Differences Between Semi-Solid Filling Machines vs Liquid Filling Lines

In the pharmaceutical and cosmetic industries, the setup of a product’s filling line is distinct. That’s why along with formulations; its filling technology is fundamentally crucial. Several formulations with viscous consistencies (gel, lotions, creams, etc.) require a specialized filling system to ensure accurate, professional, and clean dispensing.

For every manufacturer, this is crucial to understand the basic difference between semi-solid filling machines vs liquid filling lines. Understanding insight about them will help you identify and pick the right machine. This will ensure the efficient results you need for an industrial setting.

The semi solid formulation is thick and highly viscous whereas liquids (syrups, eye drops, injections) are free flowing. Every product dispensing needs its special machine. This is because, it ensures proper filling under hygienic manner.

You can have a look at the article below to read and understand the super technical points related to semi-solid filling machines vs liquid filling lines.

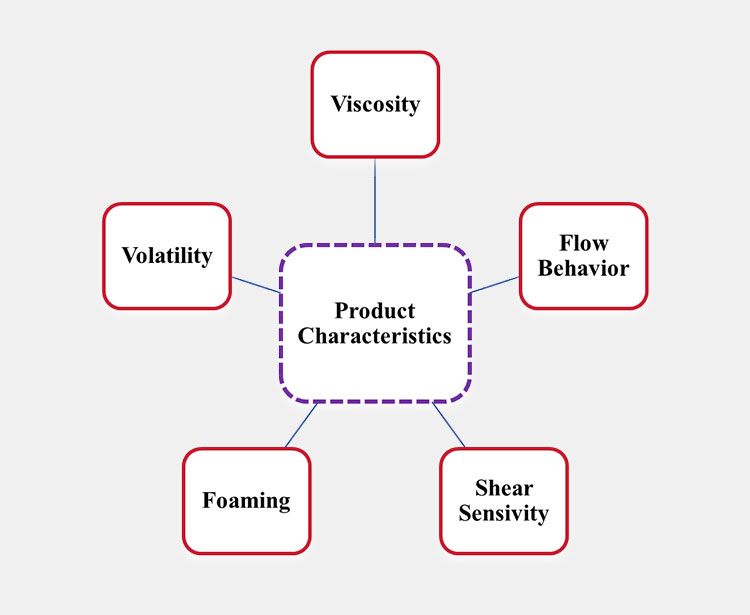

1.What are Product Characteristics and Their Impact on Filling Method?

Product Characteristics and Their Impact on Filling-Picture Courtesy: FIDELIO & Croda Pharma

The physical and chemical characteristics of the product are integral in deciding between the filling methods. Choosing the wrong filling approach can lead to dosing errors, cross-contamination, and a decrease in product quality. Here are some key characteristics that impact filling choice:

Product Characteristics and Their Impact on Filling Method

Viscosity and Flow Behavior

Viscosity and Flow Behavior- Picture Courtesy: Department of Labor

Semi-solids, such as creams, gels, ointments, and pastes, have high viscosity and a thicker consistency. Their fluidity is sluggish due to high internal resistance and frictional forces. Therefore, semi-solid filling machines use specialized filling devices that fluidize semi-solids by exerting intense pressure on them.

Liquids normally have low viscosity, are free-flowing, and easy to dispense in bottles and jars. They have minimal internal resistance and flow quickly. That’s why liquid filling lines with simpler filling systems are used, which don’t need extreme pressure to induce flow.

Shear Sensitivity

Shear Sensitivity- Picture Courtesy: Fluidan

Typically, semi-solids are considered shear-thinning, meaning that their viscosity decreases under higher shearing forces. However, extreme shear can affect emulsion stability, resulting in phase separation or loss of structural integrity of gels. Hence, semi-solid filling machines use low-shear filling systems and don’t feature high-speed pumping devices, as this changes the consistency of semi-solids.

Some liquids are extremely shear-sensitive, and their ingredient components may denature or aggregate on subjected to excessive forces. Consequently, liquid filling lines are comprised of gentle filling systems that don’t cause product agitation.

Foaming and Volatility

Foaming and Volatility- Picture Courtesy: Renascent

Due to the physical nature of semi-solids, such as higher thickness, they don’t tend to foam. Similarly, they have minimal volatility due to higher solid content or a viscous medium. Hence, they’re filled with standard filling devices. Sometimes, vacuum-assisted loading may be employed to extract entrapped air.

The liquids with more surfactant content are prone to foaming, leading to inaccurate fills and leaks. Alcohol or solvent-based liquids evaporate swiftly, posing safety, dosing, and contamination hazards. For handling foaming liquids, bottom-up nozzles are used in liquid filling lines. Whereas, closed systems and nitrogen flushing are needed for volatile liquids.

2.Table: Semi-solid vs Liquid Product Physical Characteristics

Difference between semi solid VS liquids- Picture Courtesy: WEST Lab

Here is a brief overview of the differences between the physical characteristics of semi-solid vs liquid products:

| Characteristics | Semi-solids | Liquids |

| Viscosity | High viscosity, thixotropic | Low to moderate viscosity |

| Flow Behavior | Non-free flowing | Free-flowing |

| Shear Sensitivity | Experience loss of structural integrity and texture change on high shearing | Destabilization of liquids on shearing |

| Foaming | Minimal foaming ability | Foaming may happen in liquids with high surfactant ingredients |

| Volatility | Low | High evaporation risk for solvent-based liquids |

3.What are the Structural and Technical Differences Between Machines?

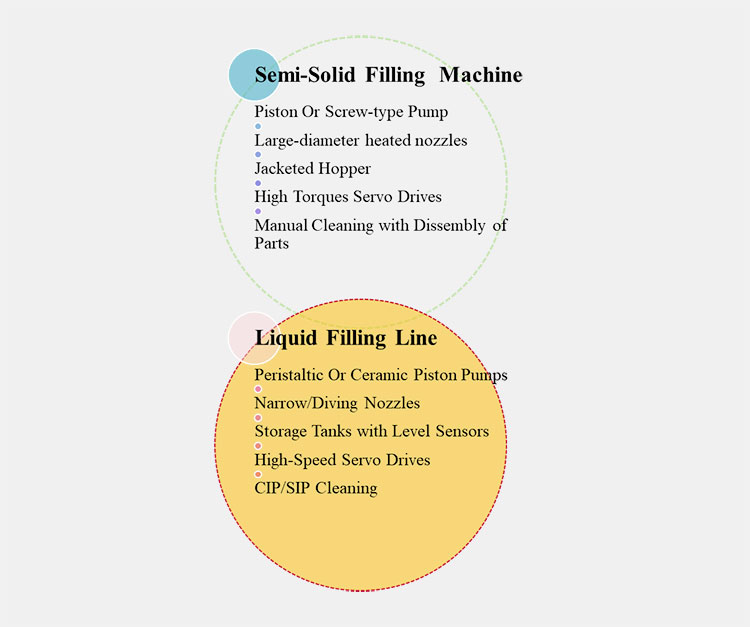

It is a common misconception that semi-solid filling machines and liquid filling lines are identical to each other; in fact, there are many structural and technical differences between these two machines. These differences are listed below:

Structural and Technical Differences between Semi-Solid Filling Machines and Liquid Filling Lines

Filling Principle

Filling principle- Picture Courtesy: IWK

Semi-solids and liquids behave differently, and thus, they require different filling principles. In a semi-solid filling machine, like tube filling machines, piston or screw-type (auger) pumps are integrated, which generate adequate forces to force thick products through nozzles. In addition to this, to further increase fluidity, these machines are also equipped with heating systems to hot-fill semi-solids.

Liquid filling

In contrast, peristaltic or ceramic piston pumps are present in liquid filling lines, for example, a syrup filling line and a vial filling line. They operate on a simple gravity or time-pressure filling mechanism to deliver consistent and precise dosing of free-flowing and medium viscosity liquids.

Nozzle Design

Semi – Solid Nozzles Design- Picture courtesy: AnC Precision

The semi-solid filling machine accommodates high viscosity of semisolids by using large-diameter nozzles and heating elements to prevent the risk of solidification and clogging. Shut-off valves instantly stop the fluid flow once the desired fill volume is attained are also found in these devices. These valve throttle products back to the hopper to reduce product wastage.

Liquid Filling Nozzles

The nozzles found in liquid filling lines, for instance, eye drop filling lines, are narrow with anti-drip features to prevent splashing or foaming. Moreover, a diving design for accuracy is also used in a liquid filling machine to assist in filling containers from their bottom.

Hopper & Transfer System

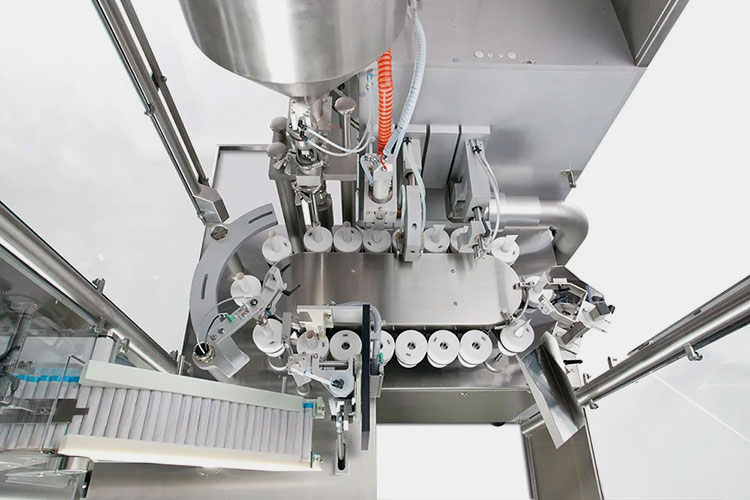

AIPAK Semi Solid Filling Machine

In a semi-solid filling machine, jacketed hoppers with temperature control systems are used for maintaining the temperature of semi-solids in hoppers, which in turn ensures the constant flowability. These hoppers are also fitted with gentle agitating mechanisms to preserve uniform consistency without over-shearing.

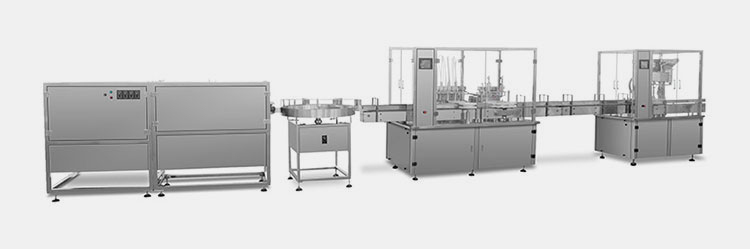

AIPAK Liquid Filling Lines

In liquid filling lines, precise product dosing is attained through tank-level sensors that continuously monitor the level of liquids in the storage tank and alert operators when a predefined limit is reached. Also, the hopper & transfer systems are integrated with CIP/SIP systems for quick and hygienic cleaning and filling.

Viscosity Handling

AIPAK fully automatic tube filling machine

To handle the high viscosity of semi-solid material, semi-solid filling machines are equipped with high-torque servo drives. These parts are essential in maintaining the smooth flow of semi-solids.

AIPAK Liquid Filling Lines

Due to the free-flowing nature of liquids, speed, accuracy, and sterile dispensing are given more importance in liquid filling machines. In contrast to a semi-solid filling machine, liquid filling systems are designed with high-speed servo drives that assist in fast and accurate product loading.

Automation and Control Systems

Automation and Control Systems- Picture Courtesy: Fill2 Package Machine

Although HMI touch screen and PLC control systems for batch production are integrated in both semi-solid filling machines and liquid filling lines, their jobs are entirely different. With HMI/PLC computerized controls, hopper heating, agitator velocity, piston movement, and timing of nozzle shutdown are regulated in the semi-solid filling machine.

Advanced PLC systems in liquid filling lines control tank-level check, anti-drip timing, pump speed, time-pressure fill monitoring, and weight-checking during liquid dosing. Completed automated liquid filling lines also include inline capping, labeling, and conveyors for seamless productivity.

4.What are the Applications of Semi-Solid Filling Machines vs. Liquid Filling Lines in Industries?

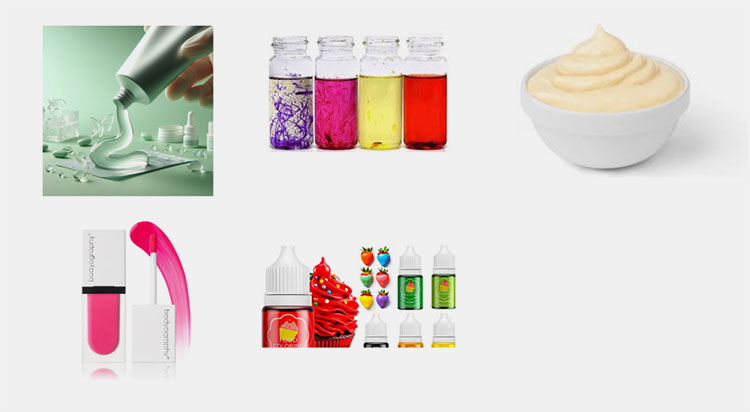

Applications of Semi-Solid Filling Machines- Picture Courtesy: Pharmaceutical Networking

Semi-solid filling machines and liquid filling lines process diverse kinds of products; for this reason, their industrial applications also differ. Below are some significant applications of both of these systems:

| Applications | Semi-Solid Filling Machine | Liquid Filling Lines |

| Pharmaceuticals | Pharmaceutical manufacturers use specialized devices, for example semi-solid filler for ointments to dose gels, creams, and ointments in tubes, cartridges, and jars. | Medications in the form of solutions, suspensions, emulsions, vaccines, and syrups are dispensed by high-performance equipment, such as liquid filling lines for syrups under GMP, FDA, or EMA-compliant aseptic conditions. |

| Cosmetics | In the cosmetic sector, products that need controlled viscosity, such as creams, lotions, hair masks, toothpastes, balms, and waxes, are filled by these machines. | Fills serums, toners, body washes, hand sanitizers, and shampoos. |

| Food | Ideal for loading honey, chocolate spread, pastes, sauces, and thicker condiments. | Best for packing juices, oils, dressings, and flavoring syrups. |

| Chemical | High viscosity liquids, for example, adhesives, paints, gels, and sealants are packed using this device. These products require an intense pumping force. | Fills free-flowing and surfactant-based liquids, for instance, detergents, cleaning agents, dishwashers, disinfectants, liquid fertilizers, etc. |

5.What are the Quality Control and Validation Requirements of Semi-Solid Filling Machines Vs Liquid Filling Lines?

Maintaining quality control and fulfilling validation requirements are nonnegotiable in both semi-solid filling machines and liquid filling lines. Based on product characteristics, the focus areas of quality control vary among these two filling systems. Here are some key differences and similarities in quality control and validation requirements:

Quality Control and Validation Requirements

Precision Tolerance Comparison

Precision tolerance is a pivotal part of the quality control process and is different for both semi-solid filling machines and liquid filling lines. When their precision tolerance is compared, it is noted that semi-solid filling machines have more lenient criteria of about ± 1.5% of fill volume/weight.

On the contrary, liquid filling lines have a stricter precision tolerance, usually around ± 1.0% of fill volume/weight. This is because semi-solids don’t flow consistently, while liquids are free-flowing, and their extremely precise control is needed because it directly affects dose accuracy.

Cleaning Validation and Cross-Contamination Prevention

Product accumulation risk is higher in a semi-solid filling machine and can cause physical or chemical cross-contamination between successive batches. That’s why manufacturers must critically validate their residue removal protocol and conduct swap sampling for difficult-to-clean areas. They also ensure that cleaning detergent is validated for tough product deposition to prevent cross-contamination.

Liquid filling lines generally dispense sterile products in which microbial growth and contamination are a bigger risk; thus, they need CIP/SIP cleaning validation and rinse water testing.

GMP & FDA Compliance

As per 21 CFR Part 211.160 FDA protocol, both the semi-solid filling machine and liquid filling line must satisfy hygiene and traceability standards. Liquid filling lines must be operated under aseptic or sterile conditions, like those of cleanrooms, as mandated by regulatory authorities.

Operators are expected to follow simple GMP safety guidelines, such as gloves, PPE, and eye goggles when managing semi-solid filling machines, while full aseptic PPE and sterile handling are mandated for operating liquid filling lines. For traceability purposes, proper documentation and batch records are necessary for regulatory compliance.

6.How to Choose the Right System for Your Product?

Selecting a Right System for Your Product

Selecting the right system is a major investment and directly impacts your production, efficiency, accuracy, and profit margins. So, here are some key factors to consider to make your investment worthwhile.

Product Viscosity: The product viscosity is a significant decisive factor. If your product is more viscous or has a thicker consistency, a semi-solid filling machine would be more suitable for it. However, for free-flowing or medium-viscosity products, liquid filling lines are typically the most efficient choice.

Batch Size: Small batches or testing applications need manual or semi-automatic filling systems. Piston-driven filling systems are a more cost-effective choice for small-sized businesses. Mass production and continuous operations are well-managed by high-speed liquid filling lines.

Container Type: The packaging type usually dictates the design and engineering of filling machines. For example, tubes, jars, and cartridges require the use of semi-solid fillers. Whereas, liquid filling lines easily handle ampoules, vials, metallic cans, and bottles.

Required Filling Accuracy: High-value formulations and injectables demand precise micro-dosing, so liquid filling lines with peristaltic or servo-driven systems are more preferred choice for them. If dealing with non-free-flowing or viscous products, select semi-solid filling machines with a piston system, as they uphold reliable filling accuracy in spite of high-density substances.

Budget And Space Constraints: The liquid filling line is the assembly of various machines and conveyors; hence, it needs higher investment and more floor space. But they are capable of delivering efficiency and automation. In contrast, semi-solid fillers are generally compact and affordable if you’re running a small startup or low-volume business.

Conclusion

In summary, semi-solid filling machines are ideal for dosing non-free-flowing and high viscosity semi-solids, while liquid filling lines are specifically engineered for free-flowing liquids. Semisolid fillers generally feature heating and advanced pump and piston systems to handle thick materials. In contrast, simpler volumetric flow or time-pressure systems are found in liquid filling lines. These systems must comply with GMP and FDA standards to ensure hygiene and accurate filling. With a wide array of customizable technologies, AIPAK offers filling solutions tailored to various product viscosities and packaging types, aiding manufacturers in their business endeavors.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine