Semi-Solid Dosage Manufacturing: Equipment Solutions for Creams & Gels

Have you realized that the ointment you use to treat your wound is a semi-solid dosage form? There must be so many other medications in your medical box, you use more often comes under the types of semi-solid dosage form. This dosage form offers an effective way to deliver drug to skin and internal mucosa. This is the reason; people prefer to choose semi-solid dosage form for frequent application.

This topic gives you understanding about types of semi-solid dosage form, their uses, compositions, production, advantages and limitations. All these information contribute to highlight the role of semi-solid dosage form for society.

| Dosage Type | Key Consistency | Required Equipment | AIPAK Solution |

| Ointments & Creams | High Viscosity | Vacuum Emulsifying Mixer | High-shear homogenization & vacuum degassing |

| Gels & Lotions | Shear-thinning | Liquid Filling Machine | Piston pumps with heating jacket |

| Suppositories | Melt-to-solid | Suppository Filling Line | Precise temperature control & rapid cooling |

1.What is semi-solid dosage form?

What Is Semi-Solid Dosage Form? –Picture Courtesy: Medical News Today

Semi-solid dosage form is defined as a pharmaceutical preparation that has consistency between solid and liquid. It is thicker than liquid but can spread conveniently on skin or mucosa. These preparations are formed upon different bases and these bases have integral role in maintaining uniformity, stability and efficacy of semi-solid dosage form.

2.What are the privileges of semi-solid dosage form?

Semi-solid dosage forms holds chief place in pharmaceutical industry and it offers several privileges to the society which is stated below:

Localized effect:

Semi-Solid Dosage Form Gives Localized Effect-Picture Courtesy: Hansaplast

Semi-solid dosage forms are capable of producing localized effects, especially on skin and mucosa. This ability is helpful in making healing faster and effective.

Less systemic side effects:

Semi-Solid Dosage Form Does Not Enter Blood Stream To Produce Effects So Less Systemic Side Effects Are There-Picture Courtesy: KB Electric LLC

Semi-solid dosage form is given usually by skin. It does not go through first pass metabolism neither reaches to blood stream so systemic side effects are minimized.

Ease of applying and removing:

Semi-Solid Dosage Form Is Easy To Apply And Remove-Picture Courtesy: Medical Associates Of North Texas

Semi-solid dosage form is convenient to apply and remove without causing any trouble or pain.

Increased contact time:

Semi-Solid Dosage Form Offers Increased Contact Time-Picture Courtesy: Strouse

Semi-solid dosage form has ability to stay in longer contact to the localized area unlike liquids and allow drug to produce profound effects over extensive period of time.

Versatility:

Immediate Release Semi Solid Dosage Form-Picture Courtesy: Deep Heat

Semi-solid dosage forms are available in different preparations that have controlled drug-release rates like immediate or modified release.

Patient compliance:

Semi-Solid Dosage Form Offers Non-Invasive Way Of Drug Delivery That Favors Patients Like Children-Picture Courtesy: CarePlus Pharmacy

Semi-solid dosage form presents a painless and non-invasive way of delivery drugs to skin and mucosa. This feature increases the patient compliance especially for children and old age individuals.

Appropriate for sensitive areas:

Semi-Solid Dosage Form Is Suitable To Treat Burns Due To Localize Effect-Picture Courtesy: The London Scar Clinic

Semi-solid dosage form is applied to sensitive areas like wounds, rashes, burns or mucosa where other dosage forms cannot prove to be effective.

Potential to include vast number of drugs:

Lipophilic Drug Containing Semi Solid Dosage Form

Semi solid dosage form has defined potential to include hydrophilic (water soluble) as well as lipophilic (fat soluble) drugs, depending upon the type of base used in formulation.

Stability:

Semi-Solid Dosage Form Is Chemically Stable When Formulated Accurately-Picture Courtesy: Healthline

Semi-solid dosage form possesses chemical stability and keeps the potency of drug over long duration when prepared accurately.

3.What are the types of semi-solid dosage form?

Semi-solid dosage form is pharmaceutical formulation that possesses soft consistency. These preparations are a mixture of solid and liquid and offers efficacious way to deliver drug to skin and mucus membrane. It has several types which are illustrated as follows:

Ointments:

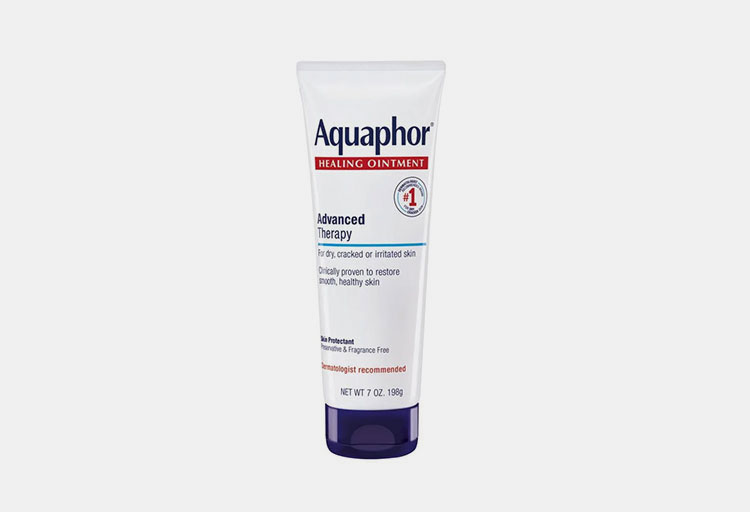

Ointment Is Used To Heal Dry, Cracked & Chafed Skin

Ointments are semi-solid dosage form, having thick and greasy consistency. They provide dominant effects on skin or mucosa by protecting or lubricating it.

Examples: antibiotic ointments, steroid ointments, moisturizing ointments.

These ointments can be medicated or non-medicated.

Medicated: main drug is dissolved or dispersed in a vehicle. For example: antibiotic ointment.

Non-medicated: these ointments are intended to give physical effects like lubricating or protecting effect.

Ointment bases can be of four kinds:

Oleaginous base: it is also known as hydrocarbon base. By nature it is greasy, occlusive and water-repellent. Hydrophobic drugs are incorporated in this base. It is used to give protective effect.

Example: white petrolatum.

Absorption base: it has ability to absorb small amount of water, less greasy but shows more versatility. It is used for incorporating the aqueous solutions and works as an emollient.

Example: hydrophilic petrolatum.

Water removable base: it can be washed by water and found to be less greasy. It is used in medicated and cosmetic ointment.

Example: vanishing cream.

Water soluble base: it can be completely washed by water due to being non-greasy. Used as drug carrier for hydrophilic drugs.

Example: polyethylene glycol ointment.

Creams:

Cream Is Used To Treat Acne

Creams are semi-solid emulsion, used for the purpose of applying it externally on skin or mucus membranes. They have soft, less greasy consistency and good spreadability than ointments. They are appropriate to apply on hairy and moist areas and possess fast drug release.

Example: Anti-fungal creams, steroid creams, cosmetic creams.

They are divided into two types, oil-in-water (O/W) creams and water-in-oil (W/O) creams.

Oil-in-water creams: these preparations have water as continuous phase and oil is dispersed in it. It is non-greasy and can be washed by water. They are used as hydrating agent and possess fast absorption.

Example: moisturizing creams.

Water-in-oil creams: oil is continuous phase while water is used as dispersed phase. These are greasy and occlusive by nature. These are used to provide protective barrier and best to use on dry skin.

Example: cold creams.

Pastes:

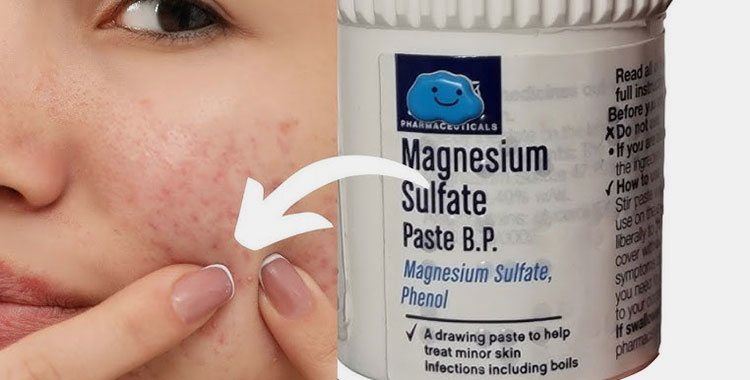

Magnesium Sulfate Paste Is Used To Treat Skin Infections

Pastes are semi-solid dosage form, which contain high amount of fine, insoluble solid particles dispersed in an ointment base. They have thicker and stiffer consistency as compared to ointments and creams. They are supposed to be ideal for localized effect as they stay longer, cannot melt or soften easily at body temperature. They can conveniently absorb secretions because of containing increased solid content so widely used for oozing or weeping skin conditions.

Examples: zinc oxide paste, salicylic acid paste, magnesium sulfate paste.

Pastes can be of two kinds, fatty pastes or non-greasy pastes.

Fatty pastes: insoluble solid drug is incorporated in lipophilic base to form fatty pastes. These pastes are used to provide protective and anti-inflammatory effect.

Example: magnesium sulfate paste.

Non-greasy pastes: such pastes are formed by using water soluble bases like polyethylene glycol to form non-greasy pastes. These preparations are easy to wash off and less occlusive. They give lubricating effect.

Gels:

Anesthetic Gel

Gels are semi-solid dosage form, which is comprised of a liquid phase intertwisted in three-dimensional polymer network that contributes in structure and viscosity of formulation. These preparations are clear or translucent and provide rapid drug release and absorption. They have non-greasy nature and can be washed off easily.

Examples: diclofenac sodium gel, aloe gel, lidocaine gel, metronidazole gel.

Gels are divided into two types, hydrogels and organogels.

Hydrogels: they contain water as liquid phase and are non-greasy by nature. They give soothing & cooling effect.

Example: carbopol gel with active drug.

Organogels: they possess organic solvents like alcohol as liquid phase. They are greasier than hydrogels.

Example: lecithin.

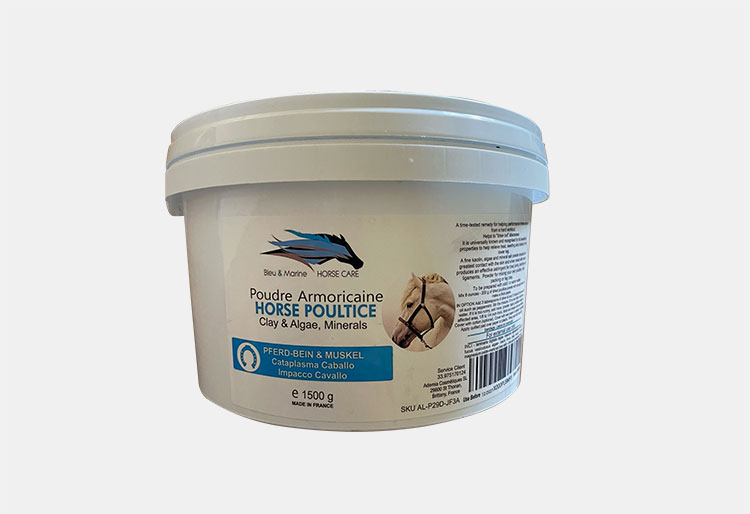

Poultices:

Poultice-Picture Courtesy: GB Heritage

These are semi-solid preparations, also known as cataplasms. They are soft, wet masses of medicinal plant material, clay or powder that are initially heated and held in place with cloth or bandage for applying on affected area. The purpose of applying warm formulation is to increase the blood flow and draw out the toxin or infection from respective area. They can be used as analgesic, anti-inflammatory or antimicrobial formulation and made from natural substances.

Examples: mustard poultice, kaolin poultice

4.What are the uses of semi-solid dosage form?

There must be some reasons that semi-solid dosage forms are extensively used. They offer a safe route to deliver medicine to skin and mucosal membrane. The way of using semi-solid dosage form is discussed below:

Treating skin diseases:

Clotrimazole Cream Is Used To Treat Ring Worm

Skin diseases like eczema, dermatitis etc. is very common and their first line of treatment is to apply medicine locally. Semi-solid dosage form offers a rapid way of delivering drug to affected area of skin and often uses to treat fungal or bacterial infections, acne, rashes or allergies.

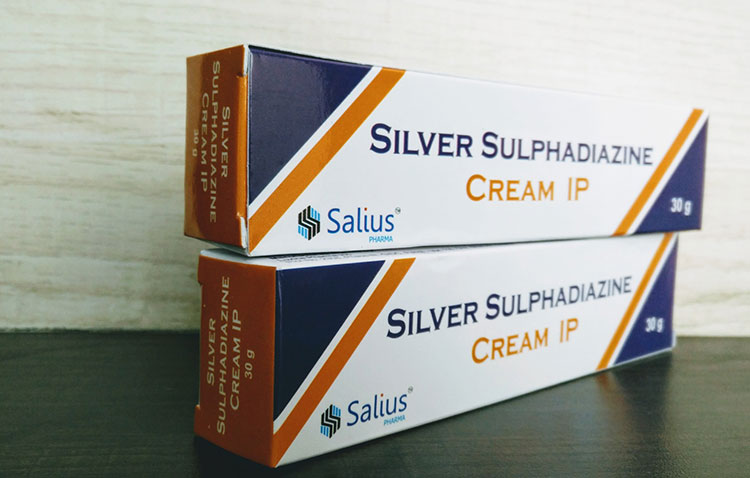

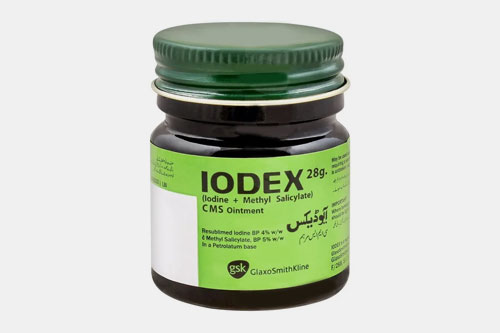

Healing wounds & burns:

Herbal Ointment Is Used To Treat Wounds

Accidents can occur anytime and leave the person with wounds or burns. Semi-solid dosage form provides effective way to treat them and prevent infections.

Silver Sulfadiazine Cream Is Used To Cure Burns

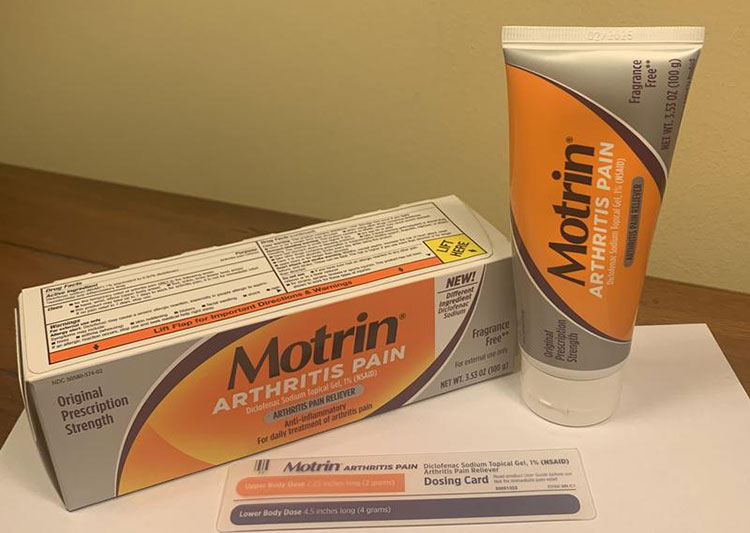

Relieving pain:

Diclofenac Sodium Gel Is Used To Treat Arthritis Pain

Pain is a very common problem of society; either it belongs to joint pain or nerve pain. Semi-solid dosage forms like gels, creams are used extensively as pain relieving agents.

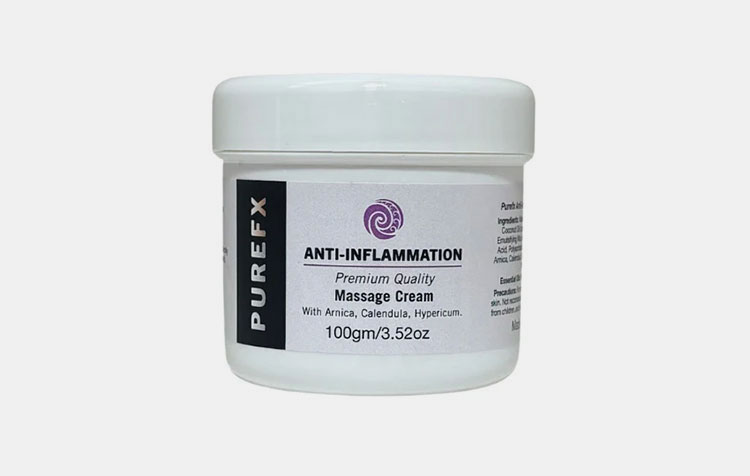

Working as anti-inflammatory agent:

Anti-Inflammatory Cream-Picture Courtesy: Aurora NZ

Semi-solid dosage form such as creams, gels, ointments are used as anti-inflammatory agent and play their role in reducing swelling and redness.

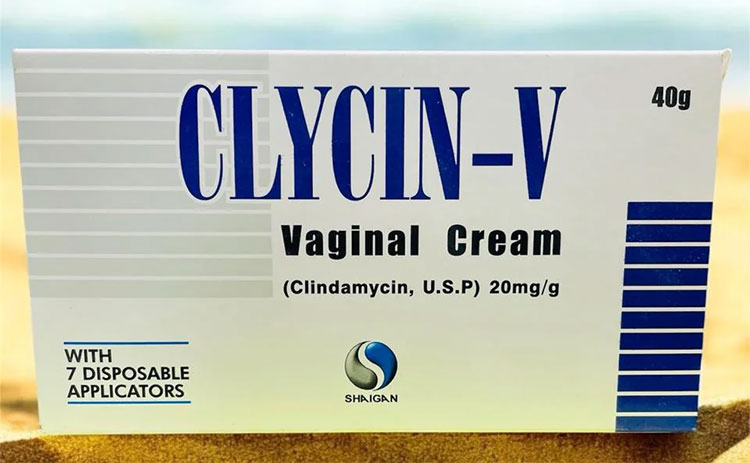

Protecting mucosa:

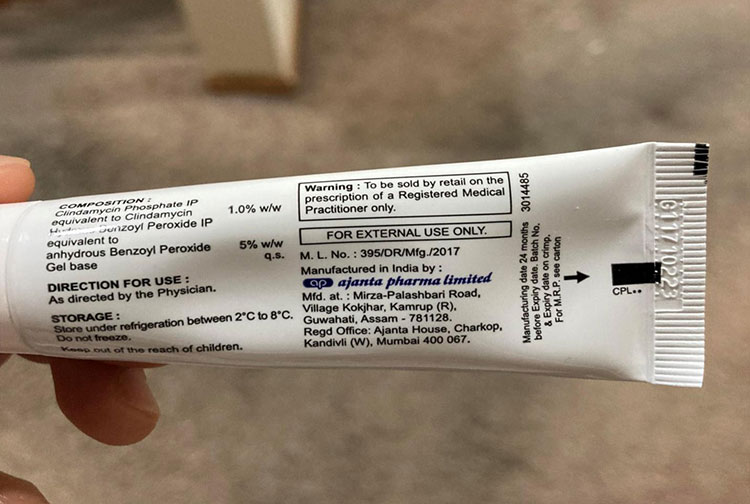

Clindamycin cream is used to treat vaginal infection

There are many semi solid dosage forms are used to treat mucus membrane related diseases like vaginal creams, rectal gels, nasal gels etc.

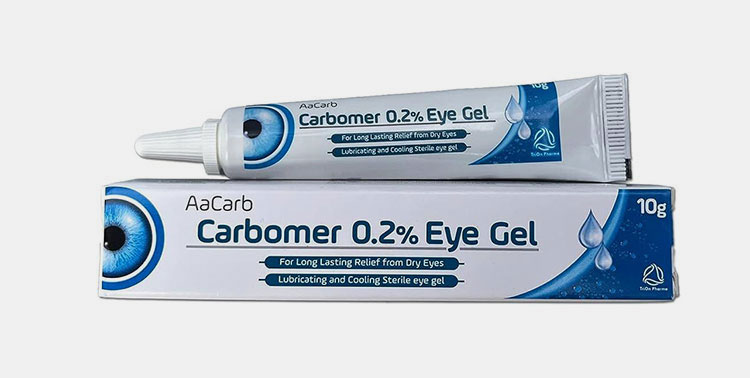

Lubricating agent:

Lubricating And Soothing Eye Gel

Semi-solid dosage form is used as lubricating and soothing agent that heals dry, chapped and cracked skin successfully.

Cosmetic uses:

Glycolic Acid Cream Is Used To Moisturize The Skin-Picture Courtesy: Luxur

Semi-solid dosage form is used as moisturizers, anti-aging creams etc. Active ingredient is incorporated in required base to formulate semi-solid preparation that is utilized to heal skin problems.

5.What are the limitations of semi solid dosage form?

Semi-solid dosage form is offering so many advantages and playing vital role in treating skin related conditions and diseases but, somehow it also has limitations. These limitations can affect the overall outcome we achieve by using semi-solid dosage form.

Restricted penetration:

Semi-Solid Dosage Form Offers Limited Absorption Of Drug By Skin-Picture Courtesy: SkinKraft

Semi-solid dosage form allows the drug to get absorbed by skin or mucus membrane, this feature results in poor absorption of drug and limit the systemic drug delivery. These formulations can easily applied or removed so contact time of drug with localized area may get affected.

Inaccurate dosing:

Inaccurate Dosing-Picture Courtesy: Cleveland Clinic Health Essentials

Accurate dosing is very difficult as you apply it by your own application techniques. So applying precise dose is still challenging.

Risk of contamination:

Risk Of Contamination Increases Due To Human Contact With Formulation-Picture Courtesy: Shutterstock

Most often, semi-solid dosage form is applied by using hand. This can increase the risk of contamination due to human contact. These preparations are sensitive to microbial contamination so precautions must be taken.

Stability problems:

Semi-Solid Dosage Form Starts Drying Out-Picture Courtesy: iStock

Sometimes semi-solid dosage form shows stability problems if not store in optimum conditions. We encounter physical instability like drying out or phase separation etc.

Irritation:

Allergic Reactions Cause By Semi-Solid Dosage Form-Picture Courtesy: Allergy Affiliates

Semi-solid dosage form can cause allergic reactions. Moreover, due to being greasy, messy or sticky patients feel discomfort after applying it.

6.What is the composition of semi-solid dosage form?

Semi-solid dosage form contains important ingredients that are combined to give dominant effects. Composition of semi-solid dosage form is discussed below:

Base:

Base Constitutes The Bulk Part Of Semi-Solid Dosage Form-Picture Courtesy: Gran Valeda Mexico

Base formulates the larger part of semi-solid dosage form and it decides the type of preparation. Different bases are used, which are discussed below:

| Bases | Examples |

| Hydrocarbon bases: | Paraffin, petrolatum. |

| Absorption bases: | Lanolin, hydrophilic petrolatum. |

| Water removable bases: | Emulsifying agents like anionic or cationic. |

| Water-soluble bases: | Polyethylene glycol. |

Active pharmaceutical ingredient (API):

Active Pharmaceutical Ingredient (API)-Picture Courtesy: DU Organics

The main drug or therapeutic agent is used as active pharmaceutical ingredient. This ingredient can be dissolved, suspended or emulsified to get the desirable effects.

Emulsifiers:

Emulsifiers-Picture Courtesy: SBR International

Emulsifiers are used in creams to make the formulation stable and avoid phase-separation. Example includes sodium lauryl sulfate.

Humectants:

Humectants-Picture Courtesy: GetVedgy

This humectant is used to keep formulation wet and avoid drying of it. It retains moisture in preparation and its absence can cause defects like drying out. Example includes glycerin.

Preservatives:

Preservatives-Picture Courtesy: Healthy Starts At Home

In order to prevent microbial contamination, preservatives are added, preferably in aqueous preparations. Example includes paraben, benzyl alcohol.

Antioxidants:

Antioxidants-Picture Courtesy: SD Precise Bioscience

Antioxidants are added to keep formulation safe from oxidation. Example includes: ascorbic acid.

Gelling agent:

Gelling Agent

Gelling agents are incorporated in gels or creams to improve consistency of formulation. Example includes xanthan gum.

Penetration facilitators:

Penetration Facilitator-Picture Courtesy: Reddit

These are added into formulation to facilitate the penetration of it through the skin. Example includes dimethyl sulfoxide (DMSO).

AIPAK Expert Insight: The Science of Air-Free Emulsification

"The biggest enemy of a high-quality semi-solid product is trapped air. Micro-bubbles not only ruin the appearance of creams but can also lead to ingredient oxidation and dosage errors. At AIPAK, our Vacuum Emulsifying Mixers utilize a complete vacuum environment during the mixing process. This ensures that even the most viscous ointments are perfectly smooth, stable, and de-aerated, which is crucial for achieving consistent density in the final tube filling stage."

7.What containers are used to dispense semi-solid dosage form?

Containers play a crucial role in keeping formulation stable. Most commonly, semi-solid dosage form are dispensed in tubes or jars.

Tube:

Usually semi-solid dosage form is packaged in tube. Tube is a collapsible container, which means it can be easily be squeezed or compressed to reduce its volume. It is made from aluminum or plastic or laminates. More often, sterile preparations are likely dispensed in laminates (combination of plastic & aluminum).

Tube is suitable container as it protects the formulation from contamination or exposure of air. It is very convenient to use and keep the product hygienic as preparation draws with a narrow nozzle.

Jar:

Amber-Glass Jars-Picture Courtesy: PREMIUM Vials

Jar is wide-mouthed packaging container in contrast to tube. It is made up of plastic or glass. It makes easy access to formulation and suitable to dispense thicker preparations. It has rigid body and closed with a screw-on lid to keep product stable and hygienic. Opaque or amber glass is used to protect light-sensitive formulations.

8.What is the manufacturing process of semi-solid dosage form?

Manufacturing Process Of Semi-Solid Dosage Form-Picture Courtesy: Sleepy Bee Supplies

Manufacturing process of semi-solid dosage form includes several steps to ensure a high quality product. Steps of whole operation are described below:

| Steps of manufacturing process: | Information: |

| Formation of base: | Commonly used bases are oils, waxes, emulsifiers, or polymers.

Heat lipid soluble bases and water soluble bases separately at 70-75 C. For making creams, mix both lipid & water soluble bases by stirring. You can use a mixing vessel or emulsifying machine to perform this step, as a result of it emulsion or dispersion is formed. |

| Mixing active pharmaceutical ingredient (API) into base: | Active pharmaceutical ingredient is dissolves, dispersed or emulsified in prepared base, according to its solubility. Homogenization method is used to make sure that API is mixed well into the base. |

| Incorporation of other ingredients: | Other ingredients like stabilizers, preservative, humectants etc. are mixed into the mixture of API and base. Homogenizers are used to perform uniform mixing and minimize the particle size to attain a refined texture of formulation. |

| Cooling: | Cooling process is carried out to make formulation becomes more thicker and to the consistency required as a semi-solid dosage form.

Cooling of mixture is done during the mixing process to avoid phase separation in future. |

| Filling & packaging: | The formulated product is transferred into filling machine where precise filling and sealing of semi-soli dosage form is performed. All process is carried out under hygienic conditions.

Packaging container like tubes, jars are used and machine is selected according to the container required for packaging. For example tube filling machine is used to fill tubes. |

| Quality control: | Different test are performed to ensure the quality of final product. Viscosity, pH, drug amount, microbial presence, spreadability and stability are tested. |

9.What are the key machines that contribute in manufacturing semi-solid dosage form?

Manufacturing of semi-solid dosage form demands for efficient equipment. List of important machines used in manufacturing is present below:

| Key machines used in manufacturing | Image |

| Water purification system:

Water purification system is used to purify water, which is utilized during production of semi-solid dosage form. Water carries microorganisms and can increase the risk of contamination. This water purification system ensures the use of purified water. |

Aipak Water Purification System |

| Jacketed vessel with agitator:

This machine has different purposes, like it is used for heating, cooling or mixing ingredients. Temperature is kept controlled under the vessel and an agitator is also there to perform mixing during heating or cooling of formulation |

Jacketed Vessel With Agitator |

| Vacuum emulsifier homogenizer:

This machine offers consistent mixing of preparation resulting in homogenous mixture. Particle size is also made reduced to avoid grittiness in formulation. A desirable semi-solid mixture is produced after passing through this homogenizer. |

Aipak Emulsifier Homogenizer |

| Tube filling line:

Semi-solid mixture is filled in required packaging containers and them sealed accurately by the help of tube filling line. Automated equipment is preferable in pharma industry to attain high productivity. Sterilized tubes are used to fill the formulation and different material tubes such as plastic, laminates, aluminum can be used according to demand of product. |

Aipak tube filling line |

| Jar filling line:

This machine is used to fill and seal semi-solid mixture into jar with great precision. Jars are washed, dried and then filled accurately. Capping is done to seal the formulation. |

Jar Filling Line-Picture Courtesy: Lenis Machine Inc. |

10.What storage conditions are favorable for semi-solid dosage form?

Semi-solid dosage form can lose its stability and efficacy if not stored properly. For awareness it is very important to learn about storage conditions that favor semi-solid preparations.

| Factors affecting storage conditions | Image |

| Temperature:

Appropriate temperature to store semi-solid dosage form is 15-25 C, at room temperature. Few products require refrigeration (2-8 C) Avoid exposure to heat as it can cause defects in preparation like phase separation, melting or degradation. |

Picture Courtesy: Wikipedia |

| Humidity:

Below 60 % relative humidity is acceptable. Increase humid conditions can favor microbial growth in aqueous formulations. |

Picture Courtesy: House Fresh |

| Light exposure:

Prevent exposure to light, especially UV light. For light sensitive products, use opaque or amber glass. |

Amber Glass Jar |

| Air exposure:

Exposure to air can cause oxidation or dryness in formulation. Prevent the formulation from being exposed to air by using air tight jar or tubes with proper sealing. |

Air Tight Tube |

| Packaging container:

Use such packaging material that does not react with formulation like aluminum, plastics, laminated tubes. |

Laminated Tubes |

| Contamination by microbes:

To save product from microbial contamination, preservatives are added. Also hygienic conditions are observed during whole operation. |

Formulation Contains Preservative |

11.What factors can influence the effectiveness of semi-solid dosage form?

There are some factors that can influence the effectiveness of semi solid dosage form. When you are well informed about such factors, it becomes easier to get utmost benefits of semi-solid preparations.

| Factors: | How they affect? |

| Viscosity:

Viscosity Can Affect Drug Absorption-Picture Courtesy: FemiClear |

Viscosity plays an important role; it is the ability of preparation to resist the flow. Optimal viscosity is required for good effects because low viscosity can cause increase drug release while high viscosity can slow drug release. |

| Spreadability:

Spreadability Contributes In Uniform Drug Delivery-Picture Courtesy: Skincare.com |

It shows the preparation’s capability to spread. Good spread ability causes optimum absorption of drug and dominant effects are produced. |

| Drug solubility in base:

Good Drug Solubility, Good Drug Effects-Picture Courtesy: Depositphotos |

Good solubility of drug in base results in fine absorption of drug into the localized area. |

| Stability of formulation:

A Stable Semi-Solid Formulation |

Stable formulation can produce prominent effects while degraded formulation cannot deliver drug properly to skin or mucosa. |

| Skin condition:

Damaged Skin Absorbs More Drug-Picture Courtesy: Healthywomen |

Drug is absorbed more quickly through damaged skin as compared to intact one. |

12.How much time semi-solid dosage form takes to expire?

Expiry Date Is Mentioned At Packaging Container-Picture Courtesy: Reddit

Semi-solid dosage form can expire between 2-3 years from the date of production. Formulation type, packaging and storage condition have integral role in keeping the formulation stable. Expiry date is printed on labels to avoid any trouble.

13. Solving Common Semi-Solid Production Issues

Issue: Ingredient Separation (Phase Separation) in Creams?

AIPAK Solution: High-shear homogenization at precisely controlled speeds ensures that oil and water phases are permanently bonded into a stable emulsion.

Issue: Inconsistent Dosing in Tube Filling?

AIPAK Solution: Our Tube Filling Machines use servo-driven piston pumps with "blow-off" functions to ensure clean cut-offs and 1% filling accuracy, even for thick materials.

Issue: Particle Grittiness in Ointments?

AIPAK Solution: Integration of a specialized Colloid Mill or fine-mesh filtration within the mixing cycle to ensure a particle size of less than 10 microns.

Conclusion:

"Scaling Your Semi-Solid Production?" From laboratory-scale vacuum mixers to fully automated high-speed tube filling lines, AIPAK provides the GMP-compliant equipment you need to ensure product stability and quality. Contact our technical experts today for a customized production line layout and a free equipment quote. Request a Semi-Solid Equipment Quote & Consultation.

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine