Types of Pharmaceutical Processing Equipment

Have you ever seen how a small pill passes through several types of pharmaceutical processing equipment till it reaches you? Pharmaceutical companies over the past decade have pursued tremendous achievements related to medicines. The manufacturing industry is mainly based on Good Manufacturing Practices (GMP) for producing safe, quality products and compliant with regulatory standards. The diversified production comprises purification, mixing, production, filling, packaging validation, and many procedural steps.

Therefore, the whole process is possible with types of pharmaceutical processing equipment to bring safe and effective production. This article introduces some key pharmaceutical processing equipment that can help a formulator in incorporating some flexibility and business acuity when preparing for manufacturing.

1.Why Pharmaceutical Processing Equipment Matters?

Pharmaceutical processing equipment plays a significant role in the manufacturing industry. Though this is mainly involved in the treatment of raw material till the final finished product. The role of machinery impacts the effectiveness of medication. We have highlighted the major reasons why it is important and matters to manufacturers to make the right choices.

Ensuring Product Consistency and Purity

Consistent & Pure Preparation- Picture courtesy: U.S Validation Service

Pharmaceutical preparation is based on medium to large production batches. The types of pharmaceutical processing equipment help in maintaining the consistency of batches with the help of automation and advanced working features. Due to the enclosed structure and good quality materials, they’re easy to clean and reduce the problems of cross-contamination. Consequently, the prepared product is composed of pure medication with accurate substances as decided in the protocol.

Compliance with International Regulations

Compliance with international regulations

The international regulatory organizations, such as the FDA, EMA, and WHO, mainly focus on designing and processing pharmaceutical equipment that is specifically safe for your production and quality. They keep inspecting and focusing on maintaining the audit to evaluate any minor errors if that occur in the process flow. Thus, pharmaceutical preparation is ideal and up to a high level of potency.

Supporting Efficiency and Scalability

Supporting Efficiency and Scalability- Picture Courtesy: Syntegon

The pharmaceutical companies want nothing but to approach supporting and innovating machines to carry out formulation with excellent efficiency. Therefore, integration of pharmaceutical processing equipment ensures coping with high demand with scalability. So, whatever the required demand you have, the modern and automatic system can flexibly perform them without requiring much input.

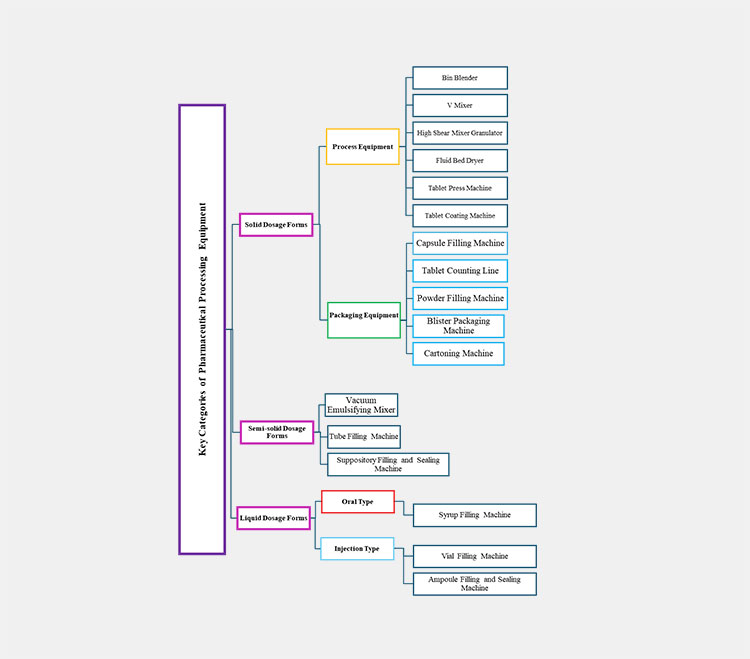

2.What are the Key Categories of Pharmaceutical Processing Equipment?

The key categories of pharmaceutical processing equipment are described below:

Classification of Key Categories of Pharmaceutical Processing Equipment

Solid Dosage Form

In pharmaceutical processing, solid dosage equipment is of central focus and is associated with the preparation of solid dosage forms, like tablets, capsules, and others. Diverse types of these systems are being used to handle and automate both upstream and downstream processes, for instance, mixing, granulation, tableting, and others.

Process Equipment

The process equipment of solid dosage formulation includes:

Bin Blender

AIPAK Bin Blender

Unlike a fixed blender, a bin blender is a type of industrial blender that comes with detachable bins to allow ease of material loading and mixture discharging. It rotates along a fixed axis, resulting in three-dimensional motion that mixes dry ingredients evenly.

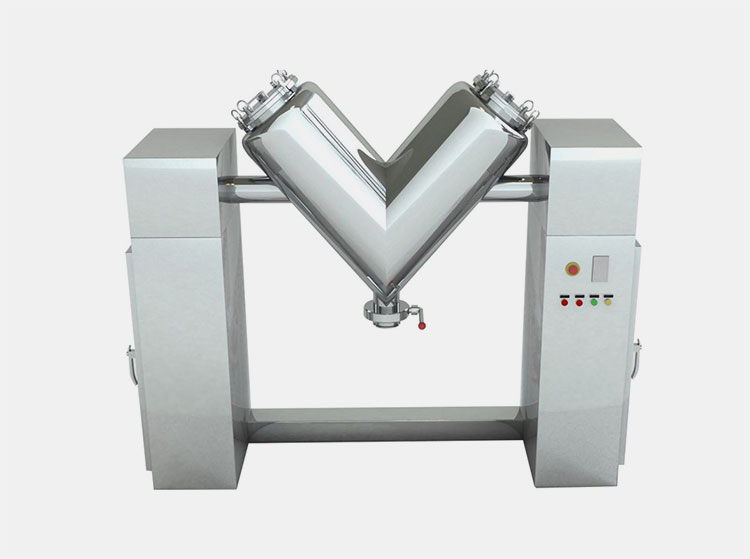

V-Mixer

AIPAK V-mixer

A V-mixer, also called a twin shell blender, is a dedicated unit used for dry mixing of powders and granules. This creates a solid-solid mixture through its characteristic tumbling motion. Structurally, it features a distinct V-shape fashioned by the joining of shells at an inclined angle.

High Shear Mixer Granulator

AIPAK High-Shear Mixer Granulator

By using a high-shear mixer granulator, manufacturers can produce compressible granules. This machine generates intense shearing forces through its rotor-stator mechanism, which consists of impellers and angled blades. These forces are pivotal in grinding, emulsification, dispersion, and dissolution of materials.

Fluid Bed Dryer

AIPAK Fluid Bed Dryer

When it comes to drying and granulation in pharmaceutical manufacturing, the fluid bed dryer has a significant role. It is a one-pot solution as it not only creates granules by mixing powders with liquid binder but also dries them simultaneously.

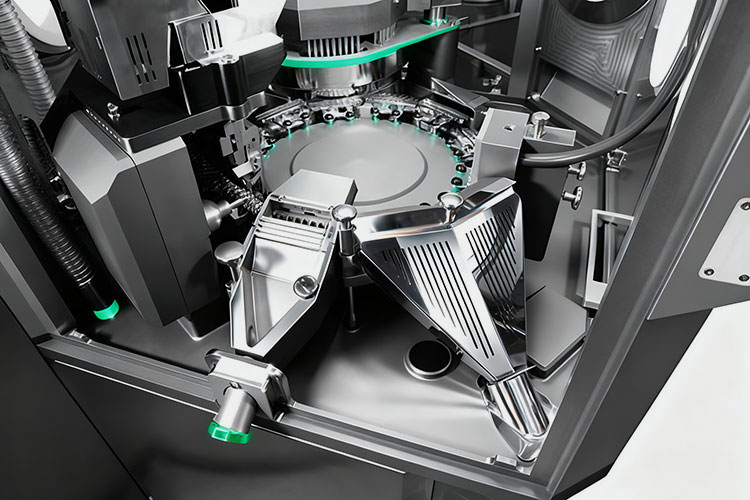

Tablet Press Machine

AIPAK Rotary Tablet Press Machine

With the help of a tablet press machine, the powders or granules are compressed through high pressure and are converted into solid tablets. The movement of tooling (punches and dies) exerts pressure to compact tablets. Based on the level of complexity,

There are two major tablet press types such as ; a single punch press, constitutes one set of tooling (two punches and one die cavity. Therefore, it can produce only one tablet per cycle. On the contrary, a rotary tablet press is a high-speed device built with several sets of toolings integrated radially in a turret. Its production efficiency is several times higher than that of a single punch press; thus, it is integral for mass tablet manufacturing.

Tablet Coating Machine

AIPAK Tablet Film Coating Machine

The tablet coating machine is a sort of auxiliary equipment that applies protective coatings or functional coatings on tablets. These coating substances can enhance the stability and swallowability while also improving the visual appeal and pliability of tablets. The basic types include sugar coating, which coats sugar-based films on the tablets. Here, the spray nozzles periodically release sugar solution that gets coated on the tablet as the rotary pan spins.

In film coating, organic and water-soluble films on tablets, pellets, and granules are applied. In this machine, a spraying solution in atomized form is sprayed through the nozzles on rotating tablets present in the drum. In an enteric coating machine, acid-resistant coating is applied, which allows the targeted and controlled release of ingredients in the intestine.

Packaging Equipment

Packaging machines are a diverse group of systems that are specifically developed for automating packaging processes. They enclose, box, or wrap the products in containers or protective cases to secure them from long shipping, distribution, and retailing. Some basic packaging equipment includes:

Capsule Filling Machine

AIPAK Capsule Filling Machines

One of the most vital systems in the capsule production is the capsule filling machine, as it is involved in the manufacturing of two-piece hard gel capsules. This machine supports manufacturers at every stage of pharmaceutical processing- from R&D to large-scale commercial manufacturing. This is available in manual, semi-automatic and automatic capsule filling machines, which are based on the user’s demand.

Tablet Counting Line

AIPAK Tablet Counting Line

After manufacturing medication, tablet counting line are utilized to secure medicines in bottles. This is composed of six integrated machines. The main function of the bottle unscrambler is to sort, orient bottles. The second unit is a filling machine that counts the number of tablets with a sensory detector accurately. The integrated desiccator inserter places a desiccator in each bottle.

The capping machine ensures caps are applied to bottles using torque, pressure, or both. The induction sealing machine applies firm sealing over each bottle using electromagnetic radiation. A labeling machine is a high-speed device that applies labels to bottles. These labels are affixed in a wraparound manner, on the front/back panel, or top corner, using mechanical pressure or bottle rotation for accurate label placement.

Powder Filling Machine

AIPAK Powder Filling Machine

For accurate, safe, dust-free dispensing of free-flowing and non-free-flowing powders, the powder filling machine is used. This is considered a specialized unit in every pharmaceutical industry and is capable of dealing variety of containers. When it comes to precision and professional results, this top-notch equipment is the solution. Today, this is available as an auger filler, a vacuum, and a net-weigher filler. All related units are compliant with cGMP and ideal for advanced filling of medicated and non-medicated products. Due to its safe, fast, and accurate properties, it is an essential piece of equipment in various other fields as well.

Blister Packaging Machine

AIPAK Blister Packing Machine

A type of primary packaging machine that inserts pills, suppositories, and gummies in cavities made normally of plastic is called a blister packaging machine. The blister cavities are formed by heating and molding devices integrated in this system. After product placement, they are sealed with aluminum foil. Some common kinds of this system in pharmaceutical processing include thermoforming, cold-forming, ALU-ALU, and ALU-PVC blister packaging machines.

Cartoning Machines

AIPAK Cartoning Machine

With the help of cartoning machine, containers are placed into cartons. Normally, this equipment transforms cardboard sheets into three-dimensional, robust boxes by erecting, folding, and sealing them. Product containers are inserted through the sides or from the top of the box. Depending upon the direction of product placement, the types of cartoning machines are horizontal and vertical cartoners.

Semi-Solid Dosage Form

Various types of semi-solid processing equipment are pivotal in dosing semi-solid medications, such as pastes, gels, and more, in different containers for enhanced protection and safety. Here are some principal machines that are a part of these systems:

Vacuum Emulsifying Mixer

AIPAK Vacuum Emulsifying Mixer

To manufacture stable and good quality creams, ointments, lotions, or any formulation with viscous consistency, you must apply vacuum emulsifying mixer. It mainly works under vacuum and high mixing speed. The purpose of using this machine is to attain uniform dispersion of all ingredients in a solution. Also, the equipment processed under eliminates air bubbles consequently there are no chances of oxidation inside the vessel. This is an integral machine used in general manufacturing of medications also with nanotechnology-based medication. Because in such medication critical mixing is particularly important to support target drug development.

Tube filling machine

AIPAK Tube Filling Machine

A tube filling machine has a central place when manufacturers want to fill their gels, creams, ointments, and paste products into the tubes. The working principle of this system is mainly based on the volumetric product dosing that allows brands to dispense a measured quantity of their product into every tube. This device is capable of performing steps, for instance, tube feeding, orientation, product feeding, sealing, coding, and trimming of surplus tube material to have a smooth and appealing tube finishing, and finally ejection of packed tubes.

Suppository Filling Machine

AIPAK Suppository and Sealing Machine

The suppository filling and sealing machine is a unique type of pharmaceutical processing equipment that is used to encapsulate medicated preparations, generally in semi-solid form, into suppository molds or shells. This dedicated system is designed to produce suppositories that are administered in the body cavity, for instance, rectum, vagina, and urethra, and melt at body temperature to release drug substances.

Its working steps constitute melting of base material, mixing of API, adding medications into pre-formed shells, cooling and solidification of filled materials, sealing, demolding, trimming, and discharging. Mostly, it comes in a fully automated form, providing efficiency and precision to productions.

Liquid Dosage Form

The primary purpose of liquid processing equipment is to fill liquid preparations into a wide array of containers.

Oral Type

The oral type of machine is used to fill syrups emulsions, and related formulations such as:

Syrup Filling Machine

AIPAK Syrup Filling Machine

A syrup filling machine is a specialized device that fills syrup formulations and suspensions in diverse types of bottles with precision, speed, and hygiene. Typically, it features volumetric fillers like pistons and pumps that handle accurate product dosing.

This machine normally consists of other key components, including a supply tank, hoppers, filling nozzles, valves, motors, and sensors. During the equipment operation, fluids or semi-solid preparation stored in the hopper are pulled into filling devices by the suction forces and pressure generated by pumps and pistons, and then dispensed into bottles via filling nozzles.

Injection Type

Various liquid formulations for injectables are also known for sterile preparations. Below mentioned are some common sterile & injectable processing equipment:

Vial Filling Machine

AIPAK Engineering Vial Filling and Machine

One of the most widely used equipment in injectable pharmaceutical equipment is the vial filling machine. This machine doses a precise volume of medication in vials with the aid of various technologies, like a piston, peristaltic pump, and time-pressure fillings. It is equipped with multiple filling heads, which boost both flexibility and filling speed.

In addition, this device is also integrated with stoppering and capping systems that work in coordination to securely seal vials. Depending upon the model, this equipment can process everything from small batches to high-speed production capable of dosing hundreds of vials per minute.

Ampoule Filling and Sealing Machine

AIPAK Engineering Ampoule Filling and Sealing Machine

For packaging delicate ampoules, utmost care and dosing accuracy are essential. That’s why the ampoule filling and sealing machine plays a vital part in pharmaceutical manufacturing. This equipment is bespoke to ensure safe, sterile, and gentle handling of medication; consequently, it is indispensable for preserving product integrity.

Similar to a vial filling machine, it doses parenteral drugs using advanced filling technologies, for example, piston or diaphragm pumps. However, instead of stoppering vials, it seals ampoules using a gas flame. The heat melts the glass at the ampoule opening, which is then molded and closed to create a tamper-evident seal.

3.How to Choose the Right Equipment?

Selecting the right equipment is crucial for a smooth transition between planning a project and execution. Manufacturers work in collaboration with the equipment supplier to achieve a successful outcome on the project implementation. In this section, we’ll share some important factors to consider when purchasing equipment:

Factors to consider to Choose the Right Equipment- Picture Courtesy: Trexin

Production Capacity: The production capacity of prospective equipment should align with the intended scale of production. A mismatch between equipment capacity and production needs can result in operational bottlenecks, suboptimal use of the system, and needless costs.

Material Compatibility: Understand the chemical and thermal conditions needed for the operation of the equipment. Ensure the machine is built from compatible materials, for instance, stainless steel, nickel, and aluminum, so that it can endure harsh conditions without breaking down.

Regulatory Requirements: Before finalizing your choice, ensure the equipment complies with all essential quality and safety measures, like GMP, ISO, and FDA. Verifying these requirements safeguards medicine’s safety and efficacy, while minimizing the risk of costly recalls and financial penalties.

Budget: Choosing a machine isn’t just about initial purchase cost. Manufacturers should also allocate considerable budget for ongoing expenses, like maintenance outlays, energy bills, and spare parts. Factoring in these long-term expenses helps in preventing financial stress and allows for a better return on investment.

Importance of Working with Reliable Suppliers

Importance of Working with Reliable Suppliers

Experience and reliability matter greatly when selecting equipment for pharmaceutical processing. A trustworthy supplier not only provides durable and high-performance machines but also holds the necessary certification to show regulatory compliance. In addition, they are recognized for timely delivery and offer continuous post-sales services, such as training, spare parts availability, and repair assistance.

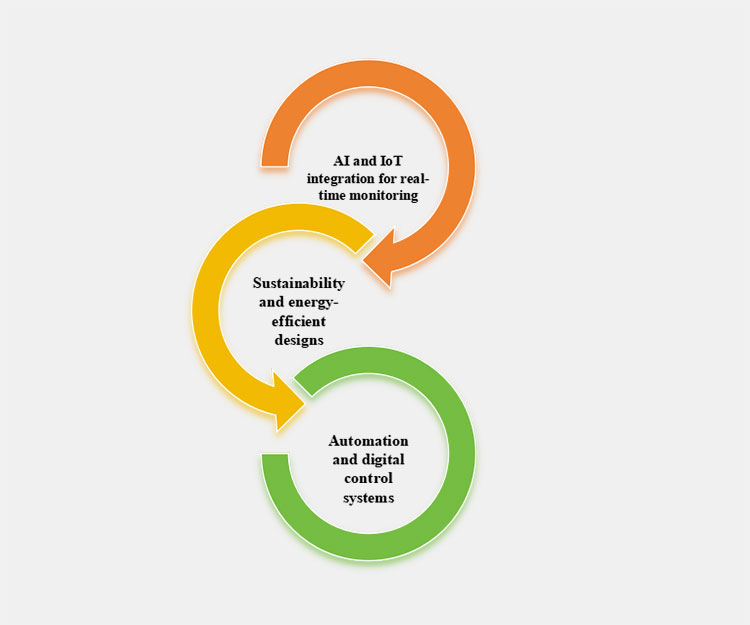

4.What are the Latest Trends in Pharmaceutical Processing Equipment?

The pharmaceutical processing industry is continuously growing with effective and innovative trends. Some of the latest trends are mentioned below.

Latest trends in pharmaceutical processing equipment

Automation and digital control systems

Automation and digital control systems in pharmaceutical manufacturing have transformed the traditional methods of manufacturing to optimize efficiency while mitigating the potential risk of human error. Integrated digital technologies have consequently elevated quality assurance and cost-efficiency. However, these innovative trends require strict regulatory compliance, involve increased expenditure, and skilled personnel for the effective deployment of systems.

AI and IoT integration for real-time monitoring

AI and IoT incorporation in manufacturing systems allow real-time monitoring and predictive modeling analysis. The IoT mechanism enables immediate monitoring of critical parameters of the equipment such as pressure, temperature or humidity. The AI integration in pharmaceutical processing equipment allows risk prediction and assessment in real time to avoid downtime. Effective implementation of these systems optimizes continuous manufacturing and improved product integrity.

Sustainability and energy-efficient designs

By keeping in view the environmental impact, pharmaceutical manufacturers are incorporating eco-friendly and energy-efficient modified designs. Latest pharmaceutical equipment is designed with strong focus on sustainable materials, enhanced energy utilization and strategic implementation of waste management. These methods are required as they reduce carbon footprint, comply with regulatory requirements and perfectly align with sustainable goals worldwide without compromising production quality.

5.What are the Applications Across Industries?

Types of pharmaceutical processing equipment applications

The application of pharmaceutical processing equipment is not limited to the manufacturing of conventional therapies. Rather, these machines have proven useful in a variety of healthcare sectors, such as:

Pharmaceuticals: There is no compromise on the precision, safety, and quality of pharmaceuticals, as the health of patients depends upon it. The pharmaceutical processing machines, from mixers to granulators, tablet presses, and encapsulation machines, are integral in ensuring regulatory compliance and maintaining batch reproducibility.

Nutraceuticals & Dietary Supplements: It is imperative that nutraceutical & dietary supplements have appealing colors, finishing, appearance, and flavor profile to promote patient adherence. To achieve this, nutraceutical brands rely on capsule fillers, tableting systems, coating & polishing equipment. These systems guarantee an attractive product look, precise dosing, and high productivity.

Herbal Medicine: It is easier to take herbal pills rather than grinding and mixing them at home. So, to support the conversion of traditional remedies into standardized doses, modern pharmaceutical machinery is vital. This meticulous operation ensures stability, safety, and optimal shelf-life of products.

Veterinary Medicine: Just like the preparation of human medications, the manufacturing of veterinary medicines also requires the application of specialized pharmaceutical instrumentation. Mixers, solid dose equipment, filling, coating systems, and more aid in developing products tailored for animal use in the veterinary sector.

Conclusion

In today’s continuously evolving world of pharmaceutical manufacturing, it is crucial to choose the right pharmaceutical equipment. This strategic investment not only boosts operational efficiency but also maximizes return on investment. Advanced processing machines, from mixers to packaging machines, ensure product safety and quality and market competitiveness by maintaining uniformity across every batch and minimizing contamination risk. For more information and purchase inquiries, click here to connect with AIPAK. Our dedicated customer representatives are ready to assist you.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine