Vertical Packing Machine:The Complete Buying Guide In 2024

Vertical packing machine is used in various sectors of activities. Among them, the pharmaceutical sector critically uses this unit to protect and transport its products. Not only this, but pharmaceutical packaging is also the most complex packaging among all sectors. Today, we want to talk about different aspects of the vertical packing machine that you are seeking for your business.

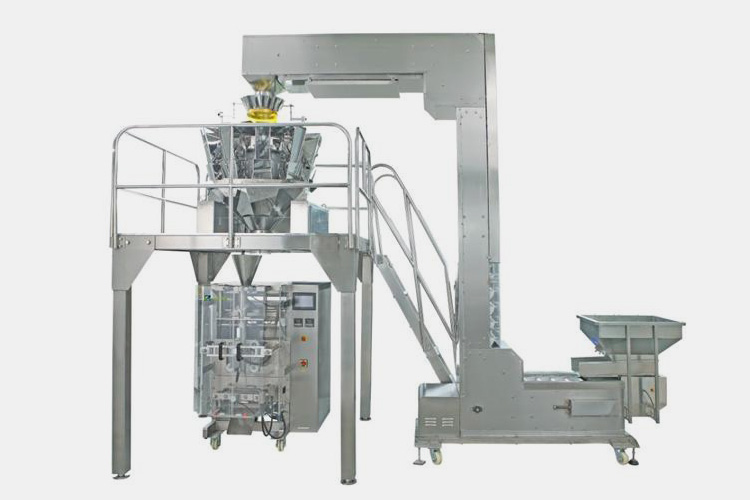

1.What is a vertical packing machine?

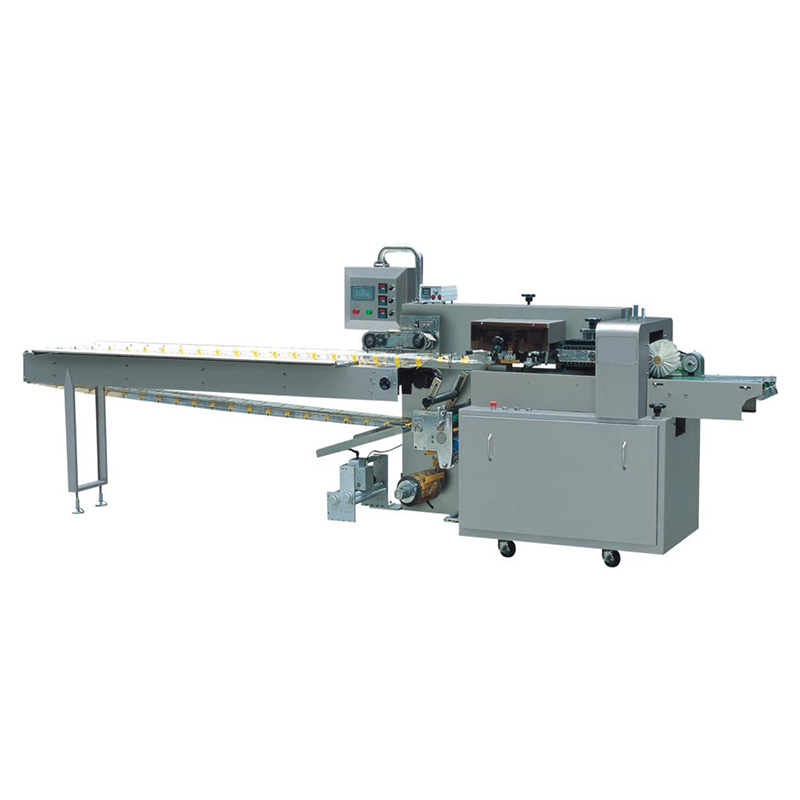

A vertical packing machine is a kind of pouch forming, and filling machine created in a vertical structure. It is primarily used for industrial packaging and processing; thus offers a convenient and effective way of automatic packing, saving your time and expenditure.

Vertical packing has many types. Some of them are standalone while some can give production with integrated equipment like data printing, cartoning, etc., This compact machine is a multifunctional packaging solution for various industrial sectors implemented for sugar, shampoos, tea, fertilizers, etc.,

To get different pouch styles, a vertical packing machine has been improved to adapt it. You can make various kinds of packaging, for example, pillow pouch, gusset sachet, quad seal, etc.,

2.What are the industrial applications of vertical packing machines?

It doesn’t matter what category product you are packing; the vertical packing machine is all-rounder equipment. The key industrial application of vertical packing machines is mentioned below:

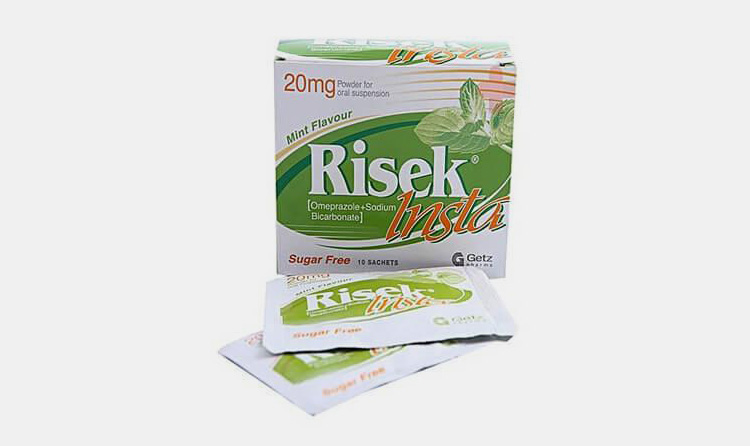

Pharmaceutical Industry

Vertical packing machine has diverse pharmaceutical applications to form, fill, and seal the product in a unit dose packaging. For example, therapeutic powder sachet, single-unit ointments, balms, etc.,

Nutraceutical Industry

A vertical packing machine is high-speed packing equipment capable of packing vitamins, electrolytes, granular, proteins, powders, and other nutraceutical items safe and fresh from filling to end-user.

Fertilizer Industry

A vertical packing machine is state-of-art equipment capable of protecting fertilizer under rough handling and storehouse condition. Good packing can even prevent fertilizer under a torrent of rain.

Pet Food

From aquatic food to birdseed, from dog treats to horse fees, every pet product packaging must be in a way that ensures an appealing appearance and good quality. Various pet foods are best packed using a vertical packing machine.

Meat and Poultry Industry

In the busiest lifestyle, everyone is trying to lead a healthier lifestyle. A vertical packing machine is ideal for packaging meat and poultry products efficiently and delivers the maximum benefits to end-users.

Dry Snack and Crackers

You must have observed that dry snack gets soggy and stretchy when leave in an open environment. This is due to moisture content. A vertical packing is a perfect solution for the dry snack production sector that ensures freshened products for a longer time.

Chemical Industry

A vertical packing machine is a piece of leading equipment for packaging chemical products. The machine carries a complete array for vertical fill and sealing of chemicals in bags or pouches. Furthermore, the machine is suitable to offer safety of personnel and the environment against chemicals.

Fruits and Vegetable Firms

A vertical packing machine is an economical solution used in storing fruits and vegetables with advanced bagging technologies. A vertical packing machine is a highly efficient and hygienic equipment conducive to the packing of fresh vegetables and fruits.

Confectionary Industry

Packaging of confectionary items is a challenging job. A vertical packing machine construction develops a continuous motion with a gas flushing system ensure seamless packing of sticky, soft, and sweeten products like gummies, etc.,

Dairy Industry

Milk and dairy products are extremely perishable which necessitates proper packing in order to protect and prolong the shelf life of the product inside. A vertical packing machine ensures temperature and moisture-controlled packing best for storing products like cheese, yogurt, milk, butter, etc.,

Grain Industry

If food packing integrity is not well-controlled and tested, its safety can be compromised. For the storage and transportation of grains, a vertical packing machine is significantly important. A vertical packing machine is an ideal solution to protect food against the chemical and physical hazards.

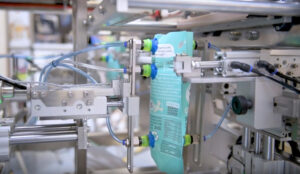

Cosmetics Industry

Cosmetic packaging is very important for the identification of a brand, business success, and product safety. In order to preserve the quality of high-performance ingredients; a vertical packing machine ensures an oxygen-free environment via flushing with protective gas.

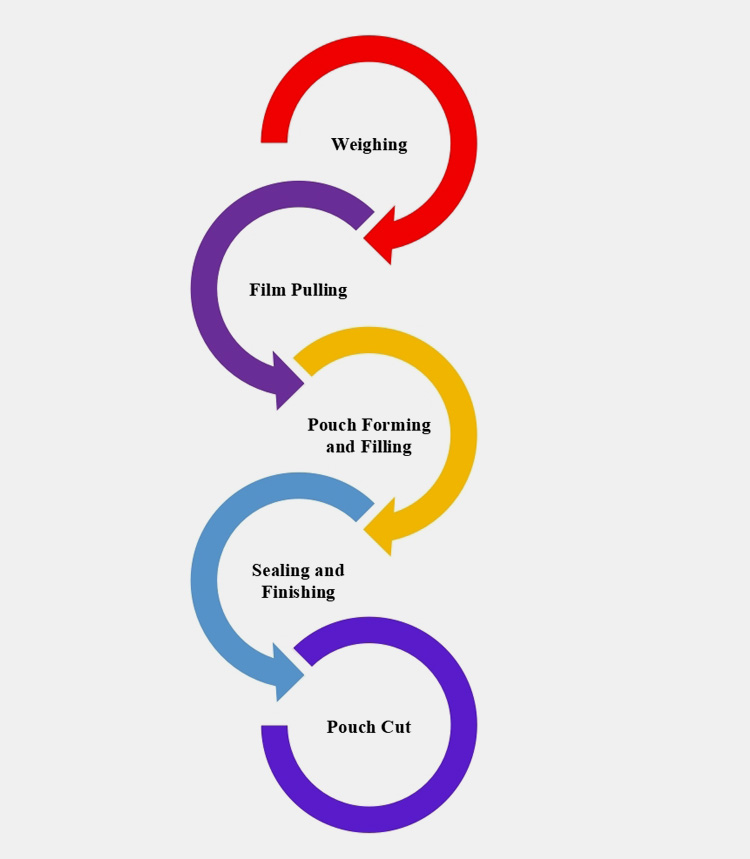

3.What is the working principle of a vertical packing machine?

The basic working principle of a vertical packing machine is discussed below.

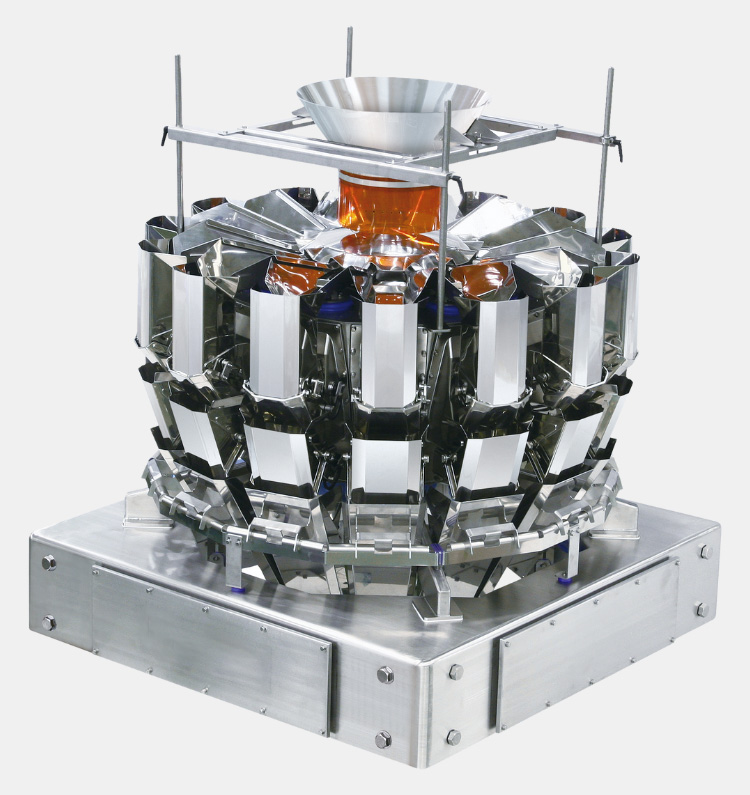

Step 1: Accurate Product Weighing

A vertical packing machine is designed with a spectacular weigher packing line helping you for an accurate weighed or volumetric dispensing of ingredients in respective pouches.

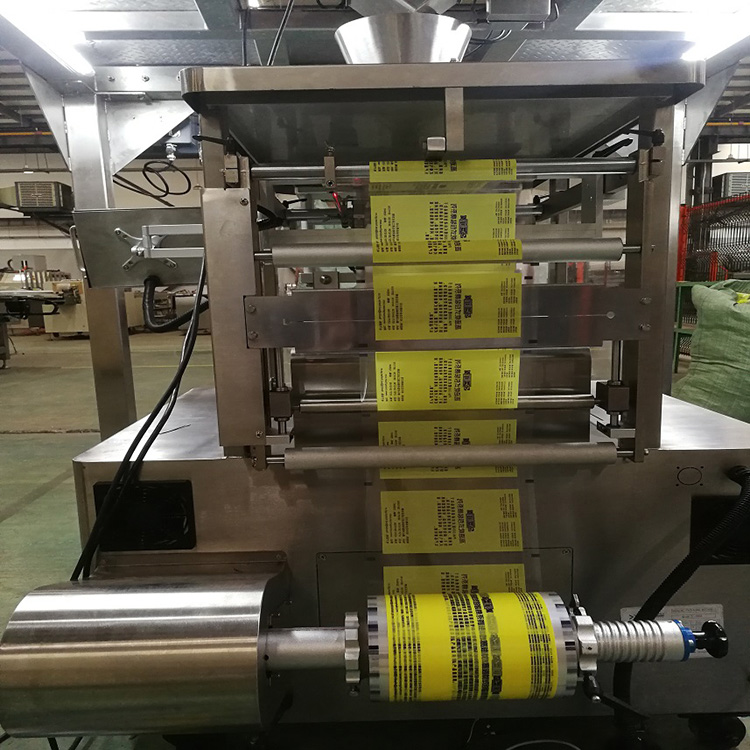

Step 2: Film Pulling

This system is accompanied by the unwinding of the roller and tensioner. A long film is wrapped in a roll known as a roll of film. A vertical packing machine forms a pouch from a thin film of plastic controlled by either servo motor that drives and pulls the film over the reels of the film pulling section. It perfectly and continuously works to pull the film smoothly and reliably.

Step 3: Pouch Forming and Filling

Product enters the system via tube former. The bags or pouches of various sizes are formed via a bag or pouch former. For different sizes, you need to change the forming tube, its change over time requires several minutes. Besides having the capability of bag forming, it also fills the bag via tube former with bulk ingredients. The bag former is made up of stainless steel and is safest for suitable pharmaceutical and foodstuff.

Step 4: Sealing and Finishing

A sealing section is composed of two sets of sealing devices. A vertical sealing jaw seals the edges of the film altogether. Hence vertical sealing jaws make a vertical pattern. If you follow a vertical sealer and press on the bag former it forms a flat or net pattern. Various sealers can perform various sealing patterns that ensure a high product packaging quality.

Step 5: Pouch Cut

There is a blade inside the sealer that cuts the edges of a pouch on the flat bottom after forming a seal.

4.What are the main parts of a vertical packing machine?

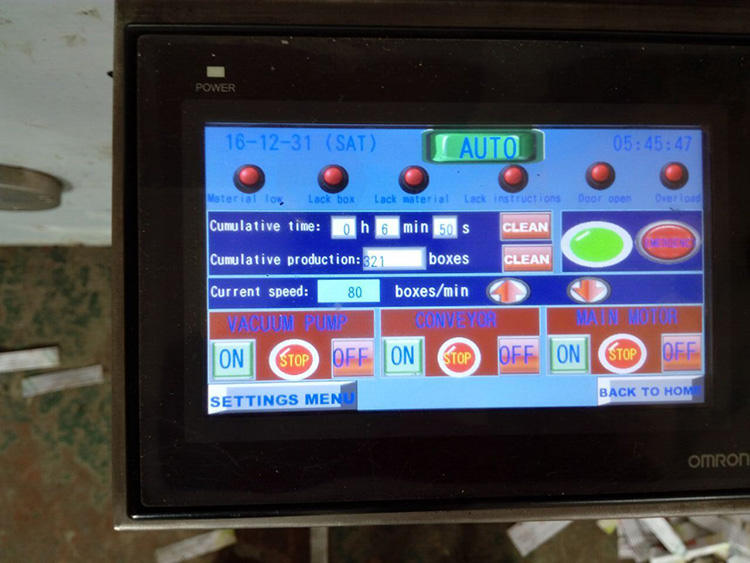

Touch Screen

Film Holder

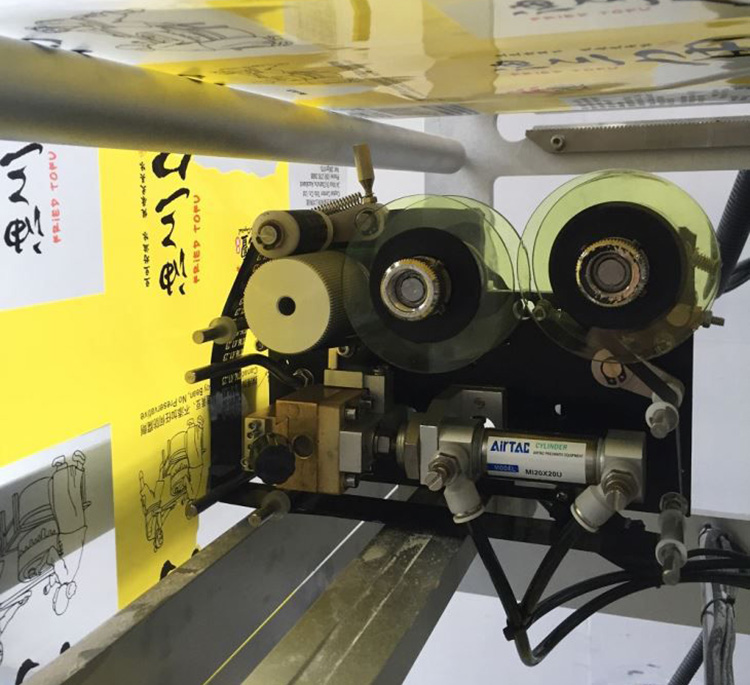

Ribbon Printer

Bag Former

Weighing Device

Film Cutter

The main structure of the vertical packing machine is described as followed:

| PART | DESCRIPTION |

| Weighing Device | A vertical packing machine is featured a weighing device processed with a micro-computer that allows accurate measurement of filling ingredients. This section allows an easy and faster calculation to ensure a scientific, understandable, and time-saving procedure. |

| Roll Film Device | A laminated film is placed on a shaft assembly known as a roll film device that supports the device to form a pouch or bag. |

| Tube Former | A vertical packing machine has a tube former where flexible packaging material enters in a thin flat strip form. |

| Film Unwinder | A film unwinder is responsible for unwinding film into the device offering easy operation and film tension. |

| Dancing Arms | This is the section of film unwinder that offers speed feedback to unwind the control circuit. |

| Bag Printer | After the dancing arms, a film sheet travels to a thermal or inkjet type data printer unit. A printer designs a desirable code (date, instruction, registration mark, graphic, etc) on the film. |

| Film Collar | A film folds around the tube collar so that the length of the film with two edges overlaps each other. |

| Film Former | A sheet of the film enters a tube forming assembly via film collar. A film former can be set up to various sealing styles such as lap seal, or fin seal. |

| Film Registration | A film registration includes a sensor and adjustment for detecting a registration mark for the final placement of the end seal and cutting. It is used on film with pre-printed information or graphics. Furthermore, with the help of a sensor, this component ensures the film stays in a perfect state on the forming tube. |

| Sensor | A sensor is responsible to identify the sealing portion of the film, and technical problems, and identify edge trimming. |

| Film Pull Belt | There are generally two film pull belts, a right side, and a left side. It is typically a vacuum belt that ensures better gripping control during, a humid or cold process environment. |

| Hopper | Hopper is responsible for holding the filling ingredients and transporting them downward for further procedure. |

| Rotary Jaw | The rotary jaw offers a completely airtight and premium quality sealing of the bag. As the pressure exerted by rotary jaws while sealing film is much higher, it is reducing the risk of product contamination against environmental hazards. Furthermore, it enables the filled product to retain properties for an extended period. |

| Vertical Sealing | This is responsible to seal the sides of packaging film with the help of upward and downward movement of sealing jaws. |

| Horizontal Sealing | Horizontal sealing jaws are responsible for sealing the top of the filled bag and performing the bottom sealing of the next one. It also trims and splits the pouch from each other. |

| Cutting Blade | A cutting blade is responsible for the separation of individual pouch via sharp knives or cutters. The material used for cutting blades is made with stainless steel. |

| Display Screen | The display screen helps in the monitoring of process parameters, feeding data, and technical notifications. |

| VFD | A variable frequency device (VFD) is responsible for regulating the speed and torque of the power supply of the vertical packing machine. |

| N2 Gas Filling Device | This device is responsible to fill an N2 gas in bags in order to replace oxygen with nitrogen. This section helps to prevent filling products against humidity. |

| Bag Discharger | After filling, sealing, and cutting, the pouches leave the system via a bag discharger. |

5.What are the advantages of a vertical packing machine?

The key benefits of a vertical packing machine are mentioned below:

SPEED

A vertical packing machine is capable of packaging products at a very high speed. The machine is ideal if you’re intended to achieve a high speeds packaging output with sustainability and accuracy, and reduced downtimes and losses.

PERSONALIZATION

A vertical machine is suitable for packaging various bulk-size product filling into respective pouches involved from ‘Grams’ to ‘Kilograms’. Furthermore, the machine is flexible when it comes to achieving personalization and easy changeover with minimum interruption.

PRODUCT’S STABILITY

Various consumable products are filled and packed using vertical packing machines in a compact and safe condition. This will lead to giving you maximum product stability and shelf life.

LOWER OPERATIONAL COSTS

With a low cost of packaging, a vertical packing machine supports an optimized operational cost. The machine is designed with innovative technology and has an extended shelf life and minimum maintenance cost.

HIGHER THROUGHPUT

A compact design of a vertical packing machines helps you with a longer packaging run thus giving a high throughput.

MULTI-FUNCTION DESIGN

A fully automatic machine featured weighing, filling, packaging, sealing, printing, and cutting at one time. Hence this equipment is a one-stop solution for the entire packaging steps. A vertical packing machine smoothly performs this job with the lowest noise.

VARIOUS SIDE SEAL

This is one of the premium features of a vertical packing machine. You can feed the production requirement of film’s length, width, and range of product’s weight using the HMI interface

INTELLIGENT CONTROL SYSTEM

A high accuracy micro-computer control system enables the weighing and filling procedure scientific, has a low error, and is easier to operate.

SOLID AND DURABLE FRAME

The entire structure of the machine is made up of food-grade stainless steel. Thus, the machine is highly resistant to bad environmental conditions and durable for extended usage. Furthermore, a well-constructed machine is fixed with a heat dissipation fan for non-stop use.

VARIOUS FILLING MATERIAL

This machine is capable of handling a wide variety of woven, non-woven packaging materials like PET, PE, nylon, aluminum, etc.

WIDE APPLICATION

You can pack different types of (powder-fine or coarse), edible (cocoa powder), chemicals (calcium carbonate), pharmaceuticals (lyophilized medicines), etc. using a vertical packing machine.

6.What are the types of vertical packing machines?

A vertical packing machine offers various types that can be categorized into basic sections.

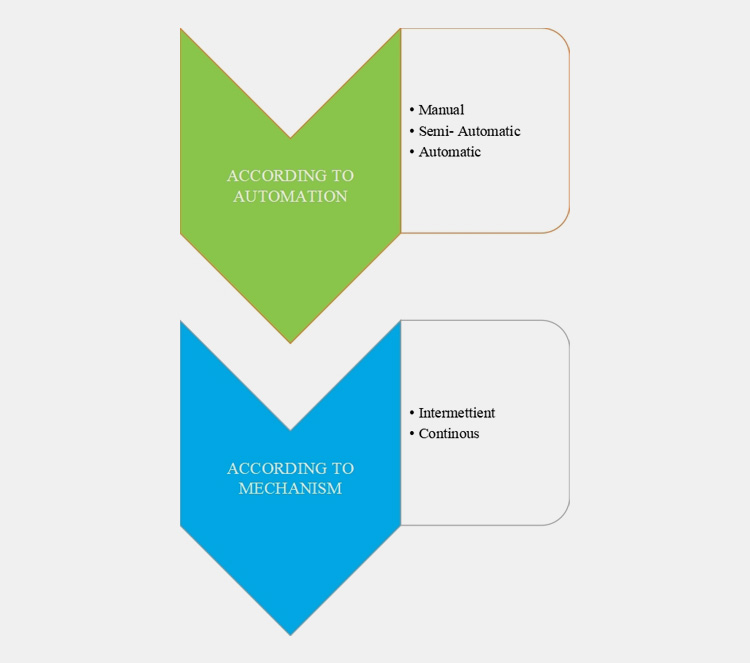

- According to Automation

- According to Mechanism

ACCORDING TO AUTOMATION

Followed by automation, a vertical packing machine is categorized into the following types:

Manual Vertical Packing Machine

A manual vertical packing machine is a compact, small and precise packing solution for small businesses that is driven manually.

Semi-Automatic Vertical Packing Machine

This is an innovative, versatile, and perfect solution for packaging than a manual vertical packing machine. The entire functioning of the machine is performed automatically instead of manual feeding and discharging.

Automatic Vertical Packing Machine

An automatic vertical packing machine performs a high-volume production line in various industries. This machine is featured with programmed automation, easy-to-use with time economical properties.

ACCORDING TO MECHANISM

The basic mechanisms followed by the vertical packing machine are discussed below:

Intermittent Vertical Packing Machine

An intermittent vertical packing machine has a stop action during a film feeding pitch. At this time, the top and bottom sealing are made by an end seal unit which is fixed in its position. This form of packaging is suitable for small batches where dropping motion doesn’t damage your packaging product.

Continuous Vertical Packing Machine

A continuous type does not confine to a stop motion with a continuous film feeding. Unlike the intermittent type, the end sealing unit moves up and down by following the film feed motion. This up and down movement prevents the damage of products that may occur by dropping. A continuous type is required for high-speed and large production.

7.What bagging designs does a vertical packing machine offer?

The bagging designs by a vertical packing machine are described in two sections:

| ACCORDING TO THE SEALING STYLE | ACCORDING TO PACKAGING STYLE |

|

|

ACCORDING TO THE SEALING STYLE

A vertical packing machine is an advanced technology that ensures various sealing styles. Such as:

Stand up Packing

They are also known as a ‘daypack pouch’. They are flexible type packaging presented in stand upright on its bottom with excessive storage space.

4- Sided Seal

This is a high-demand sealing due to its stability and strength. They are formed by two pieces of film that are completely sealed all around the four sides leaving an opening. Such sealing does not have a gusset.

Flat Packing Round Hole

A flat pouch doesn’t have a fold or gusset and can be sealed across the edges or bottom.

3-Sides Seal Packing

They are commonly used as a single serving, such as instant soups, food supplements, and drinks.

Premade Zipper Packing

They are also known as ‘press-to-close’ packing. They are re-sealable and cost-effective. They are the most popular packaging designed with closure and several benefits.

Premade Slider Packing

They are a useful form of vertical packaging where a flexible opening slider is attached to one side of the bag. Hence it enables the re-sealing property can be used multiple times.

ACCORDING TO PACKAGING STYLE

A vertical packing machine allows an extensive packaging style adopted by different brands as a signature. We have discussed some common packaging styles below:

Pillow Packing

This is a traditional style of packing forms a pillow or pouch-shaped bagging. This type of packing is commonly utilized in the pharmaceutical sector.

Quad Seal Packing

This type of packing is involved four-sided sealed corners offering a huge packaging space to fill the material.

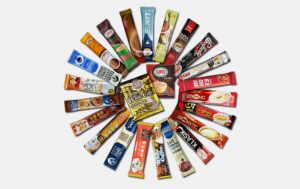

Stick Packing

This is the most suitable form of packing for the pharmaceutical, beverage, and cosmetic industry, etc., This is the most suitable and affordable packaging for a single-serve format.

Zipper Bags

A vertical packing machine features an ideal solution for preserving items that are easy to carry and ensures safety in the form of a zipper sachet. This is a form-fill- re-closable zipper that is presented with hanging holes and various shapes

8.What are the top four maintenance tips for vertical packing machines?

Vertical packing machines should be operated and maintained by trained and experienced individuals. Shrinkwrap if the machine is not installed for a long time. Never leave tools on the machine or main body. To avoid mishaps and increase the working life of the machine regular maintenance should be carried out according to the manufacturer’s guidelines.

| Daily |

|

| Weekly |

|

| Monthly |

|

| Yearly |

|

9.What are the problems and solutions for vertical packing machines?

| Problem | Reason | Solution |

| The machine or part of the machine is non-functional. |

|

|

| Knives do not cut film. |

|

|

| Failure of the heating unit. |

|

|

| The film feeding unit is not working. |

|

|

| The pouch or pack counter is not working. |

|

|

10.What are the points to be noted before purchasing a vertical packing machine?

The following points must be considered for purchasing a vertical packing machine.

Support or Aftersales Care

Depending on the business distribution, the packaging machine is sent to the place where a purchaser has to install and set up for operation on its own. So, in order to avoid complications during this process, you must confirm if support or aftersales care is provided for installation and post-installation.

Compatibility with Product & Production Site

Each vertical packing machine is featured with different sizes, output, packaging styles, sealing styles, and accommodation. Therefore, you must examine your product packaging, the production site, and enough space for secure installation and operation before choosing a machine.

Competitor Vendor

When choosing a machine, it is preferred to consider a manufacturer or distributor who has proven experience and a good record for manufacturing machines. It is more likely to receive suitable suggestions and some research for your production site.

Featured Machine

A vertical packing machine can manage a variety of products, styles, and sealing. This machine is great at high-value-added packaging. Before purchase, you must look for a suitable featured machine that can handle your production line professionally.

11.Describe the importance of vertical packing machines in the pharmaceutical industry?

In pharmaceuticals, a vertical packing machine is of prime importance because:

- It ensures faster packing of the finished products for storage and transportation.

- The machine is responsible for greater output, higher productivity, and maximum profit for your business.

- Ensures a proper calibration of the machine to pack dosage form correctly.

- Ensure ingredient weighing before filling and sealing

- Confirms the quality standards assigned by international regulatory bodies.

12.What is the future market growth of a vertical packing machine?

A vertical packing machine is an automatic streamlined product packing system frequently used in pharmaceutical, foods, and cosmetic regions for packing a variety of products.

The global market growth of a vertical packing machine is valued at 1985.9 million USD recorded in 2019. Furthermore, it is expected to grow up to 3121.8 million USD by the end of 2026 with growing of 6.6% CAGR during 2021-2026.

CONCLUSION

The vertical packing machine is a one-stop solution for weighing, filling, sealing, and packing your manufactured product.

Now, shopping for an innovative vertical packing machine doesn't have to be stressful. Aipak understands your needs for different types of packaging machines and provides the best packaging automation for your production line. Plan your first buying and free consultation with a machine specialist now!

Don't forget to share this post!

Stick Packing Machine Related Posts

Stick Packing Machine Related Products

Stick Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine