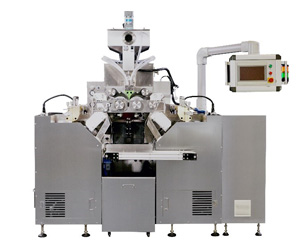

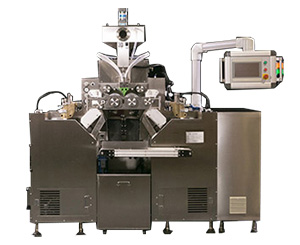

8 Questions To Answer Before Requesting A Softgel Encapsulation Machine

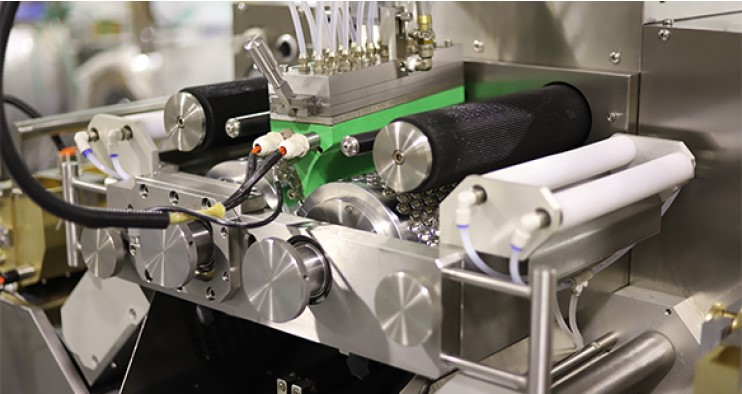

Since the invention of the softgel encapsulation machine, surprisingly a little changed has been executed in its processing. Fast forward over 90 years, the manufacturing and design principle of the machine has remained intact; although many manufacturers now enjoy introducing impactful features to enhance the viability and better services to their consumers.

Thinking to contact a softgel encapsulation machine manufacturer? Let’s talk about it!

8 Questions to Answer Before Requesting a Softgel Encapsulation Machine is a potential glance at the answers that your manufacturer seeking before recommending you the right equipment.

Table of Contents

Ⅰ.What Do You Want to Fill into The Softgel?

Knowing your fill material in softgel capsules means what type of substance you are intended to encapsulate in the gelatin shell. In other words, the filling material is an actual ingredient designed to enhance the well-being of your body.

This is not the end of the story!

Softgel capsules also contain the content you can also use for dietary, cosmetics, gaming, or topical purposes. So what is your production requirement among them?

For instance:

Oily Liquid

This merely refers to an oily substance that you encapsulate. Ordinarily, it is composed of all critical ingredients that have been formulated to form a substance in an oily form. They can also be mixed with other extracts obtained from plants or animal sources. For example vitamin E capsule, jojoba oil capsule, retinoid, etc.

Solution Fill

This refers to the fill that results from the mixing of a broad range of ingredients to form a stable solution. A solution fills are encapsulated that are capable enough to be absorbed in your body and fasten the reaction or body response.

Cosmetic Ingredient

Softgel capsules are used for everyday cosmetics. They are best known for encapsulating skincare and haircare solutions, serum, oils, suspensions, and so on. Manufacturing designs for such capsules are a little bit different, they contain a notch or cut that ensures easy opening as compared to oral or medicinal softgel capsules.

- Slurry

- Capsule in Capsule

- Bio-Capsule

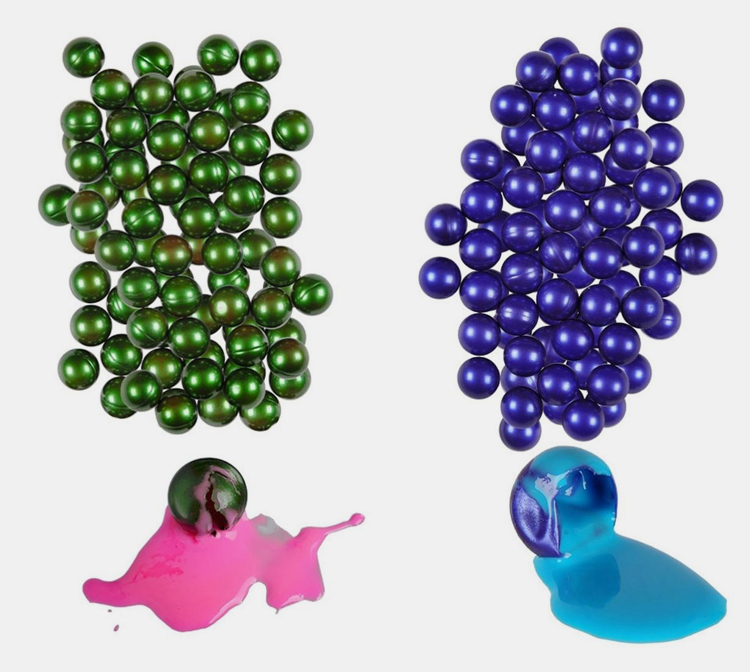

Paintball Encapsulation

Does some vendor merely ask if you are using the machine for gaming purposes? Certainly, this game is much more popular nowadays where players use paintballs to hit their opponents. So, it is essential to inform your size, capacity, colors, type of paintballs, etc to your machine supplier.

Ⅱ.Which Type Is Your Softgel? Gelatin Or Vegetable?

If you are manufacturing softgel capsules; you must know whether it’s vegetarian or non-vegetarian. It is important to mention the origin of your softgel capsules.

Gelatin

Gelatin capsules both hard and soft merely originated from hydrolysis of the collagen of bovine, fish, or swine. This capsule is mostly not accepted by some groups of people who are forbidden from using such animal products.

Gelatin capsules have 13-15% of moisture content in them. Furthermore, they are not suitable for sensitive and hygroscopic content.

Vegetable

With advanced technology, vegetarian or vegan capsules are formulated which is considered the best alternative. This capsule is mostly accepted by a large group of people due to its potential health benefits and natural source. While vegetable capsules have 2-7% moisture content in them. These capsules are considered ideal for encapsulation of sensitive and hygroscopic ingredients.

| PARAMETERS | GELATIN | VEGETABLE |

| Sources |

Bovine, Porcine, Fish |

Plant sources |

| Nature |

Collect from bones, hoof, and connective tissues. |

100% natural and non-toxic. They are safe for long-term use. |

| Stability |

Gelatin capsules are unstable to heat and humidity. |

They are stable to heat and humidity. Plus, they have a long-term shelf-life. |

| Preservative |

They contain a preservative. |

Vegetable capsules do not contain preservatives and are safe for the patient. |

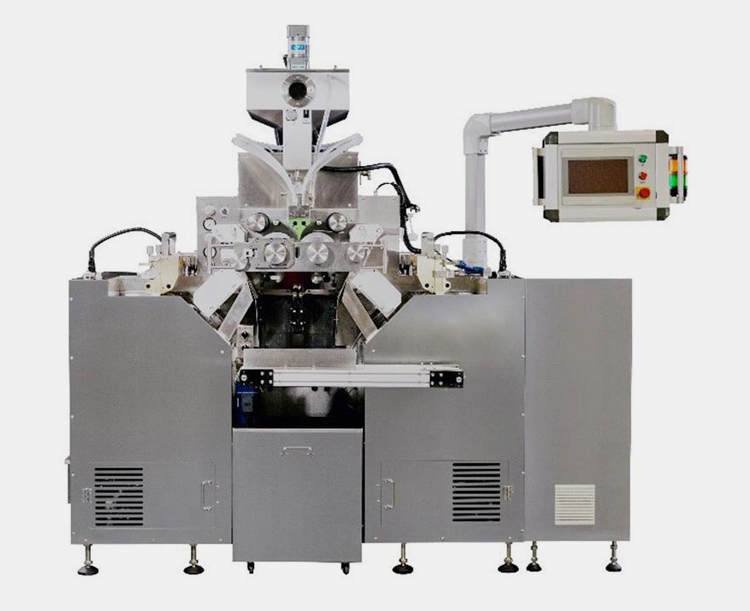

Ⅲ.What Production Capacity Do You Require? How Many Per Minute or Hour?

Knowing the production capacity for a new machine is a realistic approach to enhancing seamless productivity. Unplanned equipment procurement will cut your capacity goal dramatically, e.g softgel capsule size, quantity, material property, etc.

If you’re new or unaware of calculations; good vendors are there to support you in this matter also. Here, we are giving you a small illustration based on calculating the production capacity of softgel capsules.

Suppose a liquid pill after final drying size φ3.5mm with a dripping speed of approximatley= 14pcs/second.

An estimated capacity per hour would be= 14×3600S=50400 caps per hour.

Similarly, φ8mm softgel after final drying size with a dripping speed of approx.: 3pcs/second.

An estimated capacity per hour would be= 3×3600S=10800 caps per hour.

Seamless capsules after the final drying size φ3mm with the dripping speed of approx.: 20pcs/second.

An estimated capacity per hour would be= 20×3600S=72000 caps per hour.

Thus, providing the following information allows the vendor to offer you the right option.

For e.g:

SEM- 100: 2000 pcs/hour

SEM-250: 6000pcs/hour

SEM-250B: 80,000pcs/hour

Ⅳ. What Voltage Do You Require?

Every encapsulation process begins with power voltage. Indeed, your working facility voltage is of course not always compliant with machinery. For this, you will need to adopt a controlled setup to get stable performance. The power requirement for small or large-scale encapsulation equipment may require different voltage and phases. Such as:

For example:

- SEM-50: 220V

- SEM-100: 220V/380V

- SEM-250: 220V/380V

- SEM-250B: 220V/380V

Keep your electrical requirement updated when contacting a vendor. In case of non-compliance, you will get several solutions in order to sustain the smooth running of the unit.

Softgel Capsule Mold and Production Speed Guidance Chart

Adopting the softgel capsule shape, size, and mold cavity guidance chart. You can also determine the production capacity.

| Shape | Softgel Size | Mold Cavity Number | Max. Production Capacity |

| Oblong | #4 | 76 | 18240 |

| #6 | 51 | 12240 | |

| #8 | 48 | 11520 | |

| #10 | 45 | 10800 | |

| #16 | 42 | 10080 | |

| #18 | 28 | 6720 | |

| #20 | 28 | 6720 | |

| Oval | #4 | 80 | 19200 |

| #6 | 70 | 16800 | |

| #8 | 56 | 13440 | |

| #10 | 52 | 12480 | |

| #20 | 40 | 9600 | |

| Tube | #6 | 51 | 12240 |

| #8 | 32 | 7680 | |

| #10 | 30 | 7200 |

Ⅴ.For Different Filling materials, We Will Preparing Different Storage Tanks? What Do You Require?

The preparation of the softgel encapsulation process is comprised of two prime steps. First, where all essential ingredients (gelatin, plasticizer, water, preservative, colorant) are mixed and stored in a storage tank or tank A. On the other hand, filling material such as medicine, supplements, or cosmetic ingredients is prepared is stored in tank B. This tank is specifically designed with a three-layered structure (inner, jacketed, and insulator layer) to ensure uniform heating till encapsulation.

Every consumer belonging to the cosmetic, food, and paintball industry can utilize its applications.

Ⅵ.How Do You Want the Softgel Dried After Filling?

As far as softgel capsules are filled, you will need to go for a drying system. Many manufacturing departments go in combination with a capsule machine. While some can be acquired as a standalone piece. You will be offered a tumble dryer designed with lightweight baskets that ensures efficient changeovers and hassle-free cleaning with a thorough inspection. You can disassemble, clean, and reassemble them with an automatic capsule transfer configuration.

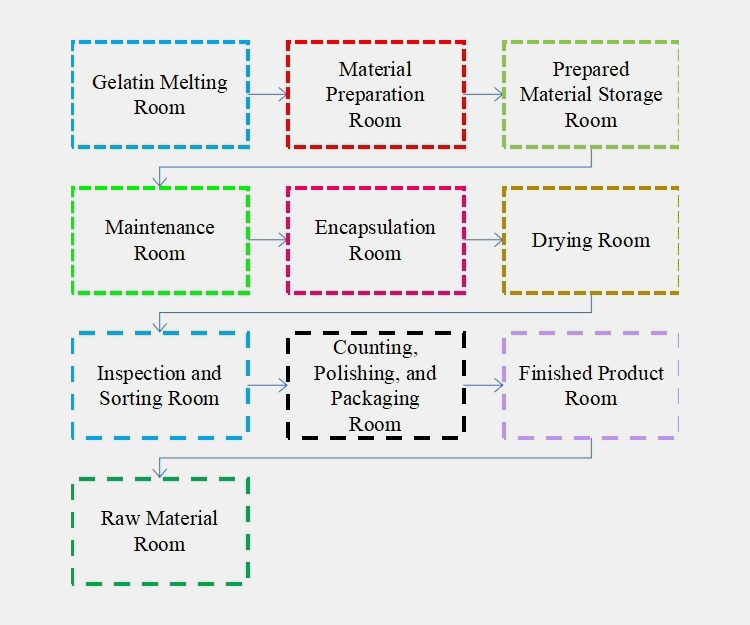

Ⅶ.What's Your Factory Layout?

A small softgel capsule is comprised of a series of production steps that must be taken one by one to ensure 100% throughput. For lab R&D, middle trials, or large commercial scale, you cannot miss any procedure involved in the process.

Your vendor will need to assess your laboratory layout specified for each step. For example

- Gelatin Melting Room

- Material Preparation Room

- Prepared Material Storage Room

- Maintenance Room

- Encapsulation Room

- Drying Room

- Inspection and Sorting Room

- Counting, Polishing, and Packaging Room

- Finished Product Room

- Raw Material Room

An Illustration represents the Facility Layout

Ⅷ.What's Your Budget for This Softgel Production Line?

When exploring softgel encapsulation equipment options, the size of your budget might be a factor. You might be facing a large upfront cost when purchasing or upgrading encapsulation equipment, so for a superior and premium quality product, a higher price tag tends to come. Many customers are not willing to absorb the upfront expenditure offered by the vendor; in some cases, various companies may sell subpar machinery or some supplier do not sell equipment with longevity in mind. We suggest not comprise quality machinery for capitalizing on the investment. Always give a clear picture to the vendor and talk straightforwardly to add priceless equipment to your facility.

Conclusion

Most of the buyers contact their vendors for quotations without doing the proper workout. This is indeed a waste of time for you as well as the manufacturer. That’s the reason we have designed 8-Questions to Answer Before Requesting a Softgel Encapsulation Machine for sincere advice when contacting the supplier. Taking some time to discuss above mention information with the supplier is very necessary. For more questions, contact us for a free consultation.

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine