How To Import The Best Tube Filling Machine:the Complete Guide in 2025

Have you ever face the problem of filling the liquid, semi-liquid and paste in tubes. Have you ever come across the idea of using a Tube Filling Machine?

Are you confused and are unable to perfect choice?

Let me take you on the journey of buying an ideal Tube Filling machine that will save you from the hustle of filling liquids manually. In this guide, I will describe to you each and everything about a Tube Filling machine, and will help you to make a wise choice.

Let’s start the journey of buying a Tube Filling Machine.

Q1) What is a Tube Filling Machine?

AIPAK Tube filling machine

Tube Filling Machine is an equipment used to fill liquids, semi-liquid, paste, cream, grease, and other the pharmaceutical products in tubes of different sizes and shapes. The chemistry of these products makes it a difficult task for you to package them. Thus, being a good manufacturer in pharmaceutical industry you opted to use Tube Filling Machine to make the packaging of liquids easy.

This machine fills your product in an elegant manner and saves your time and energy. For a well-known time, these machines find their use in the packaging industry. But with the advancement in science and technology and with the increasing demands of customers there have been lots of changes induced in the system of this machine. These changes have increased the accuracy, efficiency of the machine, and makes your task easier. Thus, benefiting you in all possible ways.

Q2) What are the parts of a tube Filling Machine?

The machine is composed of different parts and components that are connected to each other in a deliberate design. Each part has its own assigned function and every unit of the machine performs the specific actions that collectively give the outcome of your choice. It is very crucial to fix all the parts of the machine properly, only in this way machine will be able to perform the filling of tubes in the most efficient way, and you will get the huge load of filled tubes in a minimal time period.

Let’s discuss the different parts of the machine for better understanding of the working of the machine.

Body of the Machine:

It is the main skeleton of the Tube filling Machine, and it works as a structural system that supports the whole frame of the machine. All the major and minor units of the machine are intact inside this frame. As, the body of the machine holds all the internal and external parts of the machine, it obvious that it must be made up of some hard material like high quality stainless steel. The high quality of the manufacturing material will protect the body of the machine and all its parts from temperature changes, corrosion and other damage that may occur because of harsh environment.

- Storage Units:

These are the containers that are needed to hold up the material of filling. They are made up of hard stainless steel material to stand with the temperature changes and are placed at the top of the machine, so that they will have an elevated position to ease the process of filling.

Different tube filling machines have different abilities of filling the material in tubes and thus the types of the containers also differ accordingly.

- Filling Nozzles:

The effectiveness of the machine highly depends upon the filling nozzles. There are different grades of nozzles depending upon the type of liquid like simple low density liquids or high density complex liquids, you want to fill in the tubes. The core function of nozzle is to control the flow of liquid when it leaves the filler tank. They fill the liquids in the tubes through a tri-clover action, and in this way the direction of flow doesn’t get disturbed. Also the size of the nozzle matters a lot in this regard. For liquids of large volumes, you will need larger size nozzles.

- Coding Jaws:

These are designed in such a way that you can easily adjust and set the machine as per your requirements. So you just take holds of the filling and sealing of tubes, it guarantees you about the shape of the product and yield high-tech products. Its functioning doesn’t depend upon the thickness and material of the tubes.

- Dosing Pump:

It is designed in a positive compact manner and is used for the displacement of substances. It produces an accurate flow of substance in water, steam, or gas flow. It fills the dosing unit and then fills up this dosage into the tank as per your requirement. It is operated by the use of an electric motor present inside the machine, but you can also control it by using some internal or external control systems.

- Control unit:

This is the most sensitive part of the machine, as all the major working units are present inside it. It controls and regulates the different systems, and with the advancement in the technology the modern Tube Filling Machine is primarily based on the touch screen panel to control and operate different tasks. You can adjust the speed and other parameters until the final product produced by the use of a control unit. But one thing that matters is to have a trained technician who fully understands its operating systems so that you will get high efficiency and accurate results.

- Discharge unit:

This part of the filling machine is involved in the filling of containers. The components involved in the filling of the materials from tank to filling tube are controlled by the discharge unit. It is a very important component of the filling machine as it accurately measures the quantity of filling material for the filling of a tube. The quantity and speed of filling material are controlled by a device. Thus, you are free to adjust the parameters as per your desire.

- Tube Holders:

This part of the filling machine is involved in the holding of the produc-filled tubes. Depending upon the capacity of the machine of holding the tubes in each cycle, the number of tube holders varies. A machine with high capacity can have as many tube holders as needed. They work on a high rotation speed as their speed needs to be matched with the filling speed of discharging tube. The machine guarantees you consistency about the filling of tubes, and this is only because of movement of these holders. It holds the tubes tightly during the whole process, and as it is automatically operated thus you don’t need to worry about the whole production process.

- Hopper:

It is like a funnel and is involved in the displacement of filling products from one place to another. Hopper is an integral part of the filling machine because it composed the materials smartly into the equipment. It looks like a container and is located at the upper part of the machine that makes the perfect filling of substances and its size is the same as of the original machine. It is easily adjustable so you can control the right angle of filling.

- Electronic Box:

As the name indicates this part of the machine is like a box that contains all the electric supplies needed for the working of the filling machine.

Generally, an electric box has four components:

- Air switch, it is for the protection of the electric circuit from any shock.

- Wiring board, it helps to connect all the wires through a VFD unit.

- PLC, this is too present in the electric box and through this system, you control the operations of your machine.

- Transformer, it is a very important part of the machine present inside the electric box.

- Motor:

It is the powerhouse of a filling machine, it works by converting electrical energy into mechanical energy. Depending upon the load of the machine the capacity of the motor varies, thus if you want a high production rate then there will be a need for a big and high-capacity motor. You can seek expert advice in the selection of motor.

- Safety System:

The safety of the tube filling machine is very important for protecting the different parts of the machine, and also for the sake of your safety too. In case of any problem in the working operation of the machine, the bell rings and alarms you about the emergency. It will also warn you about the damage that may occur to your product. It is very easy to stop the machine during a trouble shoot, the system will check for the problem that occurred and after fixing it will give you a go ahead to start the process again.

The above-mentioned parts are the major components of the machine that you need to know before purchasing a tube filling machine. There are so many other minor parts of the machine that are present inside the machine, but you don’t need to train yourself for those parts.

Q3) How does a Tube Filling Machine works?

The working principle of the tube Filling Machine is quite simple, as the machine is fully automatic so you just need to monitor the whole process of production. Also, you should know how to control and adjust the operations as per your requirements. The filling of tubes is a major function that the machine performs, the tubes will be placed at the tube holders where these will be rotated over the rotary table and are placed at different units. This action will then be followed by the filling, sealing, and printing of bottles.

Filling is the main process of this machine and for this purpose different types of fillers are available, here I will going to guide you about the filling of liquid, gas and adhesives.

Gas filler:

It works like a gas compressor and the required pressure through a gas booster pump. It fills carbon dioxide, coal, and gas, etc.

Liquid Filler:

It uses high pressure than the normally required pressure and fills liquids.

Adhesion Fillers:

In filling of pastes a volumetric system is used to monitor and control the amount of paste required.

These machines find their uses mainly in large industrial sector, especially pharmaceutical sector. They fill the plastic tubes and then laminate them.

Q4) What are the advantages of a Tube Filling Machine?

Packaging is part and parcel of any business, and aesthetically appealing product catches the buyer’s attention readily. Good fancy packaging of products increases the sale and benefits the manufacturer. In the pharmaceutical industry packaging of medicines and other related products is important and is the demand of your consumer too. No one will go for a badly packed product. So, any problem or negligence during the packaging of the product will badly affect your overall sales and you will be left in a loss.

So, there are too many reasons for you to buy a good quality Tube Filling Machine. I will mention some major benefits of the Tube Filling Machine for you.

- Reliable and Consistent:

There is a 100% guarantee about the quality and reliability of results. You don’t need to worry about the excessive filling of product in the tube, the quantity of product for one batch will always remain the same as set by you through the control panel. Also, there won’t be any product loss like the one that happens in the hand filling of bottles.

- No Waste of Product:

There is no waste of your product, the tube filling machine accurately measures and then fills the products in the tubes. It saves you from the hustle of hand filling of product, also the hand filling is the very messy process of filling the tubes, creating a lot of garbage to clean afterward and also there is loss of product in hand filling.

- No Labor Cost:

This machine will be going to save you a lot of money in terms of labor cost. You don’t need to hire plenty of workers for the filling of tubes, there is only need of one trained operator who will go to operate the machine and monitor the process afterward. This will also be going to save you from the error that arises from the hand filling of tubes.

- Multitasking:

This is one of the biggest advantages of a Tube Filling Machine you can ever think of. It performs more than one function at a time, and you can always change the shape and size of the product as per your requirement. It can fill thin, thick, and viscous products easily. Thus, it handles multiple products and saves your money spending on different equipment.

- High Efficiency:

The tube filler fills the tubes with great efficiency, there is no chance of error, you just need to set the level of the machine once, and then it performs the operations accordingly.

- High Production Rate:

This machine surely increases your overall production, you can compete in the market as some tube filling machines have the capacity of filling 120 tubes in a minute. Thus, you can increase your overall sale of products and can generate great revenue.

- Friendly Working Environment:

Although the process of tube filling seems very easy, in reality, it’s a little long process that needs you to control and operate some of the systems of the machine. If you once fix the time of filling, speed of the pump, and time of the order once then you don’t need to do the work again and again. So it empowers you as an operator and gives you the confidence of high-efficiency results. Also, it allows you to perform other tasks during the monitoring process.

- Option for Up gradation:

You always have the choice to move from a simple to complex tube filling machine. At the start, if your production is less then you can opt for a machine with 2, 4, 6, 8 tube holders, and then with the increase of production, you can move towards advanced technology having more than 16 tube holders. So it always goes in your favor.

Q5) Are there any disadvantages of a Tube Filler Machine?

There are no such disadvantages of a Tube Filling Machine except the damage may occur from the improper handling of the machine. Two problems that may arise include:

The tubes may over melt at the end of the process but this can be managed by using cold water.

The use of high frequency for filling of tubes may lead to damage of the inner surface of the tube, this can be easily tackled by properly adjusting the frequency.

Q6) What are the different types of a Tube Filling Machine?

There are different models and types of a Tube Filling Machine, and each type is designed in a way to obtain different results. You have the choice to choose the one that is fit to your requirements. The three main types of Tube Filling Machine are:

- Fully Automatic Tube Filling Machine

- Semi-Automatic Tube Filling Machine

- Rotary Tube Filling Machine

I will give you a brief overview of each type, along with the advantages and disadvantages of a specific type.

- Fully Automatic Tube Filling Machine:

This is a fully automatic machine, and as there is only very limited human interaction so the chances of error are near to zero. The fully automated operations of this machine make it an ideal choice for industrial uses. It can fill and package a huge load of tubes in one cycle. The suction of the product is very convenient because of the dosing system, also the accuracy of a machine is very high due to the bottom filling that shuts the nozzle after filling, thus also guarantees a clean and efficient production. There is no issue of tool adjustments for the working of the machine, you just need to give commands through a touch screen and the machine will automatically perform the given task. It has a special safety system that ensures lubrication, as well as product quantity, is measured very precisely. It also comes in different shapes, sizes, capacities, and designs to give you freedom of choice.

The only thing is that it feels a bit expensive at first, but when you observe its huge benefits and positive impact on your overall production and sales you will not feel the cost.

- Semi-Automatic Tube Filling Machine:

AIPAK semi-automatic capsule filling machine

As the name suggests this machine is not a fully automatic one and is also known as a semi-automatic tube filling sealer, it fills lotions, pastes, creams, and adhesives, and is useful in a small-scale industry as it produces 30-35 bottles in a minute. These machines also come in different shapes, sizes, capacities, and designs, but most of the time these machines are comparatively small in size than the fully automatic tube filling machine. Although it is small in size it too requires a properly trained technician to operate the machine.

The main feature of this machine is a temperature control sensor, up to the mark measurement of product level, it performs the function of filling and sealing of bottles very precisely. Although it is semi -automatic you only need one operation for its functioning. Some manufacturers choose this machine only to compliment the fully automatic machine as it can serve you better during hours of breakdown and will also increase the overall production.

The price of the machine varies between the different manufacturers and you can check for the best one at negotiable rates.

- Rotary Tube Filling Machine:

This is also a unique type of filling machine which finds its use in the pharmaceutical industry, the most interesting fact about this machine is that it is available as fully automatic as well as semi-automatic one, so you can always go for the one that suits you the best.

This machine has some very unique features in terms of elegant finishing since the construction design is very promising, also the base of the machine is very heavy. It has high demand in the industry as it can perform filling, crimping, sealing, batch coding, and ejecting of products all in one cycle.

It will increase your productivity in a friendly working environment and decreases your labor costs. You can adjust the parts of rotary filler for accurate filling of product, and it is very easy to operate these machines.

This machine finds its uses in industries like the food and beverage industry, cosmetic industry, pharmaceutical industry, and nutraceuticals industry.

So now you are well aware of different types of Tube Filling machines, and you have also gained knowledge that these machines come in different models and sizes depending upon the manufacturer, you can choose the one which fulfills your requirements and suits you in all aspects.

Q7) What are the major Industrial applications of a Tube Filling Machine?

With all the discussion you surely get an idea that how useful this machine is for industrialists. This machine has a huge contribution in many important industries including the food and beverage industry, pharmaceutical industry, pesticide industry, and cosmetic industry.

Let me tell you some important applications of this machine in different industries.

- Food and beverage industry:

Packaging and filling is an important component of any big or small-scale food industry, for enhancing the sales of food products and ensuring the safety of its consumers, the product must be packed intact. So this machine plays a vast role in the food processing industry. It precisely fills and packs the product in the tubes. The choice of the machine will depend upon your demands regarding the size and quantity of the product.

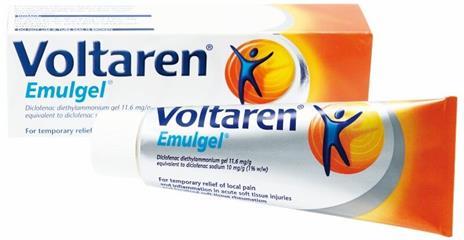

- Pharmaceutical industry :

This is one of the main industries that use the Tube Filling Machine, there is a huge impact of this machine on the filling of paste, tubes, ointments, and other medical products in different types of containers and tubes. It fills the product most accurately and efficiently. Besides filling it also sorts out the product at the end of the process. There is no such pharmaceutical industry where this machine is not used.

- Pesticide industry:

It is a fundamental demand of pesticide products that products must be filled accurately, the filling of all pesticide products in containers and tube is carried out by this machine. The hand filling of pesticides is a dangerous as well as a tiresome process for the manufacturer.

- Cosmetic industry:

There is another huge industry which uses Tube Filling Machine as the main equipment for filling and packaging of cosmetic products. Most of the beauty products come in the form of tubes that are precisely filled using this machine. All creams, shampoo, beauty creams, hair and body products are filled through this machine.

Now after knowing about different applications of the Tube Filling Machines, it is completely your decision to choose the one you want. Always go for the machine with high accuracy, greater efficiency, and gives mass production.

Q8) What is an ultrasonic tube Filling Machine?

This is the most advanced equipment that uses ultrasonic technology to fuse the product molecules and fills them. It is the best choice for pharmaceutical industries in the modern world. The only disadvantage of this machine is the adherence of product molecules on the walls of the machine, and it makes the cleaning and sanitization of the machine difficult.

Q9) Why you should invest in a Tube Filling Machine?

This machine has become an integral part of the pharmaceutical industry and is a must for filling products in the tube. We have got so many reasons for you to invest in this machine.

- Although this machine is quite heavy on your pocket, it will save you a lot of time and energy, and gives huge production in a minimal period.

- Tube filling is a difficult process and it requires precision in filling and this machine guarantees you the right quantity.

- PLC control system has made it very feasible for you to operate the machine.

- It guarantees you the efficiency and accuracy of filling.

- It will give you the same quality product in each cycle of the production process.

Q10) What are the main problems of a Tube Filling Machine and how you can fix them?

With the passage of time there may arise some issues in the Tube Filling Machine, and these problems may result in the stop of working of the machine. You need to address and fix these problems at urgent basis so that your production will not be effected. The common problems may include:

- Diameter of Tubes:

Tube size is very crucial in the filling process, and when there is need of filling the tubes of different sizes the operator may got puzzled about the correct size of the tube when he/she wants to fill two products at the same time. This problem can be resolved by pouring a single product at a time.

- Short Pump Durations:

This will cause a problem in the volume of filling products. If the duration of the pump is short it will fill the less quantity of product, and in case of high pumping duration, the tube may burst.

You can adjust this problem by adjusting the time of pumping.

- Pathway Connections:

As the machine is made up of different small pathways that are required for the movement of materials through the different parts. If these pores suck air it will make small bubbles in the product thus affecting the quality and quantity of the product.

- Worn out Parts:

As the machine is made up of so many different parts and like any other mechanical part they are also worn out because of the continuous working of the machine. To resolve this problem, you need to have a keen observation of all parts of the machine, also always check the lubrication of the parts.

- Level of Tube Fillers:

In this case, there is an uneven level of product in the tubes. It may cause the loss of product. This problem may overcome by checking the level of the machine and placed the machine properly before the filling.

- Tube Holders:

They are the most important part of the machine, and for the proper functioning of the machine, the tube holders must have a strong grip over the tubes. In case of losing grip, the bottle may slip and the production process would need to stop. To resolve this problem you can lower the hitting pressure of tubes and also adjust the grip of holders properly.

Q11) How you can maintain a Tube Filling Machine?

Like other equipment’s Tube Filling Machine also need proper maintenance. The right handling of the machine is necessary for the machine for performing various tasks smoothly and efficiently. The care of the machine will definitely save you from any of the potential damage, and you will get beneficial result without any hustle.

Here I am going to share with you few important measurers that you need to adopt for the proper working of the machine.

- Before operating the machine make sure the machine is well lubricated, and if it is not so then refill the lubricant as it will save the friction of the parts of the machine against each other.

- Make sure that all parts of the machine are intact and are working properly

- Always look for the leakage before running the machine, fix it if there is any leakage.

- All sensors must be working properly.

- Clean the inside and outside of the machine.

All these safety measures will last your machine for a longer period and save your time and energy.

Conclusion:

Now that you are fully aware of every aspect of the Tube Filling Machine, you know the benefits you can get from this machine, all the industrial applications of the machine. You can make your mind and can choose the one that fulfills your requirements.

Tube Filling Machine Related Products

Tube Filling Machine Related Posts

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine