Gummy Making Machine:The Complete Importing Guide In 2024

How gummy bears are manufactured in a factory? Are you looking to start up the manufacturing gummies? Before importing a gummy-making machine, we suggest having a look at this guide. Here you can explore fruitful information that will help you when shopping for an efficient gummy-making machine.

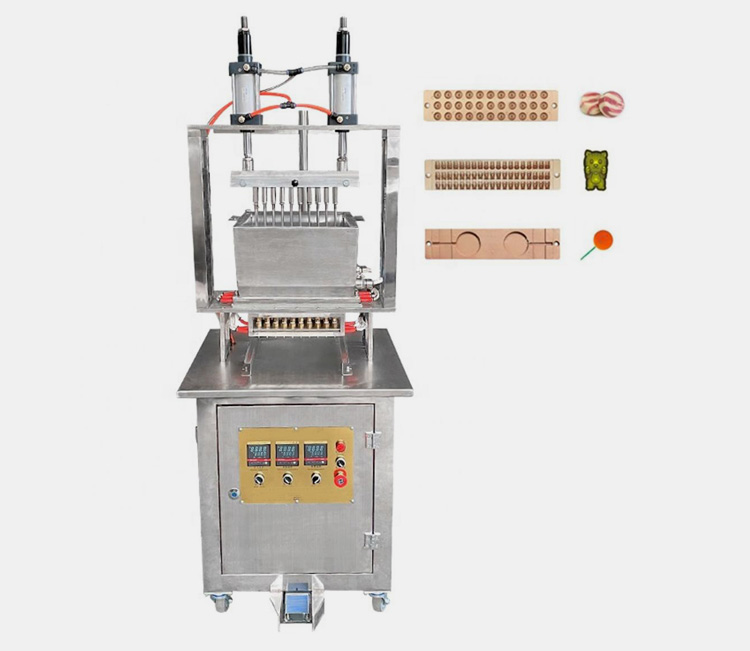

1.What Is Gummy Making Machine?

Gummy making machines are widely used to make gummy products like candies, supplements, nutritional aids, and vitamins. These machines produce a variety of shapes and products and that’s why are much popular in the international market. Traditionally this process was much time consuming but nowadays gummy making machines are commercially found in industries where mass production takes place and market demand needs to be fulfilled. Even more than 20,000 gummies can be produced in a single batch.

2.How does Gummy Making Machine Benefits You?

Gummy-making machines are famous for their precision, accuracy, and yield to produce gummies in large numbers. Some other benefits that are obtained using a gummy-making machine are:

Automated Production Setup

Gummy making machines are highly automated that produces thousands of gummies in no time. Machines are controlled with smart HMI’s (Human Machine Interface) that allow monitoring of processes at any time. Initially, you just need to introduce the slurry into the machine and the rest of all work is carried out through defined automation.

Minimum Workforce Requirement

As the process is based on automation therefore less labour force is required that indirectly reducing the operational cost.

Variety of Shapes

Molds of gummies can easily be replaced in these machines. As a result of this, manufacturers can produce a number of shapes by only changing their mold. Its means, that no extra amount is need to be wasted in a separate machine.

Less Contamination

Gummy making machines are mostly made up of stainless steel. This reduces the chances of contamination, and all the parts can easily be removed for cleaning.

User Friendly

Machines are easy to operate and provide human safety with highly effective sensors.

Low Maintenance Cost

Gummy making machine requires a high investment initially but later on, it recovers its investments in less time. Machine maintenance is also very low as its parts can easily be removed and replaced. Applying grease on parts increases machines' life.

3.What are the industrial uses of gummy making machines?

Confectionery Industries

Popularly used in the food processing industry as developing mouth savories in the form that appeals to you such as Jellybeans, Fruit jelly, Sour belts, Gummy Sharks, and Jelly bottles. The jelly you use to decorate your mouth-watering desserts are made here too.

Nutraceutical Industries

Biotin, a vitamin B known to have beneficial effects for healthier skin, nails, and hair can now be excitingly taken in the form of gummies.

For consumers who search for vitamin supplements, you may find a variety of gummies to ensure you get your daily dose of required nutrients.

Pharmaceutical Industries

Prenatal vitamins which are taken by pregnant women can be infused with gummies to have something delicious and nutritious too.

In many OTC wellness products, CBD gummies aid in conditions like anxiety, inflammation, and epilepsy.

You don’t need to run after your children to take that one spoon of multivitamin's syrup or a tablet now, excitingly available as gummies in the shapes of cartoon characters, gum drops, and gummy bears.

Cosmetic Industries:

Owing to the concerns of skin care products, gummy manufacturers incorporate Hyaluronic Acid, into gummies which makes the skin hydrated, smoother, and also an effective anti-acne. Cosmetic applications also involve Keratin with gummies for stronger and healthier hair and nails.

4.What Are The Types Of Gummy Making Machines?

Unlike traditional gummy making processes which is involved with human efforts, modern gummy making machine can be categorized into:

According to Automation

- Manual Desktop gummy making machine

- Semi automatic gummy making machine

- Automatic gummy making machine

According to Production Capacity

- Small scale gummy making machine

- Medium scale gummy making machine

- Large scale gummy making machine

According to Automation

| Manual Desktop Gummy Making Machine

This is a small and compact machine that allows the manufacturing of gummies for small production batches. The machine can be perfectly adjusted on a desktop and is easy to carry from one place to another. The entire working procedure is based on manual handling; although the machine is suitable to get professional and precise quality output. |

Semi-Automatic Gummy Making Machine

A semi-automatic gummy making machine uses both human and machine capabilities. Processes are divided among both and human assistance is required at every level in this type of machine. From injection of material to moving it into every next process i.e., cooking, depositing, molding, and cooling, all are done by human assistance. |

| Fully Automatic Gummy Making Machine

|

According to Production Capacity

Small Scale Gummy Making Machine

This is an economical and less laborious option to achieve quality gummy bear on a small budget. This machine is ideal for the obtained continuous production of gummy bears for limited or small-scale batches., for e.g home-based, R&D, or beginners. The machine occupies less space and less manpower. This machine has production capacity varies from 80, 150 to 300 kilograms gummies/hour. |

| Medium Scale Gummy Making Machine

If you’re running a moderate gummy production; then we suggest to go for a medium scale gummy bear making machine. This machine is driven automatically with less manpower and more accuracy. It is recommended for the pharmaceutical, nutraceutical, and confectionery industry where production capacity requirement varies from 150 to 300 kilograms/hour or more. |

| Large Scale Gummy Making Machine

|

5.What are the Main Components of Gummy Making Machine?

Dissolving Tank/Cooking Tank

A dissolving tank is specially designed to cook the ingredients e.g., glucose, water, and granulated substance. This system has mixer inside with a double jacketed covering.

The system is capable to produce and control the required heat to maintain consistency and uniformity throughout the process.

A dissolving tank is equipped with a pneumatic valve as well as a filter device to protect syrup blockage in the lobe pump.

Storage Tank

When the syrup is ready it is transferred from the dissolving tank to the storage tank.

A storage tank is accompanied by high-level sensors that detect the appropriate level of syrup. It is also double jacketed with a mixer ensuring a sustained temperature and uniform mixing. This device is equipped with pipelines that will help to adjust the water level in syrup.

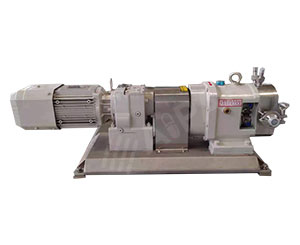

Lobe Pump

A lobe pump enables transferring of syrup from the dissolving tank to the storage tank. Similarly, when syrup is ready the lobe pump transfers them from storage to the deposit unit (gummy line).

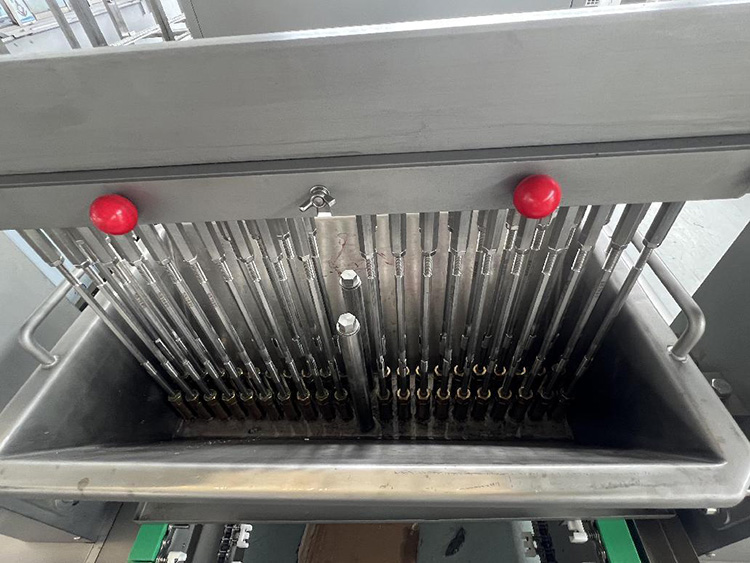

Dosing Unit

This unit is equipped with small dosing tanks that hold flavoring, coloring, and active ingredients. They are also transferred with the help of a lobe pump.

Control Panel

Acontrol panel is equipped with all different controlling options involved in the system such as temperature, mixing speed, water level, discharging speed, etc.,

Hopper

Hopper receives prepared slurry for making gummies. As mentioned earlier lobe pump facilitates transferring of ingredients from storage tanks into hoppers. Hopper is equipped with a heater to maintain the quality of slurries at the correct temperature and at a molten state.

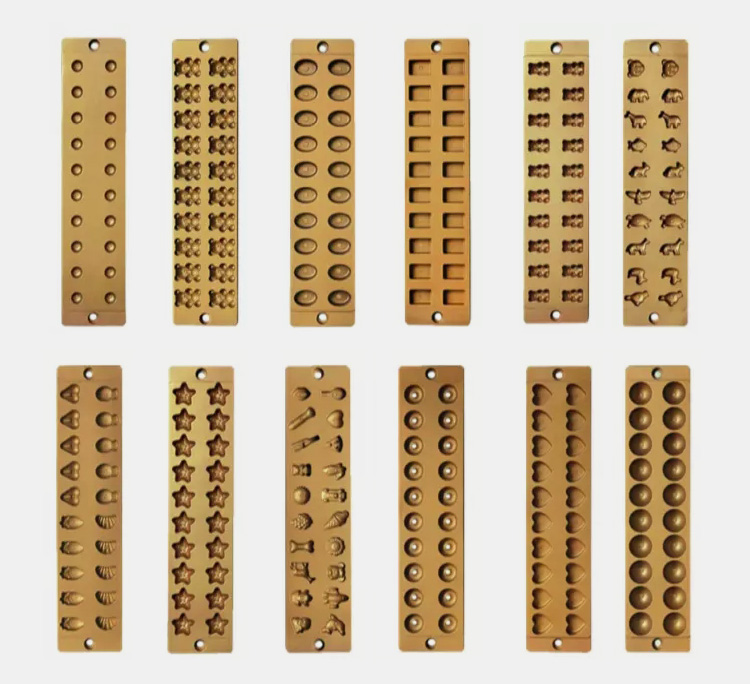

Mold

Gummy assembly is equipped with mold of various shapes and sizes. You can give shapes to your gummies using a mold of your choice.

De-Molding of Gummy

Soon after passing through cooling unit, the molding plate is pressed with thimbles that release the formed gummies onto the conveyor belt.

Cleaning Brush

Cleaning brushes help in the clearing of sticky gummy fragments and ensure a cleared final product.

Cooling System

Heat plays an important role from dissolving to gummy formation. Once hot gummies are formed, they acquire a chewy texture by the help of cold air. Gummies are passed through cooling unit via a conveyor belt and solidified.

Transport System

In gummy making machine, a transportation system holds significant responsibility to move ingredients from one station to another. For e.g mold, demolding, gummies from drying to cooling tunnel, and discharge.

Pneumatic System

To perform various activities gummy making machine is provided with air pressure. For e.g pushing material from one station to another, driving units, moving conveyor belts, cooling tunnels, pumps, etc., You can regulate pressure via control pressure.

Lubricating Device

Most components of gummy making machine are movable; an automatic gummy machine is designed in a way that notifies level of lubrication. You can regulate the greasing and oiling of the machine’s components to overcome friction and enable smooth functioning.

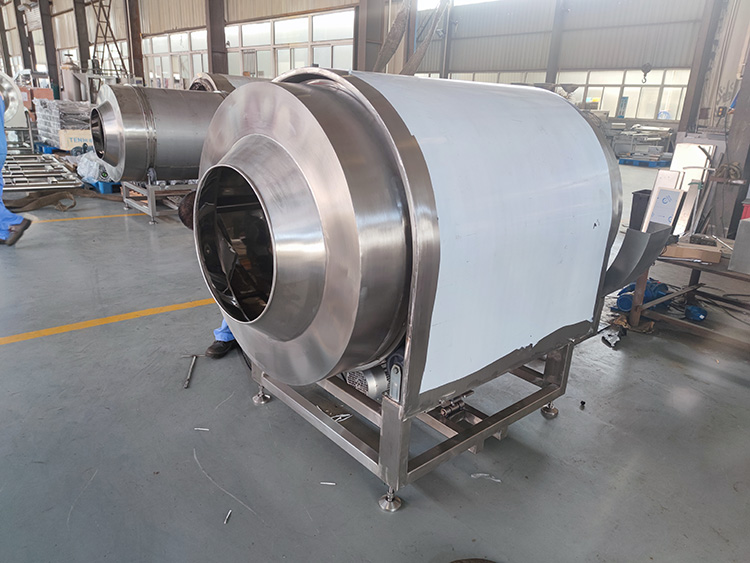

Oil Coating Machine

Oil coating machine is specially designed to coat the external surface of gummy bears with oil, syrup, or wax to enhance its appearance and taste.

Sensor

A strong sensor system is equipped in gummy making machine to detect unwanted irregularities before and during operation and notifies the screen. If any mishap occurs, machine stops ‘immediately’.

Dust Collector

During the procedure, sugar, carb, or starch content are released; machine has ability to recycle them via dust collector.

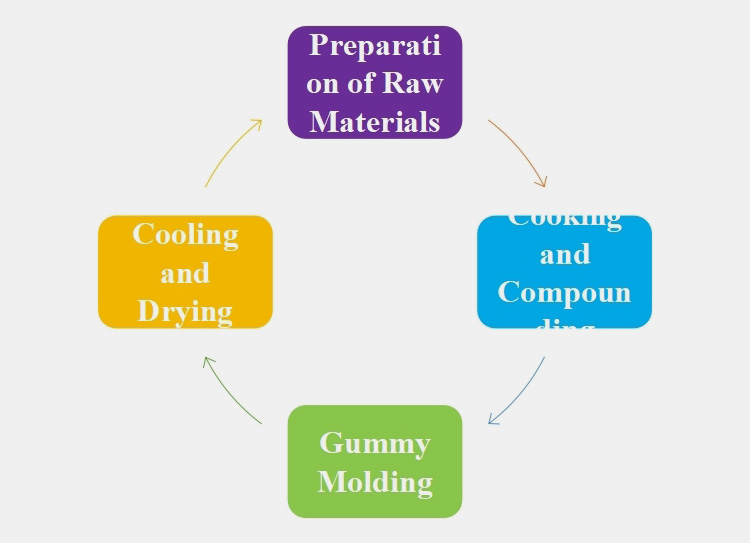

6.What is the working principle of gummy making machine?

It is important for operators to know about the working principle of gummy manufacturing machines for a smooth work process. Some steps involved in the working principle are:

Ⅰ.Preparation of Raw Materials

First, all the required raw ingredients used in gummy manufacturing are prepared according to the recipe. Measure the proper amount of materials before placing them in the hopper.

Ⅱ.Cooking and Compounding

Gelatin, pectin, and water are poured into a dissolving pot and heated for 15-20 minutes for obtaining syrup of desired consistency. Then the syrup is carried to the buffer tank.

These tanks are available in different sizes and are used for blending, cooling, and mixing. Flavors, acids and colors are added to these tanks using metering pumps.

Ⅲ.Gummy Molding

After thorough mixing, the blended syrup is transferred to the depositor for injection of syrup into molds. Servo motors are used for injecting accurate amounts of syrup into molds. Depending upon the design of molds, gummies have different shapes.

Ⅳ.Cooling and Drying

These filled molds are moved by conveyors to a cooling tunnel where liquid syrup is solidified at low temperature for 6-10 minutes.

After cooling, the gummies are transported to sugar or oil coating machines and finally, these candies are stored in the drying room for 8 to 12 hours which removes moisture from gummies.

7.What Are the Top Manufacturing Countries of Gummy Making Machines?

With the bulk production of gummy making products, you have a number of global manufacturers of gummy making machines. Many developing countries with advanced technology are now producing gummy making machines with high level automation.

Continuous research and development is being carried out to bring advancement in equipment. Some of the global giants in manufacturing gummy making machines are:

- Chocotech: Germany

- Baker Perkins: United Kingdom

- Tanis OTC Equipment: Netherland

- Aipak Pharmaceutical:China

- CapPLUS Technology:Turkey

8.What Are the Rules for Importing Gummy Making Machine?

While importing a gummy making machine you have to follow some rules, such as:

Machine Specification

Initially finding the desired machine with the best match production capacity needs to be searched. Going through the websites of global manufacturers for gummy making machine, all the information regarding the machine can be gathered.

Asses Your Budget

The budget for a gummy making machine can be estimated only by determining the production capacity and level of automation. High cost is required for the larger production batches. Besides these two parameters; speed, quality, molding capacity, and components are also main factors to buy a suitable machine that matches the production capacity.

Contacting the Manufacturer

After finding the best manufacturer, the next step is to contact them and ask for quotations of the respective gummy making machine.

Import Facilities and Local Duties

The next step is to check whether the manufacturer provides globally supplying facilities or not.

Always consider local duties charges that possibly increase the overall cost.

Local supplier

If direct importing from a manufacturer becomes a difficult task then you can go for a local authentic supplier also. It can be verified by the manufacturer with successful machine deliveries within the country. This also helps you in a way that you can contact them anytime instead of waiting for a response from the manufacturer.

9.How To Deal with Problems and Troubleshooting When Operating Gummy Making Machine?

Some of the major problems while using a gummy making machine are:

Improper Mixing

When improper mixing of ingredients is carried out due to non-standardize weight calculations the mixtures become thin. The mixing process does not properly give the desired results of the mixture.

This problem can be rectified by following standard mixing parameters and pouring a prescribed amount of ingredients to get an ideal mixture.

Reduced flow of ingredients

Another problem arises when gelatine sometimes blocks the inlet of a process and disturbs the whole system.

Unclogging the passage to a better flow of ingredients can troubleshoot this problem.

If the machine speed reduces at any level, the input supply of ingredients gets disturbed and sometimes causes greater damage to the whole batch. The size of all rest production in line also gets affected.

This problem can be rectified by close monitoring of speed after several intervals and also checking the flow speed of the process.

Damaged products

If the alignment of machine and its parameters gets disturbed due to any unwanted activity, ultimately damaged products are produced.

Close monitoring of parameters and proper alignment through alignment gauges of machine can avoid this type of material damage.

10.How Do You Maintain Work Efficiency of Gummy Making Machine?

Any machine if maintained properly as per manufacturer guidelines will give optimal performance throughout its working life. Regular maintenance will not only increase the efficiency of the machine but also reduce costs incurred due to unwanted operation halt. Given below are some key points to consider.

- Regularly inspect all moving parts of a machine. These include belts, flywheels, gearwheels, etc.

- Employ appropriate cleaning SOPs after each batch.

- Oil and lubricate moving parts of a machine.

- Replace parts as per the manufacturer’s recommendation.

11.How To Verify Quality of Gummy Making Machine?

Once you have placed your order the next step would be to inspect the working of the machine. The manufacturer will provide all relevant documents including compliance and quality control certificates. After receiving the machine in wooden crates, it is important to look for each component in the presence of a customer representative. The quality testing procedure continues from manufacturing each component to its final delivery. After delivery, you need to verify the components and working of gummy making machine by:

Operational Qualification Testing (OQ)

As its name shows, this test verifies the operation and functional properties of the gummy making machine with respect to its given specifications. All mentioned parameters must be verified; an OQ certification will confirm that everything is in proper order.

Installation Qualification Test (IQ)

This verification certificate entails that gummy making machine installation is done at assigned premises. IQ certificate guarantees a successful inspection.

Factory Acceptance Test (FAT)

This test demonstrates all respective aspects of gummy making machine at the factory. You can go through all limitations and check various types of syrup that can be handled by the gummy making machine. Once all the tests are passed manufacturer will be received FAT certification.

12.What Is the Future Prospect of Gummy Making Machine?

The Future awaits improvement in safety, speed and effectiveness or efficiency of Gummy making types of machinery. One specific area is the starch dryer which poses the hazard of explosion.

Maintaining hygiene by ensuring microbiological safety parameters eradicates the threat of contaminants in gummies. To skyrocket your business, you must consider different aspects of bringing more exciting and appealing shapes, colors and flavorful gummies to the markets.

There are few quality standards of course which you need to adhere to to ensure safe use of gummy candies accordingly to FDA approval. The market of gummies is expectedly progressive and is predicted to garner a revenue of 44 billion USD by 2030.

Conclusion

The world of gummy bears is sweet and colorful. Gummy making is a gateway to entering and fulfill the demands of consumers. Aipak pharmaceutical is your perfect partner in this journey. Our innovation and research ensure that you are always at the cutting technology. Get in touch; we've got a team of high-tech experts waiting to help your project off the ground.

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours