2 Important Things You Need To Know About Vacuum Emulsifying Mixer

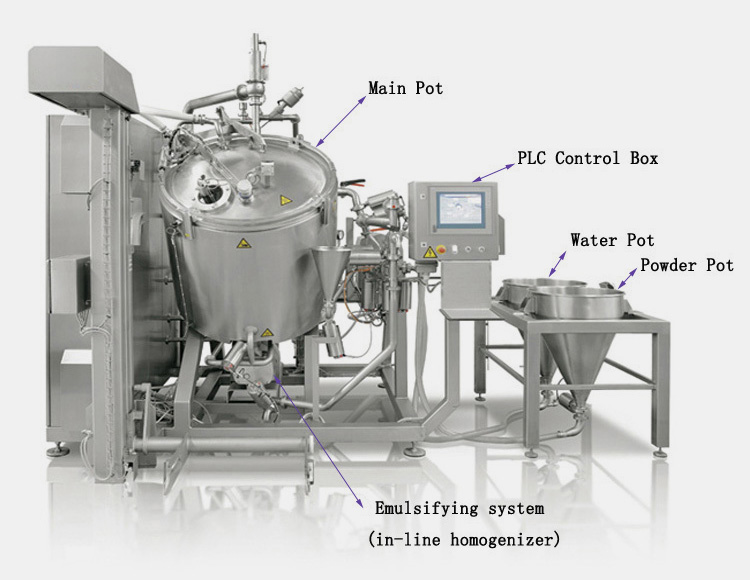

The vacuum emulsifying mixer is commonly composed of a slow-speed mixing system, high-speed, heating/cooling system, top cover lifting system, feeding and discharging system, and safety control system.

Currently, it is mainly suitable for the production of paste, cream, gel and high viscosity mixed products in pharmaceutical, cosmetics, food, chemical engineering, biology and other industries.

It can homogenize, emulsify, shear, mix and disperse the paste, cream (or colloid) material under negative pressure or positive pressure.

With the increasing automation level of the emulsification equipment on the market, the vacuum emulsifying mixer is more in line with the new production standards in the pharmaceutical and other fields. But there are 2 important things that you must know when using a vacuum emulsifying mixer. Once you master these points, you can save yourself a lot of trouble in the future application process.

Three necessary steps to operate a vacuum emulsifying mixer

Preparations before stating the machine

First of all, check whether there are any safety risks in the vacuum emulsifying mixer and surrounding working environment, such as whether the appearance of pipelines and equipment is intact or not damaged, and whether there is water leakage on the ground.

Then you should strictly check item by item according to the production process and the operation and use rules of the equipment to ensure that the requirements of the rules are met, and then focus on the following inspection methods.

First, check the condition of the lubricating oil and coolant, replace the turbid lubricating oil or coolant, and ensure that the liquid level is within the specified amount.

Second, check whether the switches and valves are in the original position, and manually check whether the action is sensitive and effective.

Third, check whether the safety devices such as limit position, emptying and decompression are normal and effective.

Fourth, check whether there are sundries in the pot.

Fifth, check whether the power supply is normal, whether there is a fault display after power-on, etc.

The sequence of starting and feeding, the selection of cleaning methods and cleaning supplies, the feeding method, the environmental treatment in the process of work, etc.. are prone to damage or use safety problems caused by carelessness.

For example, when using, foreign bodies fall into the emulsifying pot and cause damage(the most common), for the purpose of saving trouble, the operation sequence is not in accordance with the provisions of the damage and material scrap, manual feeding when the material leakage to the ground is not cleaned up in time, causing personal safety problems such as slip and collision, etc.

In addition, in the process of work, abnormal sound, odor, sudden vibration and other abnormal phenomena, the operator should immediately check and properly handle, must put an end to the production of the idea of processing, so as not to work with disease leading to serious damage and loss.

Reset after production

The work after the production of the equipment is also very important and easy to ignore.

Many customers, after the completion of production, although there is a thorough cleaning of the equipment as required, the operator may forget the reset step, which is easy to cause equipment damage or leave a hidden danger of safety.

You should pay special attention to the following points after using the equipment.

First, evacuate the liquid, gas, etc. in each process pipeline. If automatic or semi-automatic equipment is used for pipeline transportation, attention should also be paid to handling the materials in the pipeline according to the regulations;

Second, empty the sundries in the buffer tank and keep the buffer tank clean.

Third, clean up the vacuum pump, check valve, etc. of the vacuum system (if it is a water-ring vacuum pump, pay attention to the jog check before the next operation, if the rust is dead, it must be manually removed and then powered on).

Fourth, reset all mechanical parts in normal state, the inner pot and jacket keep the vent valve normally open.

Fifth, turn off the power of each branch and then turn off the main power.

Cleaning method of vacuum emulsifying mixer

Cleaning is an important step in a vacuum emulsifying mixer maintenance. In the mixed production of food, pharmaceutical, daily chemical and chemical engineering industries, the common cleaning methods are: immersion cleaning method, scrub cleaning method, ultrasonic cleaning method, CIP cleaning system and jet cleaning method.

According to the size of the vacuum emulsifying mixer, the complexity of the design, the processing of different materials, the suitable cleaning methods will be different.

For example, the general materials, small equipment, cleaning method will be slightly simple, encounter the chemical composition of special material cleaning method, cleaning agent also need special selection, specific according to the actual needs to make the choice.

The common cleaning methods of the vacuum emulsifying mixer are as follow

Immersion cleaning method

The chemical and thermal energy of the cleaning agent at certain temperature and concentration can be used to soften or dissolve the residual material adhering to the tank, which is a simple and easy to operate cleaning method.

Jet cleaning method

In a certain pressure, detergent or water through a certain shape of nozzle to high shear emulsifying equipment need to be cleaned parts of the spray, remove dirt, is a common cleaning method.

Brush

Use a rotating scrubber to scrub away the dirt, and the decontamination effect is better.

Ultrasonic cleaning

For some vacuum emulsifying mixers with high cleanliness requirements, the general cleaning method may not meet the cleaning requirements. In this case, the ultrasonic cleaning method can be selected.

CIP cleaning system

Commonly known as in-place cleaning system, it is widely used in food and beverage production enterprises with a high degree of mechanization such as beverages, dairy products, fruit juices, fruit pulps, jams, and alcohol. For production equipment with stricter sanitation level requirements, CIP cleaning method can also be used.

Cleaning method can be used for a single vacuum emulsifying mixer, can also be used for the entire emulsifying unit production line, different equipment combination, the used cleaning method will be different, large or multiple production equipment and cleanliness requirements are higher, the choice of cleaning method is more complex.

The pre-use inspection, preparation and post-use cleaning of the vacuum emulsifying mixer are crucial to the machine. As the saying goes, a good beginning is half the battle. When you learn to handle the beginning and the end carefully, the whole process will become more smooth.

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine