Types Of Vacuum Emulsifying Mixer For Pharmacy

An interesting phenomenon of drug formation begins with mixing. Every pharmaceutical product follows a multistep mixing procedure to form an excellent and smooth textured product. With more advancement in technological sciences has emerged innovative solutions for mixing job. Yes, we are talking about a vacuum emulsifying mixer.

You must have aware of this technology; a closed system with internal pressure gets lowered than atmospheric pressure to create a vacuum. In the context of mixing and drying, this technology has been a game-changer since pioneered in the 1970s. In this interesting article, Types of Vacuum Emulsifying Mixer for Pharmacy will be discussed.

Table of Contents

Ⅰ.What are the types of vacuum emulsifying mixer for pharmacy?

Vacuum emulsifying mixers are classified on the basis of various aspects such as:

BASED ON AUTOMATION

Automatic Vacuum Emulsifying Mixer

These mixers are offered with high shearing head that moves with high velocities. These have blades and homogenizer for mixing and emulsification of high viscosity substances respectively.

These mixers are fully capable for executing mixing and emulsification steps without necessary human aid. By using vacuum system, the materials are automatically drawn in machine.

Due to automation, the mixing and dispersion is achieved quickly. Cleaning of these mixers is easy owing to installation of CIP system.

Semi-automatic Vacuum Emulsifying Mixer

These mixers are capable of functioning itself and with operator aid. These materials are poured by human in water and oil pots. The machine performs emulsification itself while materials are removed by humans.

Cleaning and maintenance procedures in these mixers are complicated as these are not offered with CIP and SIP.

BASED ON PRODUCTION SCALE

Laboratory Vacuum Emulsifying Mixer

These mixers are employed in laboratory and small scale pharmacies because of their small size and portability. These are used for blending various chemicals with specific mixing values.

These machines are cost-effective solution for small business because of their affordability and easy installation.

Large Scale Vacuum Emulsifying Mixer

These mixers are equipped with latest technology and are used in mass production of creams, paste and suspensions in chemical, pharmaceutical, and food industry.

The large scale mixers are provided by touch screen automated panel, timers, and recorder. The forces generated in these machines facilitates shearing, mixing and dispersion. They provide large output in short period.

BASED ON DESIGN

Bottom Homogenizer Vacuum Emulsifying Mixer

Here, the homogenizer is located at the bottom of pot. The upper part has scraping stirrer. Impact force is strong in these mixers and materials are quickly emulsified.

Air bubbles are not formed due to direction –top to bottom-of emulsification force. The materials are mixed with help of gravitational force. The price of these equipments is less but it is quite difficult to clean these machines and these usually require CIP systems for cleaning.

Top Homogenizer Vacuum Emulsifying Mixer

These equipments are supplied with top entry homogenizers and these are usually present at the top of cover. The mixers handle variety of materials and are easy to clean due to position of homogenizers. These mixers help to attain uniform and thorough mixing

Fixed Homogenizer Vacuum Emulsifying Mixer

This type of mixer is typically employed in mixing of substances on large scale. In this mixer, the lid is attached to pot body and cannot be separated.

The movement of stirrer brings materials in space between stator and rotor resulting in hydraulic shear which brings about emulsification. These mixers are employed in cosmetic, fertilizer, paper, medicine, and personal hygiene industry.

Ⅱ.What working principle do types of vacuum emulsifying mixers for pharmacy follow?

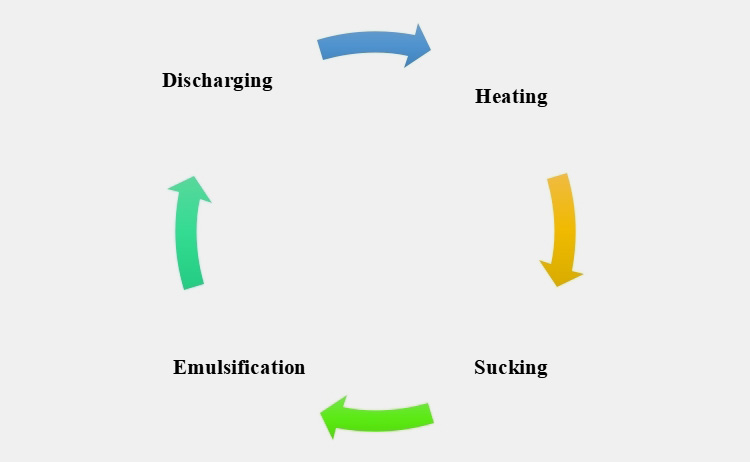

The basic working principle is same for all types of vacuum emulsifying mixers. Some fundamental steps are penned below for your understanding.

Heating

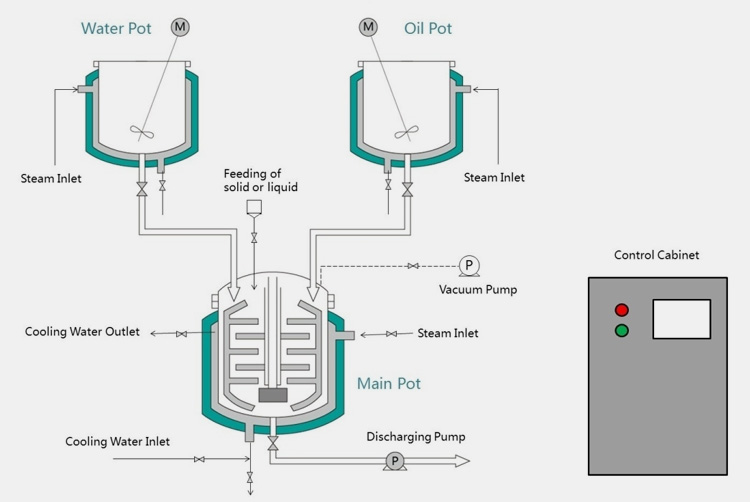

In first step, water pot and oil pots are heated by electric current or by steam unit.

Sucking

Water and oil are then drawn in by emulsifying pot via soft pipes.

Emulsification

The mixing is carried out by the primary agitator. During this stage, the materials are continuously blended, stirred, mixed, and cut by the rotary vanes resulting in formation of new interface of materials continuously. This process is repeated till particles are of the size of 200nm- 2µm.

The hydraulic pressure and centrifugal force produce impact on particles thousand times per minute resulting in emulsification of raw materials. This resultant mixture is of superior quality and bubble free.

Discharging

The materials settle down at the bottom of emulsifying pot and are extracted through the discharge valve located at the lower part of the machine.

Ⅲ.What are the general applications of types of vacuum emulsifying mixer for pharmacy?

Every mixing function such as emulsifying, suspension and dispersion is performed by vacuum emulsifying mixer. These mixers are essential in almost every industry for carrying out mixing of various pastes and creams.

Some of useful applications of these equipments are given below:

| Industry | Application | Picture |

| Pharmaceutical Industry

|

Every pharmaceutical industry requires mixing and emulsification of lumpy particles. These mixers process cohesive particles for formulating eye drops, syrups, suspensions, creams, tablet coating agents, and aseptic injections. |  |

| Food Industry

|

Vacuum emulsifying mixer are integral in food industry for blending of difficult to process food and beverage such as meats, oils, cereals, dairy, etc. These mixers are used for dissolving sugar and nutrients in various blends while preserving their physical and chemical properties. |  |

| Chemical Industry

|

In chemical industry, these equipments aid in emulsification of various chemical formulations such as insecticides, pesticides. These are used to mix solute pigment for forming paints, lubricants, and polishes. |  |

| Cosmetic Industry

|

The role of vacuum emulsifying mixer in cosmetic industry is to maintain colour and scent of chemicals while mixing. These mixers uphold stability of pastes and are used for manufacturing sunscreens, perfumes, gels, foundations. |  |

| Personal Hygiene Industry

|

These equipments are employed for upholding the thickness and physical properties of various blends during preparation of personal hygiene products such as toothpastes, soaps, shampoos, body wash etc. |  |

Ⅳ. Do you know the structural components of types of vacuum emulsifying mixer for pharmacy?

Vacuum emulsifying mixers are comprised of several mechanical and electric parts for carrying out uniform blending and emulsification of various cohesive powders. Some important parts involved in functioning of these machines are detailed below:

| Vacuum Pump

This structure has two attached pipes; one is connecting vacuum pump to water tank while other is connecting the emulsifying pot and gas-liquid separator. Due to this, emulsifying pot remain under vacuum when operating. |

|

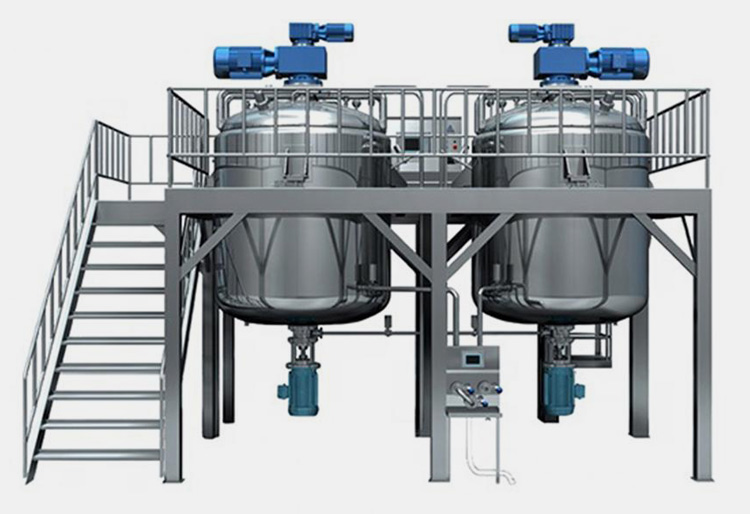

| Mainframe

It is composed of oil tank, water tank, and emulsifying pot. Oil tank dissolve oily or fatty substances. Water tank is used to dissolve polar materials. Emulsifying pot is employed for mixing substances that are drawn from oil and water tank. |

|

| Mixing Unit

This is used to breaking the lumps of particles. These are the blades that aid in smooth blending of pastes and pumping of high viscosity liquids. It is also composed of scrapper that removes the materials sticking to walls. |

|

| Homogenizing Unit

It is high shear homogenizer formed of rotor and stator for uniform emulsion of particles. Its rotation velocity is 0-3600 RPM |

|

| Electric Control System

This comprises of switches and wires for providing power supply for rotation of moving parts of machines. |

|

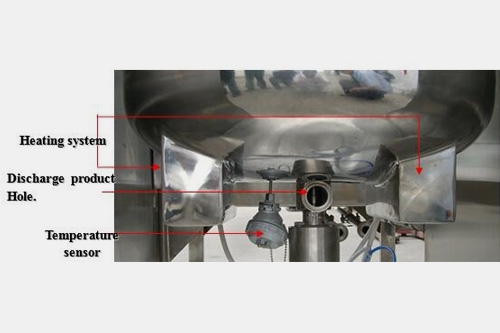

| Heating System

It is formed by electric rods and steam pipes for heating the machine. |

|

| Discharge Valve

Through butterfly valve and stainless steel pipes, the paste or suspension blends are removed from the machine. It can be equipped with pump for rapid removal for products. |

|

| Pressure Gauge

This is used to examine pressure inside the main body. |

|

| Mirror

Interior working of mixers is easily seen when light is illuminated on mirror |

|

Ⅴ.Why are types of vacuum emulsifying mixer for pharmacy significant for your business?

Types of vacuum emulsifying mixers are vital component of pharmaceutical manufacturing line. Having this equipment in your tablet or capsule manufacturing plant provide you edge over your competitors.

Following are significant advantages it holds:

| Production efficiency | Vacuum emulsifying mixers are equipped with cutting-edge technology thus providing you more production capacity. These mixers are beneficial in mixing bulk quantities of ingredients in less time resulting in more products in market. |

| Mixing period | Time is a valuable commodity that has no substitute. Vacuum emulsifying mixers provide superior mixing results in relatively short period. These equipments decreases your mixing time |

| Manufacturing Cost | These machines with latest innovative technology decrease operational cost by operating on low energy and saving your power expenses. These machines have minimal down times that cutbacks your repair cost. |

| Product Wastage | Vacuum emulsifying mixers greatly reduces the product waste. These machines also lower the wastage of raw ingredients further saving your operational expenses. |

| Uniform Mixing | These mixers produces homogenous blend of fine particles. These can create small or medium sized lumps and are perfect for mixing creams and syrups. |

| Safety | These equipments have furbished with guard rails that protect technicians. These machines also relieve operators of repetitive task and prevent them from being injured. |

Ⅵ.What are the main features of types of vacuum emulsifying mixer for pharmacy?

Vacuum emulsifying mixer is handy equipment for producing ointment and salves. These machines can perform slow and fast mixing. Some features of these machines are discussed below:

- These equipments have mixing volume about 5 litres to 2000 litres.

- These mixers have PLC control system with integrated touch screen for controlling and managing machine operation.

- Vacuum emulsifying mixers are manufactured following the CE, FDA, and GMP guidelines.

- Vacuum blending is used to prevent scattering of materials in air and is excellent for sanitation.

- These are furnished with safety emergency switches, pressure valve, and vacuum relief gauge.

- These mixers are high shear mixing having maximum viscosity of 400 mPas.

- These machines employees tap or chilled water for cooling and electricity or steam for heating.

- Vacuum emulsifying mixers have better drying at decreased temperature.

- The cover of main frame is disengaged easily for quick cleaning and maintenance.

Ⅶ.How types of vacuum emulsifying mixers for pharmacy are different from other mixers?

Vacuum emulsifying mixers having vacuum technology to achieve good and uniform mixing. It performs homogenization and emulsification of two substances belonging to different physical states. With the aid of vacuum pump mixing performance is increased and this mixer has better product handling as compared toplanetary mixers and multifunctional mixers. Through using hydraulic pressure, impact, and centrifugal force thousand times per minute vacuum emulsifying mixers disperses and blends materials evenly and quickly. Mixing of powders in vacuum decreases aeration that causes deterioration of blades and produces void free products.

Whereas, in other pharmaceutical mixers for e.g., planetary mixer, no shearing force on materials is applied and these are employed for simple mixing. Other mixers may produce less efficient blending due to aeration and bubbles.

Conclusion

The application of vacuum emulsifying mixers generally depends upon the kind of processing material. These mixers provide best mixing results because of presence of vacuum technology. Technological advancement has led to superior emulsification in reduced time. These mixers are worth having in your manufacturing line due to their high amalgamation capability without product and material wastage. In Types of Vacuum Emulsifying Mixer for Pharmacy we tried to deliver maximum knowledge you are seeking for. Still, if you’ve any question, Please contact us for free support.

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine