High weighing precision and efficiency

Easy to operate

Automatic material conveying, weighing, filling, date-printing, finished product outputting

Want A Free Consultation

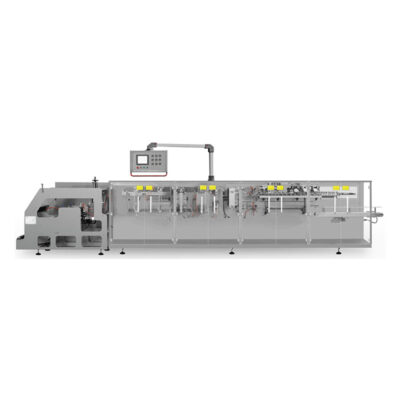

High Speed Automatic Zipper Bag Premade Doypack Gummy Packaging Machine

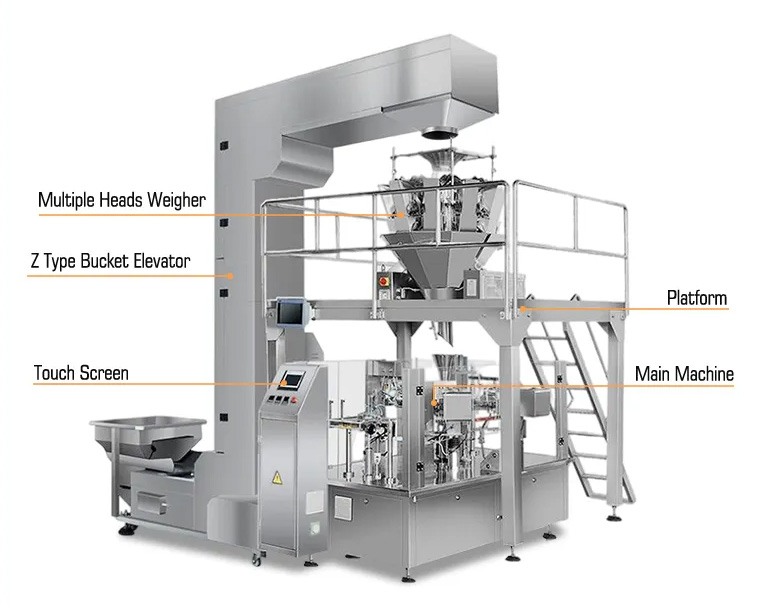

AIPAK high speed automatic premade doypack gummy packaging machine uses stainless steel 304 shell for food grade required.With automatic detection,it is no pouch,no pouch opened completely,no filling,no sealing.With horizontal infeed conveyor,the gummy packaging machine suits for bag with zipper and there is zipper opener system,independent temperature control system,PLC adjust bag width clamping,automatic lubrication system.The whole gummy packaging machine can automatically complete feeding, quantitative weighing, bag filling, date printing, sealing and packaging, and finished product output. It is mostly used in food production and packaging industry.

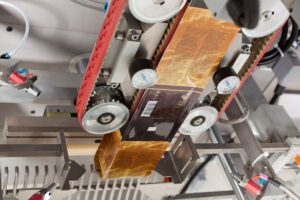

AIPAK Gummy Packaging Machine Details:

AIPAK Gummy Packaging Machine Application:

FEATURE

- Automatic rotary packing machine adoptsprecision indexing device and PLC to control each action and working station to makesure the machine operates easily and does accurately.

- The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch..

- Automatic checking system can check bag situation, filling and sealing situation.

- The system shows 1.no bag feeding, no filling and no sealing. 2.no bag opening/opening error, no filling and no sealing 3.no filling, no sealing..

- The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

DATA SHEET

|

Model |

APKRL-GD-ZK130G |

APKRL-GD-ZK160G |

APKRL-GD-ZK200G |

|

Working Process |

1. Loading bag 2. Opening bag 3. Blanking 4. Adding liquid 5. Reserving 6. Reserving 7. Crossing bag 8. Reserving → (vacuum) 1. Connect the tape 2. Close the cover 3. Primary vacuum 4. Secondary vacuum 5. Tertiary vacuum 6. Fourth vacuum 7. Seal 8. Seal cold cut 9. Vent 10. Open the cover and take out the bag |

||

|

Sealing style |

Instant heating sealing and instant cold cutting after sealing to ensure beautiful sealing |

||

|

Packing speed |

35~60bags/min(By Product Characteristics) |

||

|

Packaging Materials |

Aluminum foil bags, paper bags, nylon bags and other film coated bags |

||

|

Packaging specifications |

W:50mm-130mm L:80mm-200mm |

W:80mm-160mm L:80mm-210mm |

W:130-200mm L:≤300mm |

|

Total Power |

5.5KW |

||

|

Drive power |

380V 50HZ |

||

|

Overall Dimensions |

2100mmx1400mmx1600mm(L*W*H)not include lifter |

2420*1700*1800mm |

|

|

Weight |

2.2T |

||

|

Use environment |

Room temperature 10-40 ℃, 30-90% RH, no dew, no corrosive gas, no dust and other harsh environment |

||

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951