HFFS Machine: The Complete FAQ Guide in 2024

Pliable packaging has transformed greatly around the world today. Manufacturing a flexible package that is well presented and innovative functionally comes real. Ever heard of such a machine that can package your product by forming, filling, and sealing All-In-One? This is called a horizontal form fill and sealing machine.

Getting to read this article you’ll be acknowledged of all the specific details required for an industry or a manufacturer to know this machine’s profile.

1.What Is HFFS Machine?

A HFFS machine is commonly used equipment in the packaging world for solid products with no flowability ratio.

They’re designed with two molding and two sealing stations: ideal for changing from one packaging size to another in no time. So, this machine is suitable for large production companies where a frequent changeover takes place.

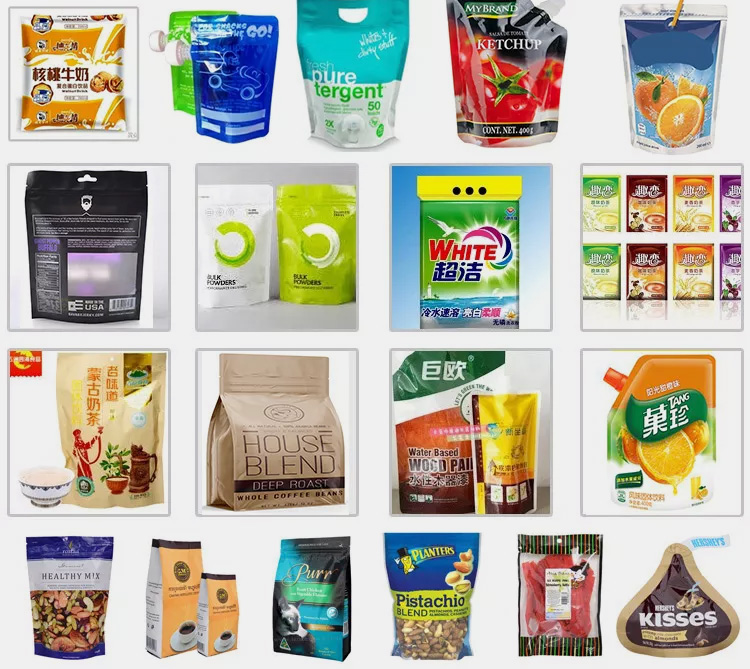

Generally, this machine is utilized for fragile material with a low-drop rate. It is also preferable for those who need different packaging styles such as stand-up pouches, zipper bags, spout bags, etc which results in better product presentation.

Moreover, the machine is also equipped with a drill device that holes into the top seam for various purposes such as hanging on a rack.

2.When Does HFFS Machine originate?

There’s no doubt, inventors always trying to bring something new in their area of interest, and every time a new and unique advancement evolves into what was originally intended.

in 1949, Bartelt Harold and Donald Bartelt, the inventors of the HFFS machine; tried to develop an advanced packaging solution that opened, fill, and close the pre-made glued envelopes required for storing electrical tools. Similarly, this invention received huge attention as a labor-saving machine in the packaging world.

Soon after, they were realized with achievement and patented as HFFS machines and presented an innovative generation of HFFS machines. Since then, day by day new innovations is emerging according to consumer demand and the competitive market.

3.What Are the Industrial Applications Of HFFS Machine?

An HFFS machine is the most popular choice being preferred in the packaging industry. Many companies use this technology as they give you forming, filling, and sealing jobs simultaneously with greater benefits. The industrial applications of HFFS machine are mentioned below:

Foods Industry

Whether fruit, vegetable, or meat items; your packaging process can be highly expedited and automated with HFFS technology. The machine can help you to store your product in airtight pouches or bags with more extended shelf life and freshness.

Nutraceutical Industry

Just like food products, the packaging of products such as protein powders, nutritional supplements, and energy drinks also requires sealed packaging that can preserve their quality, potency, and efficacy.

Pharmaceutical Industry

HFFS technique is widely accepted by and used in the pharmaceutical production sector with reported below 0.1% chances of product contamination. It offers high production at a reduced operational expenditure and gives a high assurance of safety and sterility.

Cosmetic Industry

Besides foods, HFFS machines are commonly used in the packaging of cosmetic products including wax beans, facial, and hair treatments, etc.

Household Cleaning Products

HFFS machine is of significant value when it comes to the packaging of household cleaning products. A confined packaging ensures a quality product with enhanced fragrance and power, such as dishwashing powders, detergents, floor cleaners, etc.,

Stationery Industry

HFFS machine is widely used in the packaging of stationery items and tools efficiently, for instance, erasers, clips, sharpeners, etc.,

Medical Equipment Packaging

Various medical tools such as surgical or personal protective equipment (PPEs) are dispensed in a modern and effective way by using an HFFS machine.

Fresh Vegetables and Meat

Keeping the diverse demands and requirements of consumers in mind, an HFFS machine provides an absolute solution for the vegetable and meat industry to maintain the products as fresh as riped from farms.

Chemical Industry

The global market value of HFFS machines is high and the chemical industry is one of them that greatly requires it. The reason behind this is the product and users' safety against harmful chemical entities.

4.What Are the Advantages of An HFFS Machine?

An HFFS machine is a significant and the most preferred choice of packaging in various production sectors. Yet, like all equipment, this machine thrives more in special events than other options. You must make sure of all below benefits an HFFS machine offers before making an investment.

Cost- Economical

This is the most preferable financial benefit where an HFFS machine gives an ideal packaging of material in a versatile way. These machines are equipped with weighers that help in assuring that each product has the right quantity of material, the right size, and the right volume.

Thus, you’ll save your material against wastage, and you won’t have to deal with any raw content before and after packaging i.e., packaging trimming. Because a form fill seal bag is created up to a specific size of your product.

Time Efficient

An HFFS machine carried a high continuous or intermittent speed to form, fill and seal the product at one time. This high velocity where hundreds of bags are formed and filled per hour improves your productivity with reduced capital cost. So, if you’re going to make a short production run i.e. 1000 bags/hour then it won't save money, but if you double the time then it works the best.

Reduced Labour Cost

This machine can be run for 24 hours which required only a few minutes of protocol entry or changing of packaging film (mostly required at every six-hour, or production capacity). This means the entire process can be processed automatically without any technician or staff. So, this free up the staff burden, but it doesn’t mean that HFFS operation doesn’t require any training before use. An employee must be trained in order to set up the protocol and changeover the equipment.

Versatile Packaging Options

An HFFS machine is equipped with modern features that offer user safety as well as products. Moreover, HFFS works best with plastic material but not paper. Despite this, the consumer prefers plastic bag as it has an acceptability rate. So, HFFS machines are ideal for local or low-budget consumers,

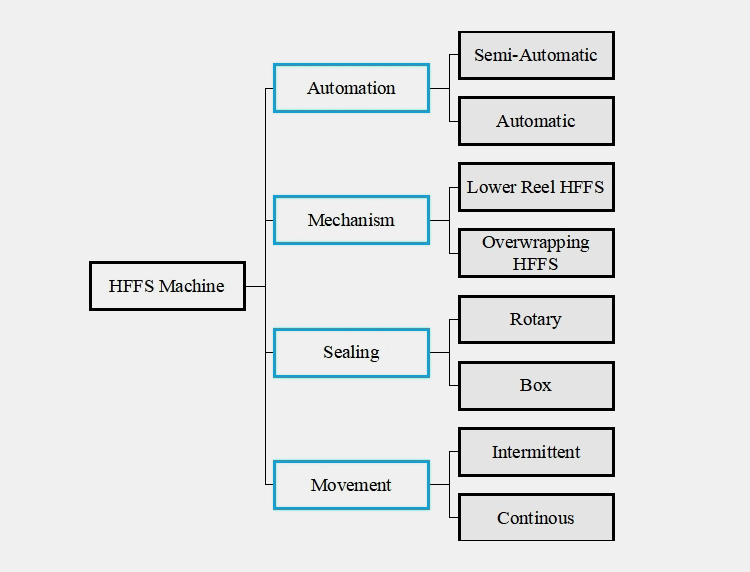

5.What are the Types of HFFS Machines?

To understand the types of HFFS machine; it is broadly classified into the following categories.

According to Automation

An HFFS machine is the most versatile piece of innovation in today’s market. They are available according to the mode of automation you need to meet your production line and international demands.

Semi-Automatic HFFS Machine

This machine is suitable for small-scale production departments such as laboratories, clinical setups, etc., A semi-automatic HFFS machine is different via the degree of automation, but it gives accurate and fast throughput similar to an automatic machine.

This machine is accessible and can be obtained on a low budget where production capacity varies in hundreds of pieces per minute.

Automatic HFFS Machine

This machine is the fastest packaging solution that features multi- programs to make bags, fill, and seal them.

Here, it can deal with various shapes and sizes of products and packaging styles. This machine can operate hourly without human interaction; giving 100% accurate results in no time.

According to Mechanism

Lower Reel HFFS Machine

This equipment mounts the packaging product below where a lengthways seal over the forming tube facing upward. This machine is suitable for packaging of delicate and sensitive products.

Overwrapping HFFS Machine

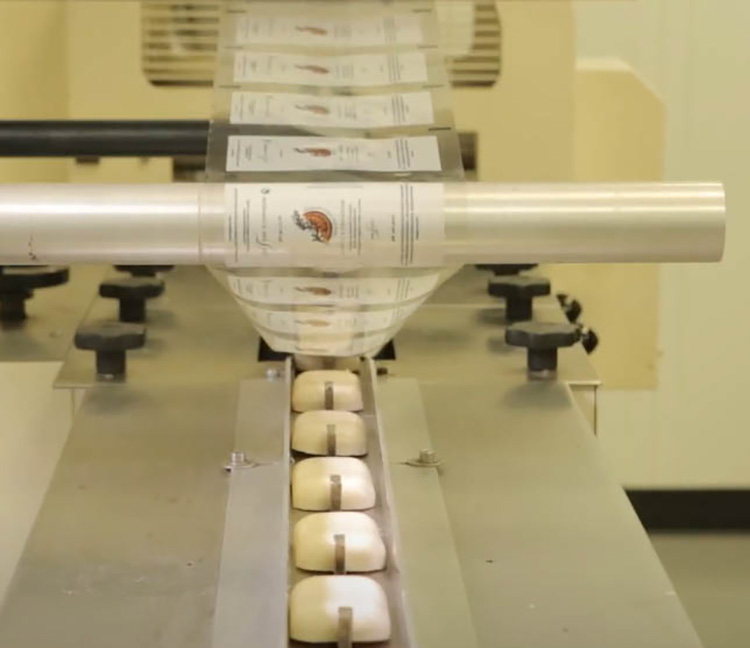

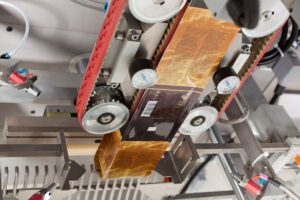

A sealable film is received from the film roll which is wrapped all around the product and then sealed using heat sealer bars. This machine is a widely used option for both aesthetic and flexible properties required for a huge variety of products.

According to Sealing

HFFS machine technology can also be categorized according to End Sealing.

Rotary Motion

As its name indicates, the sealing of each pouch or bag takes by via the rotational movement of the end seal. It gives high production speed typically more than 300 pieces per minute (depending upon bag length and crimp radius).

Box Motion

A sealing process is achieved by horizontal and vertical jaws motion; it provides high sealing integrity and speed for a broad range of products. The maximum speed observed in box motion is about 130 pouches/bag per minute.

According to Movement

Intermittent

Nowadays, intermittent movement for pouches or bags in HFFS is commonly utilized. For instance, an interval in motion of process (start-stop-start). In this type of HSSF machine, pouches are stationary during a procedure such as sealing and filling, it moves to the next phase/station once the operation is completed.

Continuous

A continuous motion HFFS machine allows various processes with no interruption hence you can achieve ultra-fast packaging for a variety of bagging styles.

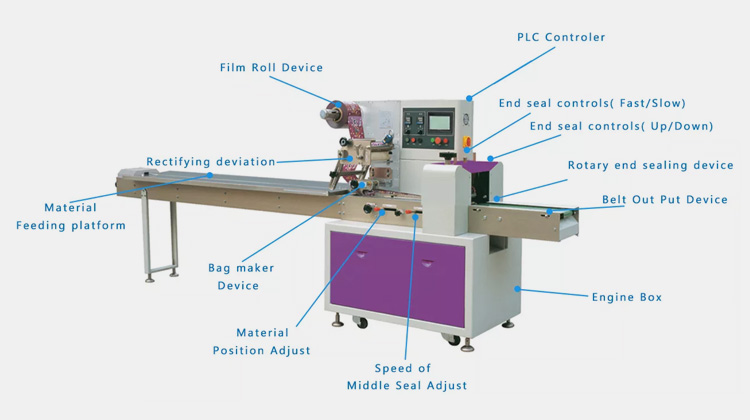

6.What Are the Parts of the HFFS Machine?

Parts of the HFFS Machine

| No. | Parts | Description |

| 1. | Material Feeding Platform | Putting your product on the feeding platform will transfer to the formed film. |

| 2. | Film Roll Device | The device helps in holding for constant and straight delivery of film prior to forming. |

| 3. | Conveyor | This is equipped with a set of roller assemblies; a motor and an adjustable belt that ensure a flexible movement of packaging product smoothly. |

| 4. | Rectifying Deviation | A photoelectric sensor allows error-free procedure. |

| 5. | Bag Maker | This is also known as a folding unit, former wrap, or bag former that creates a film to pack the product efficiently. It assists you in adjusting the width and film elevation during the process. |

| 6. | Safety Cover | Full-cover safety cover, equipped with safety protection switch (warning shutdown), to avoid accidents in operation. |

| 7. | Touch Screen | The most integral part of the machine where an automatic touch screen system that helps in performing all major tasks (temperature, pressure, film formation, speed, etc) with a single click.

Additionally, it displays graphical visualization for easy settings and alarm notification and wifi connection allows remote interaction with your machine. |

| 8. | Engine Box | All electrical components, moto, switches, and internal structures of the machine are fixed in the engine box. |

| 9. | Center Sealer | Heated jaws seal the bag or pouch centrally. |

| 10. | End Sealer | End sealer or crimpers separates the packed product after being treated with filling. It could be rotary or box depending upon machine to machine. |

| 11. | Belt-Output Device | Here, a packed product is delivered. |

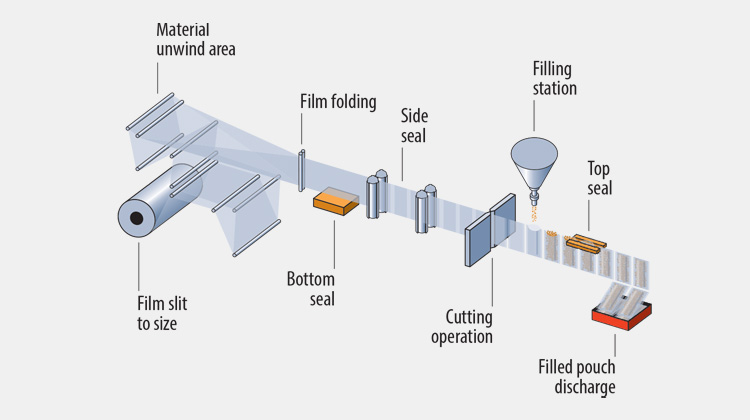

7.What is the Working Principle of the HFFS Machine?

An HFFS machine for packaging is used to attain formed, filled and sealed bags of different styles such as 3 Sided-Sealed, 4 Sided Sealed, and doy-pack. How they’re formed? the working principle of the machine is discussed below:

Unwinding

A film roll is loaded into the machine that is used to form the package. As can be seen in the diagram, the film material is unwound from the film holder.

Film Forming

As the film is opened from the unwinder it goes toward bag former where the bottom and two sides sealing occurred. Now a cutter will break the pouch layer vertically; this step is controlled by a photocell.

Filling

An opening device inflates for filling purposes. By the top stretching mechanism, a pouch is opened upward and cleaned before the material is filled. A dosing section helps the filling of form sealing via a dose unit. A formed film is separated via cutters that are present on an output belt.

Sealing

Once the material is filled, a top horizontal sealing bar helps close the bag.

Discharging

A finished bag or pouch is discharged via an outlet.

8.Difference Between HFFS Machine And VFFS Machine

| HFFS | VFFS |

| It takes the film roll and creates the bottom of the gusset decreasing the force and duration required to bring over the film through the machine. | It takes the film roll and moves it in an upward direction increasing the force and duration required to pull over the film through the machine. |

| This machine does not carry out sealing and filling at the same time. | This machine can carry out both sealing and filling at once. |

| An HFFS machine fills the product from the top of the pouch. | A VFFS machine fills the product from the sides of the pouch. |

| It has a full bottom gusset that’s why it allows 100 % filling volume. | The gusset here is not fully open which does not permit 100% filling volume. |

| Horizontal packaging can utilize tough materials as well because it uses less force. | Vertical type of packaging cannot employ tough materials because of their great force. |

9.What is Film Material Used in HFFS Machine?

The commonly used films for HFFS machines are:

Polypropylene Film (PP)

PP provides high containment and protection to your product against physical and chemical entities present in the environment. Moreover, the film creates an outer and sealant layer followed by an acrylic coating that protects the film against melting during sealing by crimping jaws.

Polyester Film (PET)

This layer commonly used as an outer layer in lamination has good heat resistance quality. It does not shrink in high temperatures and gives high strength to the packaging structure.

Polyethylene Film (PE)

It comes in three basic types:

- Low Density Polyethylene (LDPE)

- Linear Low-Density Polyethylene (LLDPE)

- High Density Polyethylene (HDPE)

All these films have high heat resistance ability that gives stretchable structure to the packaging bag extensively used for the pharmaceutical industry.

Foil Laminations

This is commonly made up of aluminum alloy that stores material in between another layer of film. The foil can be of various thicknesses and properties such as light sensitivity, and high physical barrier.

Shrink Film

Certain film falls into this category such as LDPE, LDPE, PVC, and some polypropylene. These films are mostly run at the bottom lap seal and hot-cutters end-seal.

10.What Packaging Styles Are Formed by The HFFS Machine?

Producing custom or seasonal packaging with standard designs for every product is what a manufacturer dreams of achieving. With digital features and customer demand, HFFS machines offer different packaging styles to boost your brand such as:

Stand-Up Pouch With Zipper/Slider

Zipper pouches, also known as “press-to-close” zipper pouches, are a cost-effective option for resealable packaging. Press-to-close zippers are the most common stand-up pouch closure on the market today, providing several benefits for consumers.

Doy-Pack

HFFS machine is a multi-purpose equipment creating multi-layer doy-pack in a horizontal series where you can treat them with powder, granules, or liquids.

Flat Pack

HFFS machine is designed to create flatpack and a variety of flat sachets to make them fill and seal with content with the greatest strength.

Mold-Cut Shape

An HFFS machine can produce a variety of shapes and customized options such as mold-cut, valve, and hole punch to make unique bags.

11.What HFFS Machine Does Aipak Provide?

Aipak designs and creates an extensive range of FFS series i.e VFFS and HFFS machine lines for pharmaceutical, food, medical tool, cosmetics, chemicals, and other industries. They are designed promptly according to various requests and demands results in machines standard to extraordinary.

A combination of vast experience and technology results in the development of new solutions that aimed for offering the most critical area i.e sterile preparations.

Some of their amazing HFFS series are:

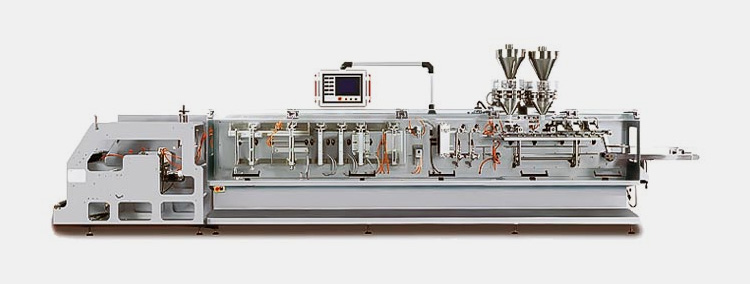

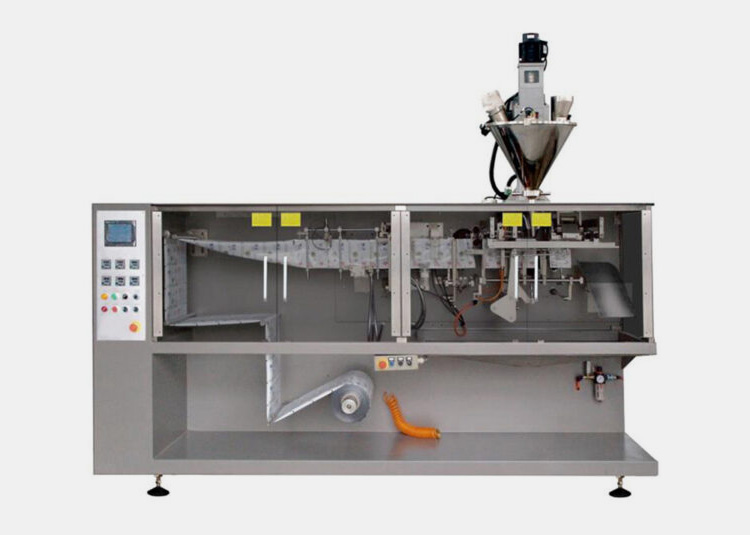

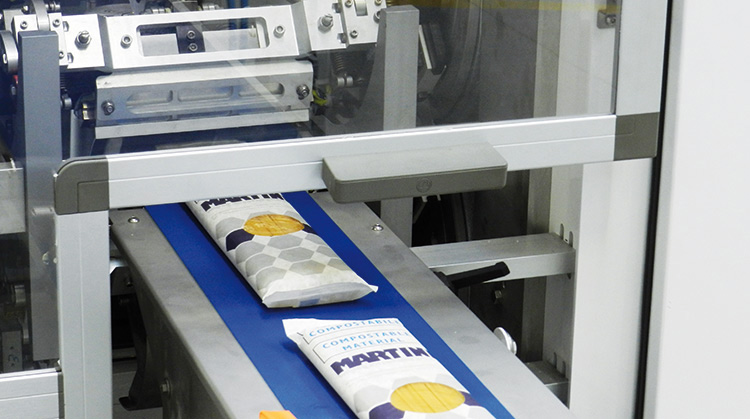

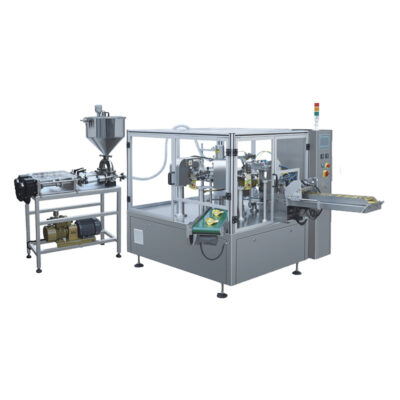

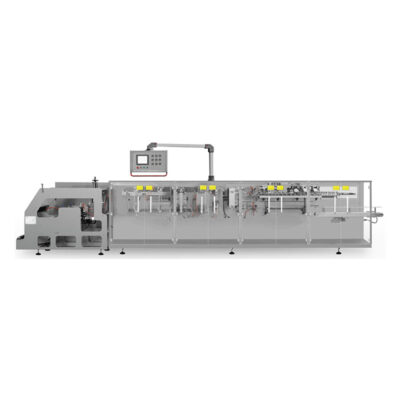

Pre-Made Pouch Filling Machine

Automatic high-speed HFFS series premade pouch filling machines are ideal for various shapes, sizes, and states of ingredients adopted to fulfill the high-quality needs for various industrial applications. A stainless steel-made machine ensures a perfectly safe system that protects against material wastage and avoids contamination.

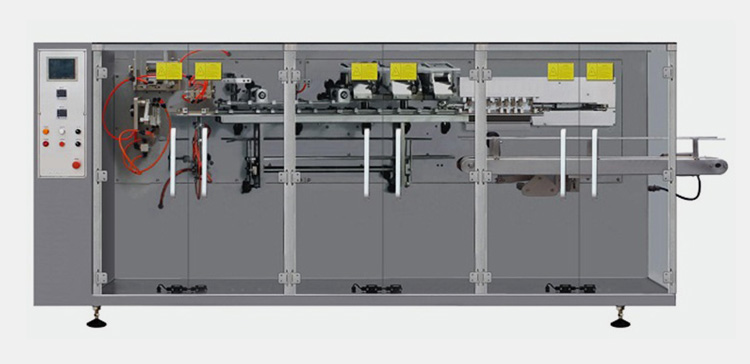

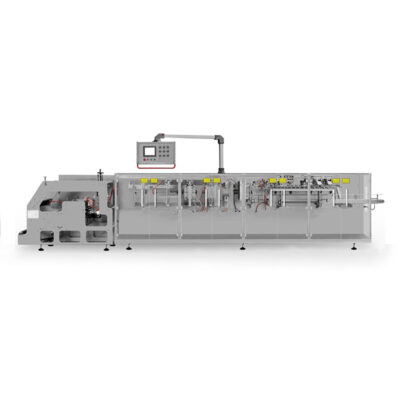

Doypack Machine

Aipak manufactures market-leading HFFS doypack machines ideal for liquid, powders, granules, and solid products. Ultra-cleaned equipment is available to offer quality services with the easy computerized specification.

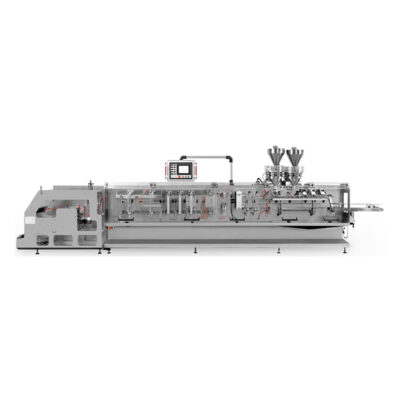

Sachet Machine

Product packaging with Aipak’s HFFS sachet machine gives product attractiveness and excellent presentation. A fast forming and filling mechanism allowing you to design an extremely commercial packaging suitable for granules, sugar, milk powders, spices, and much more. An automatic solution can create a 3-sided and 4-sided sealed sachet with better filling and sealing properties.

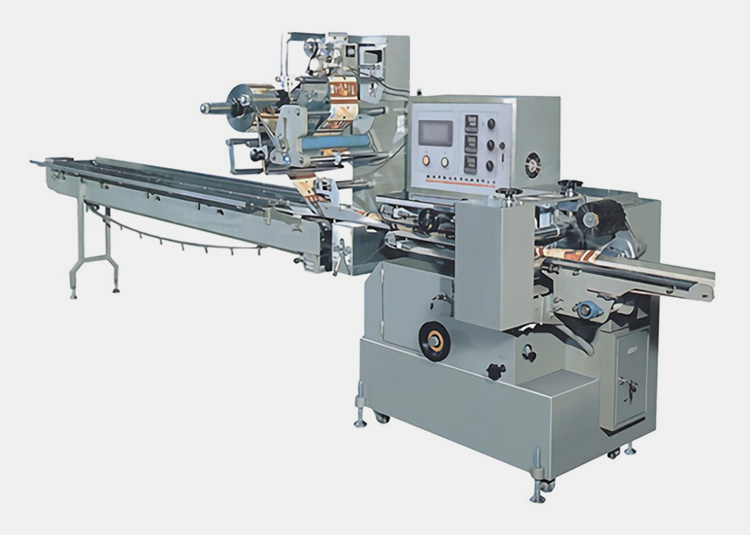

Flow Wrap Machine

An HFFS flow wrapping machineby Aipak is a perfect blend of experience, demand, performance, and quality. An automatically driven equipment where no human interaction is required; saves your time, film, material, and labor cost. The most important property of this equipment is self-diagnosis of error, thus making your packaging process error and trouble-free.

12.Technical Problems which arise in HFFS Machines and their Troubleshooting

| Problem | Possible Cause | Troubleshooting |

| Cutting of film at a deviated position | The marked area is not followed.

Marking colors is weak to detect. Te film is loosened. |

Refresh the method setting using HMI.

Refer to eye-mark-up instructions in order to increase color sensitivity. Adjust the tension of the film roll, dancer arm, and rubber roller in order to increase the degree of tightness. |

| Cutting of product along with the film | High Packing Speed

The level of the cutter is improper The pushing rod and cutter are asynchronous. |

Decrease the packaging speed of the product.

Adjust the position of End sealers and cutters referring product’s height. Refer assigned position mentioned by the manufacturer. |

| Seal with burnt crimples | The sealing temperature is too high.

Speed is too low Film quality is not compatible with temperature. |

Lowers the sealing temperature.

Adjust the normal speed. Replace the better-quality film. |

| Loose or missed sealing | The sealing temperature is too high.

Speed is too low Film quality is not compatible with temperature. |

Lowers the sealing temperature.

Adjust the normal speed. Replace the better-quality film. |

| Uncontrolled temperature | Worn out the heating element.

Thermos-control meter is damaged. |

In both cases replacing tools with newer ones is required. |

| Product jamming in forming unit | Slower product speed than film.

The length of the material is greater than the infeed pitch. |

Correction in speed and product length is required |

| Sealing of film destroys in crimper. | Improper pause offset | Adjust the pause offset. |

| The melting of Fin-seal | A high temperature of fin-seal

Dirty fin-seals |

Correct Fin-seals temperature.

Wipe off the dust of Fin-seals. |

13.How to Maintain and Clean HFFS Machine?

Cleaning and maintaining are the primary factors that should never overlook for an efficient result. For better outcomes, we have categorized cleaning and maintenance points into three stages.

Shift Cleaning And Maintenance

After every shift, clean off the scraps with the help of compressed air that are stuck to the feeding, sealing, and end-seal section. Additionally, film scraps around the cutters (end sealer) can be wiped off with a steel-wire- brush.

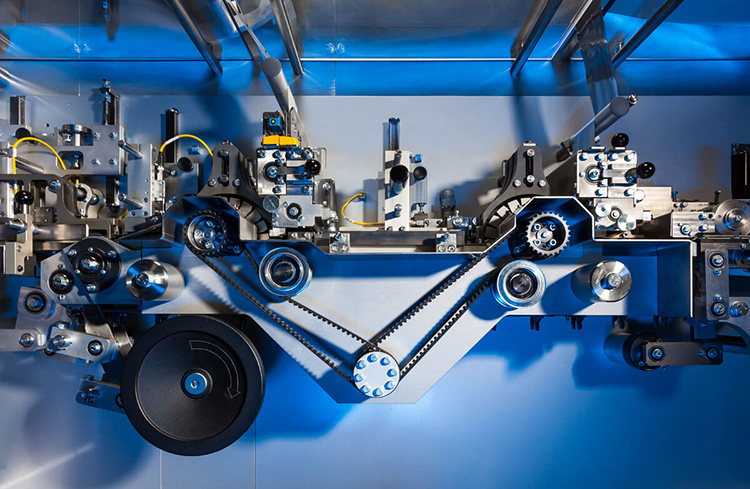

Monthly Check and Maintenance

For monthly protocol, you are required to oil/lubricate the meshing gear, end-sealing bearing, and chain wheel of the system. It is not recommended to lubricate the synchronous belt of the machine and also a flat conveyor belt. The checking of the drive chain, belts, screws, and nuts must be done and re-tighten if required. You must wipe off if carbon deposits are present.

Biannual Check And Maintenance

Biannual setup includes the replacement of worn parts, such as the drive belt, and flat conveyor belt if required. Moreover, monitoring of electric wire and wiping off dust particles from electric components must be done with the help of compressed air.

14.Tips for Buying HFFS Machine?

Every manufacturing company always seems for a machine that can meet the challenges of packaging demand and reduce production expenditure with efficient functionality.Always remember Simpler is better! That means when buying an HFFS machine, you must look for the basic points:

One-Stop-Solution

The movability of the product and the pulling of the film must be rapid. An alignment of film and product at the cross-sealer and cutter must be correct. It is necessary to examine because it helps in attaining seamless production, maximum output, and quality.

Nature of Product

The selected equipment must be flexible in terms of handling your product in various formats and packaging sizes; also, it must have a fast changeover rate to minimize downtime. This is an essential element as the continued proliferation in packaging styles is the most prominent trend in the packaging industry.

Speed Requirement

Your machine must be smarter, faster, user-friendly, and simple to clean and maintain. Additionally, it should be able to work with less number of workers.

The machine must be fast in diagnosis when a technical fault occurs and capable enough to notify you before the interruption.

A Competitive Manufacturer- Excellent Performance

There is no doubt, a low-price machine always seems equally important as packaging needs. You need to work out to find a competitive manufacturing brand and a cost-economical machine that can sustain your excellent performance and ensures good throughout.

Conclusion

There are myriad concepts about HFFS machines as an integral component of business success. The machine acts as a catalyst in terms of speeding up your packaging process in minutes rather than days. What is crucial when buying an HFFS machine? Indeed, a modular design of hardware and software parameters with user-friendly features always helps in delivering maximum production capacity in the shortest possible time. Would you like to equip an HFFS machine in your production line? Do you have any questions about Aipak Technology? Send us a short text, we will be glad to serve you shortly!

Don't forget to share this post!

Premade Pouch Filling Machine Related Posts

Premade Pouch Filling Machine Related Products

Premade Pouch Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine