How To Adjust The Capsule Polishing Machine?

When talking about a capsule polishing machine? Maybe it will be strange to you.

But when you take those capsules and tablets,

Have you ever wondered why the surface of these drugs is so clean and smooth, without any impurities?

There is no doubt that all of these are attributed to the processing of these drugs by the capsule polishing machine.

Whether you have a capsule polishing machine or not, you will learn about some elementary skills in the capsule polishing machine.

Before knowing the method to adjust the capsule polishing machine, we need to have a general understanding of the capsule polishing machine itself.

What makes you curious?

The definition of the capsule filling machine, the working principle, or its components?

I’ll talk about them one by one to satisfy your curiosity.

The capsule polishing machine is a special equipment for capsule polishing, lifting and sorting. It is also a tablet polishing equipment that is equipped with a separation function.

So where is it role?

Firstly, the capsule polishing machine can remove the attached powder on the surface of capsules and tablets (sugar coated tablets and plain tablets), make them clean, and improve the surface finish.

Secondly, it can automatically remove capsules with small size, empty shells, fragments and separated body and cap.

Do you always think that every machine has its own model?

But, the capsule polishing machine is applicable to all types of capsules and you don’t even change the mold.

Who will use the capsule polishing machine? Do you have an idea?

Maybe individuals, pharmacies, clinics, hospitals, pharmaceutical factory laboratories, academies, schools and other institutions.

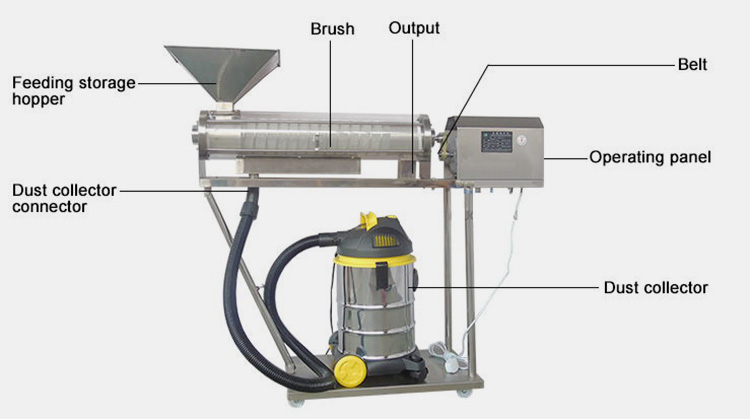

The next part is the components of the capsule polishing machine.

Here, you will understand the overall structure of the polishing machine.

If you want to fully understand the capsule polishing machine, it is the best way to distinguish one by one by comparing it with the machine.

The capsule polishing machine is mainly composed of a hopper, a polishing cylinder, a sealing cylinder, a brush, a coupling, a split bearing seat, a motor, a distribution box, a waste removal head, a discharge hopper and a frame.

You know that the polishing and conveying process of the capsule polishing machine is a closed structure.

So what are the requirements for parts that are indirect contact with capsules?

First, it is manufactured by stainless steel and corrosion-resistant materials.

Second, they are easy to destuffing and clean.

Third, they should be in line with the GMP for pharmaceutical equipment requirements.

How did this polishing process achieved?

When the capsule polishing machine is running, the brush drives the capsule to make a circular spiral motion along the polishing cylinder wall through the rotary motion, so that the capsule advances along the coil spring.

Under the constant friction with the brush and the polishing cylinder wall, the surface of the capsule shell is polished, and the polished capsule enters the waste hopper from the outlet.

What will happen after the capsules enter into the waste hopper?

Due to the function of negative pressure, the light and unqualified capsule will rise and enter into the cleaner under the effect of airflow.

The large weight and qualified capsules continue to fall down, and they are discharged through the movable discharge hopper to achieve the purpose of polishing and waste removal in time.

The powder and small fragments that were brushed off during polishing will enter the sealed cylinder through the small hole on the polishing cylinder wall and be sucked into the vacuum cleaner for recycling.

In what ways can you debug the capsule polishing machine?

Speed regulation? Polishing cylinder regulation? Cleaner regulation? Polishing time regulation?

You can understand one by one.

Capsule polishing machines’ speed regulation

The speed regulation in capsule polishing machine is controlled by microcomputer, which can realize stepless speed regulation, and can meet the requirements of polishing speed of different drugs such as capsules, sugar coated tablets and plain tablets.

The inclination angle of the main shaft can be adjusted arbitrarily within a certain range to meet the requirements of different drugs for the length of polishing time. If the speed is not adjusted, just runs the capsule polishing machine at a fixed speed.

For those fragile capsules, the rotation speed can be appropriately low, otherwise it can be appropriately adjusted high. When the capsule polishing machine is used for tablet polishing, the rotation speed can be adjusted down.

Capsule polishing machine’s polishing cylinder regulation

The inclination is adjusted by the tail support plate. The polishing effect is good when the inclination is large, and the production efficiency is high when the inclination is small.

Capsule polishing machine’s cleaner regulation

Professional industrial vacuum cleaners have two sets of dust cleaning tube devices. Each of dust cleaning tube has an air volume adjustment plate, and the air volume is adjusted according to the use situation.

Capsule polishing machine’s polishing time regulation

Adjust the tilt angle of the rack, change the height difference between the outlet and the inlet, and change the residence time of drugs in the polishing machine.

The larger the inclination angle, the longer the polishing time; otherwise, the shorter the polishing time.

However, when you adjust the polishing machine in all aspects, first you need to drag the rear section of the rack with force to prevent the rack from losing balance and damaging the rack after loosening the screws.

Second, adjust the tilt angle of the rack and retighten the locking screws.

After you finish producing a batch of drugs, the capsule polishing machine needs to idle for two minutes.

Only after wiping out the fine dust in the delivery pipe can you go on polishing the different types of capsules.

By understanding the methods to debug the capsule polishing machine, I believe it will be easy for you to solve some problems that are related to this machine when you have or want to buy it in the future.

Anytime, you should remember that knowledge is power, and you must arm the mind with knowledge because it is the key to solving problems.

Don't forget to share this post!

Capsule Polishing Machine Related Posts

Capsule Polishing Machine Related Products

Capsule Polishing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine