Your complete buying guide for Tube Filler Machine in 2025

Filling tubes with precision has always been hard. But, Tube Filler has become the solution of most of the recent problems in the Tube Filling industry.

Different types of Tube Fillers are used for different purposes to make the production successful and bug free. Saving the the time with accuracy is what makes it best.

In this guide, I am going to explain you about all the related stuff for Tube Filler that you need to know when you are going to buy it for your production line including its working, advantages and other related things.

So, lets jump on to our main topic without losing any time.

1.What is a Tube Filler Machine?

AIPAK Tube filler machine

The tube filler machine is a special type of pharmaceutical machine which is used to fill different types of pharmaceutical preparations (liquid) and fluids into the tubes.

The tube filler machine has made possible the efficient and fast filling of certain materials such as creams, ointments, cosmetic products, etc.

The filling of these products efficiently and fastly has never been easy because of the nature of these products (which causes storage and filling problems). But the tube filler machine has made it very easy.

The tube filler machine can be the perfect addition to your industry because of its broad variety of advantages.

Moreover, the tube filler machine comes in a variety of sizes, shapes, and designs and you can choose the one that best suits your business.

2.What is the latest development in Tube Filling industry?

In a world that is developing so fast, the tube filling industry is no way behind. It has developed as the needs of the world have grown bigger.

Products by tube filler machine

The forever growing population of the world has put increased pressure on production demands and consumer requirements in the tube filling industry.

However, the tube filling industry has responded well and by using the tube filler machines, they have successfully fulfilled the demands of the consumer.

The tube filler machines have also become advanced and the newer versions provide better performance (better accuracy, improved production speed, and higher efficiency).

3.What are the common applications of Tube Filler?

The tube filler machine has revolutionized many industries related to different fields. This machine has a wide range of applications in different industries which manufacture liquid preparations and then pack them in tubes.

The most significant industry is the pharmaceutical industry in which different gels, ointments, etc are packed into the tubes.

Other industries include the food industry, cosmetics industry, and pesticides industry, etc.

These are discussed in detail below.

Food Industry

The tube filler machine has vast applications in the food industry too. It is used for filling a different kinds of food products into the tubes.

These products may include pastes and sachets etc. The ability of the tube filler machine to work rapidly makes it very useful in the food industry.

The special sealing done by the tube filling and sealing machine helps protect the food products from microbial attack and so your food can last longer before getting spoiled.

The tube filler machine helps you fill your food product into containers of different sizes making sure that you fill your food product into the container that best suits your product

Tube Filling-Image Source: The Manoment Current

Pharmaceutical Industries

In the liquid preparations, the pharmaceutical industry prepares different ointments, creams, gels, lotions, etc.

Packing these preparations in a suitable container is one of the biggest challenges faced by the pharmaceutical companies. Because these products require special conditions for maintaining the shelf life.

This problem of the pharmaceutical industry is solved by the tube filler machine. The tube filler machine helps to fill the pharmaceutical preparations into the most suitable containers.

The tube filler machine has revolutionized the pharmaceutical industry by promoting efficient and safe filling of liquid preparations into the most suitable containers.

Accuracy is the key factor while dispensing any pharmaceutical preparation because any inaccuracy can cause severe damage to the patient`s health and can lead to death too.

The tube filler machine helps you achieve this accuracy. It helps you fill the exact amount of product into the tube so that there is no chance of inaccuracy while dispensing the dosage to the patient.

Moreover, the tube filling and sealing machine provides an extra advantage of sealing which helps protect the pharmaceutical preparation from the attack of the microorganisms.

Tube Filling(Ointment) Image Source- Verywell Health

Pesticide Industry

Pesticides are the chemicals that are used to kill pests. The pesticide manufacturing industry also has somewhat similar requirements.

The accurate filling of the pesticides into the tubes is very important. This is achieved by the application of the tube filler machine.

The tube filler machine also helps to fill the pesticides into suitable containers. The seal helps protect the pesticide from microbial invasion and so your product lasts longer.

Tube Filling-Image Source:chemicalpackers

Cosmetics Manufacturing Industry

Cosmetic products are mostly very sensitive to environmental factors such as heat, moisture, radiations, etc.

For saving the products from getting damaged due to environmental stress, the cosmetic manufacturers have to pack their products into specialised containers that best suit their products.

This is done by the application of a tube filler machine. The tube filler machine helps fill the cosmetic products such as shampoos, liquid soaps, etc. into the suitable containers at a very rapid rate.

The trend of using the cosmetic products is increasing at a rapid rate and in order to meet the production requirement, you have to move forward and add a tube filler machine to your inventory.

These are some of the applications of the tube filler machine in different kinds of industries. It has a wide range of applications that have solved many of the packaging problems faced by different industries.

Tube Filling (cosmetics)-Image Source: Kahan International

4.What are the advantages & disadvantages of Tube Filler Machine?

The advancement in the field of science has opened ways for many inventions that has helped humans and are still making our daily lives easier. But besides making our lives easier and making many works effortless, these inventions have disadvantages as well. So here is a brief description about the advantages and disadvantages of the tube filler machine.

Advantages of a Tube Filler Machine

1.Increased Efficiency of Production

The tube filler machine is a very efficient machine that does a lot of work in a very small time. Efficiency is the most basic feature any industry wants from a machine.

Nowadays, with an ever-increasing world population, the demand of every product is getting higher and higher.

Be it pharmaceutical industry, food industry or cosmetic industry, the requirements are rising rapidly with every single passing day.

In order to meet those requirements and fulfilling your products demand, you have to increase the efficiency of your industry which solely depends upon the efficiency of your machine.

The tube filler machine solves the problem of efficiency. Some variants of the tube filler machine are so efficient that they can fill over one hundred tubes per minute.

2.Accuracy

Accuracy of filling is another important advantage of the tube filler machine. First lets talk about the significance of accuracy in different industries.

In the pharmaceutical industry, the accuracy of dispensing the dosage is so important that any inaccuracy can lead to severe circumstances and can cause the death of the patient.

Similarly, accuracy is also very important in other industries such as food industry, cosmetics industry and pesticides industry etc.

Because of its specialized manufacturing characteristics, the tube filler machine is very accurate. You just need to set up the system in the control center and the tube filler machine will do the rest of the work on its own.

If you are an expert tube filler machine operator, you can very easily attain high accuracy.

3.Reduced Product Wastage

The tube filler machine is an advanced type of filling machine that has special features which avoid spillage of your product.

Many products such as ointments are lotions are costly and wastage of these products because of spillage during the filling process causes financial losses to your company.

You can avoid such unwanted situations by simply switching to the tube filler machine. The advanced and intelligent features of the tube filler machine avoid wastage of products to a much greater extent.

If you operate the machine expertly, you can easily avoid wastage of your products.

4.Cuts Down the Labor Expenses

The tube filler machine comes in different types such as semi-automatic and automatic. These types of the tube filler machine do not require much labor and so you can save on your labor expenses.

You shall have to hire lesser labor and so it helps you to lessen your expenses which leads to earn more profit and thus it gives your company a bright chance to grow and achieve its goals.

5.Upgradable

One of the most interesting facts about the tube filler machine is that it is upgradable and you can upgrade it anytime you want.

Whenever you feel that the tube filler machine is not fulfilling your production requirements, you can easily upgrade your tube filler machine by simply increasing the number of heads in the machine.

6.Wide Spread Applications (Multitasking)

Another interesting feature and a very important advantage of the tube filler machine is that it is not a machine with a limited scope.

A single type of tube filler machine is useful to fill a number of different types of containers at a variable speed.

Types of containers that can be filled by the tube filler machine maybe made of plastic, laminate, metal, and polyfoil.

Not only does the tube filler machine have the ability to fill different types of containers, they are also compatible with different types of products as well.

The tube filler machine is not a product limited machine but can work for wide range of products and containers.

7.Provides an easy Access to the System

If you are an expert operator, you can operate the tube filler machine very easily. But even if you are a beginner, you can quickly become an expert operator of the tube filler machine.

The reason is the simplified interface of the control unit of the tube filler machine. If you learn to operate the control unit, it means you have become an expert operator.

The control unit of the tube filler machine provides an easy access to all the parameters such as speed, amount of filling etc. and so you can easily control all the parameters by simply operating the control unit.

Disadvantages of a Tube Filler Machine

A tube filler machine has many advantages but besides these advantages, they have some disadvantages too. Here is the brief overview about these disadvantages.

1.Heat Damage

During the process of filling of the pharmaceutical preparation in the tubes, excessive heat is produced in the machine.

This heat keeps on increasing as the process continues and at a certain point, it becomes strong enough to damage parts of the machine.

If the heat energy produced during the process of filling caiuse damage to your tube filling machine, it will surely decrease your accuracy, productivity and ultimately, the efficienvcy is reduced.

In order to regain your previous efficiency, accuracy and production, you might have to buy a new machine or atleast repair the damaged parts of your tube filler machine.

In this way your company may face financial loss due to heat damage.

2.Requires a Cooling System

In order to save your tube filler machine from heat damage, a cooling system is required which controls the amount of heat produced during the process of filling of tubes.

5.Define the working principle of Tube Filler?

Before you use any machine, it is very important to now about the working of the machine. You must be aware of the working principle so that you can achieve maximum production and efficiency.

Regarding the working principle of the tube filler machine, the information below will be helpful.

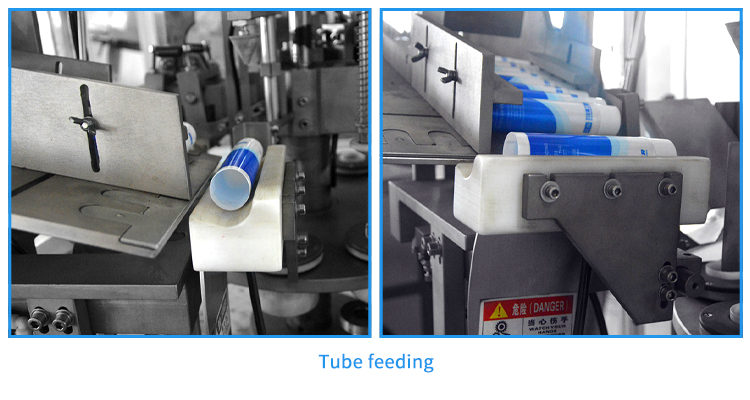

1.Placement of the Tubes into the Tube Holder

First of all, you place your containers (tubes in this case) into the tube holders. This maybe done manually or automatically depending on the type of the tube filler machine.

2.Adjustment of Parameters in Control Unit

After you are done with the placement of the tubes, you are almost done with your work. All you have to do is to set the parameters of the tube filler machine according to your own production requirements.

3.Automated Functions

Once you have set all the parameters in the control unit, the whole process becomes automated. The liquid preparations are stored in tanks and are then filled into the respective tubes with the aid of the filling nozzles. These are then packed and sealed automatically.

As an operator, you shall just have to watch and make sure that all the parameters are rightly set and that all the processes are taking place in the best possible way.

6.How many working parts are there in Tube Filler?

The tube filler consists of different parts that are assembled together and work in harmony with each other to perform the specified tasks. Each part performs its own role and so all of them hold great importance because absence of any part interrupts the normal functioning of the tube filler and so the task may not be fulfilled.

Some parts of the tube filler along with their description are listed below.

1.The Filling Nozzles

The filling nozzles control the direction of flow of the fluid when it is coming into the tube or the container from filler.

A tri-clover connection is used to attach them with product supply.

Apparently, the filling nozzles seem to be of less use but it should be noted that they are of great importance in the proper functioning of the tube filling machine.

The most important function it performs i.e. directing the liquids into their containers is very important.

It must be noted that the nozzles come in a variety of designs and you have to choose the one that suits your product the most (different liquids of different surface tensions and different densities require different types of nozzles)

The filling nozzles also control the rate of filling of containers (fill speed). The greater the size of the nozzle, the greater is the fill speed.

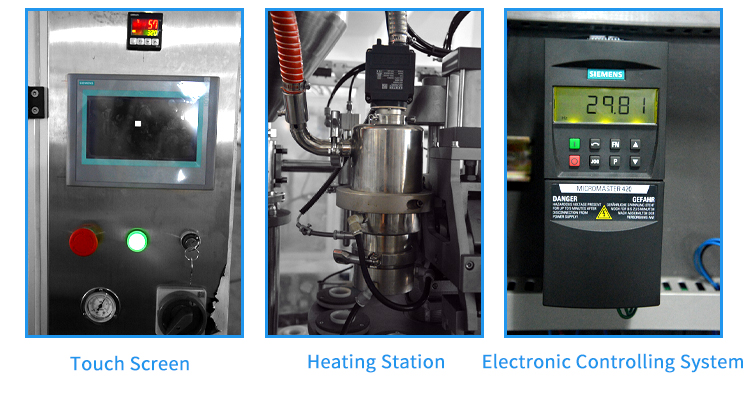

2.The Control Unit

This part of the machine is very sensitive and requires careful handling. This is the part of the tube filler machine that has control over all the parameters of the tube filling machine.

In the advanced variants of the tube filling machines, the control unit is touch screen most of the time. This makes it easy for you to adjust and customize the parameters of the tube filling machine.

You can adjust almost all of the parameters of the tube machine including the speed of tube liquid filling.

If you become expert in operating the control unit, it will mean that you are an expert tube filling machine operator and you can obtain high efficiency and a much greater production form your tube fill machine.

3.The Tanks

As the name indicates, these are the containers that keep your liquid product or the fluid product before they are finally filled into the tubes.

The tanks are available in different shapes and sizes and you can choose the one that best suits your product.

You can also get your tanks customized according to the nature of your product to get maximum efficiency and maximum production and ultimately, maximum profit.

Keeping in view the ease of flow of the fluid or liquid product from the tank into the tube, the tanks are placed a bit higher.

The material of the tanks matters a lot. The tanks should be resistant to a wide range of temperature and they should also be able to withstand different types of preparation so that they do not get damaged when holding your products.

The tanks should be resistant to corrosion and therefore we prefer tanks to be made of stainless steel.

The reason for selecting stainless steel is that it is highly resistant to many environmental factors.

4.The Coding Jaws

In order to give your products a fine and high quality finish, you need to use the coding jaws efficiently. These are adjustable in most of the advanced variants of the tube fill machines.

The coding jaws perform different important functions which are very useful in getting high production with greater efficiency.

The coding jaws help maintain the machine in a good condition.

The coding jaws also allow its users an easy access to the control over the filling process in filling the fluid in different tubes of different sizes and shapes.

5.The Discharge Unit

The discharge unit plays one of the most important tasks of the tube fill machine. This unit decides the amount of your liquid preparation that will be filled in the tube.

The accuracy of filling into the tubes depends on right usage of the discharge unit. You can get higher accuracy and greater efficiency if you adjust the discharge unit rightly.

6.The Frame

The frame is actually the whole structure that is a supporting system of the tube fill machine. It is very important because the tube fill machine is literally nothing without this.

It is that part of the tube fill machine that holds and protects the inner parts of the machine and provides support and holds the other components that are externally attached to the tube fill machine.

Talking about the building quality of tube fill machine, it must be built with a suitable material.

The material used for making the frame of the tube fill machine must be resistant to environmental factors (such as rust or corrosion) and physical damage (should be able to resist damage due to physical hit to a greater extent.

7.The Dosing Pump

This part of the tube fill machine also plays an important role in accurate dosing of the liquid pharmaceutical product into the tube.

The most important function of this part is to pump the exact quantity of the fluid or the liquid pharmaceutical preparation into the tube.

8.The Electronic Box

The tube fill machine requires electrical connections. All these connections are present in the electronic box.

Some of the most important parts of the electronic box of the tube fill machine include;

- The Relay

- The Air Switch

- A Transformer

- The PLC

9.The Tube Holder

As the name indicates, the tube holders are those parts of the tube fill machine that holds or supports the tube during the process of filling.

These tube holders are operated by the tube filling machine itself (automatically operated) and you can easily adjust the speed of rotation.

The number of holders in the tube holders also vary and depend on the speed at which the tubes are being filled.

You can ensure accurate dosing and filling of the fluid into the tubes by adjusting the rotatory speed of the tube holders accurately.

The speed of rotation of the tube holders can be adjusted in the control unit.

10.The Safety System

The safety system of the tube filling machine is very important as it ensures the safety of the operator and the machine itself.

It helps the operator from getting into any uncomfortable and unwanted situation by efficiently controlling the situation when it gets bad and thus helps prevent the situation from getting worse.

For enabling the safety system to take control over the machine, all you have to do is to press certain buttons when you face an unwanted situation and then the safety system, in most of the cases, will save your tube filling machine from getting damaged.

11.The Motor

This is most probably the most important part of any machine including the tube filling machine.

The most important function of any motor is to provide the driving force to run the machine. The motor generates mechanical energy by utilising the electrical energy. This mechanical energy then provides the driving force to help run the tube filling machine.

The type of the motor required in your tube filling machine vary depending on the number of factors, filling speed and fill volume being the most important ones.

This means the greater the filling speed and the fill volume, the greater the motor size. You have to decide the type of the motor that best suits your business.

12.The Hopper

The hopper is that part of the tube filling machine that helps move the ingredients or the prepared fluid from one part of the machine to the other.

The most important function of the hopper is to move the pharmaceutical preparation into the tank from where they are filled into the tubes.

These were some of the most important parts of the tube filling machine that play some of the most vital roles in the filling process of the tube filling machine.

7.What type of materials you can fill inside tubes with Tube Filler?

The tube filler machine has wide range of applications and can be used to fill a variety of materials from different industries. Some examples of the materials filled into the tubes by the tube filler machine are given below.

The Pharmaceutical Industries

In the pharmaceutical industry, the tube filler machine is used to fill different ointments, medicated creams, medicated lotions, medicated shampoos, medicated toothpastes and syrups etc.

Food Industry

In the food industry, the tube filler machine is used to fill ketchups, pastes etc.

The Cosmetics Manufacturing Industry

In the cosmetics industry, the tube filler machine is used to fill creams, lotions, shampoos, sunscreens etc.

The Pesticide Industry

In the pesticide industry, the tube filler machine is used to fill pesticides into the tubes.

8.How accurate filling is gained in different tubes with Tube Filler?

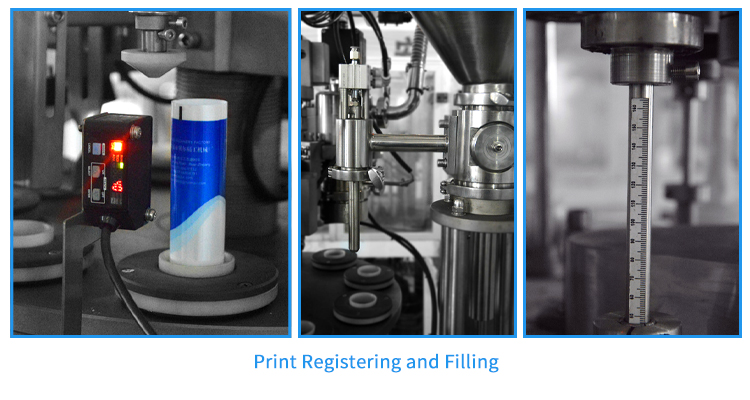

In the modern variants of the tube filler machine, all the functions are fully automated. All the parameters are controlled by the buttons of the control unit.

In the most advanced tube filler machines, the interface of the control unit is touchscreen and so the parameters such as speed of rotation can be easily adjusted.

High accuracy is obtained by adjusting the speed of rotation of the tube holder rightly. The tube holder rotates accurately and the discharge unit discharges the exact amount of the fluid into the tube through the filling nozzles.

In this way, the harmony of all the parameters of the tube filler machine leads to higher accuracy of filling.

AIPAK Semi-Automatic Tube Filler Machine

9.What Quality Standard should Tube Filler Machine Conform to?

Quality standards provide requirements and guidelines that ensure the right working of a certain product or a process. The basic requirements a tube filler machine is required to fulfill include;

Current Good Manufacturing Practices Quality Standards, cGMP

It ensures continuous production of high-quality products. The word current refers to the most recent standards.

International Standards Organization Quality Standards, ISO

These are international standards for quality control

Food and Drugs Admin Quality Standards, FDA

These standards ensure public health protection

Electronics Quality Standards CE

This guarantees that the product compliances with the EU standards for the protection of health and the environment.

The product should be made up of high-quality stainless steel, it must be safe and easy to operate. In short, the product must be user-friendly

10.Can you fill different size of tubes using the same Machine?

The tube filling machine is a machine with a much wider scope. Yes, the same machine can be used to fill different sizes of the tubes.

In addition to filling different sizes of the tubes, it can be used to fill a variety of products having different flow properties, viscosity and density etc.

Thus, the tube filler machine has a very broad range of applications.

11.What are the key points you need to remember while buying the Tube Filler?

Before choosing a machine, you should make sure that the machine fulfills all your requirements and is efficient enough to give you the desired yield. While looking for tube filler machine, you should consider the following aspects.

1.Choose the Most Suitable Machine

You must thoroughly go through the specifications of the machine and match it with your requirements before buying a tube filler machine.

You should choose the machine that best suits your requirements and that is suitable for your product type.

2.Choose the Company that has an Official Website

You must choose the company that has an official and verified website. This will make sure that you are not getting scammed.

3.Go for a Well Reputed Seller

You should always prefer buying tube filler machine from a well reputed seller that has a good rating. This ensures that you are going to get a good quality product.

4.Opt for the Best Quality

You must opt for the best available quality so that you can have the greater efficiency and your tube filler machine will last longer.

5.Try Finding the Best Price

You should always try finding the best price so that you can save your money and get a good quality product as well.

12.How the maintenance of Tube Filler Machine is done?

For the maintenance of your tube filler machine, you have to follow the following steps;

1.Disconnecting the Power of the Tube Filler Machine (When you are not using it)

You should make sure that you disconnect the tube filler machine when you are not using it. This will allow the machine to cool down so that it can start again from the resting position, having a normal temperature.

If you forget to disconnect the tube filler machine even when you are not using it, it will get heated and can lead to financial losses by causing different problems to your tube filler machine.

If you disconnect the tube filler machine, it will get cool after some time and then you are ready to go for the next step.

2.Disassembling of the Parts of the Tube Filler Machine

After the tube filler machine is cooled down, you have to disassemble the parts of it. You must carefully disassemble different parts of the machine one after another and continue doing so unless all the removable parts are disassembled.

You should make sure that you have the suitable and appropriate gear for disassembling the parts of tube filler machine. The method and technique of disassembling the parts of the tube filler machine should also be appropriate so that you may avoid ending up damaging any part of the tube filler machine.

3.Cleansing of the Tube Filler Machine

This is the most crucial step. You have to start by cleansing of different parts of the machine one after another.

In order to clean different parts of the tube filler machine, you are allowed to use different cleansing substances like fabric pieces, cleansing brushes, and water.

You must begin by cleaning the disassembled parts of the tube filler machine one after another. Complete and detailed cleansing of each and every part of the tube filler machine should be ensured.

Make sure that you are careful while cleansing the parts of the tube filler machine and apply the cleansing substances gently on the parts to avoid damaging any part of the machine and thus eventually you can avoid financial losses.

It is important to notice that the cleansing substances used for the purpose of cleansing must not be harmful so that they do not end up damaging your tube filler machine.

For the removal of the sticky stains from the parts of the tube filler machine, try using alcohol for this purpose. You can try soaking them in water for some time in order to remove those stains.

When you are done with the cleansing process, the parts of the tube filler machine are wet due to water or alcohol used in the process.

Now, in order to avoid rusting of the parts, you have to dry that moisture off the parts of the tube filler machine. This can be easily done by the application of a dry piece of cloth.

The dry piece of cloth will help remove the water or moisture content from the parts of the tube filler machine.

4.Replacement of the Disassembled Parts of the Tube Filler Machine

You should be very vigilant in examining all the parts of the tube filler machine. You must very carefully see which parts of the tube filler machine are damaged due to rusting or any other reason.

After you have managed to figure out which parts of the machine are damaged, the next thing you have to do is to replace the damaged parts of the tube filler machine.

This enhances the efficiency of the tube filler machine and also makes sure that your tube filler machine lasts for a longer period of time.

Part of AIPAK Tube Filler Machine

5.Application of a Layer of Oil on the Parts of the Tube Filler Machine

You are then required to apply a thin layer of oil on the parts of the tube filler machine involved in the movement.

Oiling the layers will help in reducing the friction so that the tube filler machine does not get hot instantly.

Oiling the parts of the tube filler machine will also help in protecting the parts of the tube filler machine from getting damaged due to rusting.

6.Reassembling the Disassembled Parts of the Tube Filler Machine

When you are done cleansing the parts of the tube filler machine, you are then required to assemble the dissembled parts back to the tube filler machine.

This step marks the completion of the whole cleansing process of to the tube filler machine.

Regular care of the tube filler machine and timely replacement of the damaged parts of to the tube filler machine will help in maintaining the productivity and efficiency for a longer duration.

Tube Filling Machine Related Products

Tube Filling Machine Related Posts

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours