Your Best Industrial Gummy Depositor Machine Supplier

Servo Single&Double Head Depositing

Controlled Depositing Speed

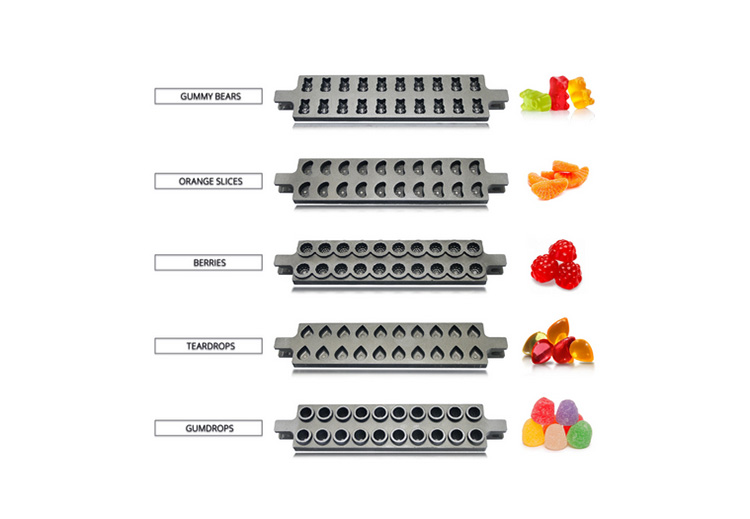

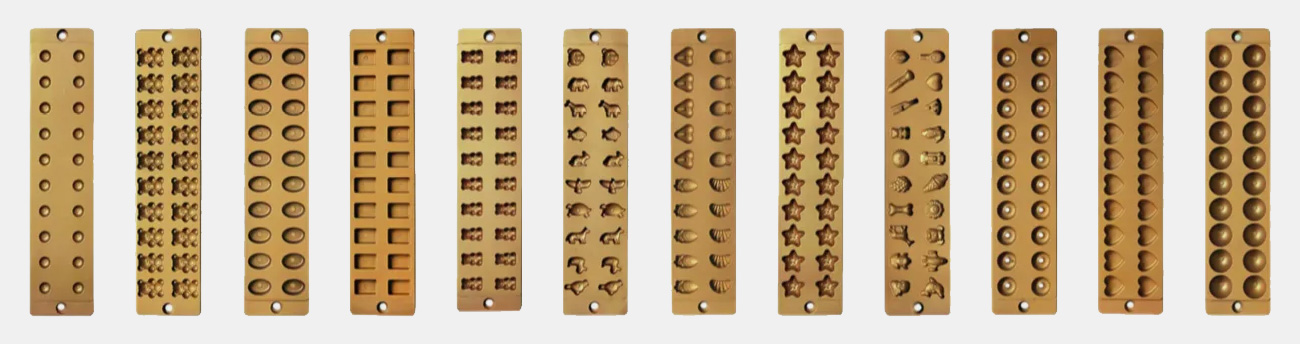

Customized Gummy Molds

Why Choose AIPAK Gummy Depositor?

