CBD Gummy Manufacturing Machine: The Complete FAQ Guide In 2025

Nowadays, gummies are available in a variety of types, shapes, and colors, and are loved by consumers all over the world. With the continuous development of gummies, CBD gummies are gradually becoming more and more popular. Do you have questions about CBD gummies and how to make CBD gummies?

CBD Gummy Manufacturing-sourced: dailydemocrat

Please rest assured, by following this complete FAQ guide of CBD gummy manufacturing machine, you will have an in-depth understanding of CBD gummies and CBD gummy manufacturing machine. Let's take a look at it with questions!

1. What Are CBD Gummies?

What Are CBD Gummies-sourced: musclemx

In addition to being used in gummies, CBD can also be used in other foods, oils, capsules, lotions, cosmetics, chemicals, pharmaceuticals and other products. However, there are strict requirements for the content of CBD, and it cannot be added casually according to any dosage and type.

2. Are CBD Gummies Legal?

Is CBD Gummies Legal-sourced: hempbombs

Laws governing the use of CBD gummies vary from place to place. You need to do your research based on where you are before deciding whether to use or produce CBD gummies.

Use or Purchase with Healthcare Approval

Use or purchase with Healthcare Approval-sourced: loyalsource

In any case, you should consider using or producing CBD gummies with local health care approval. Also, if you add CBD to any food or medicine, you need to keep the CBD content below 3%.

Obtain FDA Approval

Obtain FDA approval-sourced: knowledgewebcasts

Whether you are purchasing, using or producing CBD gummies or other CBD products, be sure to remember that the CBD gummies you purchase or produce have obtained FDA approval for production.

In general, it is legal to buy, use or produce CBD gummies if the THC content is less than about 3%.

3. What Can CBD Gummies Bring You?

Benefits of CBD Gummies-sourced: canavape

The production and use of CBD gummies strictly follows the standards set by the world, so you don't need to worry about this. The CBD gummies can bring you:

Relieve Anxiety

Relieve Anxiety-sourced: cbdfx

The cannabinoids in CBD gummies interacts with the body's endocannabinoid system to help regulate and balance body functions and relieve patients' anxiety.

Relief the Pain

Relief the Pain-sourced: sltrib

CBD gummies contain sedatives, which when absorbed by the body, release substances that relieve pain, thus helping the body to calm down.

Treat Insomnia

Treat Insomnia-sourced: hss

CBD gummies can help patients with insomnia or those who have been unable to fall asleep for a long time fall asleep easily and treat insomnia.

4. Are There Any Side Effects Of CBD Gummies?

Side Effects Of CBD Gummies-sourced: cravemag

Although CBD gummies can bring you many benefits, inevitably, they also have side effects. Its potential side effects may include:

Liver Damage

Liver Damage-sourced: buzzrx

When taking CBD gummies, it may interfere with other medications at the same time. This can cause serious side effects or liver damage. Therefore, when taking CBD gummies, avoid taking other medications at the same time.

Mood Changes

Mood Changes-sourced: livi

CBD gummies may cause irritability or agitation, drowsiness, and changes in alertness. Therefore, avoid taking CBD gummies if you are driving or exercising.

Gastrointestinal Problems and Appetite Changes

Gastrointestinal Problems and Appetite Changes-sourced: newlifeoutlook

CBD gummies may cause gastrointestinal problems and appetite changes. If you have a poor appetite, it is recommended not to or immediately stop consuming CBD gummies.

5. What Is CBD Gummy Manufacturing Machine?

CBD Gummy Manufacturing Machine-sourced: AIPAK

The CBD gummy manufacturing machine is specially designed for making different kinds of gummies with cannabidiol (CBD) oil in different colors, sizes, and shapes, and it shall be contained less then 3%. It is able to provide you with production and customization solutions for various CBD gummies.

This machine provides consumers with a discreet and simple way to ingest CBD. Through the perfect integration with gummies, the CBD gummy manufacturing machine has broad prospects and markets.

6. What Are The Advantages Of Using CBD Gummy Manufacturing Machine?

By using CBD gummy manufacturing machine can offer you several advantages, and they are:

Various CBD Gummies

Various CBD Gummies-sourced: groupon

There are various CBD gummies for your choice with the customization of shape, flavor, and color of CBD gummies. There are gelatin and pectin CBD gummies, fruit-flavored and functional-flavored CBD gummies, animal-shaped and human body part shaped CBD gummies, etc.

Increased Production Efficiency

Increased Production Efficiency-sourced: resco

The fully automatic CBD gummy manufacturing machine, it can greatly improve your production efficiency. It can automatically finish the ingredients mixing and cooking, depositing, cooling, demoulding, drying and coating. There is no need for labor work which can improve your production efficiency greatly.

Consistent Product Quality

Consistent Product Quality-sourced: 303magazine

The whole CBD gummy manufacturing making machine was controlled by intelligence. It can automatically produce CBD gummies for you according to the procedures and standards you set, and provide you with consistent product quality. By changing different molds, you can get different shapes of CBD gummies.

Reduced Manual Labor Work

By using CBD gummy manufacturing machine, it can greatly reduce labor costs. The machine can automatically produce according to the program you set. Moreover, some machines are designed to be capable of self-supervision and self-check, which can greatly reduce the manual labor work.

Improved Cleanliness and Hygiene

Improved Cleanliness and Hygiene-sourced: gummytechnologies

The CBD gummy manufacturing machine is made of food-grade stainless steel to facilitate your later cleaning and maintenance. During the production process, most of them are produced in a closed space, which can improve the cleanliness and hygiene of CBD gummies.

7. What Are The Types Of CBD Gummy Manufacturing Machines?

There are three types of CBD gummy manufacturing machines for your choice, and they are:

Manual CBD Gummy Manufacturing Machine

Manual CBD Gummy Manufacturing Machine-sourced: trufflymade

The manual CBD gummy manufacturing machine is suitable for most chocolate, caramel, jellies, hard candies, gummies and many similar syrup pourings. It requires your manual operation and mold replacement.

In addition to being equipped with an extra-large gummy syrup depositing machine and hopper, it is also equipped with heating panels and silicone molds for soft gummies and hard gummies.

Semi-automatic CBD Gummy Making Machine

Semi-automatic CBD Gummy Making Machine-AIPAK

The semi-automatic CBD gummy making machine, also called as CBD gummy depositor machine. By pouring syrup containing CBD content into different molds, the gummy depositor machine can make different shapes of CBD gummies for you.

This CBD gummy making machine adopts functions such as continuous pouring, automatic de-moulding, and fan forced cooling, which can ensure the quality and output of candy during the long-term production process.

Fully Automatic CBD Gummy Making Machine

Fully Automatic CBD Gummy Making Machine-AIPAK

The fully automatic CBD gummy making machine can provide you with fully automatic CBD gummy manufacturing and a complete set of processes including cooking, pouring (including servo central filling and pouring), finished product transportation, powder processing and recycling.

It is controlled by a PLC system, with automatic loading and unloading of starch molding, which can automatically separate the candy and the mold.

8. What Are The Main Parts Of CBD Gummy Manufacturing Machine?

The main parts of CBD gummy manufacturing machine are:

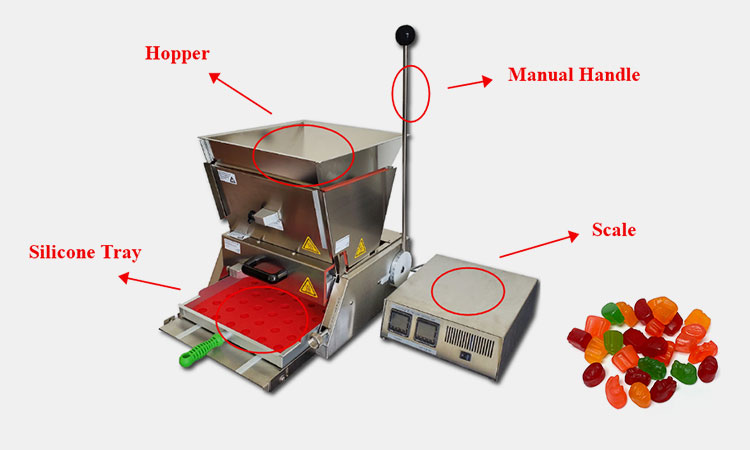

Main Parts of Manual CBD Gummy Manufacturing Machine

Main Parts of Manual CBD Gummy Manufacturing Machine-sourced: AIPAK

- Hopper

It is designed to hold and store the syrup solution and connect with the depositing nozzles. Through the depositing nozzles, syrup solution will be filled into the cavities of different molds.

- Silicone Mold

The silicone mold is used for fixed gummy shape. The silicone mold is environmentally friendly, durable and easy to de-mould, and will not be affected by temperature, causing gummies to stick.

- Manual Handle

The manual handle is used to open the depositing nozzles. You need to use this manual handle to manually adjust the pouring time of the syrup solution.

- Scale

Weighing ingredients for making CBD gummies.

Main Parts of Semi-automatic CBD Gummy Manufacturing Machine

Main Parts of Semi-automatic CBD Gummy Manufacturing Machine-sourced: AIPAK

- Depositing Hopper

The well-melted and mixed syrup solution will be loaded into the depositing hopper. The sensor above the depositing hopper will control the depositing nozzles so that the syrup solution will be filled into the mold tray cavities without wasting.

- Depositing Nozzle

After the syrup solution has been transferred from the storage tank and loaded into the depositing hopper, the sensor will control the depositing nozzles to release the solution into the mold trays.

- Molding Tray

The mold trays with cavities are applied for a fixed gummy shape. After the gummies have been cooled and dried, you can de-mold them from the molding trays.

- Electric Box

Electric box, also known as junction boxes, is designed for enclosing the wire connections. There is a control panel inside the electric box, which can protect the control panel from being damaged.

- Air Cylinder

The air cylinder offers a machine with power to deliver syrup solution from bottom to top.

- Pedal Clutch

Through the pedal clutch, you can pedal to control depositing, and pouring times and change different molds.

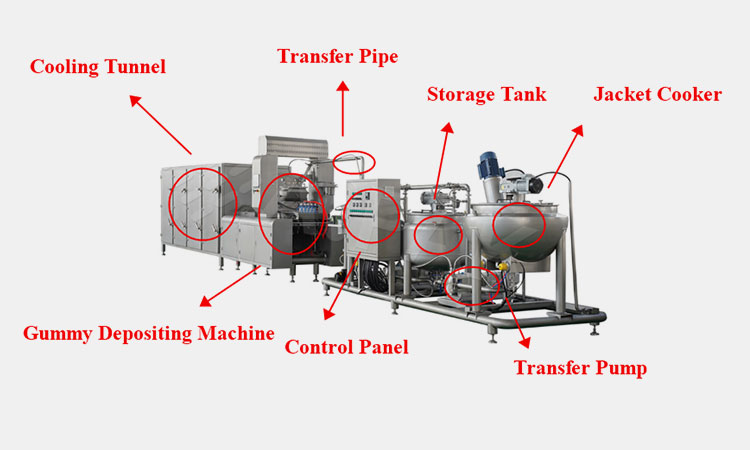

Main Parts of Fully Automatic CBD Gummy Manufacturing Machine

Main Parts of Fully Automatic CBD Gummy Manufacturing Machine-sourced: AIPAK

- Jacket Cooker

The jacket cooker is mainly for melting ingredients like sugar, pectin, gelatin, sweeteners, flavors, etc. It includes the motor, agitator, electric heating pipe, and scrap shear parts, to help heat and mix the ingredients for manufacturing the gummies.

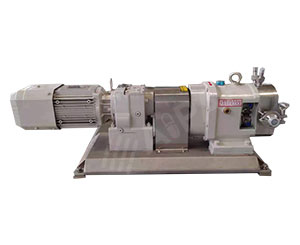

- Transfer Pump

The transfer pump, also called as LOBE pump, is used for offering the powder to move the solutions or syrups from the beginning to the depositing part. Formed by the synchronous reverse rotation of the two rotors, it can transfer syrup to the storage tank or depositor.

- Storage Tank

Consisting of boiled water circulation insulation, scraper shear, and clean ball, the storage tank can store the syrup solution after dissolving and keep the syrup temperature.

- Control Panel

The control panel is the brain of the whole CBD gummy manufacturing machine. Through adjusting the parameter, this machine will run and make CBD gummies following your set program.

- Transfer Pipe

The transfer pipe is designed for transferring the syrup solution from the jacket cooker, through the storage tank, to the depositor machine.

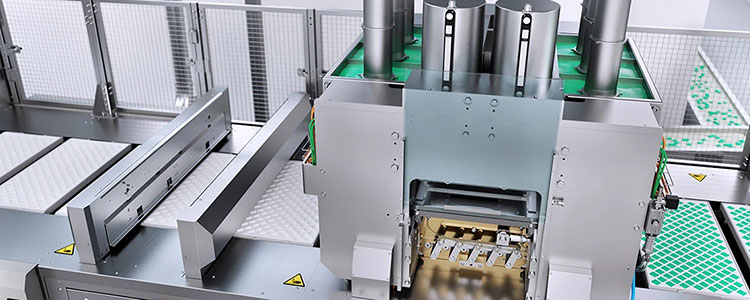

- Gummy Depositing Machine

The gummy depositing machine is mainly used for depositing the syrup solutions into the mold trays. It consists of a depositing hopper, depositing nozzles, the sensor, molding trays, air cylinder. It adopts a special design of PLC-controlled pouring, which can spray the nozzle into the mold cavity independently.

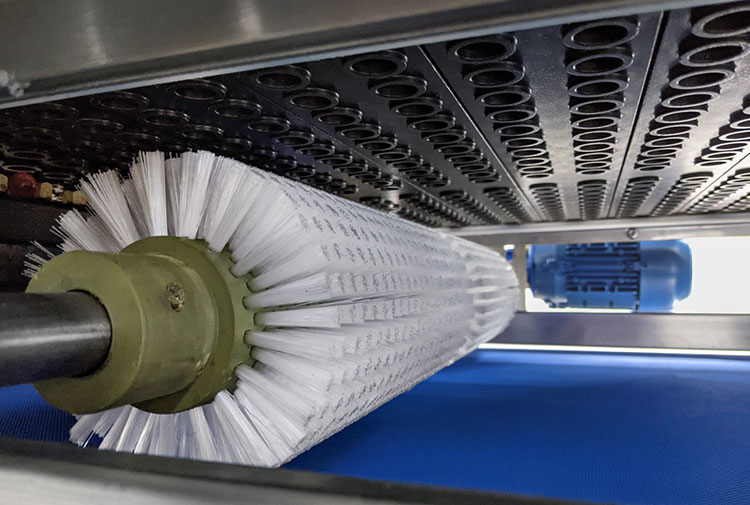

- Cooling Tunnel

The cooling tunnel adopts a sanitary structural design and can cool the molded gummies.

9. What Is The Working Principle Of CBD Gummy Manufacturing Machine?

Following the working principle of CBD gummy manufacturing machine below:

The working principle of manual CBD gummy manufacturing machine:

The Working Principle of Manual CBD Gummy Manufacturing Machine-sourced: trufflymade

Step 1: Setting Up the Depositor

Clean and disinfect depositing nozzles and other parts that come into contact with syrup solutions. Wipe clean afterwards with a clean paper towel or towel. All parts are then installed on the manual CBD gummy manufacturing machine.

Step 2: Heating Up Hopper and Piston

By heating the hopper, the syrup solutions can be kept solidified without affecting subsequent solution depositing. Preheat the hopper and piston 30 mins before use.

Step 3: Weighing the Ingredients and Cooking

Follow your own formulas to prepare your own ingredients and dosage. After preparing the ingredients, heat and mix the ingredients in batches. During the heating and mixing process, stir to mix evenly.

Step 4: Pouring Into Hoppers and Depositing

Load the evenly mixed syrup solutions into the hoppers, then close the lid and prepare depositing in the molds.

Step 5: Cooling and Cleaning

Take out the molds and put them in the dry place for cooling 10 mins. Cleaning the machine with the leftovers inside the hopper and tables.

Step 6: De-moulding

Demoulding the gummies that are cooled over.

The working principle of semi-automatic CBD gummy manufacturing machine:

The working principle of semi-automatic CBD gummy manufacturing machine-sourced: AIPAK

Step 1: Raw Material Mixing and Cooking

Mixing all the raw materials needed to make gummy including gelatin, pectin, water, sugar, sweeteners, syrup, colors, citric acid, starch, flavor, etc. and cooking them in the cooking unit according to your own formulas. Making them until syrupy, and the temperature shall be maintained at around 60-70 degrees Celsius.

Step 2: Depositing

Introducing the prepared syrup liquid into the hopper of the gummy depositor machine through the connecting pipe. The hopper maintains a set temperature to prevent the syrup from curdling or thickening.

Manually place the gummy mold on the operating table of the gummy depositor machine, below the discharge port. Activating the switch and nozzles automatically drips fudge syrup into each deposition chamber. When the trays are all filled, you can remove and put them in new mold trays.

Step 3: Cooling and De-moulding

Let the poured molds stand for about 10 to 20 minutes, and cool them to about 0 to 10 degrees Celsius. Once they are formed, they are unmoulded and dried to further evaporate the gummy's moisture content.

The working principle of fully automatic CBD gummy manufacturing machine:

The working principle of fully automatic CBD gummy manufacturing machine-sourced: AIPAK

Step 1: Ingredients Preparing and Cooking

Preparing your own formulas based on your own needs. The most basic formula is corn syrup, sugar, water, gelatin, food coloring and flavorings. Then adding all the raw materials to the cooking unit.

While heating, mix and stir. When the temperature drops, adding ingredients such as coloring matter, flavoring agents, active substances, citric acid, etc. in batches.

Step 2: Depositing

When all raw materials are mixed evenly, the syrup is removed and introduced into the depositor machine. Through the depositor machine, the syrup will be evenly dropped into the mold.

Step 3: Cooling and De-moulding

When all the molds are filled with syrup, cool the molds and let them sit for 10 minutes to wait for the syrup to settle. When the temperature gradually decreases, the gummy will gradually solidify. When the fondant has set, unmold it and place on a tray.

Step 4: Coating and Drying

By coating the appearance of gummy with different cream sugar, you can not only change the flavor of gummy, but also preventing the gummy from sticking to each other.

Enhancing appearance and improve packaging processability. After completing the gummy coating, drying again can facilitate subsequent gummy packaging and storage.

10. What Are The Differences Between CBD Gummy Manufacturing Machine and Candy Making Machine?

Differences between gummy manufacturing machine and candy making machine are:

| CBD Gummy Manufacturing Machine

|

Candy Making Machine

|

|

| Images |

CBD Gummy Manufacturing Machine-sourced: AIPAK |

Candy Making Machine-sourced: automaticcandymakingmachine |

| Purpose | l Designed for making CBD gummies which are made of gelatin and sugar; | l Designed for making all kinds of candies including soft candies, and hard candies; |

| Products | l CBD Gummies

CBD Gummies -sourced: entrepreneur |

l Hard Candies, lollipop, chocolates, gummies, etc.

Candies-sourced: houseofcandy |

| Taste | l Chewy | l Hard and Brittle |

| Capacity | l Big Output | l Medium Output |

| Manufacturing Method | l The syrup is cooked over high heat to 280 degrees; | l The syrup is cooked over high heat to 300 degrees Celsius (about 572 degrees Fahrenheit); |

11. How To Keep Your CBD Gummy Manufacturing Machine Clean and Efficient?

To keep CBD gummy manufacturing machine clean and efficient during gummy manufacturing is important. Here are the methods to keep them clean and efficient:

Regular Cleaning

Regular Cleaning-sourced: capplustech

The CBD gummy manufacturing machine has a sub-cleaning process, but regular manual cleaning is also very necessary. Manual cleaning mainly checks the nooks and crannies of the machine for food particles and residue.

Regular Inspection and Maintenance

Regular Inspection and Maintenance-sourced: syntegon

Regularly debug and inspect the machine's program. Inspection and replacement of machine parts for wear and tear. Check and debug the tightness of the screws of parts and components. Clean and lubricate some parts.

Self-Cleaning

Start the machine's self-cleaning program frequently. After each completion, it can facilitate more careful cleaning and inspection later. This not only ensures the cleanliness of the product, but also ensures the efficiency of the machine.

12. What Quality Standards Should Your CBD Gummy Manufacturing Machine Conform to?

All the good CBD gummy manufacturing machine shall conform to the quality standards of:

GMP Requirements

GMP Requirements-sourced: simplerqms

GMP is the abbreviation of good manufacturing practice. Good manufacturing practices are an important component in maintaining safety standards in CBD gummy production. It is designed to ensure that all CBD gummies are produced in a safe manner.

ISO Requirements

ISO Requirements-sourced: arenasolutions

ISO is the abbreviation of international standards organization. Following ISO standards, the CBD gummy manufacturing machine can provide standard and efficient CBD gummy manufacturing.

Risk Managements

Risk Managements-sourced: broward

When producing CBD gummies, you need to evaluate potential health and safety risks during the production process, including control of CBD quantity, improper hygiene practices, contamination of raw materials, etc. Only by following these standards can the CBD gummy manufacturing be the best it can be.

Safety Mechanism

When choosing a suitable CBD gummy manufacturing machine, you need to consider whether its safety mechanism has been improved. For example, it can produce CBD gummies for you that are intact, undamaged or uncontaminated.

13. How To Maintain CBD Gummy Manufacturing Machine?

CBD Gummy Manufacturing Machine Maintenance-sourced: hitechfm

Learn to maintain the CBD gummy manufacturing machine is vital and necessary, because it will give your machine longer shelf life and always offer you best quality CBD products with high efficiency.

To maintain the CBD gummy manufacturing machine, you shall:

Step 1: CBD Gummy Manufacturing Machine Disassembling

By disassembling the machine's parts, you can more closely inspect each part for cleanliness and wear. There is no need to worry about the machine assembly later because every part of the machine is numbered.

Step 2: Cleaning the CBD Gummy Manufacturing Machine

After disassembling the machine, wipe all parts with a clean towel for cleaning and disinfection. After air drying, use professional machine oil to lubricate and maintain non-loss parts to avoid losses caused by subsequent machine operation.

Step 3: Replacing Worn-out Machine Parts

Through inspection, worn parts will be eliminated and replaced with matching new parts. After replacing the parts, restart the machine for a test run to check whether it runs smoothly to facilitate the operation of subsequent machines.

Step 4: Installation

Reassemble all the parts that have been cleaned and replaced and conduct a test run. When there are no problems with the machine, store it in a clean, dry place.

14. How Do You Troubleshoot Your CBD Gummy Manufacturing Machine?

When using a machine, the most troublesome problem is that the machine will suddenly have unexpected problems. At this time, let us troubleshoot it together according to the engineer's steps!

Uneven CBD Gummy Shapes and Sizes

Uneven CBD Gummy Shapes and Sizes-sourced: erthwellness

The uneven CBD gummy shapes and sizes can affect the final aesthetics and quality of the product. This problem may be caused by misalignment of the mold in the pour-er. During the production process of gummy, it is necessary to fix the position of the mold and adjust the speed of syrup pouring.

Sticking and Deformed Gummies

Sticking and Deformed Gummies-sourced: deserthealthnews

There are many reasons for this problem. The reason may be that there is too much water when making the syrup. At this time, the syrup should be boiled for as long as possible. Secondly, it may be that after pouring, the gummies began to be de-molded before they were completely cooled.

CBD Gummy Manufacturing Machine Breakdowns

CBD Gummy Manufacturing Machine Breakdowns-sourced: convergentresults

Regular maintenance and inspection of the machine is required to prevent machine breakdown during operation. After using the machine, clean and lubricate it regularly, and replace damaged parts promptly.

Conclusion:

Through this complete FAQ guide in 2024 of CBD gummy manufacturing machines, you may have a deep understanding of this machine. If you are finding the best CBD manufacturing machine to boost your business productivity and flexibility, do not waste your time now, and come to us as soon as possible!

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine