Capsule Blister Packing Machine: The Complete Buying Guide In 2025

Have you ever wondered how your perfectly sealed, temper resistant and safe capsule inside an eye-catchy blister pack?

Imagine a machine that pack hundreds of capsules per minute by preserving its quality, precision and ensuring every capsule has accurate dose. The magic lies in capsule blister packing machine. But with so many packing machines available in a market, which one you can buy for your business?

This complete buying guide of AIPAK will provide you complete information about the capsule blister packing machine. In 2025, various capsule blister packing machines are revolutionized worldwide, could you invest on the right machine for the packing? What are the components and what is the working principle of capsule blister packing machine? At the end of this guide, you will have a complete information about this machine.

1.What do you know about capsule blister packing machine?

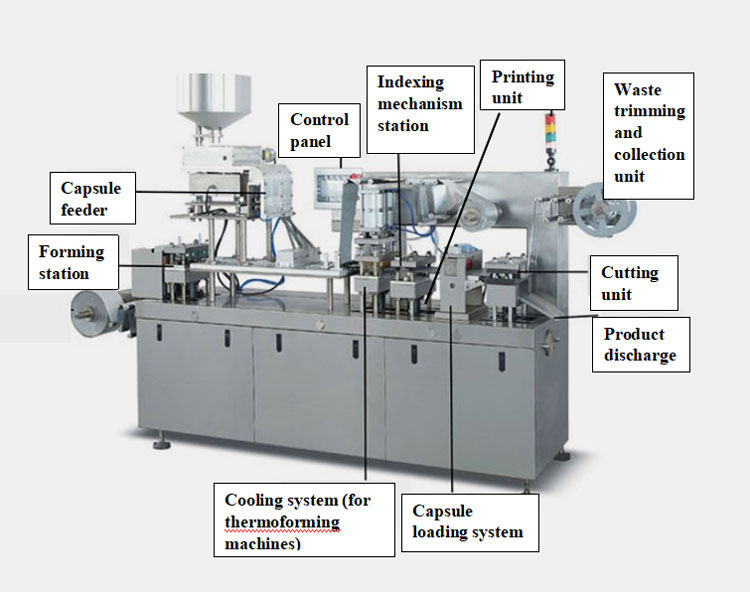

AIPAK capsule blister packing machine

A capsule blister packing machine is a type of machine that is primarily used in pharmaceutical industries to pack capsules in blister packs. The blister packs are usually pre-formed or materials used for making blisters are PVC, Alu-Alu, in which capsules reside which is covered and sealed with the help of foil.

The capsules in blister packs are silently fighting against the sunlight, moisture, heat and providing shield against damage.

2.Can you take advantages by using capsule blister packing machine?

The capsules in blister packs are lasts longer and look professional. This is not only due to just its formula but also the packaging of these capsules, which is only possible due to capsule blister packing machine. Let’s explore the benefits of capsule blister packing machine which make it possible:

Protection of capsules:

Protection of capsules

The machine makes a blister packs for the capsules in which these glossy and shiny capsules resides. These capsules are protected from external agents like oxygen, sunlight, contamination and damage. This is the way through which the shelf life of capsules increases and wastage of your capsules are prevented.

Precise dosing and temper evidence:

Precise dosing and temper evidence

In this machine, individual capsules are sealed. Proper filling of material in each capsule ensures accurate and precise dose. Precise dose make each capsule effective and treatment becomes guarantee.

The blister packs are strong and temper which makes resistant to open.

Ease of use for consumers:

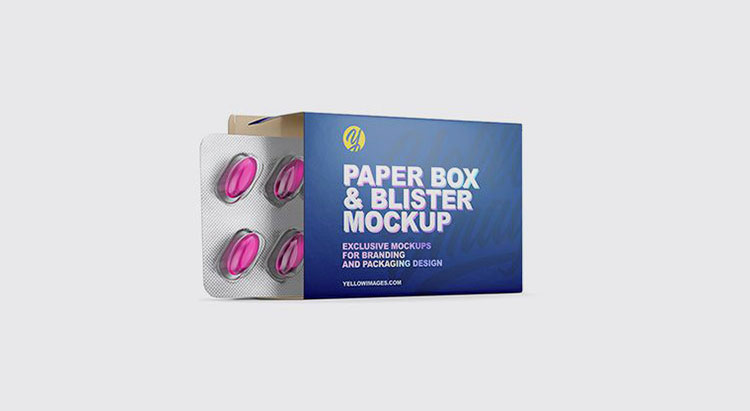

Ease of use for consumers-Picture courtesy: yellowimages.com

The capsules are packed in the blister with the help of the machine. The packs can easily be carried, store and can carry during transportation. You can easily store them without any fear of damage or leakage of the capsules. The elderly people can get benefited the most by using capsule blister packs.

Better inventory and dispensing control:

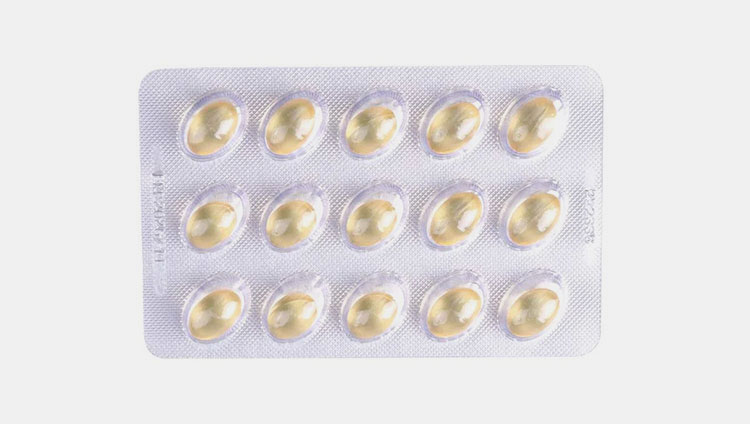

Better inventory and dispensing control-Picture courtesy: free3d.com

The packaging of capsules in blister packs allows for easy counting. The doctors prescribed you the doses of capsules and its package can aid you in figuring it counting. Additionally, you can easily track the dosage with the help of printed batch numbers and barcodes.

The pharmacist provides them to the customers the accurate quantity of dose without touching them.

Attractive presentation:

Attractive presentation

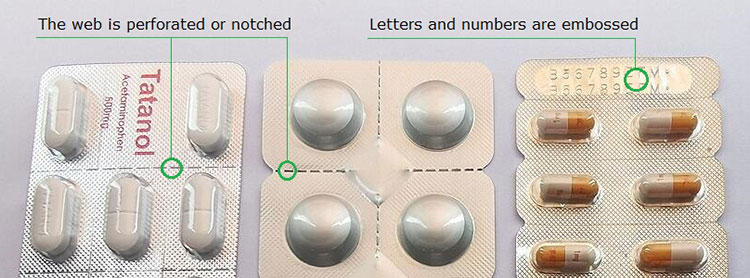

The blister packs are well-sealed and the seal is strong so, it ensures the capsules safety from the environment. The expiry date, barcode, batch number and dose print on the blister makes it attractive towards the customers.

The perfect and visual appealing of these packs satisfy the customers and can rule the market.

3.What materials are suitable and go well with a capsule blister packing machine?

In pharmaceutical packaging, every capsule is a promise of accurate dose, its packing in blister packs ensure the care, love and safety of its capsules. The materials that can be used and handled by capsule blister packing machine are as follows:

PVC (Polyvinyl chloride):

PVC (Polyvinyl chloride)-Picture courtesy: aenova-group.com

It is the most commonly used forming film which is transparent, thermoformable and strong. The film is flexible and easily can mold into the cavities. This film is suitable for drugs having short to medium shelf life. It is often combined with other materials to enhance the protection against moisture and oxygen.

PVC/ PVDC ( polyvinylidene chloride-coated PVC):

PVC/ PVDC ( polyvinylidene chloride-coated PVC)

PVDC coated PVC is suitable for semi-sensitive drugs. It can retain the moisture content. The transparency allows the visually of the products.

This film maintain the appearance and also adds chemical resistance.

PVC/PE/PVDC (Multilayer films):

PVC/PE/PVDC (Multilayer films)

This layer is multilayered having PVC makes a structure, PE has property of heat sealing and PVDC is barrier layer. It is used for advanced protection and for sealing strength. This film is suitable for high speed machine.

Alu-Alu ( Cold formed Aluminum):

Alu-Alu (Cold formed Aluminum)-Picture courtesy: ted.com

This is used for high barrier packages but does not allow the visibility of the product. The property of this film is not thermoformed, it is cold formed. This film is suitable for light sensitive drugs, in which the drugs are safe from the light.

Aluminum Foil ( Lidding material):

Aluminum Foil (Lidding material)-Picture courtesy: alfipa.com

Aluminum foil is used to seal the blister cavity. The foil is non-transparent, lit can be plain or printed. The lid is printed with expiry date, batch code and barcode and provides barrier against moisture, oxygen and UV light.

PET ( Polyethylene Terephthalate):

PET (Polyethylene Terephthalate)

It is used as a supportive layer or combine in multilayer films. It provides high clarity and mechanical strength. It improve the printing capacity on the pack and also enhance structural integrity.

4.Enlist the types of capsule blister packing machine?

The crafting styles of all the capsule blister packing machine is not alike, the world of capsule blister packing offers a great variety from breathing heat to form cavities to cold forming. Each one has its own unique style, tailored to the materials and production capacity. Let’s dive into the fascinating world of capsule blister packing machines:

Based on operation mechanism:

On the basis of the operation mechanism, like the film cavities production can be either due to heat or due to mechanical pressure. There are two types of machines that are thermoforming blister packing machine and cold forming packing machine.

Thermoforming blister packing machine:

AIPAK thermoforming blister packing machine

The thermoforming blister packing machine is a type of blister forming machine in which the capsules are packed. This machine has a specialized system through which the plastic usually PVC is heated until it can mold. Then, through air pressure or vacuum, the cavities are formed in which the capsules are filled and then sealed with a lidding material like aluminum foil.

Advantages:

This machine is ideal for those capsules to which visibility matters. It also uses less expensive materials for forming cavities and sealing. You can adjust shapes and sizes for various materials. It is ideal for fast and high volume production of the products.

You can use this machine in pharmaceutical, food, electronic, and Nutraceutical industries.

Limitation:

This machine is not suitable for light or temperature sensitive drugs or capsules.

Cold forming blister packing machine:

AIPAK cold forming blister packing machine

The cold forming blister packing machine does not use heat for forming cavities. The Alu-Alu sheet is fed in the forming station where, with the help of mechanical force, the blister cavities are formed. The products like capsules are filled in these cavities and then at controlled temperature and pressure, the capsules are sealed with the aluminum foil.

Advantages:

Alu-Alu packaging

This machine is used for the packaging of those capsules which are sensitive to light and moisture. The material used for blister packs can protect the capsules from moisture, heat and light. In this way, it provides high protection to the capsules.

Limitations:

The cold processing blister forming is time taking process as compared to thermoforming. It uses multilayered aluminum films which is more expensive. You can’t inspect the capsules without the additional transparent windows.

Based on automation level:

Some blister packing machine fully processed the operation from unwinding the film, heating, and filling, sealing and discharging the blisters while other needs the operators for carrying out the tasks. On the bases of automation, they are divided into three types. These are as follows:

Fully automatic blister packing machine

AIPAK fully automatic blister packing machine

The fully automatic blister packing machine automatically unwound the film. With the help of thermoforming or cold forming, the films are molded into the cavities and then these cavities are filled with the desired products to be packed. Then it is sealed with the help of sealing materials by applying controlled temperature and pressure.

Advantages:

This machine is suitable for quick switch between thermoforming and cold forming by forming Alu-Alu packs, high barrier ensured, and child resistant blisters formed. It does not need the help of operator and automatically enclosed and discharge the blisters. You can use it in large pharmaceutical industries, food, chemical, veterinary and electronic industries.

Limitations:

It is expensive tool and the complete changeover of the machine still needs skilled technicians. This machine is more expensive and requires high maintenance for efficient work.

Semi- automatic blister packing machine

Semi- automatic blister packing machine-Picture courtesy: inos.in

A semi-automatic blister packing machine operates between automated mechanical steps and manual operators steps. The operator fed the films into the machine. If the machine includes thermoforming station, the operator indexes the plastic sheet and then machine formed a cavities in the film.

The operators then load the products in each cavity and then place an aluminum foil over it. The machine then seal it with the help of controlled temperature and pressure.

Advantages:

It is suitable for small volume production and for startups and pharmaceutical training centers. The machine parts can easily be clean and inspect. You can easily pack the irregular products by filling and sealing them in a blister and prevent them from damage.

Limitations:

For high batch production, the operator and staff needs increases and create blister packs at slower speed. The operators may feel low and fatigues and leads to inconsistent batch production. The manual filling of capsules may cause contamination. The production capacity is low as compared to fully automatic machine.

Manual blister packing machine

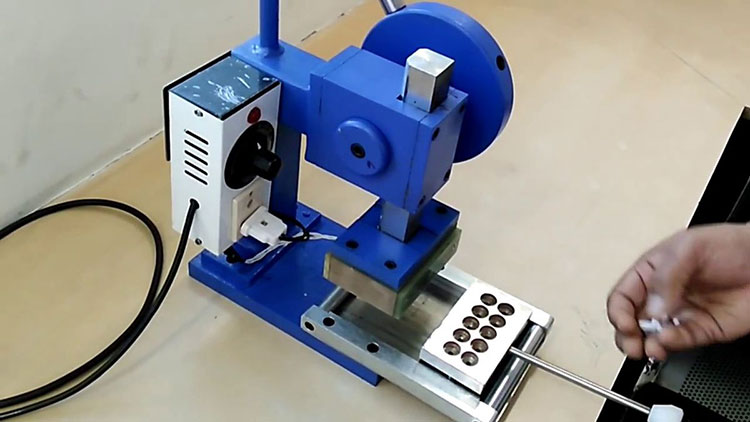

Manual blister packing machine

A manual blister packing machine is the simplest machine and the steps are carried out by hands. The operator cuts the film and the plastic is heated with hot air gun. The cavities are formed with the help of hand-lever presser and molds it into pockets.

For cold form pockets, the pre-drawn cavities supplied from a vendor and form cavities. Then, the capsules are placed in these cavities and placed an aluminum foil. The heated hand-lever is then used for pressing the foil to seal the blister packs.

Advantages:

This machine is inexpensive and good for packing irregular products in the cavities. The automated feeder have the possibility to damage the products which can be avoided by using this machine. It is ideal for use in teaching labs and personal use.

Limitations:

The production of blisters is usually 1-3 blister cards per minute which means it is slow process. The possibility of products mixed-up is high and have risk of contamination. Need trained operators for professional pocket depth creation and high seal strength production.

5.Do you know the components of capsule blister packing machine?

Do you know the elegancy of each capsule in a blister packs is due to the combined efforts of the different machine parts? Let’s discover these unconditional components:

| Components | Function | Importance |

|

Capsule feeder |

In this station, the sensors are implanted. The feeder is used to place the undamaged capsules in the formed cavities and prevent them from misplacing. | This system ensures every capsule is correctly placed in the cavities and reduce the human error and contamination. |

|

Forming station |

This station is used for forming the cavities in which the production should be reside. For thermoforming, heat plates and vacuum and pressure system are implanted. For cold forming, punches are dies are placed. | The forming station is used to form protective shell around each capsule, where its safety is ensured and protect them from damage. |

|

Capsule loading system |

This system includes brushes or guide channels which place the capsules in the formed cavities. | This system allows the correct placement of each capsule in the right cavity. Due to which, defective sealing is prevented. |

| Sealing station | This station has temperature and pressure sensors which is used for aluminum foil bonding to the filled capsule cavities. | The sealed blisters protect the capsules from light, heat, and contamination. Due to no exposure to environment, the shelf life of capsule increases. |

| Product discharge | In this station, you can collect the finishes capsule blister packs. | You can collect the blister packs easily. |

| Indexing mechanism station | This system moves each capsule pack in a timed and accurate manner. | This system maintains all machine stations in coordination like forming, filling, sealing and cutting, it also ensures high precision |

| Cutting unit | It has rotary blades which cut the blister sheet into individual packs of specific size and shape. | It finalize the packs and prepare it for cartoning. |

| Waste trimming and collection unit | It contains the trimming blades and collector which removes and collect the leftovers. | It keeps the machine and workplace clean by dispensing the waste products. |

| Control panel | It is consider as the brain of a machine. It has PLC, HMI and emergency button which can monitor and regulate the machine functions. | It provides flexibility and control functioning of the machine and produce efficient and quality capsules bristle packs. |

| Printing unit | This unit have inkjet printer which print batch number, expiry date, dose etc. on the plastic or aluminum foil. | Labelling ensures the safety and traceability of the products. |

| Cooling system (for thermoforming machines) | This has cooling chambers or cooling fans that is used in the cooling of capsule cavities before filling them with a capsule. This ensures the maintenance of the shapes and product safety. | This can protect the shapes of the formed cavities and ensure that the capsules quality remain high and effective. It can also help in proper placements of the capsules and hence, well-sealed blister packs are produced. |

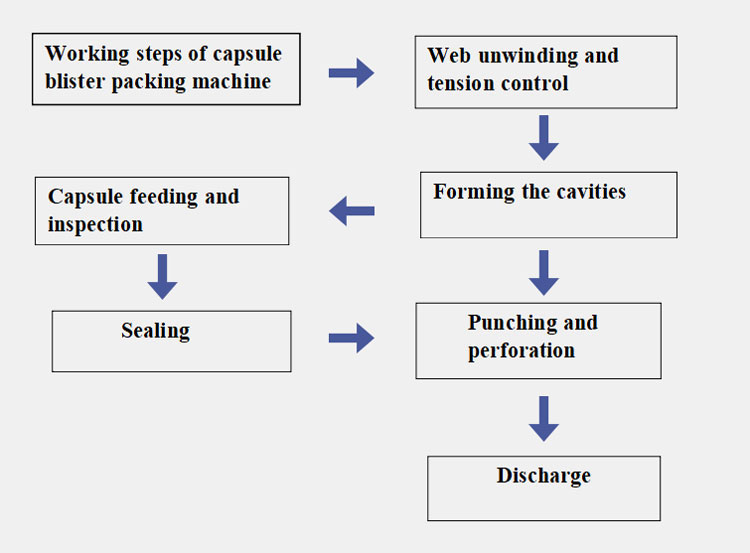

6.What is the working principle of capsule blister packing machine?

Have you ever wondered how the capsules are perfectly aligned and packed in the shiny, strong, and untouched human hands packs? This is the combined effort of mechanical choreography and thermal precision. Let’s explore the steps:

Web unwinding and tension control:

The roll of forming materials like PVC, or Alu-laminated and lidding materials usually aluminum foil is fed into the machine. The edge sensors in the machine keep the film and foils perfectly centered.

Forming the cavities:

Forming the cavities –Picture courtesy: grandpackmachine.com

The two categories of cavities forming are thermoforming and cold forming. In thermoforming, the foil is passed through a heater which heats up and soften the sheet. Then, it drops into the chamber where the air compressed pulls it into the individual pockets.

In cold forming, the foil remains at room temperature and mechanical tools make a cavities on the film.

Capsule feeding and inspection:

Capsule feeding and inspection

The capsules to be packed are fall from the hopper into the brush feeder. Here, the capsules are properly aligned before filling. Then the capsules are filled into the properly formed pockets.

The vision system make sure that the damaged capsules, leak capsules and empty capsules to be eliminated for later rejection and customer’s satisfaction.

Sealing:

Sealing

The filled cavities are then covered with an aluminum foil for sealing procedure. In thermoforming sealing, the foils are heated and in cold forming, at room temperature foil flattened. Then pressure in applied for some time to properly bonding between the foil and the plastic occur.

Punching and perforating:

Punching and perforating –Picture courtesy: jornen.com

The sealed packs sheets are then cut into individual or multipacks with the help of rotary dies. The notch-cut and snap-lines perforation also occur.

Discharge:

Discharge of blister packs

The blister packs are then discharge from the machine through conveyor. You can collect the finished capsule blisters and further proceed for the cartoning.

7.Can the capsule blister packing machine handle different sizes and types of capsules?

Yes, the capsule blister packing machine can handle a variety of sized, shapes and materials because it has adaptable and programmable systems. It is an essential tool in those pharmaceutical industries which can make and pack various drugs of different dosage and forms. The flexibility lies in:

Adjustable tooling and machine parts:

Various shapes of capsules

In the capsule blister packing machine, adjustable tools like forming dies, feeding tracks, sealing plates and cutting tools are available and can adjust according to the desired dimensions of the capsules.

It also have different formats available for various shaped capsules like oblong, round, hard gels and soft gels capsules.

Programmable settings:

The PLC and HMI is available in this machine where an operator can set different dimensions like the pocket depth formation, the sealing temperature etc. for providing good environment for each capsule.

Versatile feeding mechanism:

The feeding heads are adjustable for different capsule types like hard gelatin and soft gelatin and can handle and align them accordingly. This machine has adjustable system for various sizes, nature and types of capsules to ensure there is no damage to any capsule.

Multi-cavity design:

Multi-cavity design

This machine has a unique and customized features like it can hold various capsules in a single blister pack and the customers can get benefit if the patient is taking multiple capsules at a time. It can also be adjustable to hold capsule and tablets in a single pack and you provides convenience to the customers.

Inspection and rejection compatibility:

It has sensors which can detect the proper alignment of various capsules according to their type and size. It can also extract the damaged capsules from the machine and prevent them from placing them in a blister packs.

8.How can you maintain a capsule blister packing machine?

Behind every perfectly sealed capsule in a blister packs lies the hard work of the capsule blister packing machine. The amazing machine has a unique systems that are only as reliable as their upkeeps. For gaining the perfectly sealed and efficiency of this machine, you must be look after this machine. The art of maintenance is the only solution for smooth running.

Daily cleaning:

Daily cleaning-Picture courtesy: symclean.co.uk

Before proceeding the steps and after the batch formation, you must be clean the machine by removing dust, capsule residues and other waste materials which produce during filling, sealing and cutting.

You must use compressed air or approved cleaning agents to prevent contamination in the machine parts.

Lubrication:

You should lubricate the machine parts with recommended lubricants of the manufacturer. The lubrication of moving mechanical parts will ensure the safety and preventing strange sounds during operation.

Inspection of wear parts:

Inspection of wear parts-Picture courtesy: boomandbucket.com

You have to check the parts like heating plates, forming molds, sealing system and feeding tracks to ensure the smooth operation of the machine. If you find any damaged or wear part, then replace them to prevent the later loss of the materials.

Alignment and calibration:

You must ensure the proper alignment of the feeding system, web series and die cutting stations for damaging and losing of the materials.

You should also calibrate the pressure, temperature sensors and various other settings before the machine working.

Electrical and pneumatic checks:

You must have to check the wiring and other connections for preventing unexpected traumas. Also check the valves and pressure, temperature gauge to function properly.

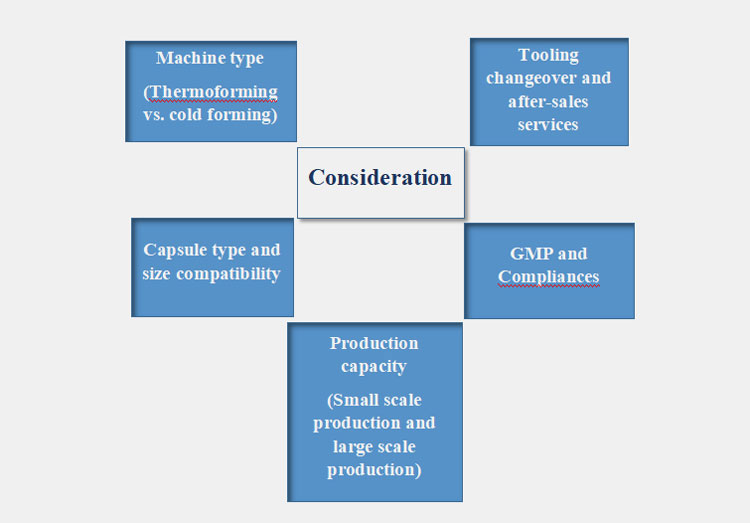

9.What should you consider while buying a capsule blister packing machine?

Imagine an investment on machine which is a heartbeat of your capsule blister production, is just look at the price tag is enough for investing in the machine? With so many types of capsule blister packing machine, how do you choose the right machine? The key factors to be considered are as follows:

Machine type:

If you are looking for thermoforming packaging, faster output and clear packaging then invest in the thermoforming machine.

If your capsules are sensitive to light and moisture, then invest on Alu-Alu or cold forming machine.

Capsule types and size compatibility:

Capsule types and size compatibility-Picture courtesy: lfatabletpresses.com

If you are packing various drug products in a single blister pack then ensure that the machine can handle various types and sizes of drugs. Check that the machine has multi-pack formats.

Production capacity:

Consider your production need then choose the right machine. The output needs depends on lab scale production, small pharmacies or large production in industries. Also investigate the per minute production capacity and speed of the machine.

GMP and Compliances:

The machine should meet a standards like GMP, FDA, and CE. If the standard meets then it ensure the safety, validation and hygiene.

Tooling changeover and after-sales services:

The machine should performs changeovers between batches and the machine parts should must be accessible for cleaning.

Choose the platforms which offers you training and where spare parts are available.

Conclusion:

In the pharmaceutical industries, production, precision and product safety is essential and for that, capsule blister packing machine meets all the requirements. There are too many machines are available but you should consider the understanding of product needs, automation level and thermoforming and cold forming processes. This comprehension guide in 2025 completely guides you about the packing machine and trusting on brands like AIPAK guarantees you high safety and productivity of your products and also ensures your business will stay competitive in the market. For more information, contact us!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine