Reliability

High Productivity & Fully Automatic

Formula Support

Want A Free Consultation

Gummy Making Machine Depositing Machine

Description:

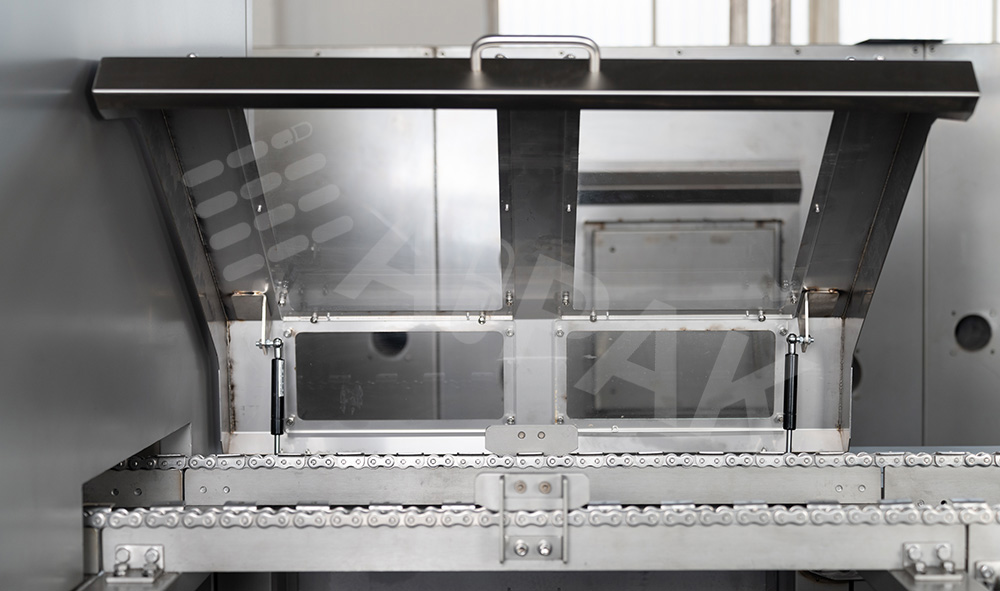

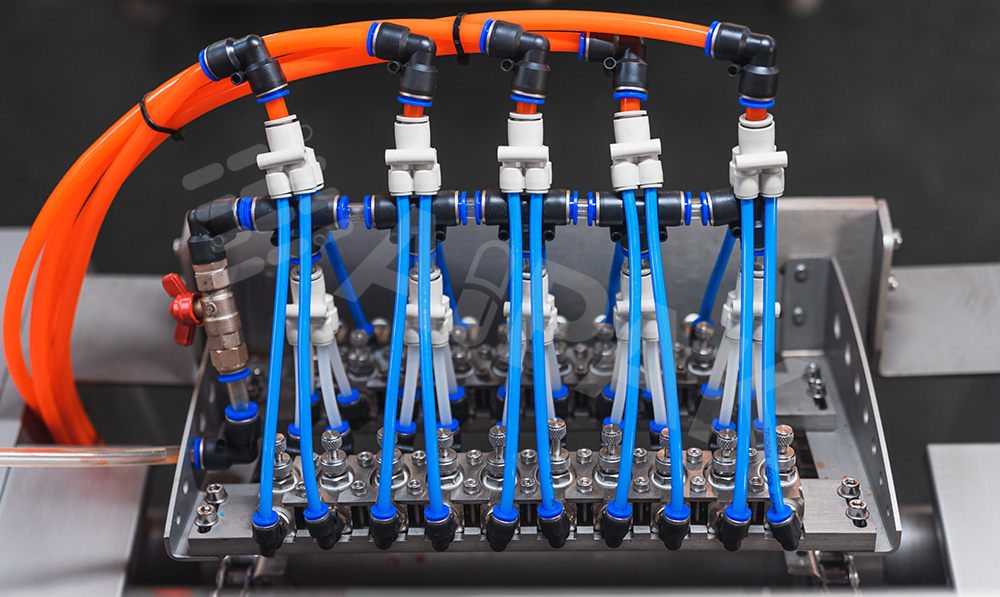

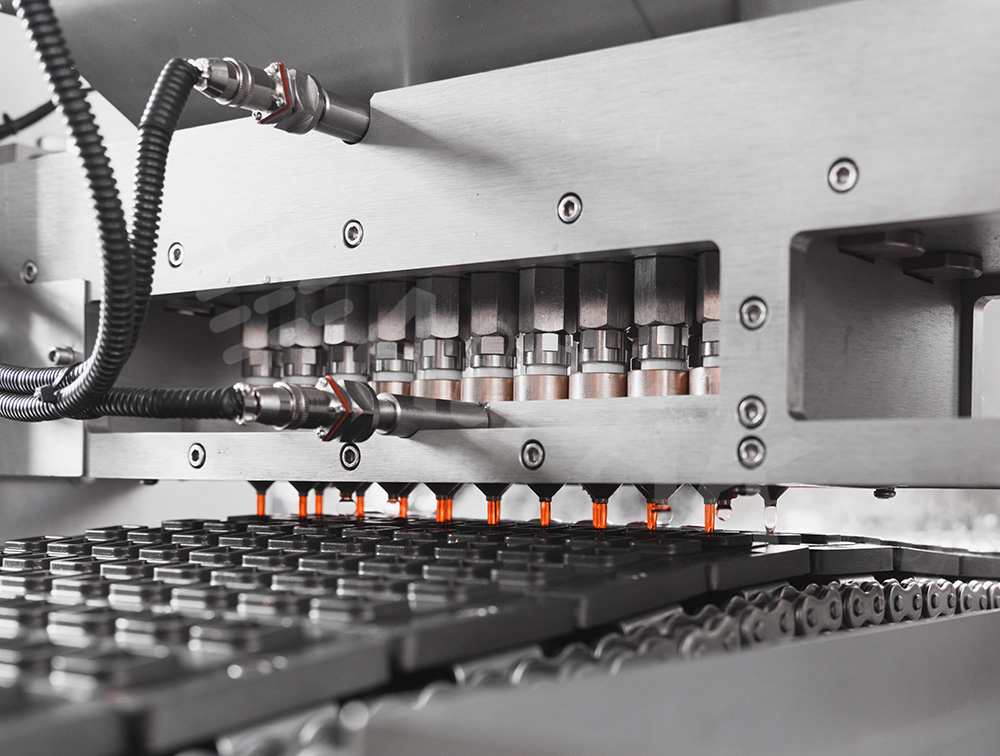

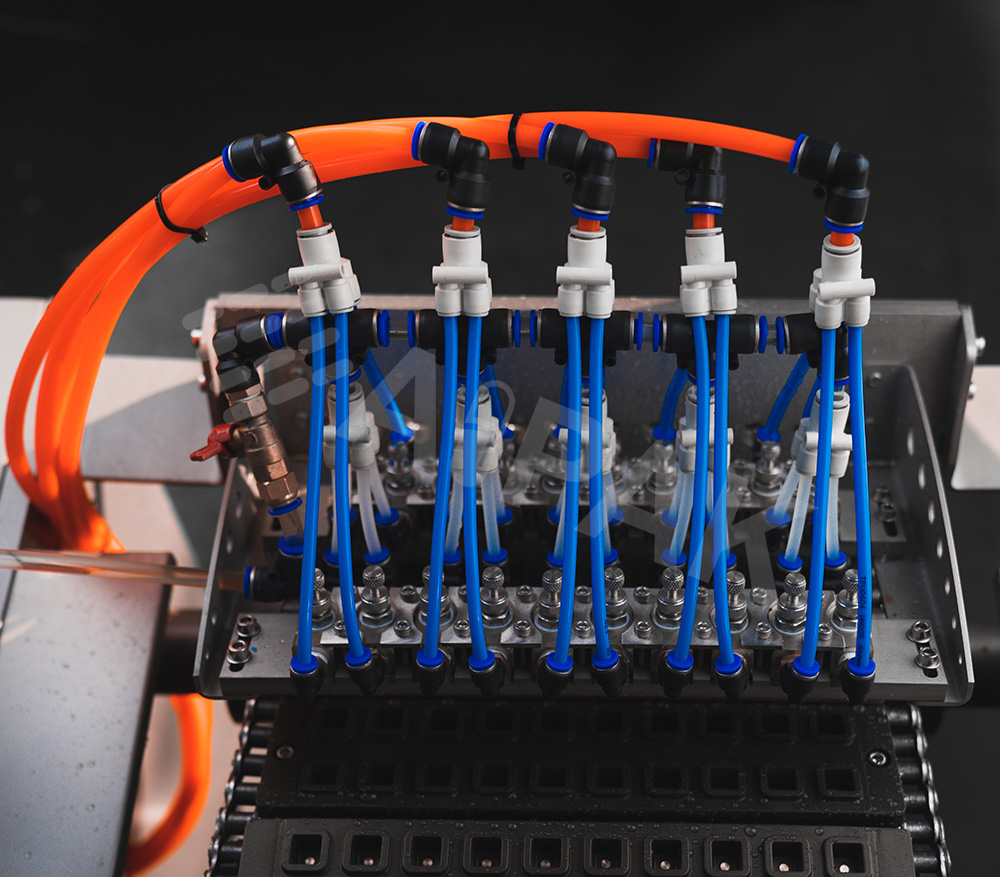

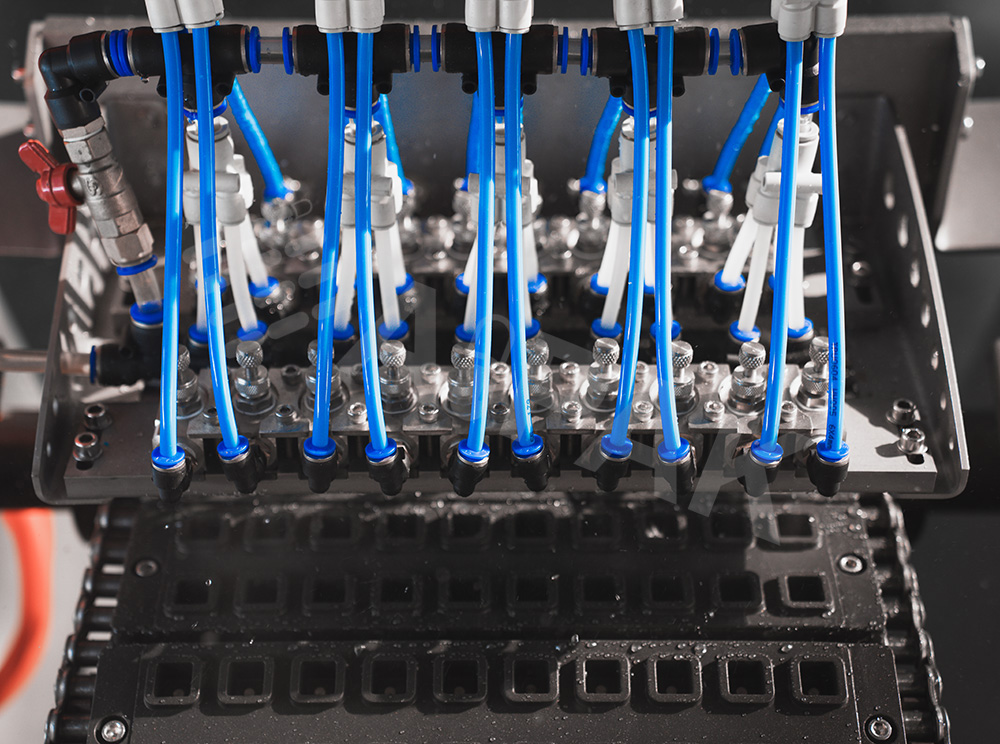

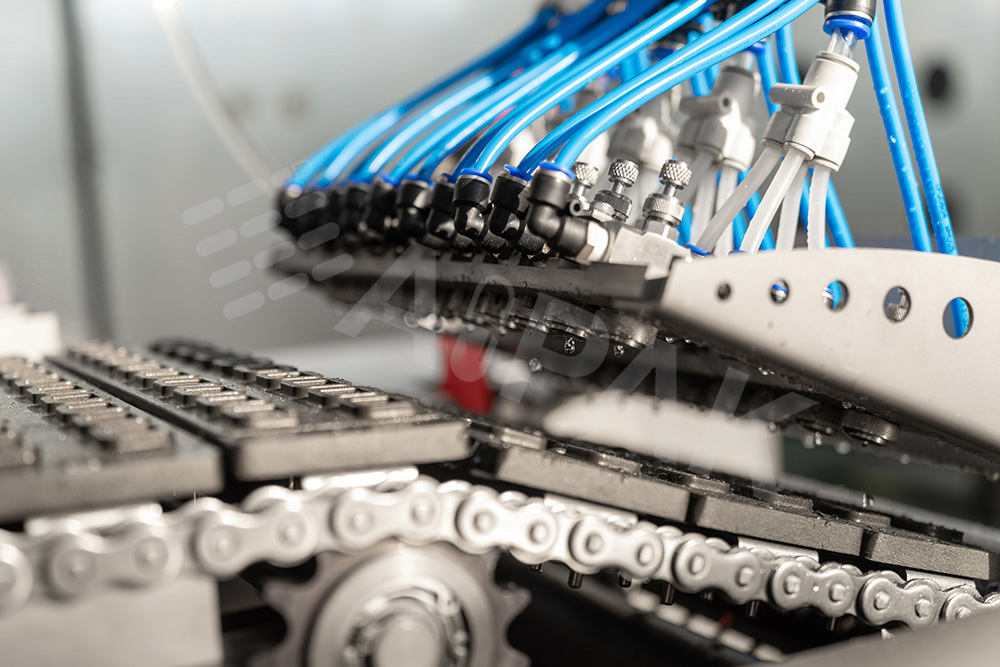

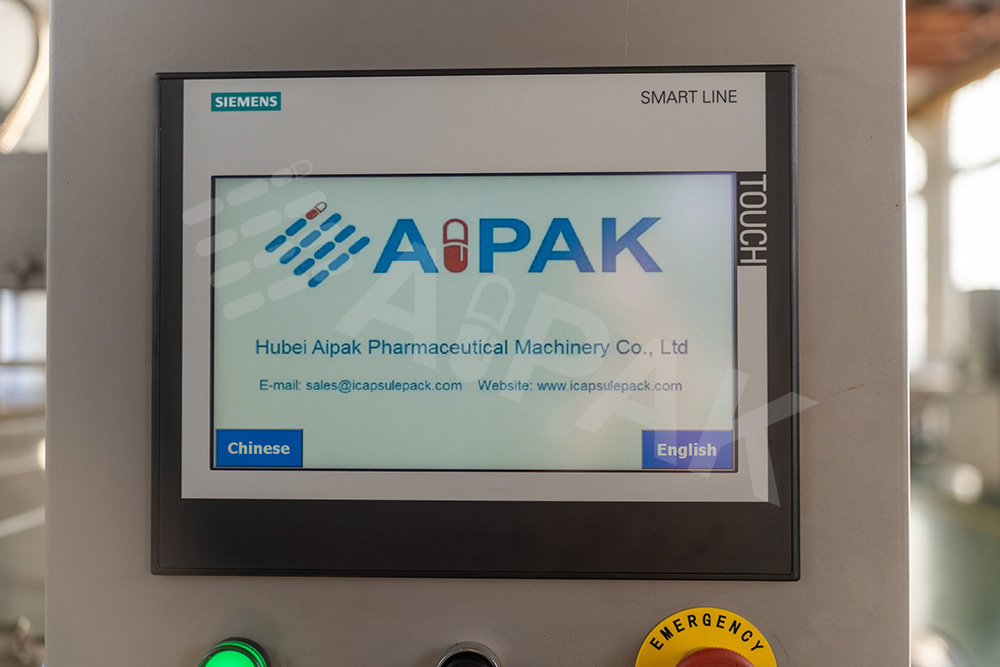

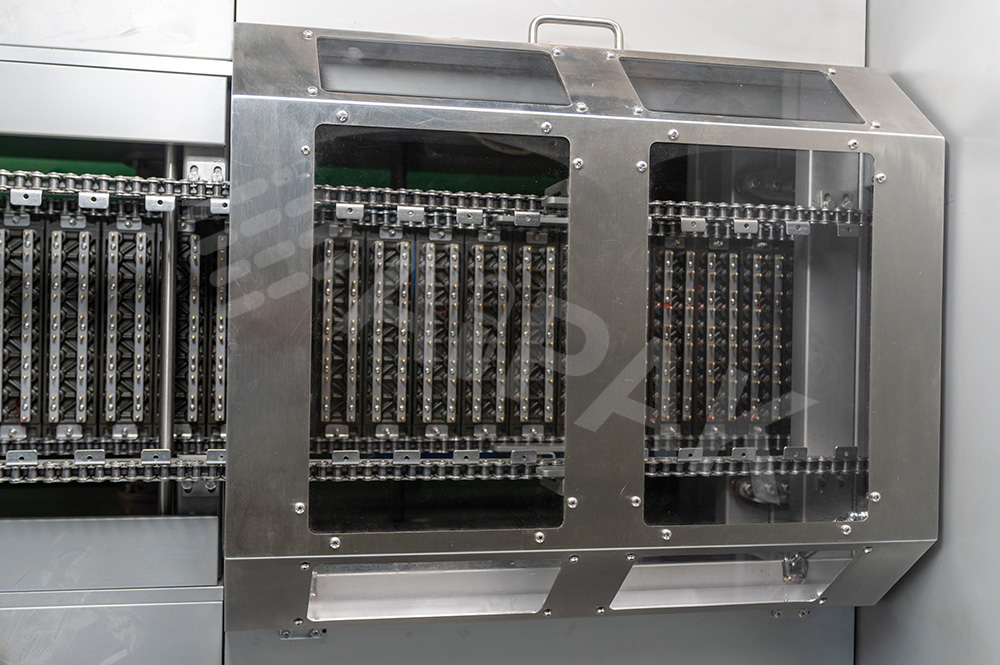

AIPAK gummy making machine depositing machine is the critical parts of the gummy bear manufacturing that is made by many components including the independent electric cabinet,Depositing head (2 hopper),24 plungers, Manifold plate, Dynamic mixer,4 dosing pump, Heating pipe, Chian transmission, temperature detecter,demold plate. demold brush, cylinder, aviation socket.electronmagnetic vale.Among which its frame is made by SUS304 and food touch part is made by SUS316.

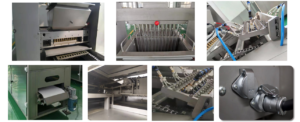

Main Parts Picture:

FEATURE

- 20 hole single pouring double hopper, spray distribution board, upper and lower two color

- Distribution board, servo conveyor, PLC program control pouring

- Special design manifold and nozzles make tail free

- Individual nozzles cone shape spray the oil to cavities of mold, for saving oil and sanitary condition

- Combine Static and Dynamic Mixer with piston type dosing pump for much better mixing with color and flavor and other ingredients.

DATA SHEET

|

Including Parts |

Independent electric cabinet,Depositing head (2 hopper),24 plungers, Manifold plate, Dynamic mixer,4 dosing pump, Heating pipe, Chian transmission, temperature detecter,demold plate. demold brush, cylinder, aviation socket.electronmagnetic vale. |

|

Depositing power |

1.5kw |

|

Hopper TMP hold power |

1.2kw*2 |

|

Maniflod TMP hold power |

2.5kw |

|

Conveyor power |

0.55kw |

|

Dynamic mixer power |

0.37kw*2 |

|

Range |

80-150kgs/h (depending on candy weight and size) |

|

Cylinder pressure |

0.3-0.5mpa |

|

Gas consumption |

0.5 m3 / h |

|

Dimension |

1500x1500x2245 |

|

Weight |

1000kg |

|

Material |

Frame:SUS304,Food touch part :SUS316 |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951