PLC inspection function

The filling part with removing static electricity system

Stirring barrel speed adjustable system

Cooling speed adjustable system

Shearing granules quantity will be working through adjustable system

Want A Free Consultation

SJ-7L High Speed Automatic Suppository Filling Production Line

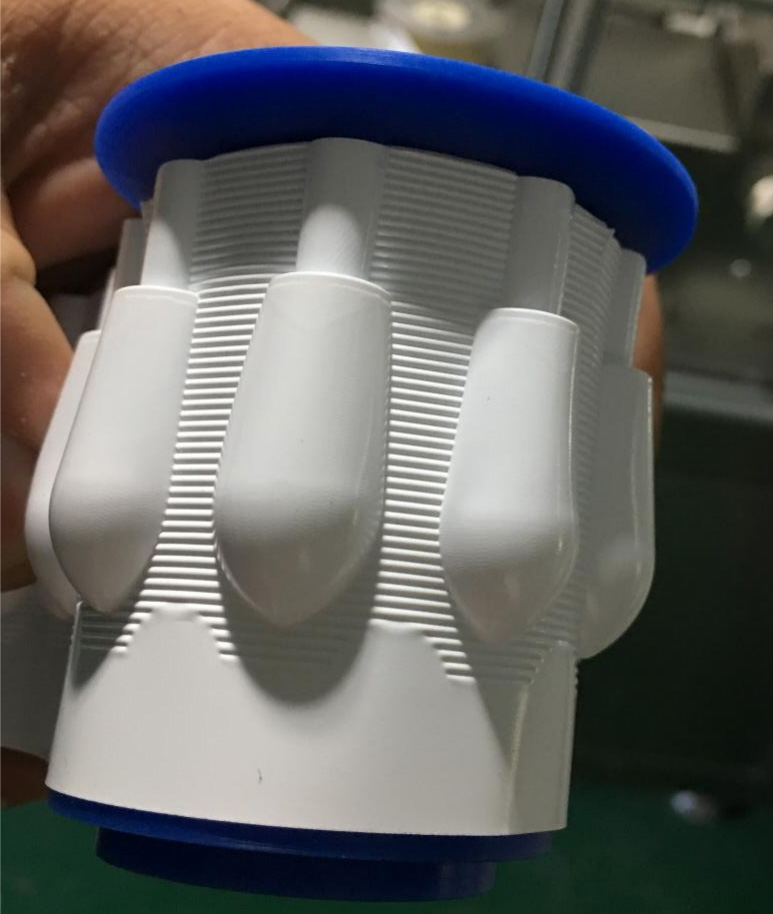

AIPAK SJ-7L automatic suppository filling production line has a stable and efficient manufacturing process, filling, freezing, sealing and other production processes to complete the whole process, and the production capacity is 10,000-12,000 grain/hour.It is suitable for the production of special shape such as bullet head, torpedo shape and duck bill, to meet the production of your suppository. (according to the specifications of your specifications).

The equipment adopts PLC programmable control and man-machine interface operation, easy operation, convenient adjustment, accurate temperature control and smooth operation.

The temperature sensor and microcomputer control system are used to realize high precision thermostatic control.

The liquid storage tank is made of 316L stainless steel, with proper volume, heat preservation and heating function, and accurate temperature control; The tank is equipped with a mixing device to ensure the homogeneity of the liquid in the VAT at any time. The reservoir can be connected with the filling mechanism through the pipe, and the liquid can be kept in circulation to ensure the fluidity of the liquid and satisfy the demand of filling.

The insertion type linear perfusion mechanism can be used to locate accurate, not dropping, and not hanging wall.

The single-grain measurement is 0.5-5g and the filling error is plus or minus 2%.

With continuous cooling design, the post-infusion suppository shell can be fully cooled and the liquid solid transformation is realized.

3Continuous strip, continuous sealing, sealing process batch number self-printing; The sealing seal should be well sealed, with neat appearance and good value of not less than 99.99%.

5 Advantage s of AIPAK Suppository filling machine

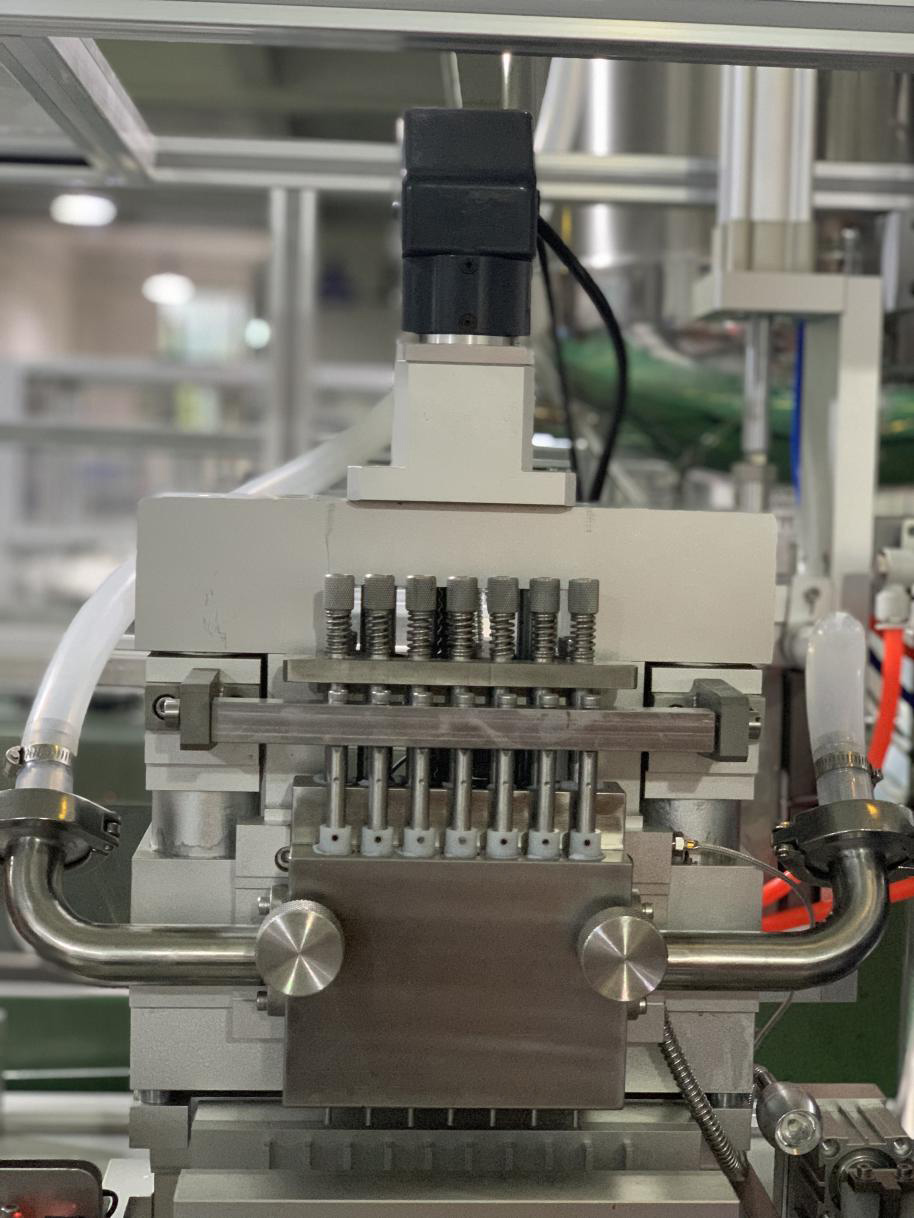

1.High Accuracy of Filling(Patent technology)

Servo high precision filling system, PLC touch screen control filling volume, filling action, filling volume for servo control, filling precision, convenient, instead of the previous manual adjustment of filling volume. Filling piston by servo motor with stroke rule, easy to observe, stable action, no jitter and splash phenomenon, load online adjustable, high precision and easy to adjust!

The plunger pump body is treated with special technology to make the sealing performance between the filling piston and the pump body better and the infusion dosage more accurate.

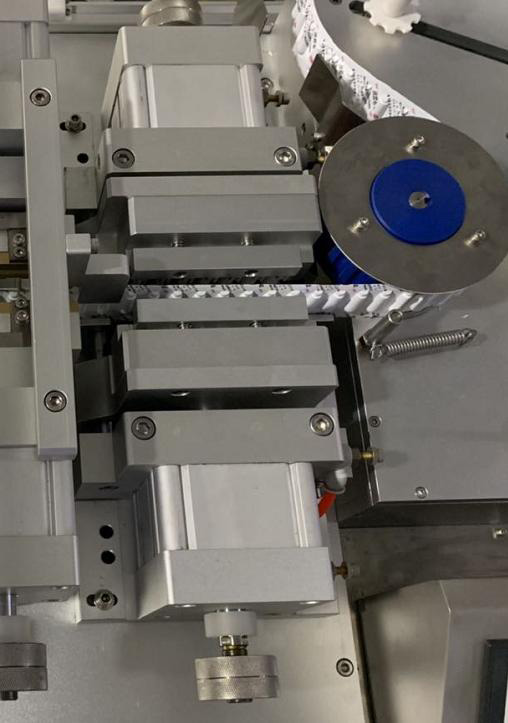

2.Combination structure of triangle knife and dot line knife(Patent technology)

Make the both of triangle and the dotted line knives completely coincide, make the bolted shell achieve the easy tear effect.

3.Shearing system(Patent technology)

Instead of the tedious manual adjustment, the shear number can be completed by adjusting parameters of the touch screen, convenient operation, accurate positioning, stable operation and efficiency.

4.Circulating cooling system(Patent technology)

The cooling system of this machine adopts the latest circulating water cooling technology, which can solve the phenomenon of slag falling off and easy fracture when the medicine is torn apart. The temperature is adjustable.

.exclusive circulation of water cooling system advantages of thick tail edge, tear off residue.

.the cooling system of the wheel is to turn to the suppository shell of the neck, not injury bubble, not pin belt. Wheels can be manually synchronized adjustment function.

.exclusive circulation of water cooling system advantages of thick tail edge, tear off residue.

.the cooling system of the wheel is to turn to the suppository shell of the neck, not injury bubble, not pin belt. Wheels can be manually synchronized adjustment function.Cooling track can adjust the distance between tracks according to the size of several different specifications.Cooling track can adjust the distance between tracks according to the size of several different specifications.

5.Sealing shear preheating(Patent technology)

The cooled solid suppository enters the sealing area: heating sealing mold (sealing) marking mold (batch number) hob (trimming the top) counting shear.

6.Mixing drum speed regulating system

Due to the different viscosity of the drug matrix, it may be impossible to immobilize the stirring effect to make the drugs evenly mixed before filling, thus affecting the drug content of the finished suppository.

7.PLC detection function

PLC online monitoring function can be used to alarm the operation failure and synchronously display the cause of failure for the convenience of timely troubleshooting operators.

8.The filling part is equipped with an electrostatic removing system

If the device is not included before the molding empty shell arrives at the filling site, the sealing quality behind the device will be affected because the upper part close to the plug shell will climb a short distance along the inner wall of the empty shell under the action of electrostatic force during the micro drug filling.

9.The filling part has no hanging wall

The filling pump body of the equipment has high precision, good sealing effect, smooth inner wall and good stability

And achieve long-term operation without hanging wall phenomenon.

10.It is easy to operate

Control station height reasonable design, simple operation of the machine.

FEATURE

1.The equipment adopts PLC programmable control and man-machine interface operation, easy operation, convenient adjustment, accurate temperature control and smooth operation.

2.The temperature sensor and microcomputer control system are used to realize high precision thermostatic control.

3.The liquid storage tank is made of 316L stainless steel, with proper volume, heat preservation and heating function, and accurate temperature control; The tank is equipped with a mixing device to ensure the homogeneity of the liquid in the VAT at any time. The reservoir can be connected with the filling mechanism through the pipe, and the liquid can be kept in circulation to ensure the fluidity of the liquid and satisfy the demand of filling.

4.The insertion type linear perfusion mechanism can be used to locate accurate, not dropping, and not hanging wall; The single-grain measurement is 0.5-5ml and the filling error is plus or minus 2%.

5.Continuous cooling design, the post-infusion suppository shell can be fully cooled and the liquid solid transformation is realized.

6.Continuous strip, continuous sealing, sealing process batch number self-printing; The sealing seal should be well sealed, with neat appearance and good value of not less than 98%.

7.Simple and reasonable design, convenient operation and maintenance.

DATA SHEET

|

Commodity |

Full automatic suppository production line |

Model |

SJ-7L |

|

Output |

10,000—12,000 pcs/h |

single dosage |

0.5—5g |

|

Dosage allowed |

<±2% |

Packaging Film |

PVC\PE (thickness0.15-0.18mm) |

|

Stirring tank capacity |

70L |

Air pressure |

≥0.7Mpa |

|

Air consumption/min |

1.5m3/min |

Water consumption/h |

50kg (recycling) |

|

Working voltage |

3 phase 380V |

total power |

7.5KW |

|

Adopt forming shapes |

Bullet, torpedo and other shapes |

Machine Weight |

2000KG |

|

Adapt Material |

Synthetic fatty acid glycerol, glycerin gelatin, polyethylene glycol etc |

Each distance of suppository |

17.4mm |

|

Overall dimensions |

L5,967mm×W1,648mm×H1,819mm |

||

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586