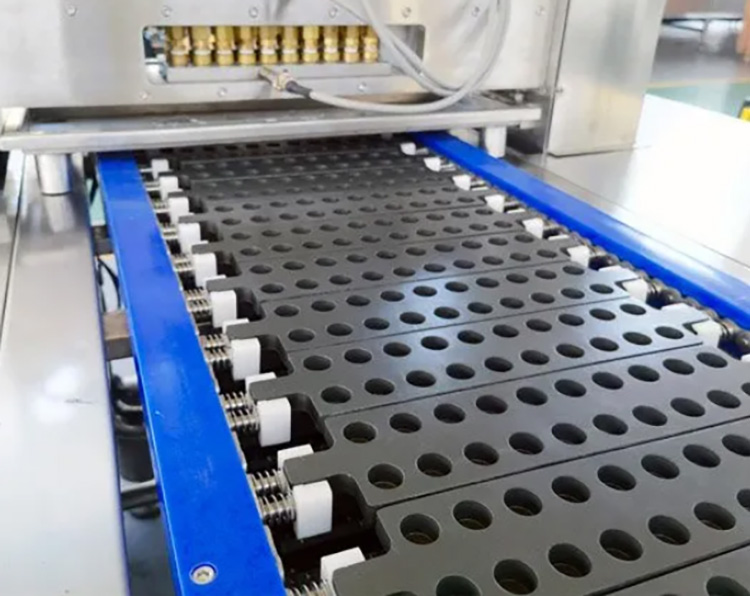

AIPAK gummy depositor can be also called semi-automatic gummy making machine or small gummy making machine,it is suitable for industrial large scale requirement of various gummy candies.The gummy depositor can produce various gummy candy with various materials in various shape&size.It is compact in appearance and structure , easy to operate.The gummy depositor machine can hold different molds,and add multiple colors to pieces.With advanced servo-driven depositing system that ensures consistent shape,size and weight.

AIPAK Gummy depositor can make assortment sizes of gummy candies, ranging from 1-7g. It has a total capacity of 6000-10000 gummies per hour.

AIPAK Gummy Depositor Machine Available Gummy Molds

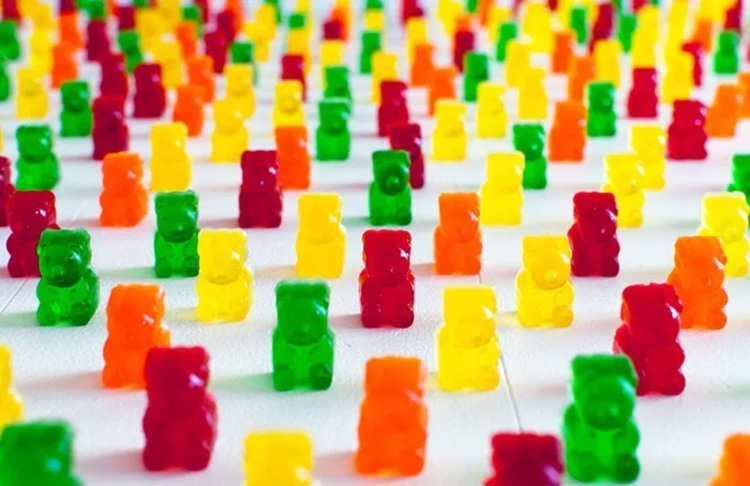

Various AIPAK Gummy Depositor Machine Products Samples

Medicated Jellies & Gummies

With an ever-increasing demand for medicated gummies, through AIPAK gummy depositor you can get various nutraceutical gummies,including all kinds of medically valuable and vitamin-based chewable candy.

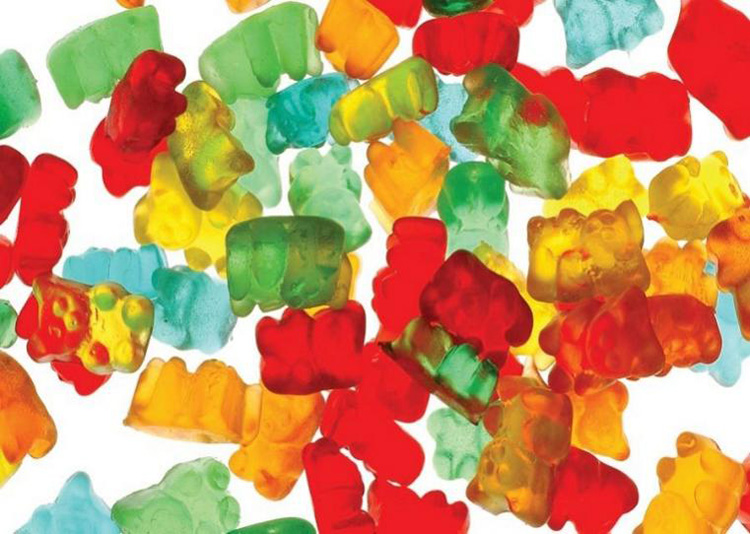

Gelatin Gummies

With AIPAK gummy depositor you can get perfect classic gummy bear recipe and much more about AIPAK efficient manufacturing equipment. Traditional gelatin gummies have always been a firm favourite in the confectionery market.

Pectin & Carrageenan Jellies

Pectin based jellies are an ideal alternative to gelatin. Made from plant-based ingredients, those following a vegan diet can still enjoy the soft or chewy texture of all their favourite jellies.

Three-Dimensional Jellies & Gummies

To offer a more varied and fun selection of jellies and gummies, AIPAK gummy depositor machine enables the production of three-dimensional shapes with a variety of colours and flavours.

The Buyer's Guide

Gummy Depositor: The Complete Buying Guide in 2024

Gummy depositor is a well-known equipment in the world of confectionery. Today, its applications are extensive in various other production fields as well. Now you can easily set your product in beautiful shapes using a gummy depositor.

This article is helpful if you’re planning to add the machine to your production line. WHY? Because this blog has some important aspects and good information that every buyer looking for.

1.What Is a Gummy Depositor?

This is a specialized machine used to make eye catching gummy products by molding them into beautiful shapes. They’re suitable for gummies and gelatin based products. A gummy depositor is typically designed with the mold of various cavities for generating specific shape products, that accepted thick viscous slurry into each cavity delicately.

Gummy depositor-created products are very fine, accurate, smooth, and uniform that sprouts elegancy. This machine is suitable for low to a moderately heated products that can solidify once set into depositor.

An industrial scale machine that is regulated by set of pumps and pipes helps in circulation of product into mold. Hence this is an ideal machine that gives you an enticing and aesthetically appealing product in an efficient manner.

2.Why Gummy Depositor Is Important?

Excellent Shaped Gummies

Gummy depositor generates smooth and good beautiful shape gummies at a very good production rate.This ultimately results in high production, with minimum production scrape rate and greater improvement in market value running of accurate and sustains controlled products with negligible scrap rate.

Effortless Gummy Depositing

The machine accompanies high degree automation ensures that production uses a little manpower to monitor. It is highly robust and reliable machine that yield gummies with high accuracy rate.

Handling Huge Production Aesthetically

A gummy depositors can produce large quantity batches in no time. A set of hoppers and nozzles make this job easier for you. It can easily adjust the deposition of slurries at an optimum velocity.

Single, Bi and Multiple Colored Gummies

Gummy depositor is made up of food grade stainless steel with single, bi, or multiple set of hoppers; hence this feature allows to create gummies with multiple colors. Moreover, this premium construction ensures a high tensile strength that is easy to clean and maintain. Also, you can flexibly replace damaged parts anytime moreover, electrical and steam control integration help significant utilization.

3.What Are the Industrial Uses of Gummy Depositors?

The gummy depositor is applicable in various production fields. Some of the important industrial uses are:

Pharmaceuticals Industry

In the pharmaceutical industry, the gummy depositor is used in manufacturing medicated gummy tablets. The demand for this machine is increasing as manufacturers prefer a new attractive way to improve patient compliance.

Nutraceuticals Industry

Gummy depositor is used in the making of nutraceutical gummy supplements in the form of soft gummy candies. The prime objective to produce gummy supplement is to motivate the individual to consume nutritional supplements regularly.

Confectionery Industry

In the confectionery industry, the production of different gummies, jellies, and candies items in fascinating shapes and colors requires a gummy depositor.

Stationery Industry

This industry deals with the making of gummy pen’s topper, various shaped erasers, decorative items such as key chains, etc., and the gummy depositor are used to generate products loved by kids/consumers.

Soap Industry

After food, gummy depositor machine is high in demand in making soaps. Nevertheless, beautiful fragrant soap bars with alluring aesthetic shapes can easily be manufactured using a gummy depositor.

4.What Are Parts Of the Gummy Depositor?

Gummy depositor has a simple construction; some of the important parts of gummy depositor are as followed:

HOPPER

A gummy depositor machine has a large option for hoppers that helps in receiving ingredients used to deposit in the cavities. Moreover, these hoppers allow heat conservation to maintain slurry in the molten state at the correct temperature. Thus, the following features ensure appropriate gummy manufacturing parameters.

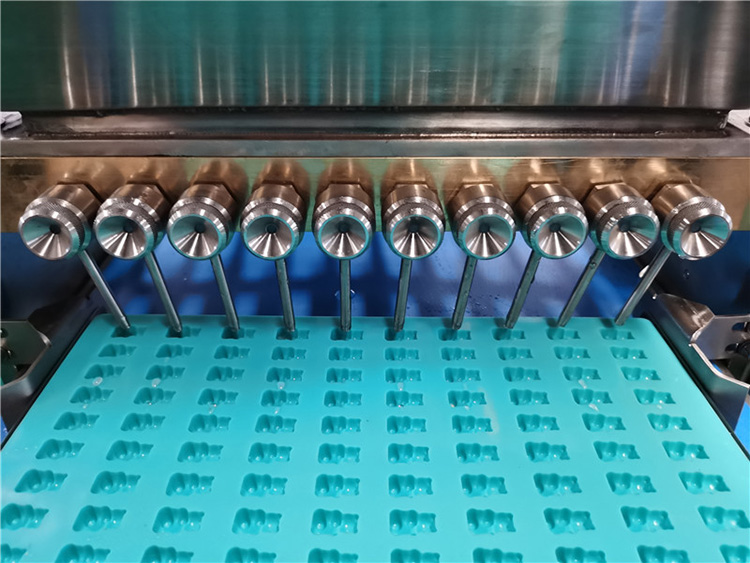

NOZZLE

The filling nozzle is attached closed to hoppers that work in conjunction with heat regulated control unit. As mentioned above, the slurry must be maintained at the required temperature therefore, the filling nozzle allows a smooth flowability of slurry in the molten state. In addition, a nozzle is available in many sizes; this nozzle is capable enough to control the right amount of slurry produced by the machine for the molding process.

ELECTRIC CABINET

The electrical cabinet is responsible for housing all electrical components required to run the operation of gummy depositor smoothly and safely.

AIR CYLINDER

The prime function of air cylinder to produce pneumatic force from air pressure that helps in producing mechanical motion in the gummy depositor.

ON- OFF CONTROLLER

This is the main switch that helps in controlling the switching on and off of gummy depositor. Moreover, in some machines there is an option to automatically OFF in case of emergency.

TEMPERATURE INDICATOR

An electric cabinet is equipped with a temperature indicator that helps in notifying the adjusted temperature. The machine itself is capable enough to regulate temperature requirements.

5.What Are the Types Of Gummy Depositors?

There are three basic types of a gummy depositor. Such as:

Manual Or Tabletop Gummy Depositor Machine

This type of depositing machine can fill molds with different confectionery mixtures like that of gummy, caramel , hard candy, chocolate etc. It’s manual settings allow small scale manufacturing of gummies with better quality. Due to it’s digital working hopper, increased productivity can be achieved at greater temperature by filling of more than 7-8 cavities at a time.

Semi- Automatic Gummy Making Machine/Gummy Depositor

A semi-automatic gummy making machine or gummy depositor is a convenient equipment for molding gummies, soft candies, hard candies, and other relevant items.

This machine gives medium to large batch production where involvement of operator is necessary for e.g. pouring solution, placing and removing mold, and pedal pressing.

It offers single to multi set of hoppers; hence single to multi-colored gummies making is also possible.

This is small and compact solution allowing a perfect integration with other equipment.

Automatic Gummy Making Machine/ Automatic Gummy Depositor

This is extensively designed automatically offering single and multi colors gummies production with designed set of hoppers, filling nozzle, temperature indicator, and high degree sanitary conditions. The machine can handle large production batches solely in no time. This machine is better option for dynamic mixing, gummy ingredients and producing defined shapes. With proper set of integrated devices, it ensures the high degree of automation to its end user.

6.How does Gummy Depositor Work?

To process a gummy depositor, you need to follow below mentioned steps:

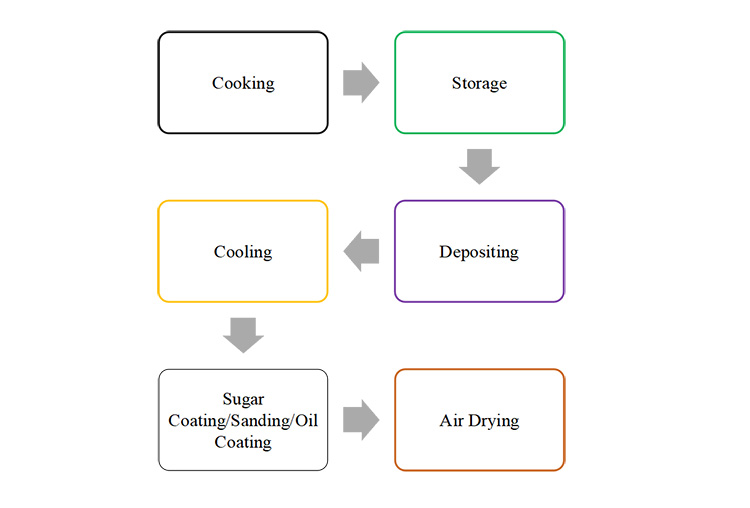

| COOKING PHASE | A gummy syrup is prepared for the purpose of gummy molding. This syrup is composed of the following ingredients like sugar, gelatin/pectin, flavoring agent, colorant, and water. This is cooked under a temperature of 108-110℃. |

| STORAGE PHASE | Once the syrup is prepared, it is stored in the storage tank or a depositor hopper/electric heated hopper.

You can pour the syrup into storage tank manually. |

| DEPOSITING PHASE | Now, manually place the gummy molding tray for filling using gummy depositor. Using Pedal Press Controller may initiate the process where slurry may drop into the cavities. Once the cavities are filled, remove the tray manually and replace it with other one. The entire process take place in this manner.

Note: A gummy depositor machine has option to control by PLC programming. Moreover, you can also process the command by using Pedal Press Controller. A single hopper is used for one color gummy deposition, whereas if you require multi- colored gummies, for this purpose you can use another one. Usually, a small lab-sized gummy depositor can yield 6000 to 10,000 gummies per hour (brand to brand). |

| COOLING PHASE | A hot slurry filled molds are cooled down in order to acquire proper shape. For this purpose, manufacturers use a cooling tunnel to drop the temperature and stabilize the shape of gummies. An optimize chilled air circulation (10 to -10℃) ensures a high setting and quickly cooling of large capacity of gummies into a stable form. |

| SUGAR COATING/SANDING/OIL COATING | An external sugar/sand/oil coating is done to enhance sweet flavor, smooth texture, and stabilize the gummy. The commonly used ingredients are citric acid, starch, sugar blend, and oils. The following coating allows gummies to withstand unfavorable environmental conditions by minimizing the chances of stickiness. |

| AIR DRYING |

Allow the gummies to mold 13%±2℃, once it acquires the shape, you can de-mold them via a gummy demolding device. A gummy depositor is commonly equipped with gummy demolding. After demolding, allow all gummies to air dry. The purpose of air drying to reduced moisture content inside the gummies. For moisture reduction, a standard drying time is 8 to 10 hours. |

7.What Auxiliary Equipment Can You Use with The Gummy Depositor?

When you see beautifully shaped gummies, you might be wondering about their procedure. Indeed, the gummy candies are produced by a passing through series of equipment. The mentioned below list described them respectively.

Syrup Cooker

A triple layered jacketed syrup cooker is the first step of processing gummy. The purpose of using this cooker to attain effective and better boiling in a safely manner. The outer layer works as an insulator that allows user safety against high temperature.

This mechanical and heating cooker is built in high speed shearing that is suitable for melting and blending the raw ingredients. Once the syrup is properly cooked; it is discharged automatically through pneumatic plug.

Emulsifier

This is optional equipment used for emulsifying the gummy's raw ingredients in a molten state. The prime reason for this equipment is to attain a uniform mixture of gummies solution.

In some production lines, instead of an emulsifier, a storage tank is used which is also double jacketed with heat inducers. The emulsifier is connected to the water tank and gummy syrup cooker via a pump and pipeline that ensures smooth flowability of content. In some cases (semi-automatic) you need to pour slurries manually.

Cooling Tunnel

A cooling tunnel is integrated with a gummy depositor ensuring a simultaneous cooling temperature of up to minus 10 C. This is necessary whenever you need to drop the temperature of the mass product. This machine equipped with a cool air circulatory connection of chillers or direct expansion helps in rapid cooling.

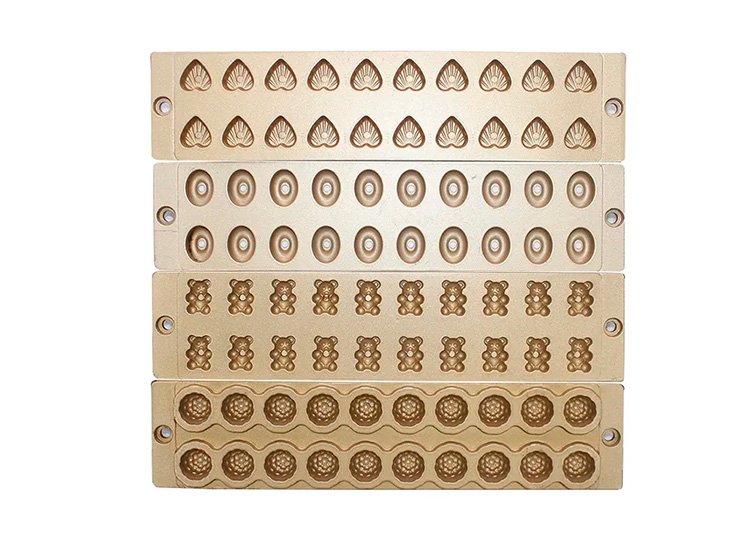

Gummy Mold (Teflon Coated)

Gummy bear depositor uses molding depositors for filling empty molding cavities. These molds can be of different shapes, sizes, and materials.

The commonly available shapes are heart shape, bear shape, star shape, fruits, vegetables, or any toy. Additionally, gummy molds are available in Teflon, silicon, and plastic. They are capable to withstand high temperatures, thus suitable for compliance with gummy slurries in a molten state.

Sugar/Sand/Oil Coating

A Sugar/sand/oil Coating is a hollow drum tumbler that helps in finishing and polishing of gummies candies.

A conveyor ensures the entrance of the product inside the rotatory perforated cylinder. Here, with the help of a coating nozzle, a continuous or intermittent shower of sugar/sand/oil solution is sprayed over the layers of gummies.

A continuous movement of the stainless steel perforated drum ensures a uniform sugar/sand/oil distribution all over the surface of the gummies. You can observe the movement in forward and backward strokes for a 100% uniform sugary texture.

Drying Trays

The gummy depositor production line is incomplete without drying trays or vented trays. This is well known that water content in newly produced gummies is commonly recorded as up to 18%. But this is surely not recommended you need to drop them down up to 13%.

Stackable gummy trays are an economical and great way to save space and achieve adequate air drying.

The gummy trays are used that help you in drying gummies at room temperature for 8 to 12 hours.

Dehumidifier

When going to the gummy depositing facility; the need for a dehumidifier cannot be ignored. This is a simple to adjust, portable, and compact device that can handle small or moderate gummy operations.

additionally, when you get the correct moisture content during preparation, gummies should get dry in 7 to 8 hour and gives a perfect product.

8.Can Gummy Depositor Produce Different Colors and Flavors?

A Gummy depositor is a versatile purchase since you can have a variety of colors and flavors with a gummy depositor. Moreover, you can also make custom flavors with this machine as well.

For double colors gummies, two separate hoppers depositors are used. Two different hoppers hold two colors. The hoppers hold a variety of flavors and colors which can be loaded in molds in a variety of combinations. Moreover, these gummy depositors are used for making filled and infused gummies as well.

9.What Different Shapes Gummy Depositor Offers?

Gummy depositors are customized with different sets of molds and depositing nozzles for forming gummies of different shapes and sizes. Furthermore, the depositing speed of gummy depositors also plays a role in creating different sizes of gummies.

A slower depositing speed will create larger and more round gummies while a high depositing speed will result in irregularly shaped and smaller gummies.

However, the design of molds is responsible for producing various shaped gummies such as square, rectangular, star, fruits, worm, bear, sharks, circles, blobs, oval, and rings.

10.Can You Use the Gummy Depositor to Produce Hard Candy?

Yes. A gummy depositor can also be utilised for making of hard candies. This is possible due to presence of continuous depositing mechanism into solid molds that produce hard, unbreakable candies.

Likewise gummy, a hard candy can also acquire shape using gummy depositor. In this procedure, raw ingredients are cooked using candy syrup cooker. The candy material is introduced into molds via gummy depositor machine using the same working principle as gummies.

Once the candy are mold and stabilized, they will pass through the cooling tunnel to solidify and take it’s desired shape without cracking. Soon after cooling coating and air-drying steps should to be done.

11.Is there any Difference Between Chocolate Depositor and Gummy Depositor?

As you observed that the functioning of gummy depositor machine can fill wide variety of products apart from gummies. However, you can say that a chocolate depositor is similar to a gummy depositor. Both of their parts are similar in features. Likely to a gummy depositor, chocolate depositor also requires additional components for it’s appropriate working.

A PLC system incorporated in both depositors controls and monitors manufacturing throughout the process .Their working includes filling of the molds by a piston or depositing nozzle which fills in the accurate quantity in the cavity. The temperature of the gummy or chocolate slurry is controlled by heating panels. The cooling tunnel allows the molten form of gummies or chocolates to solidify and rest. The difference between two that arises here is the time taken by gummies to rest longer to dry up than the chocolates.

12.Is The Gummy Depositor Machine Able to Handle High Temperature and Humidity Levels?

you are dealing with gummy syrups that are cooked at high temperatures and are wondering whether your gummy depositor is able to withstand this temperature. Well, the answer is yes.

Gummy depositors are manufactured using stainless steel alloy that is temperature resistant which assists this machine to withstand high temperatures. Moreover, this equipment is moisture proof and thus can handle high humidity levels.

It has air-cooled design and employs air for lowering the temperature of equipment instead of water thus water does not come in contact with a gummy depositor and decreases its performance.

13.How Long Does Gummy Depositor Take To Dry?

The drying time of the gummy depositor varies with the type of gummy depositor. Moreover, the drying time and process of the gummy is also depended upon environmental conditions like humidity and temperature. However, gummy depositor generally has more drying time than chocolate depositor.

Normally gummy depositor takes 72 hours to dry. In the first 48 hours, one surface of the gummy candy gets dried up and in the next 24 hours, another side is flipped for drying.

14.What are Common Problems and Solutions of Gummy Depositors?

Problems in the normal operation of gummy depositor can be the source of tension and also lead to financial loss. However, these problems can be easily fixed by following simple tips such as:

Sticky Gummies: Gummy candies might turn out to be adhesive and wet due to high sugar content , because of citric acid or high humectant content. Sticky gummies may cause a messy production process and difficulty in removing them perfectly from the mold.

Solution: In order to avoid this issue you can coat your gummies with corn starch once the cooling and setting steps have completed. Corn starch has the property of absorbing excess water content. Wetness due to humidity can be treated by drying the gummies and then storing them in an airtight container.

Non-uniformity or Variation in Gummy sizes and shapes: If you see the gummies are not similar in texture their size or shape is varying , it may be because of the inconsistent molding process and any error in gummy depositing parameters.

Solution: You must change the molds if any damage has occurred to it. Check the gummy depositor’s settings for any inconvenient error in parameters which may lead to variable filling.For removing sticking residues, flush the pumps, pipes, and cooker with boiling water. Properly check the connection of wires and cables.

Unsuccessful Blooming: Inadequate addition of water while mixing gelatin with water during gummy manufacturing may result in inappropriate, undesirable blooming strength.

Solution: If you take consideration while adding sufficient quantity of water, desired bloom strength will be achieved, as it will combine both of the ingredients gelatin and water suitably.

Insufficient Heating Of the Cooking Unit: Irregular heating due to damaged steam jacket. The desired temperature is not achieved due to faulty in-let and trap valves.

Solution: Repair the damaged steam jacket. Replace the defective valves.

Connecting Pumps Fails To Work: a missing phase, where gummy deposition is non-uniform that could be due to clogging of pumps that is because of accumulation of debris. Additionally, this could be due to poor cleaning techniques or the stickiness of viscous gummy content on the wall of the pump.

Solution: To solve the problem you must inspect and replace the missing wiring in the machine. Moreover, remove clogging by properly washout the pipes with hot water for removing stickiness.

Conclusion

A Gummy depositor is a major piece of equipment that drives the journey of gummy formation. This simple, compact, and economical machine is responsible for the entire success of gummy production. If you’re interested in purchasing a ‘gummy depositor’ from a well-known manufacturer; then we recommend, contacting us to explore the unlimited gummy production line. We AIPAK Pharmaceutical promise your business success by offering excellent machines and services. Stay Connect Us!

Gummy Depositor Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951