Toothpaste Filling Machine:The Ultimate Buying Guide In 2025

To fill and seal toothpaste tubes is a tough job that must require a robust, fast, and well-equipped toothpaste filling machine. If you wish to launch a toothpaste brand into the market or boost sales for a relative product. Then, we suggest you read this blog to know some rigorous and strategic points and operational parameters related to toothpaste filling machines.

Our objective is to make you identify toothpaste manufacturing needs and sales interventions by choosing the right selection for toothpaste filling machines.

So, it is time to differentiate your need right from the beginning!

1.What is a toothpaste filling machine?

Everyone wants shiny, white, and strong teeth. Your smile adds to your look. For a beautiful smile having white teeth are necessary. And that is where toothpaste filling machines come to play their part.

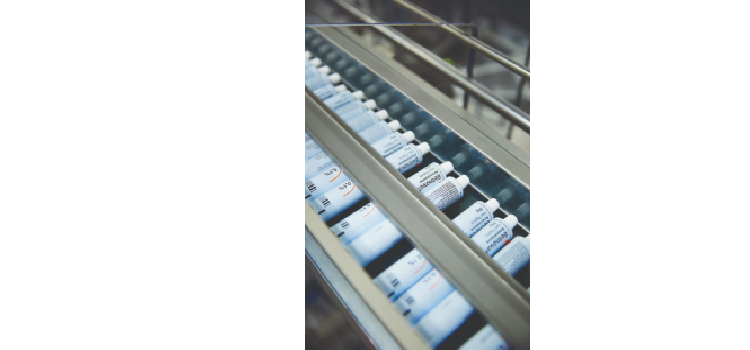

Toothpaste filling machine

Toothpaste filling machine as the term implies is the machine for packing the container with the various kinds of viscous paste. This machine plays an important role in your personal and oral hygiene.

This machine pack toothpaste having different viscosities, color and ingredients into the various sized tube.

Filling the toothpaste in striking and attention-grabbing tubes is important from a selling point of view so toothpaste filling machine has a lot of significance in the business.

These machines fill the paste in aluminum, plastic, and glass tubes. These machines seal the tubes with the hot air, prints batch number, and date on the tubes.

Various toothpastes

2.What are the different types of toothpaste filling machines?

Toothpaste filling machines come in different kinds. There are three main types of toothpaste filling machines. There are

- Automatic Toothpaste Filling Machine

- Semi-automatic Toothpaste Filling Machine

- Manual Toothpaste Filling Machine

1.Automatic Toothpaste Filling Machine

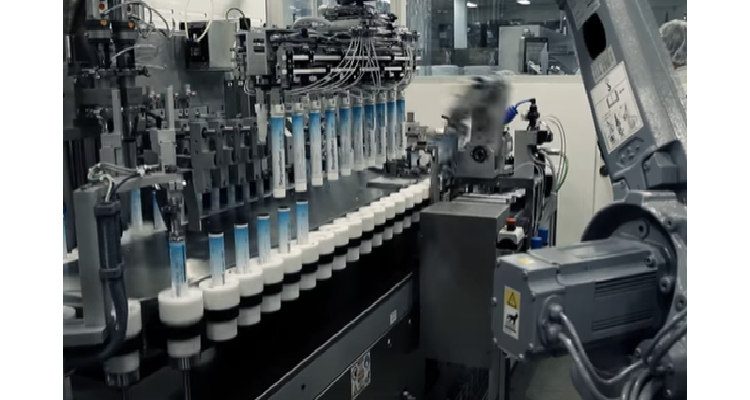

Automatic Toothpaste Filling Machine

This machine is fully automated. You can easily program different options for working. These machines are ideal for large-scale business as they remarkably increase the filling capacity of tubes. By using this machine, many tubes are filled in less time.

Human interaction in these types of toothpaste filling machines is very minimal. From tube loading to filling every process is completely mechanical.

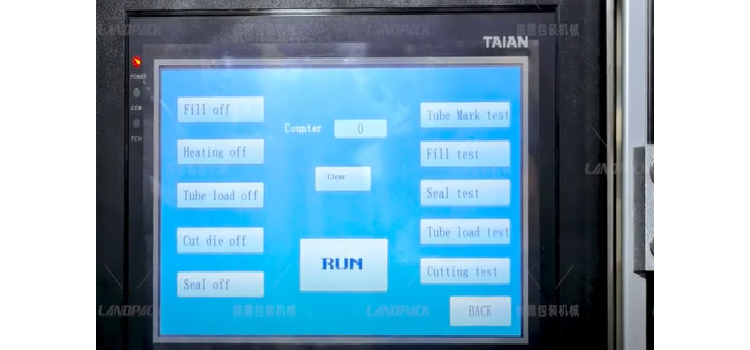

These machines have a programmable interface that allows the operator to configure operating parameters according to the need of an operation.

These machines have an automatic conveyor system by which tubes travel to the filling station. In an automatic toothpaste filling machine speed of conveyor systems can be adjusted in a programmable interface.

In the filling station, filling nozzles fill the tubes with toothpaste. This toothpaste is present in a hopper. Afterward, the tube travel to the capping station where the cap is fixed on the tube.

2.Semi-automatic Toothpaste Filling Machine

Semi-Automatic Toothpaste Filling Machine

Unlike automatic toothpaste filling machines, semiautomatic machines do not have a power conveyor. The operator has to manually load the tubes in the machines and with the help of a switch start the process of filling of tubes.

Working personnel removes the tubes from the filling station manually and then take them to the capping station. About 20-30 tubes are filled per minute.

The production efficiency of this machine depends on the working efficiency of the operator. These are ideal for small-scale to medium-scale productions.

They have nozzles, syringes, or pistons for maintaining zero drip filling.

3.Manual Toothpaste Filling Machine

Manual Toothpaste Filling Machine

In a manual toothpaste filling machine, every type of process is psychically done. Unlike semiautomatic toothpaste filling machines, in this machine filling is also done manually.

These machines do not need a power supply for the filling of tubes. These machines are useful for business which does not have electric source and compressed air.

These machines are used in laboratories and small production businesses.

3.What is the working principle of a toothpaste filling and sealing machine?

The working principle of toothpaste tube filling machine is categorized into the following steps:

Tube Feeding

2. Tube Filling

3. Tube Sealing

4. Tube Coding

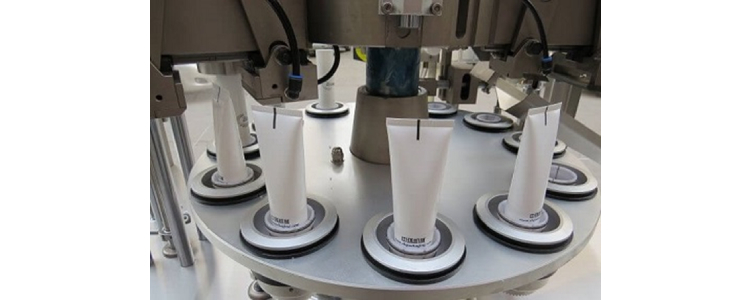

1.Tube Feeding

This step begins with the manual setting of empty tubes into the feeding unit for automatic selection of empty tubes toward the rotary table.

2.Tube Filling

The toothpaste filling machine fills the tube with the paste through a nozzle. The speed at which tubes travel to the filling station depends upon the level of automation of the machine.

Tubes go to the filling station either manually or by the conveyor system powered by the motor. The filling of tubes is done through the nozzle. There are different filling principles.

- Vacuum Filling

This filling principle involves vacuum pumps and vane cell feeding. The paste from the hopper is poured slowly into the cell by a vacuum pump. The vane cell to be filled with paste was first emptied then it moves under the hopper.

This process guarantees a continuous flow of paste.

- Volumetric Filler

There are two types of volumetric fillers which are gravity fillers and volumetric fillers.

- Gravity Filler

In these fillers, working personnel program the filling time of nozzles. This helps in filling the tube with an accurate volume of paste. The paste flows inside the tube by means of gravity in these filler machines.

- Piston Filler

Piston fillers are appropriate for packing highly viscous pastes. In these fillers, first paste is poured inside the cylinder and then pistons are used to push paste from the cylinder into the tubes. These tubes are present below the piston nozzles.

By using this filler right volume of paste is poured inside the tubes. After filling the tubes then travel to the capping station. In the capping station, the tubes are capped.

3.Tube Sealing

- Once tubes are filled with toothpaste, the rotary table will transfer them toward the sealing unit.

- The sealing unit instantly sealed the tubes using mechanical clamps.

4.Tube Coding

- Soon after sealing, the coding unit automatically prints the tubes with manufacturing code, manufacturing, and expiry date on the tail of the tube.

- After coding toothpaste tubes, they are sent to the collecting unit via discharging chute.

Working Principle of toothpaste filling machine Video Credit- IWK

4.What are the major components of a toothpaste tube filling machine?

The components of the toothpaste tube filling machine are as followed:

1.Frame

The frame of the toothpaste filling machine is made up of robust material that allows firm support entire parts of the machine.

2.Tank

Tank generally refers to a chamber that is used to hold products that is needed to be filled up.

3. Hopper:

A hopper refers to a device that signifies a funnel and basic unit for transferring dispensing material from a receptacle to another unit.

4.Filling Nozzle

A filling nozzle refers to a unit for controlling the flow of fluid into a container or tube

5.Coding Jaws

As its name shows, this device easily and quickly set the tube in jaws and jaws make them closer and sealing the tube. Upon sealing tube is transferred into another jaw where coding of batch and cutting is accompanied to produce a quality finish.

6.Dosing Pump

A dosing pump is an integral and essential component of a toothpaste tube filling machine. For each tube a pre-determined measure is required, and a different supply protocol is required which is depending upon what is being dispensed into the tubes. It is important to determine that you select the correct method for a certain application.

Toothpaste filling and sealing machine- Dosing Pump

7.Tube Container

Empty tubes are stored in an aligned manner before filling the toothpaste tubes.

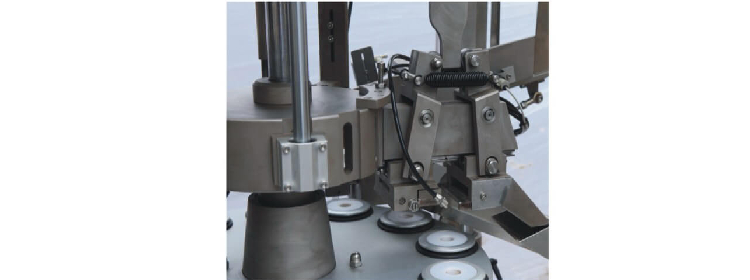

8.Tube Holders

Tube holder supports tubes for the filling process

9.Plunger Valve

A plunger valve is used for accurate filling of product to be dispensed.

10.Tube Feeding Unit

Toothpaste tubes are transferred from container to toothpaste feeding unit to rotary table where they are filled, heat-sealed, and discharged.

11.Sensor

A sensor detects the tube and fills the content in a tube. If the sensor fails to detect a tube no filling occurs, in simple words- no tube no filling.

12Cooling Unit

The cooling unit provides approximately 10 degrees cold water outside the tube to provide good sealing effects.

13Circulatory/ Rotary Unit

A circulatory unit is equipped with a rotary table that continuously rotates to tubes for the feeding unit.

14.Heat Sealing Unit

A heat sealing unit enables tube sealing after being filled with toothpaste. This unit is used once the toothpaste is being treated.

15.Discharge Unit

A discharge unit is a device that ejects filled and sealed tubes after being treated through a chute toward the collecting unit for packing.

16. Control Unit

A control unit is a device that contains components that regulate different parameters of the toothpaste filling machine.

17.Electronic Box

This is the major component of a toothpaste tube filling machine where all mandatory electric connections are centralized.

18.Motor

The toothpaste tube filling machine motor enables sufficient power control to the machine in order to perform basic functions efficiently.

19.Safety System

A safety unit helps you in operating function safely and protects you against an emergency or unwanted mishaps.

5.What are the structural features of a toothpaste filling machine?

The toothpaste filling machine is fully embodied with a highly advanced and reliable structure by cGMP standards.

- Automatic Feeding, Filling & Sealing Units

Its inter-connected design is adopted for automatic feeding toothpaste tubes which include tube positioning, filling, sealing, coding, and discharging. - Compact Structure & High-Quality Functioning

Toothpaste tube filling machine is fully compact structure, with fast and quality functioning. - Advanced Equipment Construction

This machine produces a clear and safe filling process. Part of the machine that comes in contact with the material is made up of stainless steel 316L. - Piston Head Dispensing & Easy Mechanical Maintenance

Due to reliable piston, a high filling accuracy of content is achieved. Toothpaste tube filling machine has easy assembly & disassembly of filling unit. The bucket valve, piston filling head, etc can be efficiently disassembled for cleaning and maintenance purposes. - Effective Filling Nozzle

The filling nozzle of the toothpaste tube filling and sealing machine can be extended for effective filling and protects the sealing quality of tubes under influence of material adhesion. - An Air Blowing Unit

An air blowing device is installed and the filling head features blowing and cutting out filling mode to protect the sealing quality and filling volume that are being influenced by highly viscous material. - Minimum Labour Input

This machine easily distinguishes any fault that occurs during operation and troubleshoots without necessitating the operator’s efforts.

6.Industrial applications of toothpaste tube filling machine?

Toothpaste filling machines are increasingly used in modern industries. The industrial applications of toothpaste filling machine are as followed:

- Pharmaceutical Industry

Pharmaceutical companies extensively use toothpaste filling machines. These are used to package different kinds of medicines in the tube.

Viscous medicines like analgesic creams, healing ointments as well as different kinds of syrup are filled into tubes by these machines. It is also used to fill pastes to treat allergies and various kinds of skin problems.

- Hygiene Industry

Toothpaste filling machines are an important part of the personal and oral hygiene industries. As the name indicates these are used to pack and fill toothpaste into the beautiful and eye-catching container.

These machines help you to smile better.

These are also used to pack cleaners, shave gels, conditioners, and hair gels.

- Food Industry

The food industry is the leading industry in which toothpaste filling machine has found their application. This instrument facilitates the packaging of several kinds of foodstuff into containers and tubes.

Different kinds of condiments like mustard paste and mayonnaise etc are packed into tubes with the help of these machines. These are also used in the packaging of different sauces and paste-like tomato paste.

- Stationary Industry

Toothpaste filling machines are also used in the stationary industry. These are used to pack different types of paints (oil, watercolors) and glitters in the tubes.

- Cosmetic Industry

The cosmetic industry is the main industry that utilizes toothpaste filling machines.

These are used to fill creams, lotions, and foundations in the tubes. Several kinds of sunscreens, medicated gels, and cleansers are packed into dazzling containers.

- Pet Industry

Toothpaste filling machine is very widespread in the veterinary industry. This machine is used to pack different types of medicine, skin ointments, and allergy creams for pets.

This machine is also used in filling various food products of the pets like meat paste, etc.

7.What are the advantages of a toothpaste tube filling machine?

Packaging is a very important component of one’s business. If a product has eye-pleasing and stunning packaging it will sell better. So, investing in the toothpaste filling machine is ideal for your company.

There are many pros of getting a tooth filling machine. Some of these are discussed below:

- Production Efficiency

Speed is the major factor in increasing your business. If your production efficiency is high, then you will get your product in less time in the market.

The production efficiency of toothpaste filling machines is very high. It fills multiple tubes in one cycle.

Some of the toothpaste filling machines fill about 120 tubes per cycle which leads to the filling of hundreds of tubes in one day.

This will cause getting more of your products in the market and will ultimately boost your business.

- Consistency

It is very important aspect of the business. There should not be variation in size, weight and volume of the product. If there is any kind of variation in the final product there its selling efficiency is affected.

Toothpaste filling machine is very precise and accurate. It provides homogenous and uniform end product. There is no variation in level and volume of paste in the tube.

- Decrease Labor Cost

This machine reduces your labor cost. It is an automated machine that performs its function effectively.

You do not need a lot of working personnel to manage and maintain this machine. This machine is equipped with automated cleaning which will reduce the money spent to clean toothpaste filling machines.

- Multitasking Operation

This machine fills and packages different size tubes in one cycle. It is the perfect solution for your business if you deal in various sized tubes. This machine will save time and power that will otherwise be spent on changing machine settings for packing a different sized tube.

- Product Loss

If you manually fill the tube, it will cause a lot of product loss. Using this machine is a safe way to avoid the loss of product.

The toothpaste filling machine is precise in measuring the accurate amount of paste that is filled in the tube. By calculating the exact amount of paste, it does not allow any wastage of the product.

- Easy to Operate

The toothpaste filling machine is equipped with a human machine interface that is very convenient to use.

This interface is used to set different working parameters of the machine such as the number of tubes packed in one cycle, temperature, the volume of paste, etc. This machine runs smoothly by programming these options on the machine interface.

8.How to fill toothpaste tubes? The basic operational procedure of a tube filling machine?

To fill toothpaste into individual tubes the subsequent points are followed:

1.Ensure the machine is cleaned with a ‘CLEANED’ status.

2.The packing material or tubes are inserted into the feeding unit according to the packaging order.

3. Using the smart Touchscreen control panel, select filling. heating. tube loading etc. options. and click ENTER and RUN the machine.

4. Now rest of the task will be performed automatically. Like filling, sealing, coding, and discharging. The tubes are filled with a product via piston of the machine which sends out an estimated amount of toothpaste into tubes with help of a sucking mechanism.

5. After filling toothpaste tubes are passed through the air-blowing station and sealing station.

6.The plastic tubes must go to the air-blowing unit where the air is blown out at the bottom of every tube. Then, they are sealed and trimmed and ejected out from the toothpaste filling machine.

7.The entire process should be carried out under the supervision of an expert technician.

9.How to maintain toothpaste filling machine?

Regular maintenance is always required to extend the shelf life and quality of the machine. Discussed below are maintenance parameters of toothpaste filling machine.

1.Machine Body

After each shift, you must cut off the power supply, clear the filling nozzle, rotary table, and those parts where material come in contact with stations using absorbent cotton dipped in 70% alcohol to maintain all components clean devoid of dusts.

Filling Nozzle- Toothpaste filling machine

Lubricate the large column and scale structure and replace it with new one once half a year, it should be checked and oil every week.

3. Speed Reducer

If oil level is lower than ½ than mark indication then add engine oil in time.

4. Drive System

Drive system, cam plate along with chain at machine bottom must be check and lubricated every week.

5. Inspection and Adjustment

If machine is not operational for long time, then before starting you must loosen all the parts and re-tight, adjust and lubricate them. Properly inspect the machine and begin the procedure.

10.What are the common problems and troubleshooting of toothpaste tube filling and sealing machines?

1.When vertical and horizontal codes are printed on both sides of tubes.

Solution:

- To avoid this problem appropriately tone down the lights that are irradiated by the photo-electric detector. For this, you need to adjust the settings on the touchscreen control panel.

- Heat ejector ejects tube too high that should be lowered.

2.The toothpaste machine can’t start.

Solution:

- This problem may be occurred due to electric power disturbance, no air pressure, or emergency stop is pressed.

- For this, you need to power ON the machine and check the fuse. For this release the emergency press.

- Check the connection between PLC communication with a machine.

3.Inaccurate filling volume.

Solution:

- The filling liquid may have impurities. Filling material may produce foam. For this, you need to clean the filling pipe of filter liquid.

- Electromagnetic valve interruption or plate breakdown. For this, you need to clean the electromagnetic valve or replace it.

4.Sharp edges form at one or both sides of toothpaste tube.

Solution:

- To solve this problem, you must line up the heating device vertically at the centre of the hole over the rotary table. Also, adjust the cooling water volume and lower down the temperature and pressure clamp.

5.One side of sealing is firm while other is not.

Solution:

- You need to check the firmness between a cooling ring and tube. If too loose then replace the cooling ring.

- Adjust the position of heating device it is suggested it should be vertically aligned with hole of rotary table.

Solution: Too much material is filled in tube or material adhere to the wall of tube. For that you need to adjust the filling blowing in order to halt the material spattering.

7. Tube can be released from cooling ring after heating.

Solution: Cooling ring must be too tight or high heating temperature. Therefore, you must adjust the distance between tube and heating unit (higher then 5mm).

11.What type of toothpaste squeezing material is right for you?

To squeeze toothpaste is an ideal way to dispense a wide range of products. Furthermore, manufacturers use this method as it requires cheap material and an effective way to hold the material as compared to a glass container or bottles, etc. Hence tubes are a durable and inexpensive way to protect your product against oxidation and improve its shelf life.

For squeezing toothpaste, you must require choosing the right material. To get began, we will discuss the basic types of tubes to consider such as plastic, laminated, or aluminum tubes.

- Polyethylene Tubes (PE) or Plastic Tubes

You will need to know the plastic tubes with different grades such as polyethylene (PE). The monolayer or multi-layered tubes are the best fit for daily use or product with a short half-life like lotions, shampoos, etc. It can also be provided with a barrier coating for purpose of additional protection of the product.

- Laminated Tubes

They can be made up of plastic but have an additional coating of lamination to serve extra protection and provide a high degree of lamination that offers a glossy, shiny, and aesthetic appearance to the product.

Laminated tubes are commonly used for packing toothpaste, sunblock’s, acne, or hair products

- Aluminum Tubes

These toothpaste tubes offer high barrier protection to your product and are known as collapsible tubes suitable for dispensing aggressive or delicate products. They are commonly used to dispense lotions, ointments, toothpaste, and cleansers.

Keep in mind when emptying metal tubes, the body may take a new distressing shape and cannot be recovered from in-use dispensing.

12.What are the future perspectives of toothpaste filling machine?

Toothpaste may not exactly be a glamourous product, but a hot consumer item worldwide since decades ago. Though oral hygiene has an estimated 40 billion USD global category in the USA. Toothpaste manufacturers serve as a billion-dollar firm globally. This is an era of varieties of toothpaste products primarily based on natural and unique clinical formulations.

Similarly, high consumer demand directly links up toothpaste filling and sealing unit.

According to current research, the global Automatic tube filling machine size is analysed to be in million USD between 2020 and 2021.

Report from period of 2016 to 2026 portrays growth segments by type and by applications. This assessment can be useful to expand your business by targeting a competent niche in market.

- By Type: market segment covers those machine that fill from 100 to more than 300 tubes/minute.

- By Application: market segment by application includes cosmetics, pharmaceutical, chemical, food, etc.

13.What are important buying consideration points for a toothpaste filling machine?

Research is the gate to finding quality products- similarly, whenever you plan to buy any equipment, you must scrutinize the available tool and assess whether it fulfills your needs or not.

Discuss below are some important points you must look for before procuring any machine.

1.Your Production Needs

You should know the type of production you are running, identify the needs of formulation and business. If you are running small or large production, you must take account before purchasing a newer machine.

2. User Friendly

You must look for the properties of the toothpaste tube filling machine. A user-friendly machine not only helps the operator to understand and effectively feed the orders, but it offers accuracy, precision and minimizes production downtime.

3. Cost-Effective

An ideal toothpaste tube filling machine must be opted for performing a filling, sealing packing tasks with high degree automation and no user- interference. Always keep in mind, you buy what you pay- thus, an automatic machine is the best choice to carry continuous production at an optimized cost.

4. An Adjusted Space

You must consider the measurement and dimension where you plan to place the machine. A laboratory or production unit must be cleaned, properly leveled, with proper space and hygiene to carry dispensing of pharmaceutical, foods, or topical formulations.

5. Automation

You must consider a machine with a high degree of automation. This property not only dispenses accurate content but increases productivity.

Conclusion

Toothpaste filling machines are of numerous forms having diverse designs, sizes and colors. These machines have diverse applications in many industries like the pharmaceutical, food, and chemical industry.

The smart, rapid, and durable automatic toothpaste filling machine with several working stations is devoid of requiring much labor and cost.

This blog is specially designed to make you understand the benefits, components, and applications of toothpaste filling machines and assess your own need. We hope now you will be able to choose the right machine as per your requirements.

Tube Filling Machine Related Products

Tube Filling Machine Related Posts

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine