Softgel Manufacturing Machine:The Complete FAQ Guide in 2025

Nowadays there is no denying that a healthy body is a key to a successful life. And that is why a big part of the world’s population depends on medications. But there is a little question when it comes to the benefits of nutrients, especially vitamins.

Vitamins are building blocks in the body, and any deficient body is nothing but a home for sickness. When people cannot attain their vitamins thoroughly by natural ways due to multiple reasons, let it be an unhealthy diet, deprivation of sunlight, or impaired immunity – encapsulation industry has made it possible for them to fulfil their vitamin intake through soft gelatin capsules!

Today I have gathered all the information that you would need regarding the encapsulation industry. After reading all about from the formulation of softgel capsules to their manufacturing machines in this guide, you will be able to have a thorough knowledge in this industry. Whether you are a newbie or have a little know-how regarding soft gelatin capsules, there is always so much to learn!

Let’s drive the subject directly.

1.What Is the Formulation of Softgel?

Soft gel capsules

A softgel capsule is made of two components: the outer shell, and the inner filling. The main ingredient in the recipe of a soft gel capsule shell is, of course as the name suggests, gelatin. However, it is not the only outer coating, rather the skin of the shell is made with a combination of gelatin with water and a plasticizer – a substance that increases the flexibility/plasticity of capsule shell and decreases brittleness.

Gelatin, water, plasticizer are the three components required for the formulation of a simple gel capsule. Based on the type and usage, such capsules may also include colorants as well as opacifiers – a substance used to make the formulation material opaque.

Usually, they are used in the production of tablets and other medications to shrink the penetration of light through them, especially if the substances used are photosensitive.

Other ingredients that soft gelatin capsules may incorporate are flavours and sweeteners, typically used in chewable drugs and children’s capsules.

To ensure the safety of capsule filling, certain preservatives that range from ethyl, ethyl, potassium sorbate, to propyl hydroxybenzoate are also added.

This protects the capsules from the attack of bacteria and also avoids degradation of gelatin shell against harsh environmental and other factors.

2.What Is Softgel Inner Filling of Ingredients?

The second component, other than an outer layering in the formulation of a soft gel capsule, is the inner filling.

This differs in each case according to the type and usage of the capsule. For instance, a Cod-liver capsule will have different filling than a Vitamin-E soft gel capsule.

However, the criteria for longevity and effectiveness of the drug is the same for all filling ingredients.

The one thing that can destroy a soft gelatin capsule is the chemical instability of its active ingredients. This means, to make sure your drug will retain its perfect shape even in harsh environmental factors, you must have complete knowhow of your active ingredients and how much chemically stable they are.

If talk about the types of capsule filling, they can be classified into solutions, suspensions, and neat ingredients e.g., oily fluids. When it comes to fluids, they can be further divided into three different types:

- Water immiscible volatile & non-volatile fluids: these include organic acids, aliphatic or aromatic hydrocarbons, alcohols, chlorinated hydrocarbons, esters, ethers, and essential oils such as vegetable or other aromatic oils.

- Water miscible non-volatile fluids: these include nonionic surface-active agents, for example, polysorbate 80, and other ingredients, particularly polyethylene glycols.

- Water miscible and relatively non-volatile fluids: the incorporation of these depends on the concentration of main ingredients and shell packaging of soft gel capsule, and they include isopropyl alcohol and propylene glycol.

volatile and NonVolatile Fluids-Photo Credits:Chemicool.com

What should be kept in mind is that since the presence of liquid in a gel capsule can either retain or destroy its potency, the fluids used should not be able to easily pass through the outer coating of the capsule. Such liquids contain more than 5% water consistency in them. They also have a low molecular weight and are water-soluble.

3. What Technology Is Used for The Softgel Manufacturing?

This can be confusing, so pay attention. Though it should be clear by now that a softgel capsule involves an inner filling and an outer coating, the presence of only these two components doesn’t ensure the formulation of a successful capsule. Rather there are certain factors which should be taken seriously when it comes to capsule composition. These are:

- Chemical reactions

- Physical interactions

Before I move on and explain each of these, it is better to understand that chemical reactions are what happens on the substances, and physical interaction, as the name indicates is the mingling of outer and inner compounds.

The role of plasticizer is important here, therefore, it is good to use an effective plasticizing agent.

The lesser these interactions are, the more will be the potency of your drug. By understanding each substance, you will be able to recognize and then even control the extent of these interactions.

But before that, remember that throughout the softgel formulation process, there can be a high chance of this mingling, either it is manufacturing, drying, or preserving processes.

If not controlled, the fine line between inner and outer substances will be lost, resulting in a failed formulation.

Chemical reactions

Chemical Reaction-Photo Credits:Study.com

Throughout the encapsulation process, many different chemical reactions undergo between three essential substances of a soft gel capsule – inner filling, gelatin, and plasticizer. Though water is also present, the main reaction is between the inner filling and outer coating.

Some highly common chain of events can occur between gelatin and reactive elements of your active ingredient. Thus, if you are using any substance that you find is reactive, you can lessen the degree of reactions by replacing gelatin with succinylated gelatin/modified fluid gelatin.

In the other case, the reaction may happen in polyols elements when they are esterified or trans-esterified, and the chances of this can be eliminated by making use of a shell formulation that does not include glycerol. If that doesn’t work, try mixing some of the polyvinyl pyrrolidone in the formulation mixture.

These are just a few common suspicions. Depending on the drug ingredients you use, there can be many different chain reactions that is why it is always significant to consult a professional drug manufacturer before you start making your capsules.

Physical interactions

Physical Process of Soft gel-Photo Credits: preprints

Usually, the physical interaction is the name of incorporation of inner substance with the outer coating, but at times it can also occur either within just the formulation mixture, or the shell. Since the soft gel capsule filling is in constant movement inside the coating of the outer shell, it causes both the components to come into a reciprocal relationship with each other.

This fundamental correlation has a significant value since, without it, you cannot achieve a successful final product. However, it is worthwhile to keep these interactions to a minimum level as possible.

To do this, you should remember the two factors that are responsible for their happening: the type of substances you use in outer and inner fill, and how much they are “suitable” with each other, as well as the number of other compounds such as water and plasticizer.

As mentioned earlier, the consistency of water in soft gel capsule formulation should not exceed 5% since the more water you’ll add, the lesser the firmness will be.

Thus, to obtain the optimal product shape, both the chemical reactions and physical interactions should be reduced as much as possible.

4. What is a Softgel Manufacturing machine?

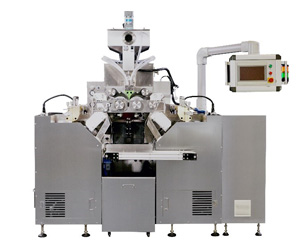

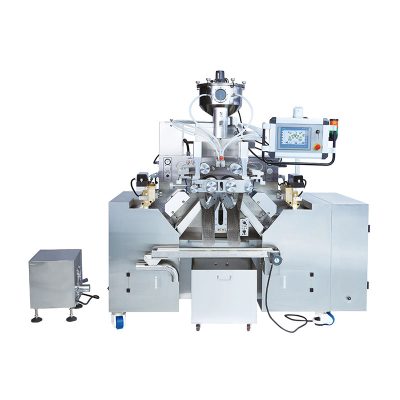

AIPAK Softgel Manufacturing Machine

Also knows as softgel encapsulation machine, a softgel manufacturing machine is a plug and play, electromechanical devices which are used to make soft gel capsules.

There are two parts in this encapsulation process which this machine is capable of. First, it fills in the two gelatin ribbons with the precisely measured filling mixture – either made of liquid or semi-liquid substances.

Different reactions and interactions take place at this step, and it is necessary to minimize their occurrences.

Next step includes the encapsulation of both gelatin ribbons as the fluid is filled in them which is done by sealing the two opposite sides of the ribbon.

What is more fascinating is that an advanced machine will let you make capsules of different shapes and colours. They also come up with a PLC system (Programmable Login Controller) through which you can manage all the filling and encapsulating process with a touch screen.

5.What Are the Benefits of The Softgel Manufacturing Machine?

A softgel encapsulation machine offers plenty of benefits. Some of them are:

- Investing in a softgel encapsulation machine will serve you in the long run as it is expected that with time, hard gel capsules will be out of the market. The pharmaceutical industries throughout the world have shifted their focus more on softgel capsules due to the comfort and benefits they offer.

- Since both the shell and inner fill of a softgel capsule is edible, it makes them more sustainable than the alternatives as there are always dangers with two-pieced capsules. Due to a lack of proper sealing, hard gel capsules cannot have a liquid filling, and sometimes when they are not fitted properly, they are more vulnerable to deterioration. All of this falls in favor of soft gel capsules.

- There are also problems with the accuracy of medicine dosage in the case of hard gel capsules since their inability to be completely sealed often leaves them in the impression of inaccurate dosage. No such problem occurs with soft gel capsules.

- On one side when sealed capsules are more protected than two-pieced capsules, the inner filling also adds to their benefits. Earlier, it was impossible to give dosage in any form other than powder, but chewable capsules have made liquid, semi-liquid, and suspensions possible.

- The innovation of soft gel capsules has not only just facilitated the world, but has also opened a new door to creativity. You can manufacture capsules in whatever shape, size, or color preferred.

- The modern softgel manufacturing machines come with latest features that is the comfort to operate the machine with a control panel, that not only make the process easy, but also safe.

- When it comes to the integrity of ingredients, especially the active ones, you won’t be disappointed either, for such a machine will make sure all the ingredients do not lose their integrity no matter what.

- The important part where you can benefit the most is if you decide to manufacture your brand of soft gel capsules. Since these machines are equipped with modern technology, they take less time with more production, thus lessening the amount of excess power, additional workers, and wasted time.

- Ever wondered why all the pharmacies have the same strange odour? That’s because the drugs and tablets there are made of components which have that strong odour. But that won’t be the case with a soft gelatin capsule filling machine because they come with the excellent ability to mask any unpleasant odour.

- An encapsulating machine that excels in the formulation of soft gelatin capsules will buy you the trust of your customers since there is no chance left that the integrity, potency, or bioavailability of your product will be damaged.

6. What Are the Drawbacks of Softgel Manufacturing Machine?

Along with lots of advantages, there are also some disadvantages of soft gel manufacturing machine, but I should explain it beforehand that these few demerits are a result of lack of certain factors such as:

- It is a big investment. If you think you do not have a sufficient budget, then I would advise you to save some more money rather than compromising because the latter case would adversely affect the working of your machine.

- Running such a complex machine is not an easy task, and even if you have a piece of thorough knowledge about it, you would still need a professional, experienced person to help you through it.

- Lastly, such a heavy machine is not portable. Though it doesn’t necessarily count as a disadvantage, it can fell into the wrong side if you want to move it from one place to another.

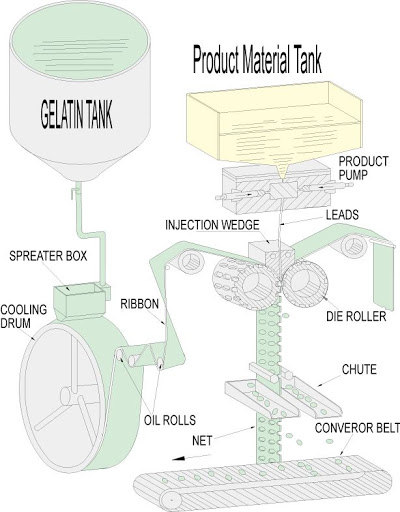

7.What Are the Components of Softgel Manufacturing Machine?

Component of soft gel-Photo Credit: kwangdah

A softgel manufacturing machine is made of several important components. It is better to understand every part before you go for your machine:

- Medicine tank: A three-dimensional shaped tank, almost like a cone, made of stainless steel. The purpose of this tank is to flow the inner filling into the pump.

- Medicine pump: Located just below the medicine tank, it pumps the inner filling and the process is done from a hopper to a station with the help of a tube.

- Material feeding pump: Consists of tubes that suck or direct the inner filling into the wedge. You can find this part right above the hopper.

- Injection wedge: This is the place where the pump injects inner filling. Almost like a wedge, its purpose is to raise the temperature which is most suitable for the material. The suitability is determined through sensors and you can also control it through the screen.

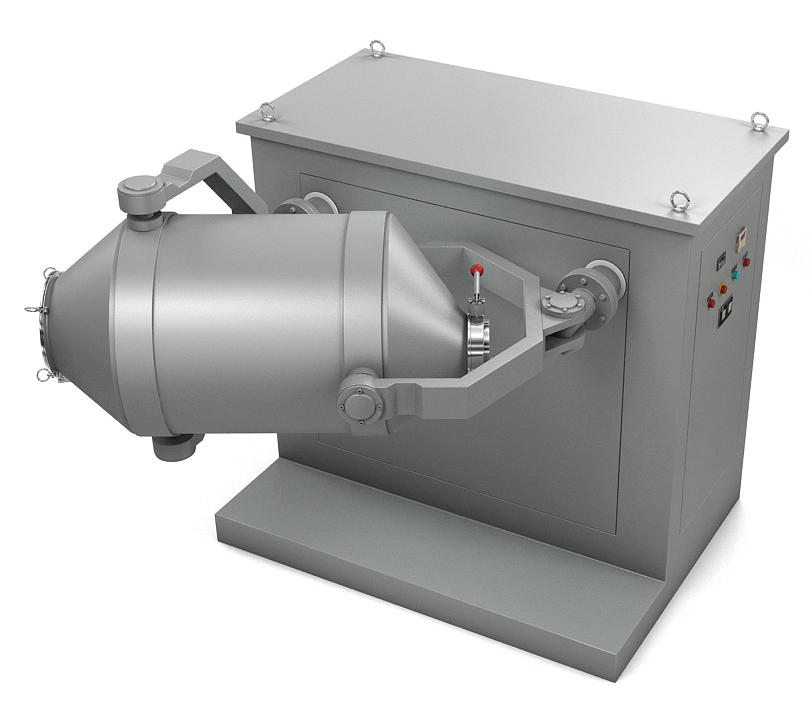

- Gelatin melting and mixing tank: Here, gelatin for the shell is melted and composed according to the required consistency. Made of stainless steel, it comes with clamps, wall jackets and valves. Sometimes, it comes within the machine but you can also get it as a separate component.

- Gelatin spreader boxes: These are located on the right and left side of the machine and their job is to spread a thin layer of gelatin for the outer shell.

- Cooling drum: It either includes a fan or is operated by water. This part works in association with spreader boxes, as the name implies, it cools the thin layer of gelatin by constantly rotating it.

- Chilling system: This part also works along with spreader boxes and cooling drum as it “chills” the gelatin on a required temperature.

- Lubrication rollers: These, like spreader boxes, are also located on the left and right side of the machine. Here, the gelatin is given the final consistency by tightening it enough.

- Tooling system: Once the required gelatin consistency is obtained, it is given the final shape in the tooling system with the rotation of two opposite “dies”.

- Stripper roller: The final shaped capsules, once successfully made, are brought out of the web through the stripper roller.

- Die roll brush: The purpose of this brush is to make sure no gelatin capsule is left stuck in the web since gelatin has elasticity in it.

- Discharge chute: After the successful formulation of gel capsules, they are dropped into this part.

- Tumble dryer: It dries the capsules and removes any moisture once they are successfully sealed.

- Drying tunnel: The drying process takes place in two steps, first in the tumble dryer, then in the drying tunnel where drying trays take the capsules.

- PLC control panel: Consists of a touch screen to manage and control the processes, PLC control panel provides a complete system in-check commands to operate.

8.What Are the Steps of Making Softgel Manufacturing Machine?

Though a brief introduction to the main parts of the soft gel encapsulation process would have given you an understanding of how these capsules are made, there is so much more to learn yet! Here are the four crucial steps in the formulation of soft gelatin capsules:

A. Gelatin Preparation

Gelatine Preparation

You may be surprised that the first step of preparation of gel capsules is not the formulation of inner filling, but outer shelling. As mentioned earlier, the outer shell is made of many substances, but the most important of them are gelatin, water, and plasticizer. Other than that, they are mixed with colourants, opacifiers, or any preservatives. The gelatin mixture is heated on the required temperature to reach the desired consistency.

B. Preparation of fill material

The next step is to form the soft gel inner filling. The ingredients may vary depending on the required results. Flavours, sweeteners, or certain preservatives may be added to the liquid, semi-liquid, suspensions, paste-forms, or oil-based solutions. After the thorough mixing of all the ingredients, they are put into the hopper.

Beginning of manufacturing process

The tooling system comes handy here as the already made gelatin ribbons are filled with an inner filling which is poured from the hopper into the wedge with the help of a pump. After that, everything happens fast since the rotating die rollers are responsible for sealing both the ribbons once they are filled. Here, the shape of the final capsule is also formulated and the resulted capsules are dropped into the chute.

C. Next Processes of Filled Soft Gelatin Capsules

Softgel Bottle

One of the qualities of a soft gel capsule is that they do not contain any moisture which can affect their longevity or potency. Thus, it is essential to remove any leftover moisture in the capsule with the help of a tumble dryer and then further in the drying tunnel. Once all the capsules are successfully dried, it is then that they are sorted, counted, labelled, or even packed.

9.What are the Technical specifications of Softgel Manufacturing Machine?

Like all heavy machines, softgel manufacturing machine also features some technical specifications which are necessary to learn in today’s world. Here they are:

Material: It is a heavy investment, so you wouldn’t want to buy a machine that gets attacked by rust and corrosion in a few years. Therefore, make sure that the machine you are looking for is made of stainless steel. Not only that, but stainless steel also gives you the facility to clean it more easily. While rubber is recommended for those parts which do not contain steel.

Dimensions: Though all the soft gel encapsulation machines are heavy, you should look for them carefully according to the space of your garage or the place you will keep your machine.

Electrical system: The power requirement can depend on both the type of machine and the type and quantity of your product since if you are thinking of preparing capsules in a large amount then surely you should get a big machine but do remember that it will also affect the rate of power.

Pneumatic system:

This includes temperature specifications which are important to take into account since any temperature change can result in deterioration of the final product.

| AIPAK SOFTGEL MACHINE | GENERAL SPECIFICATIONS |

| Die Roll Size | 200mm length and 150mm die |

| Speed | 0-4 Rpm |

| Piston Number | 20EA |

| Loading Accuracy | Less than +_0.5 |

| Feeding Amount | 0-2ml |

| Electric Specs | 220-380V |

| Required Power | 15kw |

| Dimensions | 2115x980x1982 all in mm |

| Weight | 1000kg |

| Output | 7000grains per hour |

10.What Are the Different Quality Testing Standard of Good Softgel Manufacturing Machine?

What are the quality standards? They are basically ‘documents’ that state that the machine you are going to invest in has successfully passed all the testing related to its processing of goods. You should always look for these quality standards before you get your soft gel manufacturing machine:

- International Standards Organization (ISO) standards

- Food and Drug Administration (FDA) standards

- Current Good Manufacturing Practices (cGMP) standards

- Conformitè Europëenne (CE) standards

11.What are the Main Applications of Softgel Manufacturing Machines?

You would be surprised to know that though capsules are widely manufactured in the pharmaceutical industry, it is not the only application of them. Rather, there is a long list of industries that are benefitting greatly with them. So here are some of the main applications of softgel manufacturing machines:

Medical Marijuana industry

If there is one industry that benefits more than pharmacies when it comes to soft gelatin encapsulation machines, then without a doubt it would be marijuana manufacturing industry.

Don’t be surprised as it is not an abusive drug, rather marijuana is widely used in medications for the treatment of patients suffering from chronic diseases such as epilepsy, Alzheimer, cancers or seizures.

Though there is still long debate on the use of medical marijuana, many countries allow the usage and for that soft gel manufacturing machines are very useful.

Contrary to the past, when the only dosage of marijuana was in dry, powdered form, today, you can have your intake in chewable capsules without any side-effects.

And the interesting thing is that you don’t have to go through any special process for their production, because it’s just as same as simple gel capsules!

The therapeutic power of medical marijuana has changed the game, but what you should not forget is that its usage is still not legalized in many areas, so before you think of investing in such an industry, make sure to do the related math.

Chewable Capsules

Also, the awareness regarding medical marijuana is still in process, so you may find that some people still are unaware of its health benefits. That should also be taken into account.

Supplements industry

The world has evolved a lot, and though the technology has facilitated it a lot, there is also no denying that large buildings, gas-vehicles, and other pollutions are damaging the health rate throughout the globe.

Now look at another scenario: With the rise in opportunities comes an increase in the competition too. And this has made life extremely busy.

People have no time to eat natural, healthy food, or take care of their nutrients as they are all overwhelmed in doing different tasks.

Another case: nowadays, almost everyone is aware of the risks of an unhealthy, obese body. While the gym provides a great opportunity to lose fat, some people just don’t have either the time or stamina. Which results in long-term effects on their health.

In all the three cases mentioned above, one thing is similar: the health is in danger. It gets ignored either in the load of work, racing lives, or by harmful contaminants in the environment.

All of these factors have given a boost to the supplement industry because with the help of soft gelatin encapsulation machines, people are taking great advantage by fulfilling their nutrition requirement in less time without risking their health.

Vitamin A, D, C and other nutrients come in the form of chewable, colourful, capsules and sometimes with great taste too. Especially when it comes to the children, these are proved to be beneficial.

Paintball industry

Not only the medical industries but entertainment industries are also profiting with soft gel manufacturing machines. But how? The answer is simple: instead of making capsules, these machines make paintballs.

Now there is no question in the popularity of paintballs. Since the eighties, they are loved all across the globe and are never out of season.

Though in the beginning, it were the pharmaceutical industries that were creating them, later manufacturers took the job in their hands and that is how the game flourished within a matter of years.

Over time, soft gelatin material has been getting in demand for paintballs because not only soft gel encapsulation machines make it much easier to manufacture them, but also they can be prepared in large quantities.

But what is more interesting is that paintballs made of soft gel are swifter and better in quality than previous paintballs.

As far as the manufacturing process is concerned, it is almost same as that of capsules. Just the difference comes in the inner filling since it is the paint that is the main ingredient here. The product is sealed, dried, and stored like a normal soft gelatin capsule.

Pharmaceutical industry

softgels in Pharma Industry

There is no need for a detailed explanation here. But I will try to cover all the important points. It is not the colours or tastes in capsules that these machines are most famous for.

Rather, the shift from powdered to liquid capsules is the biggest change that soft gelatin encapsulation machines have brought in the pharmaceutical industries.

Still, many people in the world cannot swallow tablets unless they choke, which makes the intake of drugs very difficult tasks.

Especially for little children, tablets are never a good option. No one likes the strange odour of drugs, and neither their bitter taste.

In such a situation, the production of soft gel capsules is warmly welcomed all over the globe since they have solved almost all the problems related to hard gel capsules and tablets.

You can easily swallow them, or chew them; they don’t taste bitter, rather are filled with liquid or semi-liquid paste that is often tasteless.

While some of them have great tastes too. When it comes to the typical odour of tablets, they are perfectly odourless!

Thus, soft gel manufacturing machines have made it very easy to prepare more capsules in less time with advanced technology.

That is one reason they are being widely used and are being successfully adopted throughout the world!

12.What Are the Different Supporting Machines for Softgel Manufacturing Production Line?

Though soft gelatin encapsulation machines are the best option for making soft gel capsules, there are also some alternatives that you can look for.

The support equipment is the machines that serve different functions in the manufacturing of gel capsules.

These range from sorting, heating, drying, to polishing, and inspecting machines. Here is a brief introduction to them:

Drying machines

Soft gel drying trays

As the name implies, drying machines are used to ‘dry’ the final product, that being said: to remove any excess moisture from the sealed capsules. The soft gel drying trays work along with drying tunnels as the capsules are placed on them inside the tunnels.

Among the many benefits of these trays, the prominent ones are easy elimination of condensation, smooth working, and little maintenance with a simple controlling system. Since they are made of polypropylene resin, they are very effective in their work.

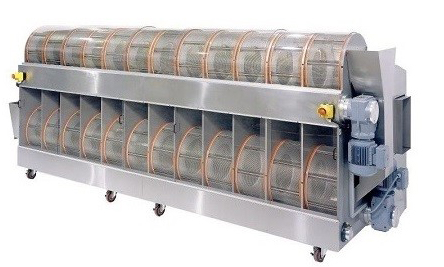

Softgel tumble dryer

Another drying machine, a soft gel tumble dryer works in tumbling motion to remove unnecessary moisture. Unlike the drying trays which require a drying tunnel, the mechanism of a tumble dryer includes fan blowers which work in combination with heat generators to eliminate dampness and moisture.

One of the reasons why you should think of a soft gelatin tumble dryer is that it gives faster results in less time. With advanced technology, you can easily operate and maintain it, and it doesn’t cost much either.

Polishing machines

Softgel polisher

Unlike drying machines which removes excess moisture from the capsules, a polishing machine will remove any impurity such as dirt or debris from soft gelatin capsules. This helps a lot since an uncontaminated drug intake is harmful to the human body.

The advantages you get with a soft gel polisher have no limit: first, these machines are very efficient in their working.

A capsule may look like a tiny object, and when they are in hundreds of quantities, any alternative worker may not be able to clean every one of them.

But in case of a polishing machine, you don’t need to worry at all since they work very accurately and leave no unpolished capsule.

Other benefits are their ease of operation, with more working in less time, as well as their satisfied rates make them a great option to use.

Softgel inspection machine

Inspection machine is the biggest assistance that soft gel industries have seen. A soft gel inspection machine makes sure that the capsules have the same quality which was required and that they are spotless, tightly sealed, and without any holes in their shell. They are so helpful because they save not only time but also the money and quality of your product.

If I talk about their advantages, there are so many of them. First of all, soft gel inspection machines are capable of generating a report for every batch of soft gel capsules they inspect to let you know their quality.

Secondly, their results are highly accurate and thus you can easily trust them. Third, they come with a Patent Transport System which is completely stable and fine in its working. Lastly, they are easy to use and maintain, and highly durable.

Softgel pulverizer

After the impaired and successfully made capsules are separated, a soft gel pulverizer is used to recycle failed capsules and thus those capsules which either have any problem with their mixture or gelatin shell are again manufactured with this machine. It gives a lot of benefits, and the top of them is the comfort and no wasted material which also saves money.

13.What are the Different Types of Softgel Manufacturing Machines?

There are three types of soft gel manufacturing machines, as explained below. Do remember that this classification is based not on the material used, but the way they function:

1. Manual softgel encapsulation machine

manual encapsulation machine-Photo Credit: capplustech

Manual machines are hand-operated, that means, you have to do everything by yourself. Though it may seem an effective idea to save on power cost, there is so much that makes this type outdated. First of all, it is time-consuming and brings the cost of labor work. Not only that increases the risks to the human body, but also endangers the quality of soft gel capsules because humans are prone to more mistakes than programmed machines.

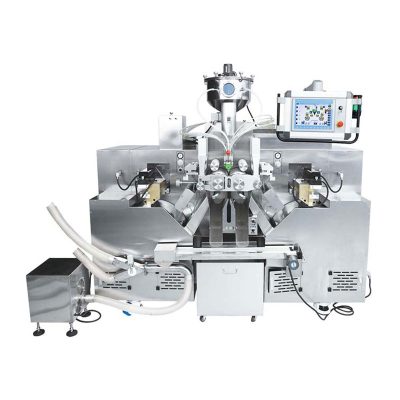

2. Semi-automatic encapsulation machine

This type of machines is better than the manual ones since they offer some automatic processing along with labor work. Since they are semi-automatic, you don't need to have a thorough knowledge or experience of them. That being said, they are easy to operate. Also, they offer a good quality final product with uniform consistency. However, since they are half programmed and half self-operated, they may not be suitable for everyone.

3. Fully automatic encapsulation machines

AIPAK Softgel Manufacurig Machine

As the name implies, this type of machines is completely programmed for every major and minor task. All you have to do is to give them instructions on a touch screen panel. Also, advanced automatic machines are faster as compared to their past alternatives. Along with the increased quality of soft gel capsules, they also offer more output with less wastage, which makes them the best!

14. How Does Softgel Manufacturing Machine Contrast With Powder Capsule Filler?

Before I explain multiple factors where both the machines differ, it is better to understand the purpose of both. As you already know, a soft gelatin encapsulation machine is used to make soft gel capsules which are filled with liquid, semi-liquid, or suspension pastes. While contrary to this, as the name implies, as powder capsule filler also makes capsules, but the inner filling is in dry, powder form.

Other difference comes in outer shelling since a powder capsule filler doesn’t make soft gel capsules, rather it makes hard gelatin capsules. Also, if I talk about their power rate and costs, both of them are related somehow. A soft gel manufacturing machine can only run in fully automatic mode, while a powder filler can be used in either fully automatic or semi-automatic modes. Similarly, the former costs more than the latter.

15.Would You Be Able To Utilize Softgel Manufacturing Equipment To Make Paintball?

Paintballs-Photo Credit: liveabout

The answer is yes, but with careful measurements. Since the inner filling is the ‘paint’, and the size of a paintball is much larger than a tiny capsule, it is suggested to take help from a professional in the settings of your machine.

16.Which Shapes And Sizes Of Capsules Do Softgel Manufacturing Machine Produce?

Capsule sizes-Photo Credit: capsulcn

There are no limitations when it comes to the shapes or sizes of a soft gel capsule. But it also depends on your machine equipment whether it is capable of making your specific shape and size. However, with a normal machine, you can easily make an oval, round, tube, and oblong shaped capsules. And the sizes can vary from 000 to 5.

17.Are There New Technologies In The Softgel Manufacturing Industry?

Today’s era is a quickly evolving era, and with each day new inventions are outdating the old ones. Which means it is a must to keep up with the pace, otherwise both you and your machine will fall out of the competition. It also relates to the sale of your product since consumers nowadays not only see the quality but uniqueness too.

So here are some of the developments in the soft gel manufacturing industry that are growing at a fast rate, thanks to modern technology:

- Material filling pump: faster and reduced noise technology.

- Spreader box system: effective use of gelatin by using less for more production.

- Lubrication system: addition of multiple, yet effective designs.

- Die system: addition of firm grip over ribbon thickness, as well as the weight of inner filling and time to make both.

- Tooling system: easy and quick maintenance and replacement of tools.

- PLC control system: addition of a fully automatic human-friendly interface.

- Security system: addition of full interlock systems.

18.Would You Be Able To Integrate Softgel Manufacturing Machines With Standalone Tumble Dryers?

Softgel Tumble Dryer-Photo Credit: pharmalabor

The answer is, yes. But again, you have to look for special modifications such as a transport mechanism is a must for such an apparatus because otherwise, it would not be possible to shift soft gelatin capsules from machine to dryer. This method is effective because it saves both money and labour and the results are better than the alternatives such as drying trays.

19.Which Factors Affect Efficiency of Softgel Manufacturing Process?

Any machine is expensive, but in case of a soft gel encapsulation machine, the price is even more since the production of soft gelatin capsules is still fresh in the market. Because it goes equally along with hard gel capsules, there is a tough competition between both industries.

Such a huge investment in such a heavy machine is going to take a lot. Also, running and maintaining the equipment is another difficult job, because no matter how much knowledge you possess, you will get the experience of its processes slowly, with time.

Experience is something which you cannot get instantly, especially if you are a beginner. You may need to hire a professional for all the instalment process and seek further guidance for usage and maintenance. But there is one thing which can save not only your time but also your money: the factors which impact the efficiency of your machine.

So, here are some of the factors that play a key role in determining the long-term health of your soft gel manufacturing machine, and you must carefully understand them:

Quality

Quality comes first. Remember, do not compromise on it no matter what. As mentioned earlier, if you think your pockets are not allowing you to go for a good quality machine, then take some time and save money.

Instead of going with a second-hand, or impaired machine which after some time may crash down or take more costs in maintenance than a fresh soft gel encapsulation machine would take, you should always go for an option that will serve you in the long term.

A good quality machine will eventually not only result in just the better production of capsules, but it will also come with advanced technology to facilitate more.

Proper ingredients and measurements for inner filling

This depends on a lot of factors, and the first one is to ask yourself: who will be consuming your capsules? Are they adults or children, or both? Is there any specific range? You must be wondering why these questions? The answer is simple: they will help you finalize your ingredients.

Regarding the manufacturing of soft gel capsules for children, the inner filling may require different tastes or other organic compounds other than the main substances. Thus, before you go for a machine, make sure to do all your homework.

Proper ingredients and measurements for the outer shell

The same formula applies to gelatin shell. A soft gel capsule must be tight, spotless, and uniform to achieve a level of perfection. And this is possible only with the proper measurement of all necessary ingredients. Other than the water and plasticizer, the shell ingredients may also require other substances such as opacifiers or colorants.

Thus, the key to a successfully sealed soft gel capsule is the before-hand careful measurement of all the ingredients required. In the absence of any, the result will be failed, impaired capsules.

Speed

Speed Must be Good-Photo Credit: speedtest

The working speed, just like quality, is important too. Because if quality promises the effective, long-term working of the equipment, then speed also makes sure the manufacturing is done in the required time. It is recommended to do some research before or consult a professional about what speed will be best for your final product and then go for a machine that works fine with the estimated speed, since it will have a direct impact on the consistency of capsules.

Versatility

Though it is optional, it is suggested to go for it. The right equipment is a must for the production of capsules, but if you have a big budget, you should consider other necessary equipment too. Having a diverse range of assists in experimenting with different processes, which can further help manufacture different products. Also, you can begin with one type of soft gel capsule and later add different options if you have already had auxiliary equipment.

Drying equipment

This is important, so pay attention. Many people do not go deeper for drying parts because they don’t know how the right drying gear can almost change the game of soft gel capsules. You cannot manufacture a successfully sealed capsule unless all the excessive moisture is removed from them. If not, they will be prone to harsh environmental factors which can deteriorate their gelatin shell.

There are many different types of drying apparatus, which ranges from drying trays to tumble dryers, and also new modifications are being made daily in them. So again, make sure you go for the right drying machine for your soft gelatin capsules because it will boost your production!

Accurate process

Understand deeply how you will be manufacturing the capsules. Have complete knowledge of major and minor steps to eliminate any confusion later, which can also result in the failed production at the final step.

20.How Would You Make Various Colors Of Softgel Capsules With Soft gel Manufacturing Equipment?

Gone are the days when drugs had only pastel colours. Today, a wide range of colours can be seen in the pharmaceutical industry, and different types of drugs are even labelled with different colours. Not only colours make supplements attractive, but also make them a fun way to take them.

With the help of a soft gel encapsulation machine, you can easily manufacture capsules of various colours and shades. This will required addition of just one more ingredient in the gelatin mixture: colourants, which mostly are food colours as they will be swallowed and thus must not be contagious. If you want to make these colours strong, you can also add opacifiers so that any harmful light rays cannot deteriorate the shades of capsules.

21.Would You Be Able To Accomplish Softgel Capsules Uniformity With Softgel Manufacturing Machine?

Uniformity is the ultimate secret ingredient in the recipe of soft gel capsules. Without a uniform mixture, either for gelatin or inner filling, you cannot produce a successful shape and form of capsules. Though it may seem a difficult job, in reality, it is very easy to accomplish. All you have to do is to take care of few steps mentioned below.

All the ingredients should be measured properly and accurately because any decrease or increase in quantity can result in impaired capsules. Also, you should make sure that the processes are accomplished properly, such as at the right temperature, and according to the right speed.

Finally, the Tooling System should be operated carefully and for that, you can make use of mini pumps and servomotors to make sure the production is completely under control. One thing that doesn’t bother in the start, but should be kept in mind is the proper maintenance and replacement of all the equipment used, as any worn-out, impaired gear can lead to a failed product.

By keeping in mind all the steps mentioned above, you can easily obtain soft gel capsule uniformity with soft gelatin encapsulation machine.

22.How Might You Use Softgel Manufacturing Equipment To Skyrocket Your Business?

It should have been clear till now that a successful product will ensure a successful business. Therefore, you must keep close attention to the following A to Z plan of having a soft gelatin manufacturing machine:

Even before the installation or maintenance processes, comes the purchasing part. You should make sure that the machine you are looking for has all the legal documents of the technical specifications mentioned in this guide.

You should also gain a thorough knowledge of your final product and what ingredients will be required using what type of advanced technology. Remember, do not compromise on quality.

After you have purchased the machine, comes the installation part. Make sure that it is done in absolute accordance with the installation specifications. Or you can also hire a professional for that, but make sure to choose the one who knows his job very well.

Even if you already know how to maintain the machine, try to go deeper as your specific soft gel encapsulation machine may require some different method depending on the gear it comes with.

Get complete knowhow of manufacturing process and understand every step. You can also talk to your manufacturer in this regard.

The support equipment is necessary, and that is why you should go for the right one that suits both your machine as well as your final product.

That’s all. By following these steps, you will end up with a soft gelatin manufacturing machine that not only works best but will also boost up your business.

Bottom line

Now comes the concluding part. I hope you with all the detailed information mentioned in this guide, you would have gained all the necessary knowledge for a soft gelatin encapsulation machine. There are many steps in the production of soft gel capsules, but the most important ones are the manufacturing of inner filling and outer shell, the ingredients of both differ according to the type of capsule.

Also, many factors are significant to achieve the proper production of capsules, such as minimizing the chemical reactions in inner filling and also the physical interactions between the inner mixture and outer shell.

Though water, plasticizer, and gelatin are the main ingredients in the recipe of shell coating, you can also add colourants and opacifiers to give it different shades and to protect it from harmful rays. Chewable soft gelatin capsules also include different tastes in them, which makes them more appealing to take in.

Along with pharmacies, other industries also take great advantage of soft gel manufacturing machines such as supplement-production businesses, or paintball industries. Though the ingredients and gear requirements differ in each case.

What should be kept in mind while purchasing a soft gel capsule filling machine is that quality should be best and advanced. The speed also affects the efficiency of the machine, so higher speed machines should be preferred. Other than that, the drying gear is the most important and should be selected wisely according to the type of product and its manufacturing requirements.

You can always add new and advanced apparatus to your machine system, which opens the door for different productions. As far as maintenance of the machine is concerned, talk to your manufacturer and learn about your soft gelatin encapsulation machine. This will help you a lot in understanding minor and major stuff about the mechanism of your machine.

Lastly, the replacement of the tools is another important step, and you should carefully examine them daily. If any part is worn-out, replace it immediately!

23.What Points you Should Consider while Buying Softgel Manufacturing Machine?

Before investing money in a softgel manufacturing machine, you should know some of these points which are mentioned below:

Digital panels

AIPAK softgel manufacturing machine

In today's tech world anything on your phone or in laptops can be organized with touch screens, so your softgel manufacturing machine must be consist of touch panels.

You should buy a machine that consists of the latest technological developments, this means that your softgel machine should be programmable logic controllers with touch screens.

These digital panels help you in controlling your machine from start to finish. You can easily control your speed by decreasing or increasing it or stop the process. It makes life easier and efficient.

Rapid cut off

Your softgel manufacturing machine should be easy to cut off or disconnected because cleaning of the machine is very essential for the production process. Through rapid cut off you can easily separate and clean all the parts. Through rapid cutoff, you can save plenty of your time.

Electronic gearing and gesture control systems

Mechanical gearing is slower for the production process, so your machine should be consist of electronic gearing and a gesture control system. Gesture control systems are the best solutions for softgel manufacturing machines. This electronic gearing consists of servo motors which make the production process continuous. One more advantage of the electronic gearing system is the output of the product is more precise.

The frame should be of aluminum

While buying your softgel manufacturing machine, you should consider the material which it is made up of because the perfect material can make many differences in your production.

The perfect material for your softgel manufacturing machine is aluminum. The main reason for choosing aluminum is it is rust free and in your environment sanitation is the main factor. Rust can contaminate your environment and the performance of a rusty machine is not good as compared to rust free machine. Another reason for choosing aluminum is the life span of your softgel manufacturing machine extended to 5 years and you don't have to change your machine for five years.

In addition to this, aluminum is easy to clean as compared to other materials and because of this factor, you can save additional time.

24.How do you troubleshoot Softgel Manufacturing Machine?

Your soft gel manufacturing machine may not run smoothly without certain technical difficulties. To fix these technical issues you have to troubleshoot your softgel manufacturing machine.

Following are the problems and their solutions which can you in troubleshooting your machine:

Sticking Softgel Tablets to the Aspic Linkage

At the time of production of these softgel tablets, they stick on the aspic linkage on the tooling system. This is due to the incompetent working of the stripper rolls and die roll brushes.

You can fix this problem by adjusting the stripper rolls and die roll brushes.

Failure of Gelatin Syrup to Stream

Sometimes the gelatin syrup could not flow competently from the gelatin mixing tank. This can be as a result of gelatin syrup irregularity or jam in the gelatin syrup passageway.

In this case, you should consider properly measuring and mixing all the ingredients for proper uniformity.

You should use a stainless-steel conical discharge system through which the gelatin syrup could flow efficiently.

Irregularity in Shapes and Sizes

This can be a result of inconsistency in the tooling system which determines the shapes and the sizes. You can sort this by properly aligning the tooling system and synchronizing the die system.

Leaking Softgel Capsules

This can be a result of inconsistency in the mixing of the ingredients in the gelatin mixing and melting tank.

You should take proper measurements of all the ingredients and ensure that the heating, melting, and mixing time is appropriate.

25.What are the Different Quality Standards for Softgel Manufacturing Machine?

Each delicate gelatin case filling machine should fulfill certain quality guidelines. This is to guarantee the machine stays safe and assure ideal execution.

Consequently, before you purchase any Softgel manufacturing machine, it is critical to affirm if it adjusts to the specified quality principles.

The following are a couple of components you ought to consider:

Container Filling Machine that is CGMP Compliant

The U.S. Food and Drug Administration has exacting guidelines, which specify that each drug machine should adjust to the CGMP norms.

It is thus that you will discover manual, self-loader, and completely programmed case filling machines produced using tempered steel. This is principally for parts that are in direct contact with the item.

Moreover, the CGMP guidelines guarantee that the Softgel manufacturing machines are:

- Easy to clean and keep up; with regards to keeping up the cleanliness of the case filling machine.

- Better dust dealing with ability, in this manner decreasing any chance of ecological contamination.

- Materials for the construction, joints, and parts ought to be FDA affirmed materials.

- Feature progressed cleaning and wellbeing methodology

To study this, you can peruse my past article on The Importance of CGMP and GMP Requirements in the Pharmaceutical Industry.

Natural Compliance Regulations

This is another perspective that you should consider at whatever point you are purchasing any Softgel epitome machine.

The machine should meet all the vital natural guidelines. Along these lines, it ought to be a machine that:

- Produce low commotion during the exemplification cycle

- Use little oil for its gelatin strip sheet

- Stable and savvy cooling framework

- Low measure of waste material, just to refer to a couple.

Notwithstanding these, the delicate gelatin container filling machine ought to be CE agreeable and ISO confirmed. Also, the machine ought to likewise fill the standard sizes of delicate gelatin containers close by the custom alternatives.

Essentially, by noticing quality, there is a high possibility that you will improve all container filling activities in your industry.

That being said, how about we rapidly audit where you can purchase these delicate gelatin case filling machines.

I accept at this crossroads, you would now be able to assess the most basic parts, working rule and clearly, know the specific reasons why you need Softgel manufacturing machines

26.How do you maintain a Softgel Manufacturing Machine?

Like different machines, sooner or later, you'll need to clean, keep up or investigate a Softgel Manufacturing Machine.

Contingent upon the unpredictability of the machine, this can be a tedious cycle. It is far more detestable when you're new to the programmed case filling innovation.

In this straightforward guide, you will zero in on two key angles:

The most effective method to clean a Softgel Manufacturing Machine.

Greasing up programmed case filler

Be that as it may, before I start on the three subjects, there are key angles you need to recollect.

1.Just prepared and ensured experts can fix, change or open a container filler

Such people comprehend and know all the significant pieces of a programmed case filling machine. Additionally, they comprehend the working guideline of these machines, be it a packing pin or donator encapsulators.

There are a few segments of the machines that must be changed by the maker or their professionals. A genuine model is the cam framework that drives the pendulum bar on the softgel manufacturing machine.

2. Check the client manual and machine particulars

All programmed case fillers accompany a bunch of guidelines (client manual/control). You need to see each part of this record before starting any upkeep system.

This ought to be your guide during the whole cycle.

3.Machine administrators/qualified professionals can clean or keep up the machine

Permitting inadequate staff to clean the machine may either harm the machine or neglect to follow the affirmed strategies. This will make your guarantee invalid.

Because of all these, how about we start our support cycle.

- Utilize a lithium base oil to cover the working surface of the cam. You ought to do this after regular intervals of activity.

- Use machine oil to grease up the case filler's joint direction of the associating pole, roller bearing, and sliding bearing. Do this after regular intervals of activity.

- Grease up and fix the driving chain with lithium base oil after regular intervals of activity.

- Continuously check the level of the oil volume after regular intervals of activity. Continuously make sure to occupy oil as expected.

- Consider supplanting the grease oil following 3000 hours of activity.

- Guarantee the oil volume for the powder-taking care of reducer stays at the suggested level. Check the oil level following 250 hours and supplant it following 1000 hours of activity.

- Swap the grease oil for record boxes following 1000 hours of activity (for beginning activity) after which, you can supplant it following 3000 hours of activity.

- Grease up the T-type shafts, moving focuses in guide metal sleeve, sliding bearing, roller bearing, and line bearing in the rotating plate of the spinning stage. You need to do this following 50 hours of activity.

- Recall uninstalling the fixing ring and T-type shaft for cleaning 1000 hours of activity. You should check for mileage as well.

As should be obvious, cleaning and lubing programmed softgel manufacturing machines are difficult cycles. It requires a strong comprehension of the vital segments of softgel manufacturing machines.

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine