The Complete Buying Guide for Blister Packaging for Toys

The toy industry is immensely based on creativity and display. The blister packaging plays an integral role in safeguarding and grabbing children’s attention with beautiful and visible toys. Consequently, this unique mode is popular and used for various purposes like protection, delivery, etc. That’s the reason behind its popularity and the widely applied method in a broad industrial sector.

This article is important, because you’ll explore various aspects of blister packaging for toys—by the end, you will be capable of selecting the right material, machine, and design ideal for packaging toys with excellent presentation. Keep reading!

1.What Is Blister Packaging for Toys?

Blister Packaging for Toys- Picture Courtesy: Peta Pixel

Blister packaging for toys is often used method for toys to provide custom protection and clarity. It is a combined solution of safeguarding with modern aesthetics. This packaging is achieved with blister packaging machine that creates a pre-formed design of a toy as a cavity. This cavity is known as a ‘blister’.

The backing is provided for complete support of a toy, which is mainly done with cardboard or any thick material like plastic. The common structures of blister packaging involved including carded, clamshells, and slide blister packaging, are widely used for simple to complex categories of toys to boost appearance as a premium quality.

Typical Applications in the Toy Industry

Blister packaging is an extensively used packaging option for the toy industry. The common applications of blister packaging are described as:

Small Toys: There is an unlimited list of toy items that are available in small sizes, such as cars, various colorful puzzles, alphabets, small dolls, and their accessories, such as dresses, make-up kits, and shoes, which are ideally packed in an organized way. This is achieved by blister packaging that performs this great job without damaging or creating messiness with smaller items.

Collectibles, such as trading cards, beautiful badges, and small ornaments, are packed in blister packaging. This is particularly important to keep them safe and to use tamper-evident packaging to preserve their integrity and real value.

Electronic Toys: With blister packaging, items such as PlayStation, batteries, electronic gadgets such as torches, mouse, computer-related devices, extension boards, and related items are completely safe from wear, tears, and shipping damage.

2.What are the Key Benefits of Blister Packaging for Toys?

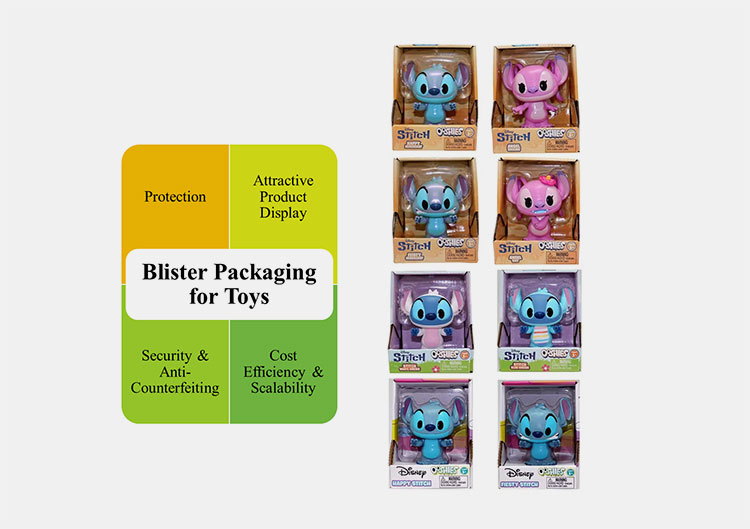

Key Benefits of Blister Packaging for Toys

In a world of branding, competition, and creativity, blister packaging for toys provides good trends, which is not only a genius idea but also gives an excellent display. Among so many significances, the following important benefits are described below:

Protection

Blister packaging is a bodyguard of toys and performs the role of dust-proof, moisture-proof proof and tamper-resistant. Whatever the condition is, it ensures that toys are good and intact during shipping, marketing, and distribution. If anyone wants to open or attempt tampering, the alteration in packaging lets you know the originality. So, the blister packaging is quite significant when it comes to knowing intactness and consumers’ trust.

Attractive Product Display

The true power of blister packaging is allowing customers to see and observe the toy held in it. This marketing strategy creates a shelf-appealing impulse in customers to pick and buy the product. The high transparency is the key factor behind the popularity of blister packaging. The visible front cavity shows what exactly you’re going to buy. Plus, its backing is offering a good medium for necessary messages from manufacturers and instructions, and branding, thus an effective solution is attained.

Security and Anti-Counterfeiting Benefits

A manufacturer always desires promising security and anti-counterfeiting properties when it comes to securing the finished product. The blister packaging for toys provides complete sealing around every curve and corner, which cannot possibly to altered. Thus, customers buy toys with full confidence without chances or risk of tampering which is crucial to know prior purchasing.

Cost Efficiency and Scalability

Every manufacturing company looks for a durable packaging option that is cost-effective and scalable for their products. The blister packaging for toys is not only boosting cost-efficiency of production but scalability as well. It is an ideal option for broad categories of toy packaging, including small, medium, large, limited, and mass production.

3.What are Main Types of Blister Packaging for Toys?

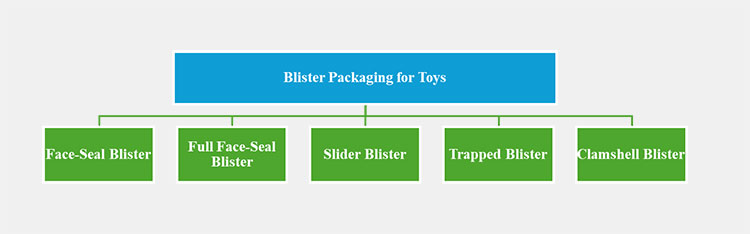

To gain a competitive edge over their business rivals, brands pack their toys in several different blister formats. These types are mentioned below:

Types of Blister Packaging for Toys

Face-Seal Blister

Face Seal Blister

This type of blister packaging is manufactured from plastic film and paperboard. The plastic cavity containing the toy is directly sealed on the paperboard using heat. The plastic covering is only present in the product region.

Full-Face Seal Blister

Full Face Seal Blister

This type is a modification of the face-seal blister, but instead of covering just the toy, the plastic film encloses the entire front as well as back of the cardboard/paperboard.

Slider Blister

Slider Blister- Picture Courtesy: Else Blister

In this packaging, the toy is put into a pre-made blister tray, which is then secured in the cardboard sleeve. The blister tray may be designed to either fold into a sleeve or slide into a cardboard to lock the product in place.

Trapped Blister

Trapped Blister- Picture Courtesy: ELSE pack

Instead of using one cardboard, there are double layers of cardboard in the trapped blister packaging type. The blister mold containing the toy is secured between two layers.

Clamshell Blister

Clamshell Blister- Picture Courtesy: Else Pack

This packaging format is distinct from other blister types because it consists of a hinged two-part plastic shell. The toy is placed into one plastic cavity, while the second half is folded or hinged over it and then sealed.

Comparison of advantages and limitations

| Types | Advantages | Limitations |

| Face-Seal Blister | Very cost-effective, lightweight, more product visibility, and easier to manufacture | Decreased elemental protection, less sustainable |

| Full-Face Seal Blister | Better protection, ample branding space, and higher shelf presence | Use more plastic, pricier than face-seal |

| Slider Blister | Easier recycling, less plastic utility, simple to assemble | Reduced tamper resistance, not suitable for fragile toys |

| Trapped Blister | Greener packaging because it uses less plastic material, and has more branding space | More expensive to produce, complex assembly because of additional cardboard |

| Clamshell Blister | Absolute protection, tamper-evident, high-end look, can be reused | Increased plastic utility, hard to open, and less environmentally friendly |

4.What Basic Materials Used in Toy Blister Packaging?

Generally, brand owners and developers use hard, impervious, compact, durable, and transparent materials/polymers that provide absolute protection and safety to inside-packed toys and protect them from elements. Some commonly used materials for toy blister packaging are mentioned below:

Common plastics

Common plastics

PVC: This plastic polymer is widely favored in toy blister packaging because of its clarity and low price. PVC has excellent thermoforming ability, so it is easily molded into complex shapes. It displays toys in an appealing way because of its smooth finish and transparency.

PET: PET in toy blister packaging is known for its transparency and high tensile strength. Manufacturers use it when they want to create blister packaging for toys with a premium look and feel. It is better at preventing oxygen from entering the packaging.

PETG: PETG is a modification of PET, where a glycol group is added to alter chemical properties and to make it more impact and heat resistant. It is harder and more ductile than PET. Not only is it transparent, but it can also be colored to enhance the appearance of packaging and to offer better product display.

RPET: RPET is a form of PET where R stands for recycled. It is developed from PET that has been utilized at least once and then recycled and introduced into the supply chain. So, it is more sustainable and durable than other plastic materials.

Eco-friendly and recyclable material

Eco-friendly and recyclable material

Nowadays, manufacturers are switching to eco-friendly and recyclable materials to promote the circular economy and to increase product acceptance by customers.

HPDE: For toy packaging, blisters are currently made from a single material, such as HPDE, making them easier to recycle. Often, HDPE has better impact, crack, and chemical resistance.

Plant-Based Plastics: Also, toy manufacturers are replacing traditional PVC with biodegradable plastics. These alternatives are manufactured from starch or PLA and are decomposed by bacteria and fungi.

Molded Pulp/Fibre: This type of blister packaging material is obtained from recycled paperboard or newspapers. Natural plant fibers (sugarcane, bamboo, and wheat straw) are compostable and offer a natural texture to molded pulp.

Paperboard: Paper-based blisters with minimal plastic windows created from paperboard packaging are another option for eco-friendly packaging for toys.

Aluminum Foil: This metallic film is used for packing high-value or fragile toys and can be reused and recycled, leading to a decrease in landfill.

How to choose the right material based on toy type

Right Material Based on Toy Type

When it comes to choosing the right packaging material for toys, its size, weight, breakability, and safety should be considered.

Small-Sized and Lightweight Toys

For small-sized and lightweight toys, for example, collectibles, PET or rPET are mostly utilized, as they have a good strength-to-weight ratio.

Medium-Sized Toys

PET with paperboard backing is excellent for medium-sized toys (dolls, puzzle sets), as this material combination offers maximum protection and ample space for branding.

Heavy-Duty Toys

Thicker materials like HDPE with reinforced paperboard backs are selected for packing heavy-duty toys (electrical toys).

5.What are the Design Considerations of Blister Packaging for Toys?

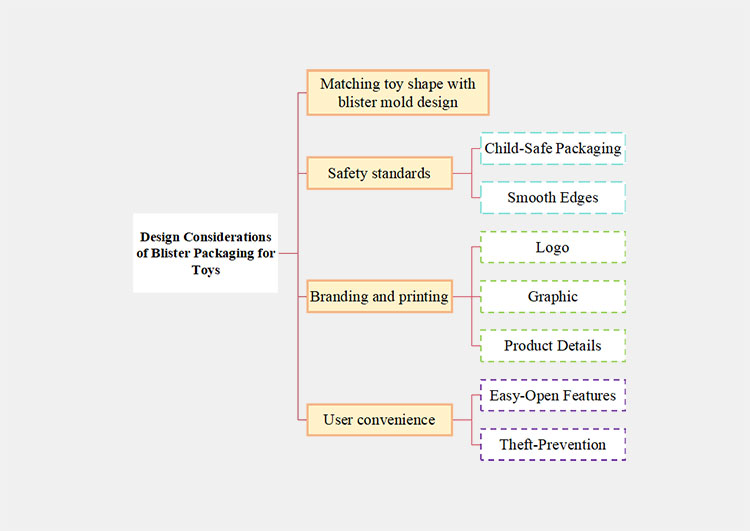

Blister packaging is not just about securing toys; rather, its design should perfectly balance user convenience, safety, and branding. To design this appropriate packaging, the following points should be taken into account:

Design Considerations of Blister Packaging for Toys

Matching toy shape with blister mold design

Toy Shape with Blister Mold Design

Calculating dimensions of toys helps the blister molds that perfectly mirror toys. Properly shaped pockets are integral in keeping the toy in place and preventing its unnecessary movement, reducing the chances of scratching and breakage. Consequently, the toy remains centered during shipping and retailing.

Safety standards

Safety Standards

Inclusion of safety features, such as the use of non-toxic materials and crack resistance, is the topmost priority when developing toy blister packaging. Here are a few safety standards for blister packaging:

Child-Safe Packaging: Design of packaging must incorporate elements recommended in CPSC and ASTM guidelines. Packaging should be child-resistant and child-safe yet have a parent-friendly design and should not allow access to small and hazardous parts.

Smooth Edges: There shouldn’t be any sharp edges or rough cuts on the packaging, as they may injure the person who is handling it. Corners, contours, and edges of toy blisters should be smooth and round.

Branding and Printing

Branding and Printing

These elements have prominence when designing blister packaging for toys because branding, aesthetics, colors, and printing directly impact customer buying choices and convey important information about toys.

Logos: Brand logos and taglines should be prominently displayed on packaging. This leads to quick product recognition and reinforces customer trust.

Graphics: Design of toy blister packaging must feature high-quality images, colors, patterns, and shapes. Attractive graphics make toys stand out on shelves. However, select that combination of graphics that complement toys instead of taking attention away from them.

Product Details: Besides graphics, packaging design must include clearly printed product details, like its name, recommended age group, usage, compliance certifications, and warnings.

User Convenience

User Convenience

To enhance user experience, manufacturers prioritize user convenience when designing blister packaging.

Easy-Open Features: Toy blisters are generally ergonomic in design, incorporating various opening and closing options for user convenience. Various features, like tear-open strips, peel-back seals, zippers, and sliders, provide easy access to parents.

Theft-Prevention: Adding theft prevention features while designing the toy blister packaging stops thieves from stealing the toys. In addition, temper-evident elements secure products against counterfeiting.

6.What is the Manufacturing & Packaging Process of Blister Packaging for Toys?

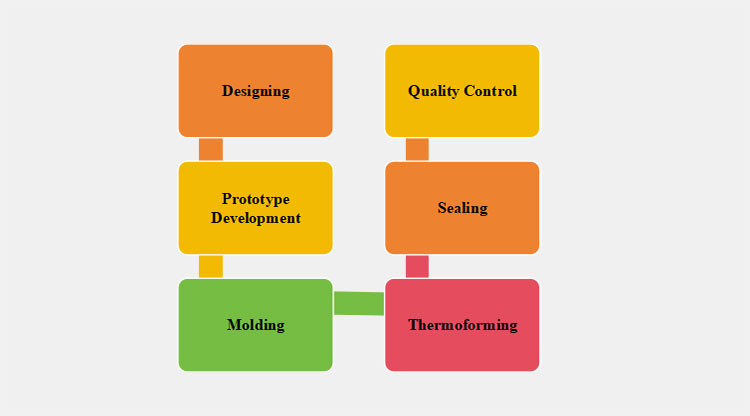

The manufacturing & packaging process for toy blister packaging is a complicated operation, consisting of steps requiring total precision and control. Here is a brief overview of these steps:

Steps from design to mold making

Manufacturing & Packaging Process of Blister Packaging for Toys

Designing

In the first step, manufacturers and developers study characteristics of products, for instance, their shape, size, and protection needs in detail by measuring their exact dimensions. Based on these characteristics, developers draw rough sketches of the blister cavities using CAD software. This design is a perfect balance of safety, usability, and branding.

Prototype Development

After receiving approval of the design, the next step in the toy blister packaging manufacturing is prototype creation. A custom plastic blister mold is developed to test the aesthetics, structural integrity, accessibility, and functionality of packaging. This allows manufacturers to improve or modify the design of packaging before going to mass production.

Molding

Before forming molds for blister packs, appropriate materials, such as copper, aluminum, or stainless steel, are selected for creating mold trays. Afterwards, these materials are fabricated to form a final mold. This mold serves as a negative impression for blister packaging for toys.

Thermoforming and sealing methods

Thermoforming

After the creation of molds, the thermoforming process is carried out to prepare blister cavities. This step typically begins with the heating of a plastic sheet to form three-dimensional plastic pockets.

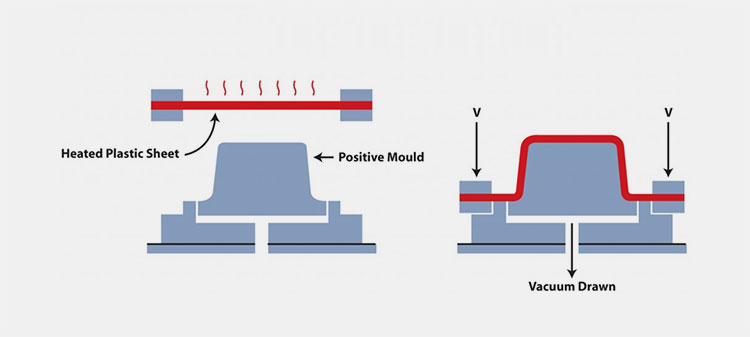

Vacuum Thermoforming- Picture Courtesy: Euro Extrusion

Vacuum Thermoforming: With heating, plastic sheets melt and become malleable, then, using a vacuum, the melted polymer is draped or sucked into the mold.

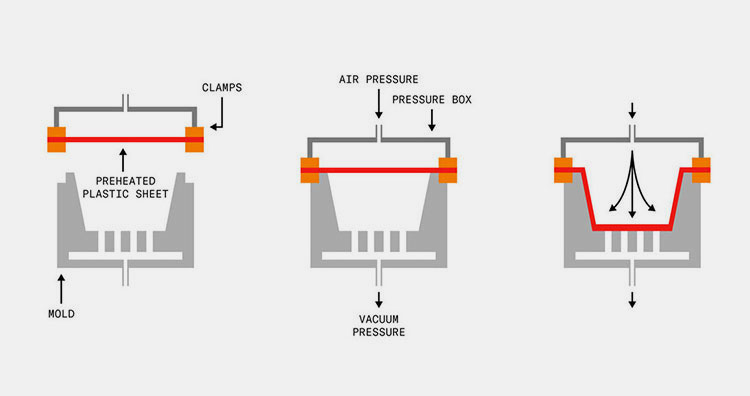

Pressure Thermoforming- Picture Courtesy: Plastic Resources Inc.

Pressure Thermoforming: Sometimes, in addition to vacuum, pressure is also applied to create blisters with intricate details. Plug-assisted mechanism stretches the film and forces it into the mold with pressure. This helps to form a blister cavity with uniform depth and wall thickness.

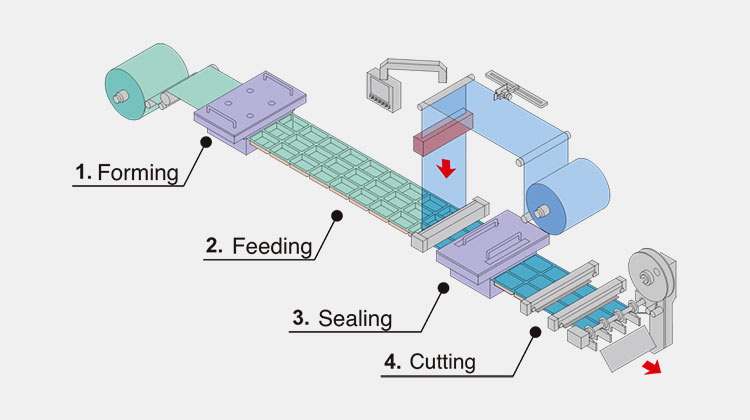

Sealing

Sealing – Picture Courtesy: omori.co.jp

Upon successfully inserting toys into blister cavities, sealing of the blister with lidding material takes place. Manufacturers use different methods, such as heat, ultrasonic rays, or pressure-sensitive adhesives, for sealing. Heat sealing is the most widely utilized method, whereas ultrasonic or cold sealing are utilized when products are sensitive to high temperatures.

Quality control and Compliance (ISO, CPSC, ASTM Standards)

Quality control and Compliance (ISO, CPSC, ASTM Standards)

After sealing, quality control assessments are carried out to verify seal integrity, impermeability, and overall physical appearance. Various compliance standards are essential in maintaining quality at par with global benchmarks for toy packaging. Here are some significant regulatory standards that ensure global market acceptance:

| ISO | It’s a globally recognized compliance standard focused on quality and safety management. ISO standard guidelines cover safety, sustainability, and quality assurance of packaging throughout the whole manufacturing operation. |

| CPSC | Applicable in the USA and stands for Consumer Product Safety Commission. The main objective of this regulation is to protect consumers and children from exposure to hazardous materials. It mandates child-safe and tamper-resistant packaging. |

| ASTM | Its abbreviation is American Society for Testing and Materials. To comply with this standard, the manufacturer must conduct selling strength checks, leak detection, and tensile properties inspections. |

7.What are the Cost Factors to Consider for Blister Packaging for Toys?

There are several critical factors that affect greatly on blister packaging for toys, some of the factors are described below.

Design complexity and customization

Design complexity and customization

In blister packaging, design intricacy and customization greatly on cost. Standard shapes and sizes are relatively affordable, in cases of customization, for instance, added compartments for batteries and toy pieces, customized shapes and distinctive prints and graphics need specialized equipment, thereby elevating overall cost.

Material selection impact on cost

Material selection impact on cost- Picture Courtesy: Silver Edge Packaging

Material selection is another factor that particularly impacts the cost. The price of packaging material like cardboard and plastic varies depending on its quality and choice. Conventional cardboard is relatively affordable, while premium cardboard with features like quality finishing, coatings, high grams per square meter and attractive printing leads to price escalation. Similarly, affordable plastics like PVC are cheaper, while sustainable alternatives in plastics such as PLA or PET are cost-intensive due to their environmentally friendly properties, which thereby increase the cost.

Production volume

Production volume- Picture Courtesy: Half Price Packaging

Production volume such as low scale and high-scale production influences the cost-effectiveness of blister packaging. Mass production generally utilizes material effectively and distributes the cost over a larger output, which reduces per per-unit cost. On the other hand, small-scale production is relatively expensive compared to mass production, since the setup charges and tool alterations in small-scale production result in leftovers, unused resources and offcuts. Therefore, it is essential to analyse the production scale for cost efficacy.

Shipping, logistics, and storage costs

Shipping, Logistics, And Storage Costs

Shipping and logistics are aspects that highly contribute to the overall cost of packaging. In transportation, large and heavy shipments are comparatively expensive and cost-intensive compared to small packages; similarly, items that are fragile requires extra care in handling as well as additional assistance, leading to cost surplus.

8.What Things Should You Know When Choosing the Right Supplier?

There are certain factors that you should know before choosing the right supplier, some of them are outlined below.

Things Should You Know When Choosing the Right Supplier

Key supplier evaluation criteria

While choosing the supplier, the main aspect to consider is that the supplier must possess international regulatory certifications such as ISO 9001, GMP and toy safety regulations. These certifications are the primary proof of reliability. In addition to that, a supplier’s past experiences, similar case studies and his customer references add to his credibility level. These essential factors must be considered before making the decision of purchase.

Overseas sourcing vs. local suppliers

The debate on the selection of a supplier, whether overseas or local, completely depends on the priorities and requirements of the business. In international sourcing, there are generally diverse options available for material choices with strategic pricing, while it is complex to coordinate and communicate with overseas suppliers, and they also increase the potential risk related to customs duties. While local suppliers are easier to communicate with and offer effortless logistics, this leads to augmented production times in business.

Importance of sampling and communication

In order to build a trustworthy and long-term relationship in business, it is highly crucial to maintain transparency and clear communication to comprehend requirements and requests on both the supplier and buyer sides. Another main factor to consider is to assess the quality and finishing of the product prior purchase, and for that, it is recommended to request samples before making the purchase, this way you can evaluate material quality and finishing, preventing the risk of business loss.

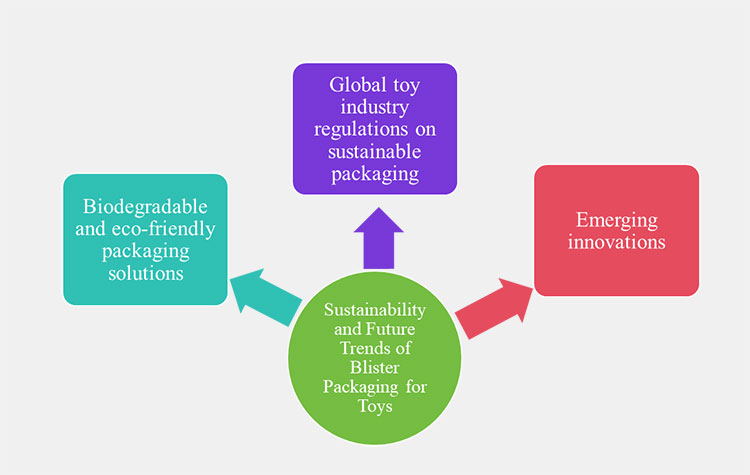

9.What are the main Sustainability and Future Trends of Blister Packaging for Toys?

The main sustainability trends and future practices in terms of blister packaging for toys are mentioned below.

Sustainability and Future Trends of Blister Packaging for Toys

Biodegradable and eco-friendly packaging solutions

In recent years, there has been a growing emphasis on the usage of sustainable materials in blister packaging for toys, in order to prevent plastic waste and other toxins, considering their environmental effects. As a result of this, manufacturers are incorporating sustainable and biodegradable materials such as eco-trays, paper-based, and plant-based materials in toy packaging. These factors also optimize brand credibility by attracting consumers who are environmentally aware.

Global toy industry regulations on sustainable packaging

Many countries have made it mandatory to comply with strict regulations in order to restrain the use of plastics in blister packaging for toys, streamlining the use of sustainable alternatives. The European Union (EU) has strict rules for labelling and waste material regulation for toy packaging; other countries are also promoting similar practices to encourage sustainability. Non-compliance can lead to legal action and strict penalties.

Emerging innovations

Emerging innovations in packaging industries, such as QR code incorporation and NFC-enabled packaging, are shaping the future of toy packaging. These innovations enable users to access user instructions, safety rules and product details with just a tap. In addition to that, attractive graphics and visual features captivate the attention of customers, which also enhances the brand name and integrity.

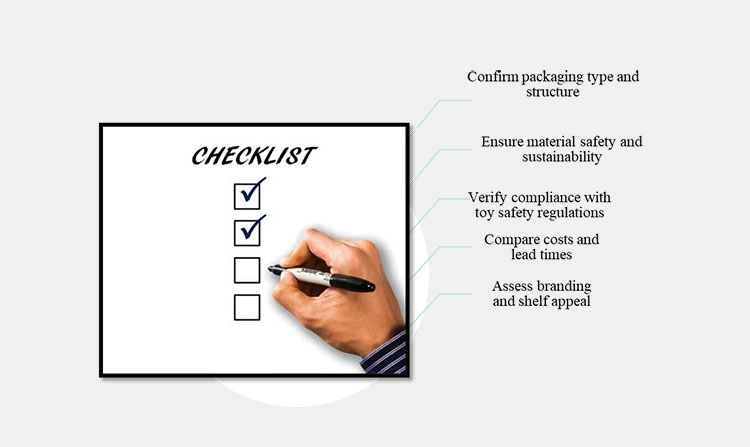

10.What is the Buying Checklist for Toy Blister Packaging?

There are several important factors to take into consideration before making the blister packaging purchase. Some of them are outlines below.

Buying Checklist for Toy Blister Packaging

Confirm packaging type and structure

There are several types of blister packaging available for blister packaging for toys; you must choose the one that is most well-matched with your product requirements. Clamshell blister is the kind of packaging that offers durable, fully enclosed, resealable option, which is ideal for premium items, in terms of their safety and care. On the other hand, there are sustainable and cost-effective options like carded blisters, which are attached to printed backs, and trapped blisters, which hold the toy between two cards.

Ensure material safety and sustainability

To ensure material safety in blister packaging for toys, it is important to evaluate materials before making the purchase. Plastics like PET and PVC are non-toxic and comply with regulatory requirements which ensures customer safety in blister packaging for toys. Other alternatives like recycled plastics and PLA are expensive, but they are eco-friendly options that enhance sustainability, leading to brand success and credibility.

Verify compliance with toy safety regulations

Compliance with toy safety regulations is one of the most important factors to consider before making the blister packaging purchase. Non-compliance with these safety regulations can result in legal penalties and product recalls. It is important to evaluate the blister packaging according to the regulatory requirements, such as labelling guidelines and standard packaging materials, in order to optimize brand integrity and consumer safety.

Compare costs and lead times

Cost-effectiveness is the main factor to consider before selecting the blister packaging. Cost varies depending on the complexity of the design structure, added customizations, and choice of materials. There are also sustainable options that promote eco-friendly packaging, but they are generally more expensive. It is also important to evaluate lead times; some factors that influence the production times are logistics efficiency and production capacity.

Assess branding and shelf appeal

Product success is driven by brand image and shelf appeal, and so, it is crucial to evaluate blister packaging before purchase in terms of your brand-specific requirements. To enhance shelf appeal, you must incorporate premium printing, attractive designs to enhance your brand’s visual impact in a competitive market.

Conclusion

The blister packaging for toys has proven ideal solution for advanced and tamper-evident protection. If you’re in the market, you must evaluate the above-mentioned points, such as production volume, estimating cost, etc., to ensure that the right packaging option is in your budget. If you’re interested in exploring more information related to blister packaging for toys, reach us to a trusted machinery supplier. Just send us a quote for a free consultation today or find a suitable solution for your brands.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine