Full Automatic High Efficiency

Best Quality High Capacity

Industrial Professional Manufacturer

Want A Free Consultation

APK-GM80Q Small Scale Gummy Making Machine Up to 80kg Gummys /hr

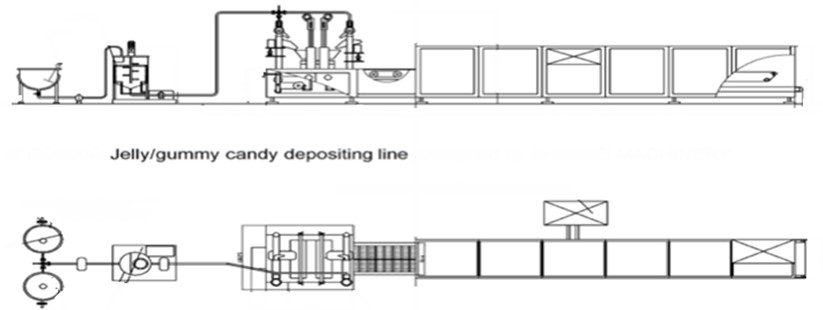

AIPAK APK-GM80Q small scale gummy making machine is fabricated based on the similar equipment of NID company from Australia. After being localized, the machine features easy operation and steady workng. The processing for the whole line include cooking, depositing (servo central-filled depositing included), finished product transfering, powder disposing and recycling system.

Sugar and carrageenan/ gelatin/ pectin dissolving

→ mixing→cooling

→ transporting

→ depositing

→ cooling

→ de-moulding

→drying

→milk coating

→packing

FEATURE

- PLC /computer process control available;

- An LED touch panel for easy operating;

- The production capacity is 80,150,300kgs/h(based on 4.0g gummy candy ) or more;

- The contacting food parts are made of hygienic Stainless Steel SUS304

- Optional (mass) flowing controlled by Frequency inverters ;

- In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid;

- Dosing pumps for the automatic injection of colors, flavors and acids;

- One set of extra jam paste injection system for making fruit jam-center filled candies(optional);

- Use an automatic steam control system instead of the manual steam valve which controls a stable steam pressure supplying to the cooking.

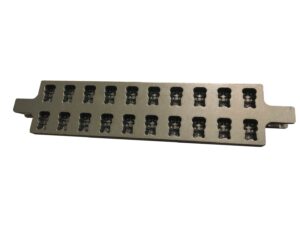

- Moulds can be made according to the candies samples provided by the customer.

DATA SHEET

|

Model |

APK-GM80Q |

APK-GM150 |

APK-GM300 |

APK-GM450 |

APK-GM600 |

|

Capacity |

80 kg/h |

150kg/h |

300kg/h |

450kg/h |

600kg/h |

|

Candy weight |

As per the candy size |

||||

|

Depositing Speed |

25~35 n/min |

25-45n/min |

|||

|

Steam requirement |

80kg/h, 0.4-0.6MPa |

250kg/h, 0.5-0.8MPa |

300kg/h, 0.8-1.2MPa |

400kg/h, 1.2-1.6MPa |

500kg/h, 1.6-1.8MPa |

|

Compressed air requirement |

0.2m3/min, 0.4-0.6MPa |

0.2m3/min,0.4-0.6MPa |

0.2m3/min,0.4-0.6MPa |

0.25m3/mi,0.4-0.6MPa |

0.3m3/min, 0.4-0.6MPa |

|

Working condition |

Temperature 20℃-25℃;Humidity45-55% |

||||

|

Electric power needed |

55kw/380V |

65kW/380V |

75kW/380V |

80kW/380V |

85kW/380V |

|

Total Length |

8m |

16m |

18m |

18m |

20m |

|

Weight of machine |

2500kg |

3500kg |

4000kg |

4500kg |

5000kg |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586