Kinder Joy Machine:The Complete FAQ Guide In 2024

Kids always love surprises- most often unwrapping is the best feeling for them. Many of them are anticipated to find what’s inside is much important than a gift!

Michele Ferrero invented the Kinder Joy egg who has capitalized on this creative urge for nearly 50 years now. Today, kinder joy has meant to provide a fun twist in the sweets industry. Kinder joy machine is well-acknowledged equipment that enclosed a rich taste of delicious chocolate in a unique colorful egg.

If you are interested to know more about the kinder joy machine- then we suggest you read this comprehensive blog. Here, you will explore the history, applications, structural, mechanical features of the kinder joy machine, and a lot more.

1.What is kinder joy?

Kinder joy is a candy, manufactured by an Italian confectionery industry “Ferrero”. It is similar to Kinder Surprise Eggs, the only difference is that the egg is divided into two halves that are opened with a tab, each half is individually sealed. One half contains a surprise toy and the other contains milky cream and cocoa cream in two layers and two balls of hazelnut wafer. The idea of toy surprise is very popular among children, and it is sold globally.

2.How does kinder joy originate?

Confectionaries and food industries always try to attract kids by providing products with fun packaging, attractive colors, and shapes; although the ingredients are essentially the same, however, they modify their presentations styles.

The relatively new concept of adding fun or surprises in sweets, candies by combining them with toys has grown from one form to another and faced criticism during its development.

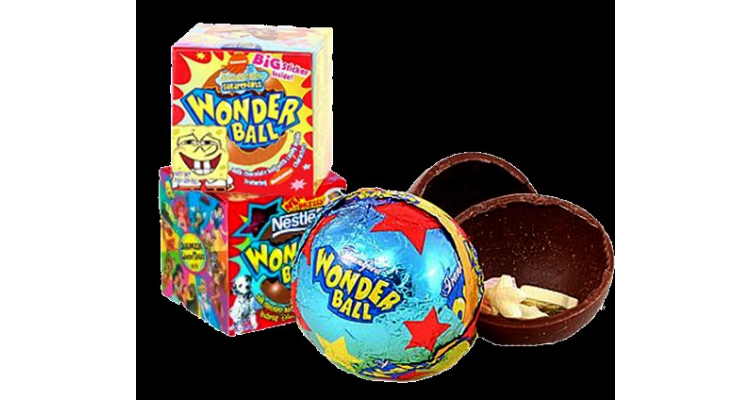

Magic ball, introduced by Nestlé in July 1997. It is a chocolate-coated capsule with a surprise toy inside. This product faced severe criticism from U.S. FDA and was soon withdrawn from the market due to likely choking hazards in children.

Kinder Joy Machine

The product was reintroduced as Wonder Ball by Nestlé in 2000, with slight modification. Wonder Ball was filled with candy pieces instead of toys, however soon in 2004 this brand was sold to Frankford Candy Co. since the product was not satisfying nutrition guidelines introduced by Nickelodeon (a licensing agency), therefore it was discontinued in 2007.

At that time, Ferrero Group was leading the worldwide market of surprise-inside confectioneries with the annual sales of Kinder Surprise Eggs reported up to 3.5 billion with a steady increase in demand leading to the growth of confectionery industries.

The extraordinary increase in sell was noticed after the introduction of Ferrero’s Kinder Joy in the United States in 2017. Ferrero group generated profit up to $153.8 million with the sale of Kinder Joy in just a few months, also it became the focus of a huge chocolate market. However, Kinder Joy was banned in the U.S. by federal law in 2018, which disqualifies all food products with non-nutritive substances.

Kinder Joy was first introduced in Italy (2001), then the market grew globally, and sell was started in Spain (2004), in Germany (May 2006), in India and China (2007), in Ireland (2015). The product was highly appreciated in China due to its high sales and honored with Nielsen China’s Breakthrough Innovation Award.

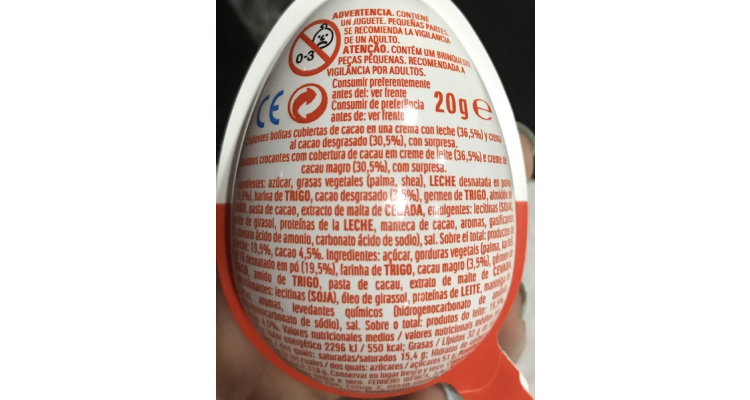

3.What are the ingredients of kinder joy?

Kinder Joy is not just candy but a yummy and exciting double treat for kids, it fills one hand with essential nutrients and on other hand, it makes them imaginative, creative, and happy.

Ingredients:

The manufacturing of Kinder joy follows standard quality and hygiene procedures combined with the best quality raw ingredients and milk without additional additives and colors.

Essential ingredients are:

- (19.5%) Cow Milk

- Sugar

- Edible Vegetable Fat

- Sunflower Seed Oil (High Oleic Acid)

- Palmolein

- (4%) Low-Fat Cocoa Powder

- Eggs

- Coconut

- Baker’s Yeast

- Salt

- Whey Powder

- Emulsifier (Lecithin)

- Palm Oil

- Raising Agents (Ammonium Carbonate, Sodium Bicarbonate)

- Lemon Juice

- Glazing Agents (Gum Arabic and Shellac)

- Thickening Agents (Tara Gum)

- A drop of poly floral honey possess mild flavor, aroma, and light color

- High-quality cereals are used in appropriate amounts to enhance aroma, flavor, and crispiness in Kinder joy. Commonly used cereals include Wheat Starch, Barley Malt Extract (powdered form), Wheat Flour, Toasted Wheat Germ, Rice, Spelt, Barley, and Buckwheat.

Nutrition Value:

Serving size per unit of kinder joy is usually (20g), equivalent to 109 kcal energy which contains nutrients.

- 3 g Carbohydrates

- 2 g Sugar

- 6 g Protein

- 4 g Fat

- 1 g Saturated fat

- 06 g Trans-fat

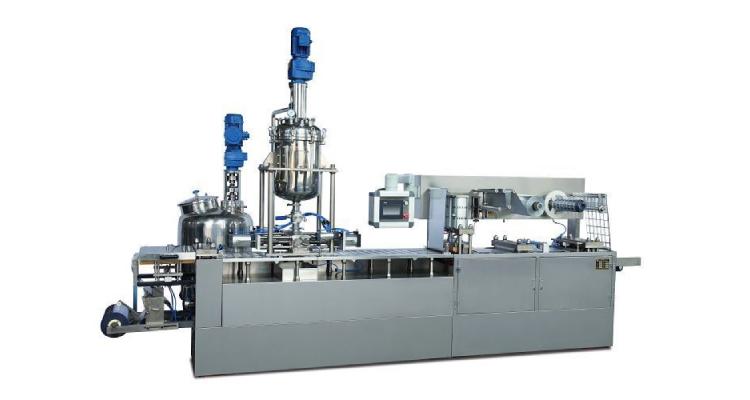

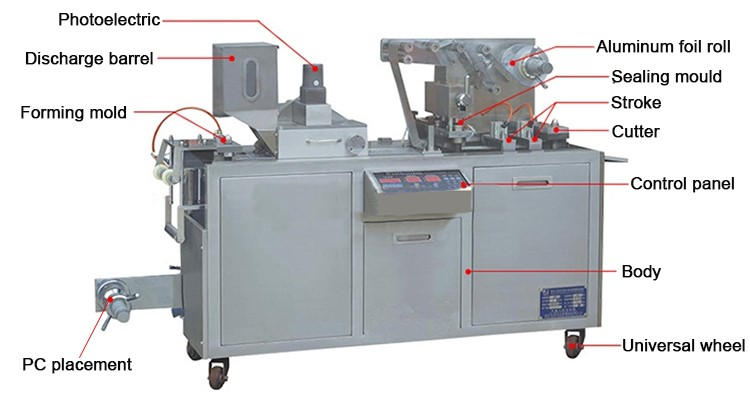

4.What is a kinder joy machine?

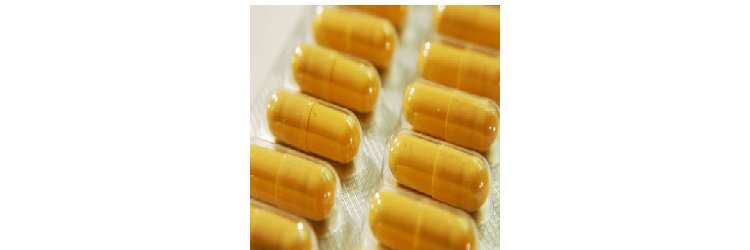

Kinder joy is packed by a special type of blister machine used for packaging tablets, capsules, lozenges, etc. as unit dose packaging. Kinder joy packaging machine contains structural cavity of or pockets of formable film by thermoform, aluminium or plastic to seal assign materials. This machine has both movable and stationary part that imparts in packing and sealing of products in pre-formed pockets.

Some important points about kinder joy machine are as followed:

- Kinder joy machine is automated with conveniently approachable control panels. It is easy to set parameters in it as per protocol requirements and monitor the operation to ensure that the quality of each packaged product is consistent.

Kinder Joy Machine

- This machine is equipped in a way that it can be easily connected with other equipment of the production line.

- Kinder joy machine is durable, made with robust materials, therefore, withstanding high temperatures and mechanical vibrations generated during operation.

- Satisfy all regulatory guidelines of the manufacturing process. Sophisticated design protects the user from any harm. Easy to clean and maintain.

Features:

- Four Main Stations for Packing Process

Four stations are provided in the machine namely indentation, sealing, cutting, and forming. All of them are fixed with four vertical columns for smooth and stable running of the operation. - Universal Feeder

There are also a universal feeder enables feeding of all types and shapes of goods such as capsules, flat, triangular, round tablets, lozenges, candies etc, which can attain a feeding rate higher than 99.5%.

- Light-weight Machine

The machine is lightweight (up to 2000 Kg) and the size is not much big and available in various categories such as automatic, semi-automatic and manual.

Kinder Joy Machine

- Stroke

Stroke, is adjustable in the range of 30-100mm. - Frequency Regulation

Stepless frequency to regulate the speed. Also, variety of feeders available as per product requirements.

5.What is the working principle of a kinder joy machine?

Kinder joy machine is generally categorized under blister packaging machine which is available in following models.

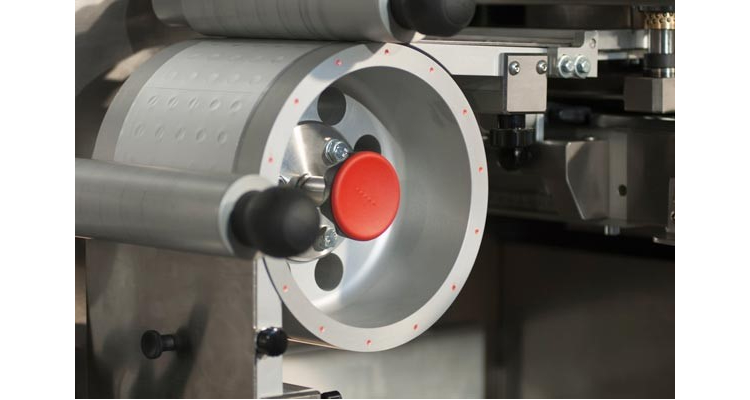

Roller Type Kinder Joy Packing Machine

- Roller-plate type kinder joy packing machine, also available in high-speed, low-speed, and medium-speed models.

- Flat-type kinder joy machine

- Roll-Plate Kinder Joy Packaging Machine

The working principle of each type is slightly different from one another.

- Roller Type Kinder Joy Packing Machine:

- Heating and softening of the forming film with the help of the heating device.

- Subsequently, the blister is drawn out to form a die roll due to negative pressure induced by a vacuum on the roller.

- The desired packaged material is filled into the blister with the help of a filling device.

- The packaged material is then sealed into the blister with the help of a heat-sealing device. Adhesive coated cover film is sealed at the top of blister material at appropriate pressure and temperature.

- Finally, with the help of an embossing and typing device, the batch number and brake line are punched/printed onto the desired part of a sealed blister.

Kinder Joy Machine

- Flat Plate Kinder Joy Packing Machine:

- Heating and softening of the forming film with the help of a flat heating device.

- Subsequently, compressed air carried this softened film into a blister in a flat molding device.

- The desired packaged material is filled into the blister with the help of a filling device.

- The packaged material is then sealed into the blister with the help of a flat plate sealing device. Adhesive coated cover film is sealed at the top of blister material at appropriate pressure and temperature.

Flat Plate Kinder Joy Packing Machine

- Finally, with the help of an embossing and typing device, the batch number and brake line are punched/printed onto the desired part of a sealed blister.

- Roll-Plate Kinder Joy Packaging Machine:

The working principle of the roll-plate type is similar to the above two types. It is considered as the combination of flat-plate and roll-type because positive pressure molding is carried out by a flat-plate molding device and sealing is performed by the roll-type sealing device.

6.What is the kinder joy making process?

The production of Kinder joy is a stepwise process that required the involvement of many parts or stations/areas of the egg packaging machine. It follows the track of egg packaging machines which are mentioned below.

1.PLC Human Interface: There is a program installed inside which helps in changing data conveniently.

- Forming Station: At this point, bubbles of a variety of shapes are formed according to client requirements.

- Sealing Station: This stage is used to seal the foil with a newly formed blister sheet. Printing of batch number and date is optional.

- Chocolate Feeding Device: At this stage, chocolate milky solution or paste or creams are efficiently filled into the kinder joy egg.

- Manual Feeding Area: Biscuits or toys are added by hand into the kinder joy blister in kinder joy packaging area.

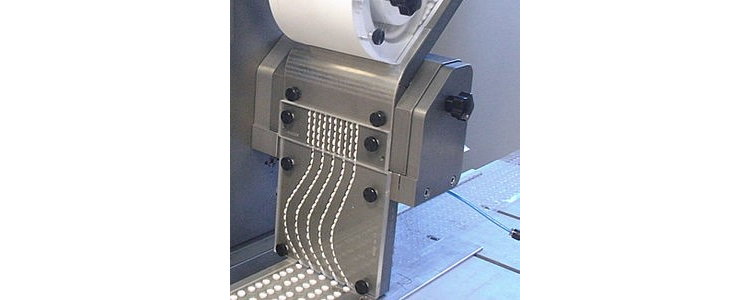

- Servo Dragging and Cutting Station: This station is used to drag the newly formed blister sheet and cut it accordingly in order one by one.

Kinder Joy Making Process

7.What are the industrial applications of kinder joy machines?

Kinder Joy Machine

Kinder joy machine design, operation, application, and appearance are similar to the machines used in the packaging department of pharmaceutical, chemical, cosmetic, and food industries.

- Food Processing Industry:

Kinder joy machines can be used for packaging and protecting fresh, frozen food, raw food ingredients, confectionaries from contamination and spoilage.

- Chemical Industry:

Chemicals are mostly harmful to living organisms in a healthy state so it is better to keep them properly packed and sealed using this type of machine.

- Pharmaceutical Industry

Kinder joy machines like blister packaging machines can be used for packaging tablets, capsules, and granules, etc.

- Cosmetics Industry

This type of machine can also be used in the efficient packaging of different sorts of cosmetic products.

8.What are the benefits of a kinder joy machine?

Kinder joy machine packaging offers a wide variety of advantages which include the following.

- Protection:

- It protects the nutrients in candy from oxygen, toxins, light, and dampness.

- Facilitate their long-term storage and management in retail stores.

- It helps in increasing the shelf life of both candy and toys in Kinder joy.

- It's packaging in two individual sections gives a pleasant visual effect and in addition, this packaging style is a source of happiness for kids.

- Freshness:

It offers unit packaging therefore if candy or toy gets spoiled/broken in one kinder joy, it will not affect other units. Additionally, it is advantageous in terms of profit, because if one piece is spoiled it will not affect the sale of other pieces like it happens to those companies which sell large numbers of candies in one bottle.

- Ease of Transportation:

The big ease it offers in transportation is because each piece is efficiently sealed and protected. It makes the distribution convenient from the manufacturer to different suppliers and finally to market.

- Protection from excessive eating:

Because kinder joy is in unit packaging, it gives parents advantage of serving desired quantity to their kids. It protects children from excessive eating, hence, protects their health.

- Advertisement:

The target audience of kinder joy is children and their parents. Food products made for children require soft and attractive packaging, fun with taste, an appearance that can increase their appetite and have a positive impact on their health.

Kinder joy satisfies all these requirements, as it comes in multiple colors with cartoons on it, clear text, and a delicious taste. In addition, a surprise toy is a plus treat for kids.

So, we can say that kinder joy machine packaging is a big benefit for the manufacturer because it increases the market value of kinder joy and ultimately the company’s profit.

- Cost-effective:

Kinder joy packaging uses printing on plastic material which is relatively cheaper than glass or aluminium material. Additionally, printing gives the advantage of presenting more and clear information at less cost.

- Customization:

Kinder joy packaging is quite flexible in choosing different colors, shapes, sizes, cartoon images, and presenting information to the customers and can be conveniently optimized.

9.How is kinder joy packaging made step by step? How does kinder joy or blister packaging machine work?

The kinder joy packaging process require following steps:

1.Pre Heating: a heating station which is present in thermoform of kinder joy machine enables heating by infra-red heaters or contact heater. It is used on blister material.

2.Forming: Material is heated which make them soft to form pockets of cavities for filling material

3. Filling: Loading: here product is filled into pockets of blister cavity automatically or manually.

4. Sealing: Lid is sealed on to filled cavity using heat as well as pressure.

5.Finishing: embossing, perforation and cutting of each unit is done at this stage.

10.What are the possible problems with the kinder joy machine? How to resolve them?

Some problems are commonly observed in the kinder joy machine or PVC blister process.

- Groove formation:

This issue may arise due to the following reasons;

- Inefficient suction due to inappropriate pressure and temperature.

- Amount of glue is used in insufficient quantity hence, less glue penetration through the plate.

- Preheating for softening film and molding time were insufficient.

- Heat-sensitive glue is used.

Solutions:

The groove foaming problem can be resolved in the following ways.

- Use of high-quality plates

- Rising preheating or molding time and temperature

- Cooling (prior to removal of vacuum) at room temperature or nearly above it just after molding may help.insufficient absorpition in edge or shrinkage

- insufficient absorpition in edge or shrinkage

It may arise due to the following reasons:

- Irregular temperature

- Heat sensitive glue

- Removal of pressure immediately after molding at high temperature may cause edges deformation.

Solutions:

- Vacuum, or high temperature pit or dent in product surface

- Cooling (prior to removal of vacuum) at room temperature or nearly above it just after molding may help.

- pit or dent in product surface

It may arise due to the following reasons.

- Large glue size and thin PVC film may cause even pitting.

- Uncleaned plate surface due to surrounding dust may result in uneven pitting of varying sizes.

- Highly viscous glue and irregular dispersion of glue.

- Less viscous glue may cause pitting in the corner side of the groove.

- Insufficient air pressure and bad

- Impure glue (not efficiently filtered).

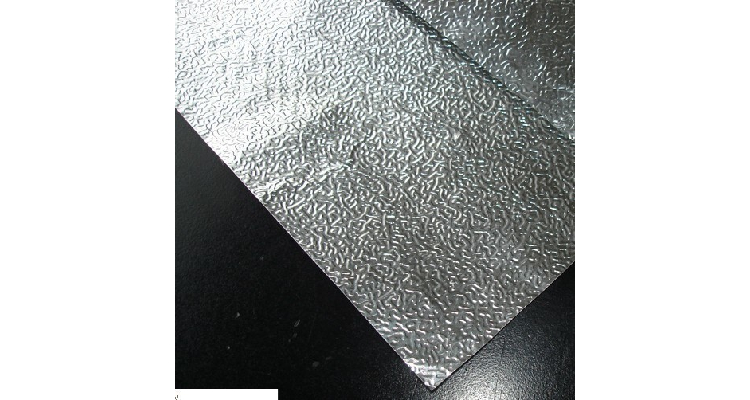

PVC film

Solutions:

- Use glue having small and uniform particle sizes.

- Complete dispersion of curing agent is essential if using it in the process.

- Proper cleaning of the plate surface prior to spraying and spraying workshop should be separated as a precautionary measure.

- Glue with desired viscosity.

- Polishing of glue after drying with ultra-fine sandpaper.

- High vacuum

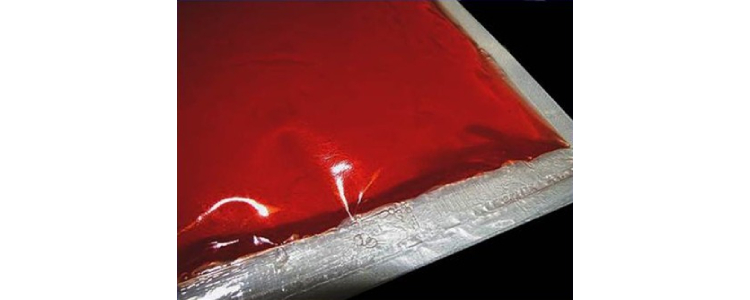

- Local orange peel:

It may arise due to the following reasons.

- Excess glue spray

- A grease on the plate surface may cause contracted holes in the glue.

- Incomplete dispersion of curing agents may result in a contracted cavity.

Orange Peel Texture

Solutions:

- Even spraying of glue in the desired amount.

- Clean plate surface

- Complete dispersion of curing agent

- Fold:

It may arise due to the following reasons.

- High temperature

- Desired pressure attains in a long time

- The back surface of the packaging is not neat, that is the edge angles are not finely chamfered.

- Improper sealing at edges:

Sealing Defects Of Kinder Joy Machine

It may arise due to the following reasons.

- Low quality or expired glue or may not be stored properly as per recommendation.

- High activation temperature of the glue.

- Temperature is less than required for the sealing of the edges of the packaging.

- Impaired spraying of glue.

- Irregular angle due to broken edge:

It may arise due to the following reasons.

- Temperature difference, (sometimes reaches to very high or sometimes very low)

- Poor quality film for packaging

- Poor adsorption:

It may arise due to the following reasons.

- Very thin and irregular coating.

- Temperature is less than required for heating and sealing.

- The appearance of ink crystals on the printed surface of the packaged product.

- Expired oil.

Solution:

- Optimize roller performance and coating process.

- Oiling of the substrate, if it does not work then use fresh substrate.

- Rising the sealing temperature.

- Use of fresh substrate or rise the coating amount.

- Before applying blister oil, there is a need to wipe the printed area on the surface of the packaging or dilute it with 5% lactic acid.

- Use fresh absorbent oil.

11.No luster on the packaged surface:

It may arise due to the following reasons.

- Insufficient coating and poor-quality absorbent oil.

- The absorbent oil is highly fluid hence, the coating is too thin.

- High dilution and contamination of unwanted solvents.

- Highly viscous solutions

- Insufficient drying temperature

Solution:

- Increasing the coating amount may work.

- Avoid the use of the diluted solution.

- Optimization of drying temperature.

For a good Kinder joy manufacturing, try to optimize one process step at a time, resolution of all issues together may reduce the chance of identifying the real problem.

12.What are the essential steps for cleaning and maintaining the kinder joy machine?

Kinder Joy Machine

Guidelines for Cleaning:

It is important to clean the Kinder joy machine properly if you want to use it for maximum productivity and increase its life.

Please see the guidelines below that can help you to clean it by yourself. Alternatively, you can appoint professional staff for it.

- Make sure that you have switched off the machine before proceeding with cleaning.

- Remove all unnecessary items or materials, foil pieces, scraps if present inside or outside of the machine.

- Use large polythene bags to cover the machine and transfer it to the washing area.

- Use purified water to clean label and all parts at least twice to attain maximum hygiene.

- Clean slowly and use a tidy cloth to wipe extra water.

- All machine parts should be cleaned properly by a compressed air jet and rubbed carefully by a clean cloth.

- Alternatively, use a solution that is available in the market-specific for removing scarps on the machine parts followed by wiping by a dry clean cloth.

Guidelines for Maintenance:

Kinder joy machine produces products on large scale, therefore, to maintain products quality and consistency it is essential to maintain the equipment regularly, particularly when it is used for prolonged operations.

- To avoid detachment of any part during operation, it is necessary to routinely check the bolts of all parts .

Kinder Joy Egg Chocolate Packing Machine

- Follow the guidelines mentioned above for routine cleaning (before and after the process) and if you are not using equipment then at least in a month. Strictly follow the rule that after cleaning there will be no water/moisture left on the equipment to avoid electric mishaps.

- Lubrication of all parts is necessary to avoid rusting. You may use oil specific to this purpose. Also, make sure that during greasing not a single drop of oil is left on the belt.

13.What are the future trends of kinder joy machines?

Technology advancement in machine engineering is rapidly evolving to meet the fast-growing world population. There is also some innovation seen in Kinder joy-type packaging machines. These advancements continuously increase production and improve quality.

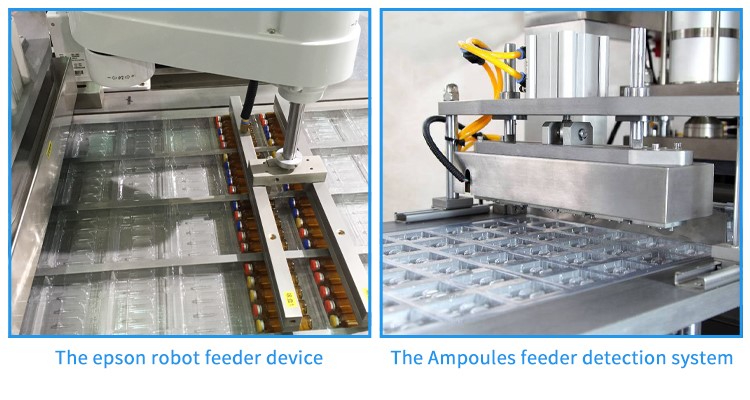

a.Artificial Intelligent Machines:

Nowadays, bundling machines which were more annoying previously are much shrewder and savvier.

Some examples include high-speed blister packaging and automatic cartooning machines that have more advanced feeding systems.

b.Advancement in the design of the Machine

- Advanced purification/filtration system in packaging machine helps in improving the product quality by reducing contamination.

- The latest packaging equipment is more integrated and flexible for operation.

- The machine is compatible with performing other similar tasks. It can deliver a wide variety of different items and can be used for multiple operations.

14.What are mandatory consideration points before buying a kinder joy machine?

Here, is the guidelines about why you should spend a huge amount on buying it and what you should consider when buying this equipment for your industry.

i) Features that attract:

- Light in weight, convenient transport, and installation.

- Advanced purification system protects product efficiently from contamination.

- Protect product from humidity.

- Cost- effective

- Safe and easily maintained.

Provides efficient sealing

ii) Design:

- The design of the machine should be advanced enough to improve the working of the machine and its adaptability.

- The machine should provide simple and fast operation.

- Should have an efficient system of thermoforming and cooling.

iii) Machine Automatic System:

- The machine should be automatic, can perform maximum functions without human involvement, and has a conveniently accessible control panel.

- Should produce all products with uniform consistency.

- Should have sensor system to ensure process uniformity and effectivity. For example, cameras, temperature detectors, movement sensors are provided to improve the quality of packaging and productivity.

iv) The Drive System:

It is the fundamental component of the machine. The machine must have an easy system to modify the speed of the process. The machine must have the feature of packing products in different shapes, filling and sealing desired items, and finally cutting each product unit independently.

Conclusion

With a rapid increase in demand for kinder joy packaging for food, pharmaceutical, and cosmetics manufacturing units, there has been a growing need for packaging systems that ensure your product safety.

You always require a kinder joy packaging machine not only to save your product but for tamper evidence also. Hence, this machine is an advanced tool that complies with protection, accuracy, and efficient handling that will directly encourage customer satisfaction and boost your business.

Blister Packaging Machine Related Products

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours

It may arise due to the following reasons.

It may arise due to the following reasons.