automatic. It ensures continuous processing with only one operator, hence in this term machine is much cost economical.

Automatic machines are extremely popular among multinational and local industries for fast and efficient production outcomes. Their incredible designs and innovative features ensure high productivity in the pharmaceutical sector.

Ⅱ.What is the working principle of types of capsule filling machines for pharmacy?

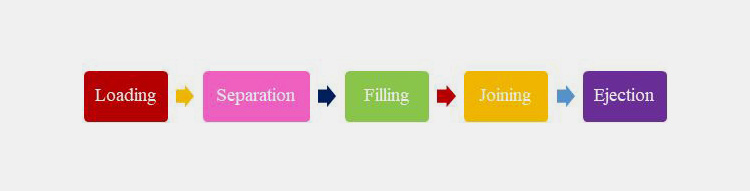

While considering manual, semi-automatic, or automatic capsule filling machines. Its central working principle is based on the above-mentioned steps e.g., separation, loading, filling, joining, and ejection.

However, in the case of a manual capsule filling procedure, you will need to separate the capsule components prior to load into the unit.

MANUAL CAPSULE FILLING MACHINE

| STEP #1 | For filling, you need to separate the capsules into the top cap and bottom base.

Fill the deeper plate with the bottom base of the capsule by using a sorting tray. You will need to shake the tray continuously. After shaking, check if all capsules are positioned correctly. |

| STEP #2

|

It's turned to fill the capsule! Spread the filling material (powder, granules, beads) evenly over the deeper plate and compress the material with the pressing tool. Clean off the excessive matter and allow the plate to fit together. |

| STEP #3

|

Now by repeating step #2, fill the shorter caps and make sure they are positioned correctly. Place the two halves together & press them down gently. Turn it over and press them again to remove the top off. |

| STEP #4

|

Gently press the capsules downward and ensure they are firmed together tightly.

Capsules are now ready to use! |

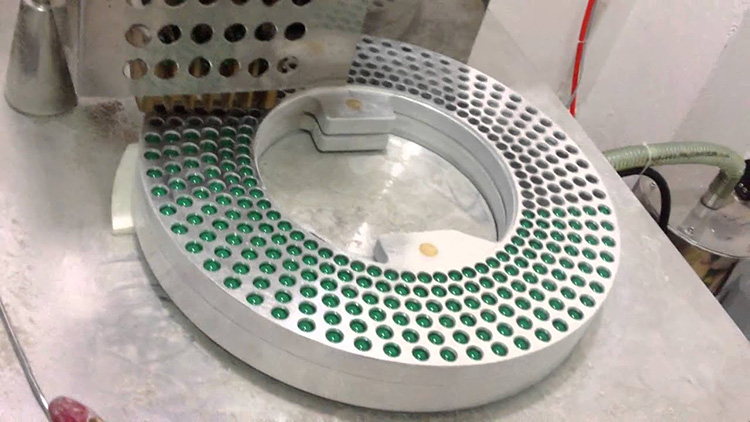

SEMI-AUTOMATIC CAPSULE FILLING MACHINE

| STEP #1- LOADING | Load the empty capsule manually into the large hopper made up of metal. Fill the powder hopper with formulation (powder or granules).

Place the circular mounting plate beneath the capsule bucket. By pressing the ‘ON’ button, a vacuum sucker will load the capsule onto the filling plate. The vacuum will automatically stop at the end of a cycle, or manually by pressing ‘OFF’. |

| STEP #2- SEPARATION | Once the filling plate is completely loaded, operate the vacuum to divide the upper and lower halves of the capsules. |

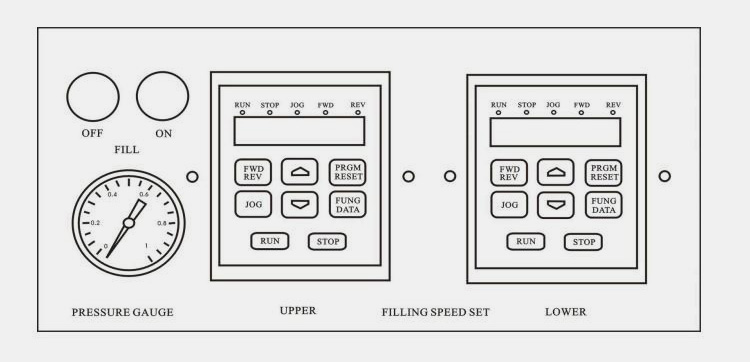

| STEP#3- FILLING | Manually pull the two halves of the filling plate to release the bottom section of the capsules.

Now, operate the machine to fill the bottom base of the capsules automatically with the dose. In semi-automatic, you can set the dose by control panel adjustment. Again, place the plate to seal the section. |

| STEP #4- SEALING &EJECTION | With the help of air pressure, two halves get closures to each capsule tightly and sealed. After sealing, they are ejected into the capsule collection box. |

AUTOMATIC CAPSULE FILLING MACHINE

| STEP #1- CAPSULE RECTIFICATION | Randomly pouring of the capsule onto the capsule delivery plate allows capsules go to the circular channel.

The capsule moves downward for further rectification as the body or cap may be not aligned. A horizontal and vertical fork helps to adjust the body downward. |

| STEP#2- SEPARATION | With the help of a vacuum separator, the upper surface of the capsule rises to leave the bodies remain downward. |

| STEP#3- FILLING | The capsule body will be conveyed to the filling unit for filling medication. This procedure follows many ways such as tamping, intermittent dosator filling, dosage cylinder filling, and vacuum filling. |

| STEP#4- WASTED CAPSULE EJECTION | If the empty capsule is failed to separate due to some reason, it will be pulled out of the mold and blown into a capsule collection bag. |

| STEP#5- CAPSULE LOCKING | The capsule tray rotates to the locking unit, at the same time the upper and lower capsule tray overlaps and locks together. |

| STEP#6- FILLED CAPSULE EJECTION | This device is similar to a rejection device. Where locked capsules are pulled out of the capsule tray and compressed air blows them toward the outlet. |

| STEP#7- CLEANING | The capsule tray now automatically moves to the first unit for capsule rectification. Compressed air ensures the cleaning of remnant powders or granules onto the tray. |

Ⅲ.What are the advantages of a capsule filling machine?

A capsule filling machine is suitable equipment for small to large-scale production lines required for the manufacturing of dosage delivery units.

This is because of its exceptional advantages. Some of them are:

Easy To Operate

With simple operating options, a capsule filling machine is an easy-to-operate device. The entire processing steps such as filling weight, speed selection, capsule adjustment, length adjustment, etc. are performed by this equipment.

Accurate Doses

This is a consistent machine, which is considered a key to every happy customer. A capsule filling machine is well-engineered equipment that produces accurately filled capsules.

Minimal Downtime

A capsule filling machine is designed for easy access for cleaning as well as lubrication. You can easily remove various parts for cleaning purpose such as hopper. Due to easy maintenance and cleaning access; this machine has maximum working life with lesser

Capable Of Filling Powder, Pellets, Or Granules

Capsule filling machine is suitable for variety of fillings efficiently, such as powders, pellets, or granules.

Fills Various Capsule Sizes

You can fill the capsules with size ranging from 000- to 5. Simply load the them, while rest of the job will be performed by an automatic capsule filling machine.

Capsule Counting

With the advancement in technological sciences, today capsule filling machines are featured with a built-in counter. This characteristic benefits you in the terms of accuracy, cost, and time.

Capsule Rejection

Capsule rejection property ensures that produced capsules are appropriately filled without any drawback or damage.

Ⅳ.Describe the major difference between types of capsule filling machines used in pharmacy?

Simply, semi-automatic and automatic capsule filling machines, both carry near to similar automation with slight differences. The mentioned differences will let you know some differences:

| Semi-Automatic Capsule Filling Machine | Automatic Capsule Filling Machine |

| The machine requires more interaction with operators. | Only one operator is required to monitor the process. |

| The machine is suitable for buyers with a low budget. | The machine costs a bit higher as compared to semi-automatic. |

| The machine can produce high output suitable for small or medium batch production. | Higher output than semi-automatic unit popular for large production batches. |

Ⅴ.From low to high production line: Which types of capsule filling machine for pharmacy is ideal for you?

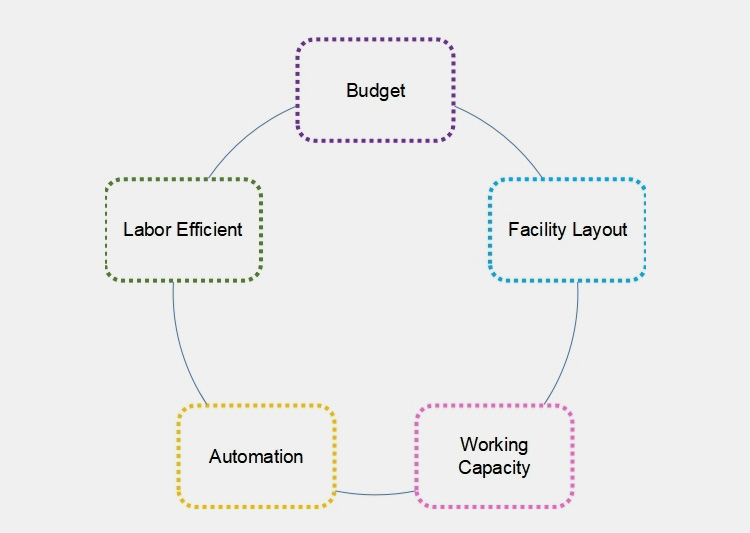

Indeed, there are extensive ranges of capsule filling machines in the market. For example, manual to automatic, various models, and from local to international brands.

On one side these machines can ease your job by offering unlimited features, but on the other side choosing the right one is a difficult task.

For this, you need to do a thorough analysis of your requirements before placing an order. You need to consider:

- Production requirement

- Budget

- Facility layout

- Type of production line

- Working capacity

- Formulation safety requirements, etc

The above-mentioned requirement must be applied to the type of capsule filling machine that you use in the pharmacy. For example:

- Is it fulfilling your production requirement? Capsule fill/hour

- Is your machine cost-effective? Manual, semi, or automatic

- Do you require a compact structure machine?

- How labor effective is your project? Etc.

By doing comparative studies, you will be able to select which one is ideal for you.

- Manual (8000 capsules per/hour from 300 holes,

- 4500 capsules per/hour from 200 holes, and 2000 capsules per/hour from 100 holes).

- Semi-automatic (approx.45,000 capsule/ hour).

- Or automatic capsule filling machine (approx. 90000 capsules/hour).

Ⅵ.Why are types of capsule filling machines for pharmacy important to the pharmaceutical industry?

For successful pharmaceutical operation, high-performance equipment plays a significant role.

The pharmaceutical industry always struggles to improve the product pipeline and demands in manufacturing. A capsule filling machine carries effective productivity and customized solution for its customer’s needs. Mentioned below are the following reasons that describe how a capsule filling machine is significant for the pharmaceutical industry.

Suitable with A High Percentage of Formulations

The capsule filling machine offers several benefits that make it rewarding equipment to operate. The capability to take a comprehensive range of various capsule sizes makes it ideal for almost any type of formulation. For instance, bulky powders to mineral or granular supplements.

Operator's safety

Practically, this machine is pleasant to use. You can enjoy smooth and peaceful work instead in a noisy environment. This machine promotes users’ safety via well-conscious safety designs. Furthermore, you can see warnings or notifications on the screen before any mishap. Isn’t amazing?

Continuous Production

A capsule filling machine is capable to produce high quantity output. It is fact that the pharmaceutical and health sector needs therapeutic medicines in a continuous flow. Therefore, an automatic capsule filling machine is of prime importance that addresses your needs as per manufacturing demands.

Saves Your Production Cost

Manufacturing cost is mainly driven by the cost of raw materials. Pharmaceutical ingredients are always a bit high in price, especially active pharmaceutical ingredients. Capsule filling machine can reduce wastage of expensive raw material during the filling procedure, this is because of its more accuracy, and precise treatment.

No Interruption More Profitability

As capsule filling machine shows low maintenance and downtime; thus, it leads to substantive savings. The machine is designed with an ejection brush cleaning unit and high air compression unit that removes piling up of debris. So, it's efficient running giving you more and more profitability.

Conclusion

This simple and easy-to-understand guide has hopefully helped you in understanding the fundamental concepts of types of capsule filling machines for pharmacy. This is not the end! A capsule filling machine is an ever-widening field that keeps on evolving day by day. If you need more informative guidance, a simple approach is to contact us directly. We always welcome you for Free Consultation and Support 24/7.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine