Nuts Packaging: The Complete FAQ Guide in 2025

All nuts are perishable! If consumed fresh, they offer unlimited health benefits to you. Do you know nuts are considered a powerhouse of essential micronutrients and gain energy? Yes! Each nut offers excellent nutritional benefits to improve 100% quality of life.

Nuts are low moisture food having approximately 0.85% moisture content and are prone to grasp moisture quickly which losses its freshness and quality. So, manufacturing companies deal with this problem by innovative methods of nut packaging where not a single molecule of oxygen can enter.

If you’re in the marketing sector and looking for a nuts packaging solution, then we recommend reading this comprehensive blog about nut packaging. Let’s discover!

1.What Is Nuts Packaging?

Nuts packaging is the most demandable requirement from food manufacturing companies. Do you know why? As nuts age, they show low palatability with reduced nutritional activity. Over time, it can be dangerous to consume as well.

That is the reason nut packaging is employed to protect them against physical and chemical degradation. They are processed in a way where a product becomes less prone to invasion by microbes or oxygen. Nuts are more prone to absorb moisture and encountering biochemical degradation. Thus, nuts packaging addresses these parameters.

The advent of nuts packaging has combat all major problems suffered by today’s manufacturers. Not surprisingly, but a vast array of production is safeguarded against potential hazards. There are broad range of film sizes, structures, machines, and styles available where billions of dollars are invested to attain good packaging. We will discuss this more in detail ahead.

2.What Is the Purpose of Nuts Packaging?

Nuts packaging carries a world of its own that doesn’t stand still. From general usage to gifts, from retail to the manufacturer, different players pose different demands when it comes to the potency and efficacy of dried fruits. The purpose of employing nuts packaging is explained below:

Nuts packaging is mandatory to stabilize the quality of dried fruits within a good experience when customers open their pack.

Manufacturers employ nuts packaging to maintain consistency, flavor, and potency with no sign of spoilage.

Nuts packaging is essential to flexible usage of product and boosting up the brand.

Another prime reason for nuts packaging is to showcase your product on store’s shelves and lightweight mode of transportation.

3.What Appropriate Packaging Materials Are Used for Nuts Packaging?

According to packaging digest, your 90% of packaging business survival is based on perfect packaging. Nuts packaging is the integral not just in appearing good branding, but also about your product must be fresh and potent. It ensures you to snack for a long! Some of packaging materials are discussed below:

Cans

This is a very safe form of packaging that ensure shielding effects of your product against environmental factors. This can be made up of either glass, tin, plastic. But commonly used material in industries is plastic. They are most user-friendly and cost-friendly way for nuts packaging.

Cartons

Cartons are commonly used material for nuts packaging. This is a better way of distributing fresh nuts but offering a flexible option for handling. They are reliable and a winning packaging solution adopted widely across the globe.

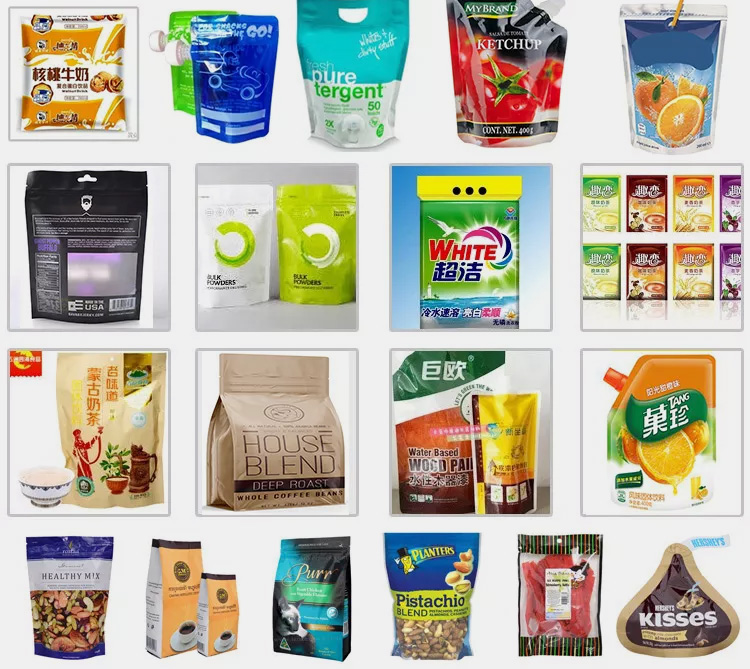

Bags or Pouches

Bags or pouches are the most suitable and economical packaging method for nuts like almonds, cashew, pistachio, peanut, and so on. They are either made up of paper, plastic, or lamination that keep your product nicely in an upright circumstance. It offers either visible or transparent packaging or entirely coating where a flavored and freshened product is guaranteed. Thanks to an inner finish that gives ultra-protection against physical and chemical troubles.

COMMON NUT PACKAGING STYLES

Stick Pack

This is a commonly used style where a flexible film is used to form a stick like the packaging to store nuts. They are single serving packaging with top, bottom, and back sides sealing.

Sachet Pack/ Four Side Seal

They are also known as flat packs, the most used packaging style around the world. This sachet is flat representing a square shape with four sealings done around all four sides.

Doypack

You can call them a pouch or standing bag where the top is designed with a re-open zipper or slider. This is the most popular feature that brings the use of food items many times. Moreover, your food is protected as well.

Pillow Pack

This packaging is great in terms of presentation, handiness, and protection. The small miniature of a pillow is a great piece of nuts packaging preferred by many brands to deliver items with ultra-protection.

4.Are Nuts Packaging Providing You Healthiest Food?

Nuts are healthy; ensuring everyone is gaining adequate nutrition from nuts packaging in a sustainable way is tricky and somehow challenging. We can assure you’re consuming a healthy dried fruit and nuts if they meet the following packaging terms.

Reclosability

Many packaging machines present nuts and dried fruits in flexible packaging incorporating the key of reclosability. It benefits you to use an item for more than single serving as fresh as possible.

High Barrier Packaging

Yes! Nuts have fats and they are more susceptible to rancid. So, many types of nuts are prone to lose quality and taste if exposed to the environment. Meanwhile, nuts packaging with high barrier elements protects against water and oxygen molecules and delivers healthy food.

Material

Nuts packaging material must be compatible with the product. In the first-world countries, consumers get healthy nuts from transparent packaging. However, worldwide the most used packaging material is plastic except in turkey where the customer prefers high quality nuts in metalized packaging.

Nitrogen Flush

If nuts packaging is done with a nitrogen flush, then thanks to this technology as it offers 100% surety that your product is entirely safe and healthy. It is done where oxygen is replaced with nitrogen to preserve the nuts for longer.

5.What Are Common Nut Packaging Machines?

Nut packaging machines are an integral component of various industries. With each passing day, new and improved types of nut packaging machines are introduced in the market. This makes the selection of these types of equipment fairly difficult for packaging lines.

Some basic information about common types of nut packaging machines is penned below for your understanding. This will help you in purchasing the right and suitable machine for your business.

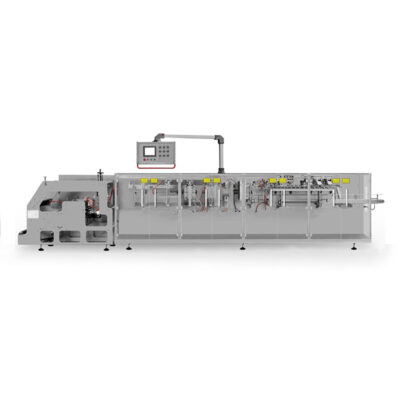

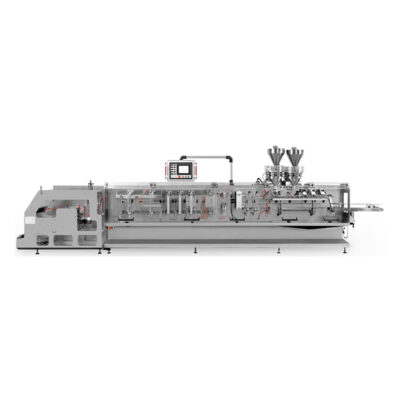

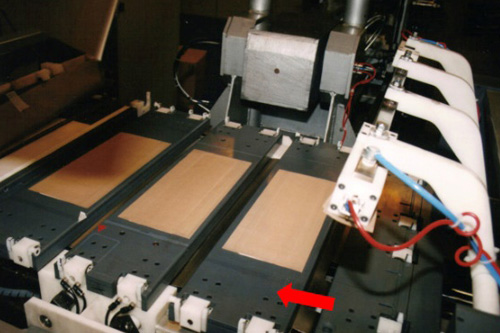

Horizontal Form Fill and Seal Machine (HFFS)

It is equipment that makes a pouch or a bag from plastic or paper film material and then fills it with nuts. Sealing is also performed by HFFS after filling. In these equipments, packaging operation is carried out in a horizontal direction.

These machines present various advantages to nut packaging lines since they save film material, have a lower packaging error rate, and can speedily package nut and other granular products.

Working Principle

The film material is shipped as roll stock and is unwind by the set of roller positioned at one end of HFFS machine. This material is folded in half and moved in horizontal direction to the forming tube which forms the bag according to the required shape. The forming collar is essential in shaping the film into a desired shaped pouch.

Vertical and bottom sealing is done by sealing elements or jaws. The nuts are filled inside partially sealed bags with the help of a dosing unit. After this, the bag is sealed from the top. The sealed bag is detached from the film web via a cutting knife and then are removed from the machine.

Vertical Form Fill and Seal Machine (VFFS)

These are the wrapping machines in which nuts in filled inside the half done pouches using gravitational force. These equipments can be adjusted to produce a variety of different packaging styles such as zipper pouches, sachets, standup pouches, etc.

VFFS machines are ideal for packaging lines with constrained space as they have smaller footprint.

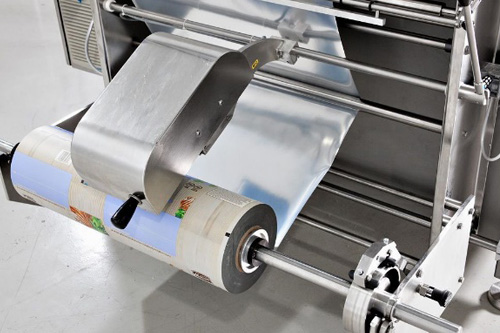

Working Principle

The first set of film rollers is employed for unwinding of film and also for maintaining said film material under proper tension. The film goes across rollers to form tube present on top of the machine. The film is wrapped around forming a tube so that it can be shaped in the required bag style.

Side and bottom sealing are carried out by heating element and then nuts are introduced in bags from top. After loading top side seals are made and cutters are employed for the separation of two bags.

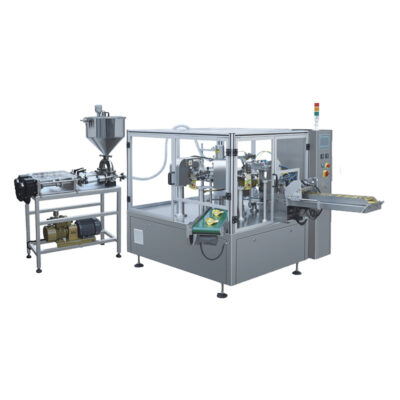

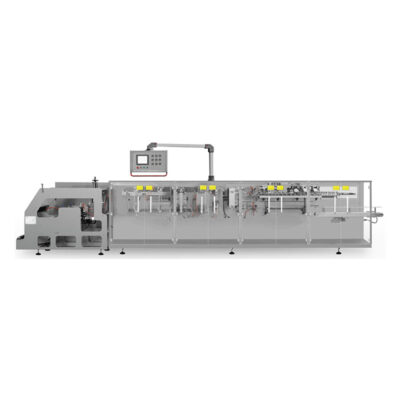

Premade Pouch Packaging Machine

This machine is the most commonly used instrument for packaging of nuts. It preserves nutritional quality for safe consumption of nuts. Pre-formed bags are available in variety of shapes and design so these equipments are best for creating your own distinct brand identity.

As there is no need for making bags hence it saves your packaging time.

Working Principle

As the name indicates, these machines employ pre-formed bags for filling the nuts. First, multiple bags are loaded inside the machine pouch loader. Grippers take bags one by one and deliver them to the opening station where the air is blown inside the bags to inflate them.

The dosing unit or auger fillers equipped with pre-made pouch packaging machines drop nuts in these inflated bags. These filled bags are then hermetically sealed by means of heat sealing plates.

Sachet Packaging Machines

These equipments are perfect for packaging nuts for retail distribution. Sachet packaging machines design 3 or 4 sided economic sachets that are the preferred choice of many consumers. These sachets are lightweight and are convenient to carry.

These machines pack small quantities of nuts in sachet. They offer businesses high speed packaging and easy maintenance.

Working Principle

Sachet packaging machines employ film roll stock for forming sachet. The unwinding rollers assist in unwinding of film and are also responsible for keeping the film under appropriate tension. Sachets are formed by the synchronized working of a cutter which cut the film into front and back halves.

These halves are passed to forming structure and are joined to form sachet like bag. Sealing elements glue sachet from bottom and sides using heat. Nuts are then loaded inside these sachets and then hermetically sealed at the top side.

Pillow Packaging Machines

It is also referred to as a pillow wrapping machine. These equipments are routinely used for packaging of nuts in pillow pouches. Pillow packaging machines consume less film material than other nut packaging machines which also saves film purchasing costs.

These styled pouches are convenient to produce, and more pouches are packaged in a short time by pillow packaging machines.

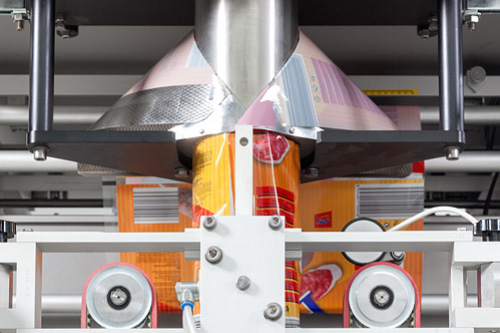

Working Principle

For packaging of nuts, the film roll is placed on the roller shaft and the product to be packaged is placed on the conveyors belt or loaded inside the hopper. The rollers unwind packaging film and cone shaped forming structure heat and shapes pillow package from packaging film.

The material is molded into the required design by forming structure and heating elements. Conveyors belts transport the products to the filling station where they are filled inside pillow pouches. Conversely, nuts are dropped into pillow packs via feeders.

Transverse sealing cutters create transverse sealing and then cut pillow bag from its partner.

6.What Are Main Parts of Nuts Packaging Machines?

It is essential to learn about various parts of nut packaging machine for properly maintaining these types of equipment. This knowledge also aids you in troubleshooting and repair for nut packaging machines.

Some basic parts of nut packaging machines are:

|

Hopper

|

This part is usually present on the top of the machine and a bulk quantity of nuts is loaded inside the hopper component for packaging. |  |

|

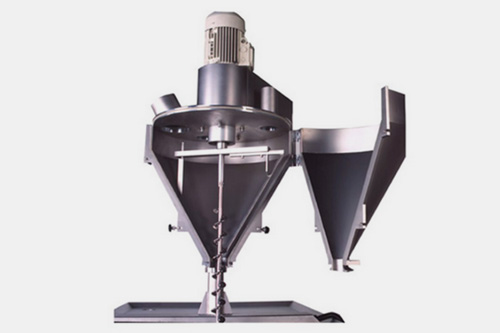

Auger Fillers

|

Nut packaging machines are customized with auger fillers for easy and convenient filling of nuts. This uses volumetric metering for dispensing large quantities of nuts. |  |

|

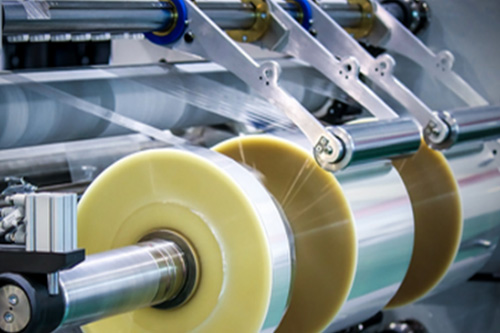

Film Unwinder

|

The purpose of this component is to unwind the film by controlling tension. This clutch like structure supplies the film to rollers. |  |

|

Dancer Arms

|

This structure has a set of rollers which prevent the film from slipping away. Dancer arms also help in proper movement of film. |  |

|

Forming tube

|

It is a cone or dome like part usually present on the upper part of the equipment. The film wraps around forming tube which helps in formation of bags. |  |

|

Registration Section

|

This unit aids in the proper placement of graphics on the pouches. This part is employed for adjusting end of sealing length and cutting of bags. |  |

|

Sealing Jaws

|

Nut packaging machines have two sets of sealing jaws-vertical and horizontal. These jaws move in up and down direction for gluing two webs of film. They perform side, top, and bottom sealing by heating film layers. |  |

|

Cutting Knife

|

Cutting blade or knife is generally located in the middle of horizontal sealing jaws and separates the two pouches. |  |

|

HMI Touch Screen

|

Various operational parameters such as temperature, bag length, and sealing position are programmed on HMI. This touch screen display facilitates easy monitoring and supervision of nut packaging operation. |  |

7.What Industry Used Nut Packaging Machines?

With the high consumer demand for packaging goods, nut packaging machines are routinely employed in every industry. These machines pack nuts in elegant and creatively designed containers which not only offer product protection but also facilitate grabbing customer attention.

Some industrial uses of these machines are discussed below:

Food Industry

Various kinds of nut packaging machines are increasingly used in the food industry for providing customers with nutritional superior nuts. These equipments prevent oxidation of nuts as well as minimize their damage. Different roosted and salted nuts such as cashews, peanuts, almonds, etc are packaged in sachets, cans, jars, and pouches by these packaging systems.

Chemical industry

In the chemical industry nut packaging machines are often utilized for packaging chemical tablets such as dish washers, chlorine purifiers, and cleansing pills in pouches or sachets.

Pharmaceutical Industry

Nuts packaging machine is a more significant technique used in pharmaceuticals to assemble and distribute a safe medicine to consumer. This equipment provides more convenience to pharmaceutical companies as medicine is supplied under strict hygiene and effective measures.

Agriculture Industry

Small granular fertilizer products, herbicides, insecticides and pest control pills are packaged into flexible and tear-proof containers by nut packaging machines. Nut packaging machines provide great many advantages to the agriculture industry since these machines prohibit deterioration of agricultural goods by environmental elements.

Cosmetic Industry

In today’s eco-friendly world solid cosmetic products are packaged using nut packaging machines. Perfumes, makeup, and various skin care items are packed using these devices. These instruments are essential in lowering the negative effect of plastic packaging film on the environment.

8.How Long Can You Keep Packaged Nuts?

Are you wondering about the safe period for nut consumption? The answer to your question is shelled nuts can be stored at room temperature and have an expiration period between 4 to 6 months. This rule is applicable to all kinds of nuts except pine nuts.

You can safely store your bags of nuts in the pantry, and they will be good for months. Nuts in kernels even last longer and can retain their taste and nutritional quality for 6 to 9 months. If you keep your nuts in the refrigerator you can increase their expiration date 50 to 100%.

Here are some tips for checking the freshness of nuts.

- If there is mold or fuzz on the nuts, then discard them.

- If they are dried, you can eat them, but it is best if you dispose of them

- If nuts have pungent, bitter, or harsh smell, this means nuts have gone bad and rancid.

- If you are unsure about quality of nuts, then taste one or two nuts. A bitter taste means nuts are unsafe for eating.

9.What Are Technical Problems and Solutions of Nuts Packaging?

Troubles and problems are part of normal machine operation which can negatively impact your production efficiency and leads to sales loss. However, these problems can be easily resolved by training your workforce and equipping them with troubleshooting hacks.

Some technical problems of nut packaging and their solutions are detailed below:

| Problem | Cause | Solution |

| Abrasion

Scratch on any layer of the pouch whether outer or inner. Serious scratches can damage the inner layer of pouch and can affect the product integrity. |

Pouches get scratched on storage racks or machines while shipped.

Leftover plastic on sealing jaws can result in scratching as well. |

The placement of barriers can lower the interaction between racks and pouches to avoid abrasion.

Properly clean the surface of sealing jaws before packaging. |

| Punctures

Mechanical piercing through the layers of the pouch can result in holes. |

Cutting blades or other sharp object prick pouch layers during processing | Prevent excess of sharp objects to packaged goods. |

| Flex Cracking

These are small breaks or cracks on the film lamination |

High vacuum or pressure setting can result in more bending of laminate material thus breaking laminate layers. | Properly adjust vacuum or pressure setting according to material malleability characteristics. |

| Blistering It is a raised structure or bubble found on sealing. A blister is area without proper sealing. |

Presence of lubricants or other contaminants in the sealing region during the sealing process | Wipe thoroughly the exterior of sealing elements and gears with a clean cloth. |

| Leaking

It is non-bound area across the sealing which results in the leakage of products. |

The temperature and pressure of sealing jaws is not properly adjusted.

Sealing time is inadequate. Presence of contaminants in sealing area |

Adjust the temperature and pressure of sealing jaws as per mentioned in the manual.

Fix the duration of sealing or dwell time. Properly clean sealing area |

| Partial Seal

Gluing or sticking does not go along the width of sealing area. |

Improper positioning of pouch or bag in sealing jaws. | Correct the positioning of pouch in the sealer so that it can get uniform heat |

| Two layers of the pouch fail to glue together resulting in vague sealing bearing. | Accumulation of debris in the sealing area.

The pressure and temperature of the sealing bar is not right |

Properly clean the sealing station.

Adjust the pressure and temperature settings of sealing jaws. |

10.Top 5 Best Nut Packaging Manufacturing Companies

There are different brands in the market providingsuitable nuts packaging solutions. We have enlisted the top 5 best nut packaging manufacturing companies to trust on:

Syntegon

This is well known leading manufacturing company in the nut packaging world. Syntegon is a reliable packaging firm preferred by the pharmaceutical and food industry. Due to its outstanding profile for the last 160 years in the processing and packaging sector; today you can find more than 3 locations across the globe.

Aipak Pharmaceutical

A leading producer and supplier of processing and packaging solutions for more than a decade. Aipak is a proven and reliable solution for the pharmaceutical industry, food industry, chemical industry, and other. The company offers an extensive packaging approach that addresses your production and integrating needs in a cost-friendly way.

Matrix

The best US company and a leader in VFFS packaging machines are known for well-engineered, compact, economical, and user-friendly solutions. Matrix promises in creating a profitable market solution to their customer globally. Their entire machinery is enriched with a wealth of knowledge and experience in packaging systems opted by diverse companies worldwide.

GEA

GEA is the world’s largest producer of packaging machinery and plants designed with advanced processing and technology. Their excellent customer services around the world have made an outstanding profile among top market players across the globe. GEA supports the customers of foods, dairy farms, pharmaceuticals, beverages, and chemicals, etc.,

Viking Masek

A north American company established in the early 2000s as a packaging technology manufacturer. Today, Viking Masek machinery is preferred globally as they provide economical VFFS packaging series with single to multi-lane packaging.

Due to their passion and excitement in manufacturing solutions; this is now among the top market leader across the globe.

11.How To Choose Right Nuts Packaging Machine For Your Production?

To select any packaging machine for your production company, one must keep in mind that every piece of machinery has differing characteristics. According considering the right type of nut packaging machine, you need to:

- A good manufacturing company is an integral point where the entire business survives. We recommend always looking for experienced and reliable nut packaging producers for your production line.

- Be aware of your product’s requirement for the type of bag it will be packaged in, how much the ability of a machine for weight filling, and sizing information about the wrapping material in accordance with a certain nut size.

- Know about the area specifications which is going to accommodate the machinery.

As said above, every machine has varying characteristics so you must check for the volume production of any nut packaging machine which would help you to decide the rates at which it efficiently produces high capacity in order to meet customer demands. - Keeping an eye on the budget is necessary to evaluate the price at which you will have to purchase the packaging machine which comes productive and successful.

- Look for the technical aspects of the machine. You will need to select a machine that complies with easy maintenance and operability.

Conclusion

People these days prefer buying nuts that are present not only in elegant, finished packs but also ensure that they get satisfaction in terms of their freshness and crispiness, quality preservability, and safety. Great nuts packaging can skyrocket your business after being able to create a good market reputation and sustain the authenticity of taste and originality in consumers’ hearts. Aipak Pharmaceuticals has realized the way to offer the best nut packaging solution you look for! Contact us now for Product Details and Queries.

Don't forget to share this post!

Premade Pouch Filling Machine Related Posts

Premade Pouch Filling Machine Related Products

Premade Pouch Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine